A stainless steel vehicle corrugated plate automatic roll welding welding device and welding method

A technology of welding device and corrugated plate, which is applied in the direction of welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems affecting the installation of aluminum honeycomb bottom plate, welding through corrugated plate, and high welding foot reinforcement, so as to ensure the consistency of welding size, Improvement of production efficiency, the effect of production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

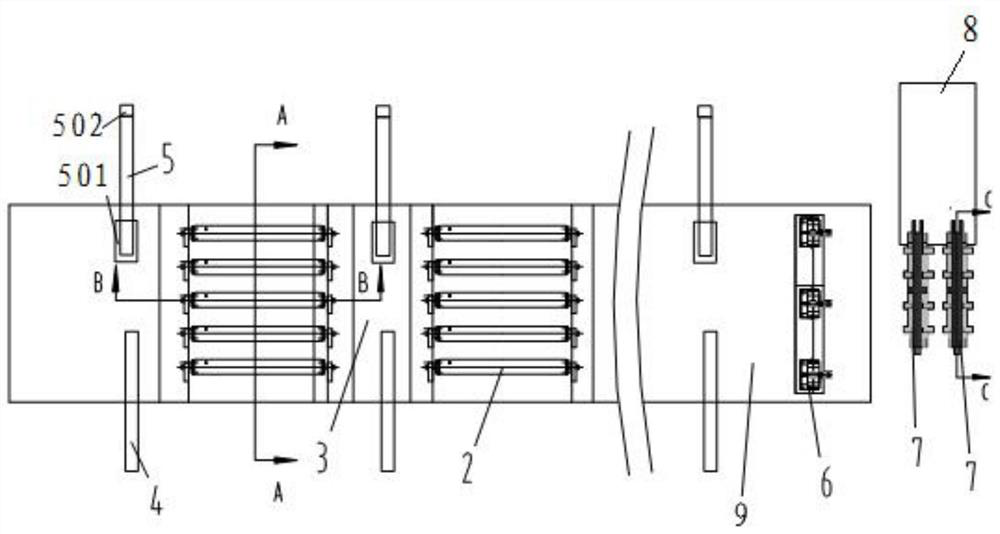

[0091] Embodiment 1. This embodiment 1 first discloses an automatic seam welding device for welding corrugated plates of stainless steel vehicles.

[0092] A stainless steel vehicle corrugated plate automatic seam welding welding device of the present invention, the device comprises:

[0093] A central axis support frame 9, one side of the central axis support frame 9 has a welding device 8;

[0094] Multiple sets of rolling support mechanisms 2 integrated in the central axis support frame 9, adjacent rolling support mechanisms 2 are separated by fixed plane structures 3;

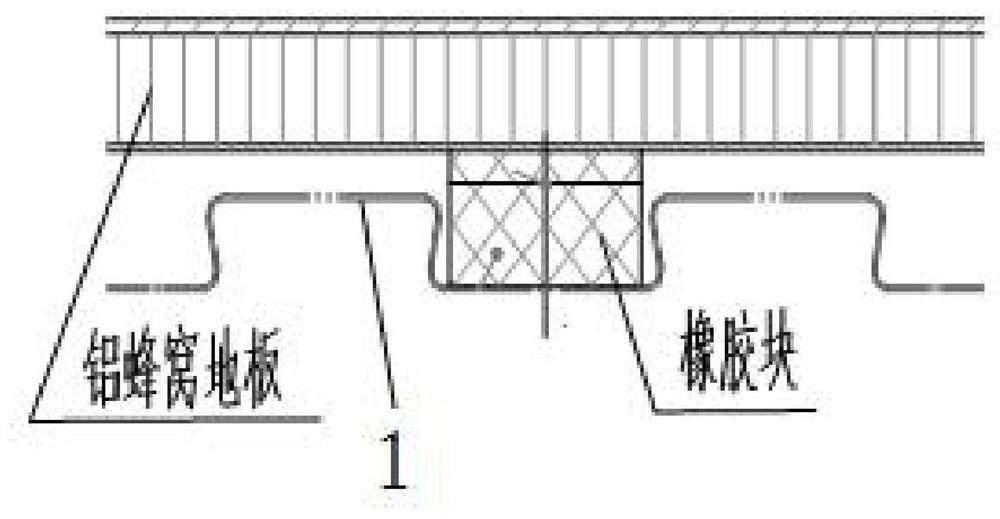

[0095] The rolling support mechanism 2 and the fixed plane structure 3 jointly support the corrugated plate 1;

[0096] The unit also includes:

[0097] The guiding and pressing mechanism 7 integrated in the welding equipment 8;

[0098] The guide pressing mechanism 7 presses the corrugated plate 1 and limits the displacement of the corrugated plate 1 .

[0099] Specifically, the welding device of the f...

Embodiment 2

[0143] Embodiment 2, this embodiment 2 discloses the automatic seam welding welding method of the corrugated plate 1 based on the welding device of the embodiment 1, the details are as follows.

[0144] The invention discloses a stainless steel vehicle corrugated plate automatic seam welding welding method, the welding method mainly includes the following steps:

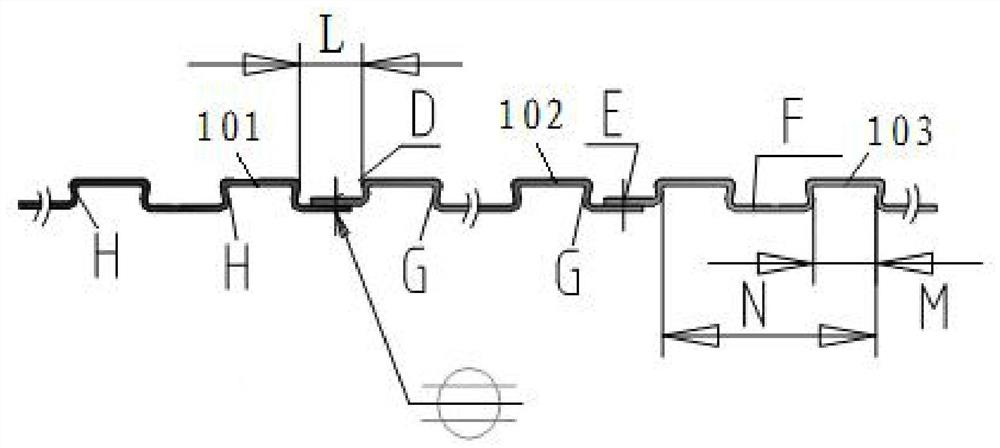

[0145] S101. Analyze the width dimension M of the small surface grooves at the crest positions of the first corrugated plate 101, the second corrugated plate 102, and the third corrugated plate 103, and analyze the overlapping of the first corrugated plate 101 with the second corrugated plate 102 and the second corrugated plate 101 The plate 102 overlaps the width dimension L after overlapping on the third corrugated plate 103, analyzes the groove length dimension N of two consecutive waves close to the overlapping position, and uses the guiding and pressing mechanism 7 to press and hold the wave crest position of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com