Refrigerator backplate

A back panel and refrigerator technology, applied in lighting and heating equipment, household appliances, household refrigeration equipment, etc., can solve the problems of high production cost, heavy weight, creases, etc., and achieve simple processing, good anti-static performance, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

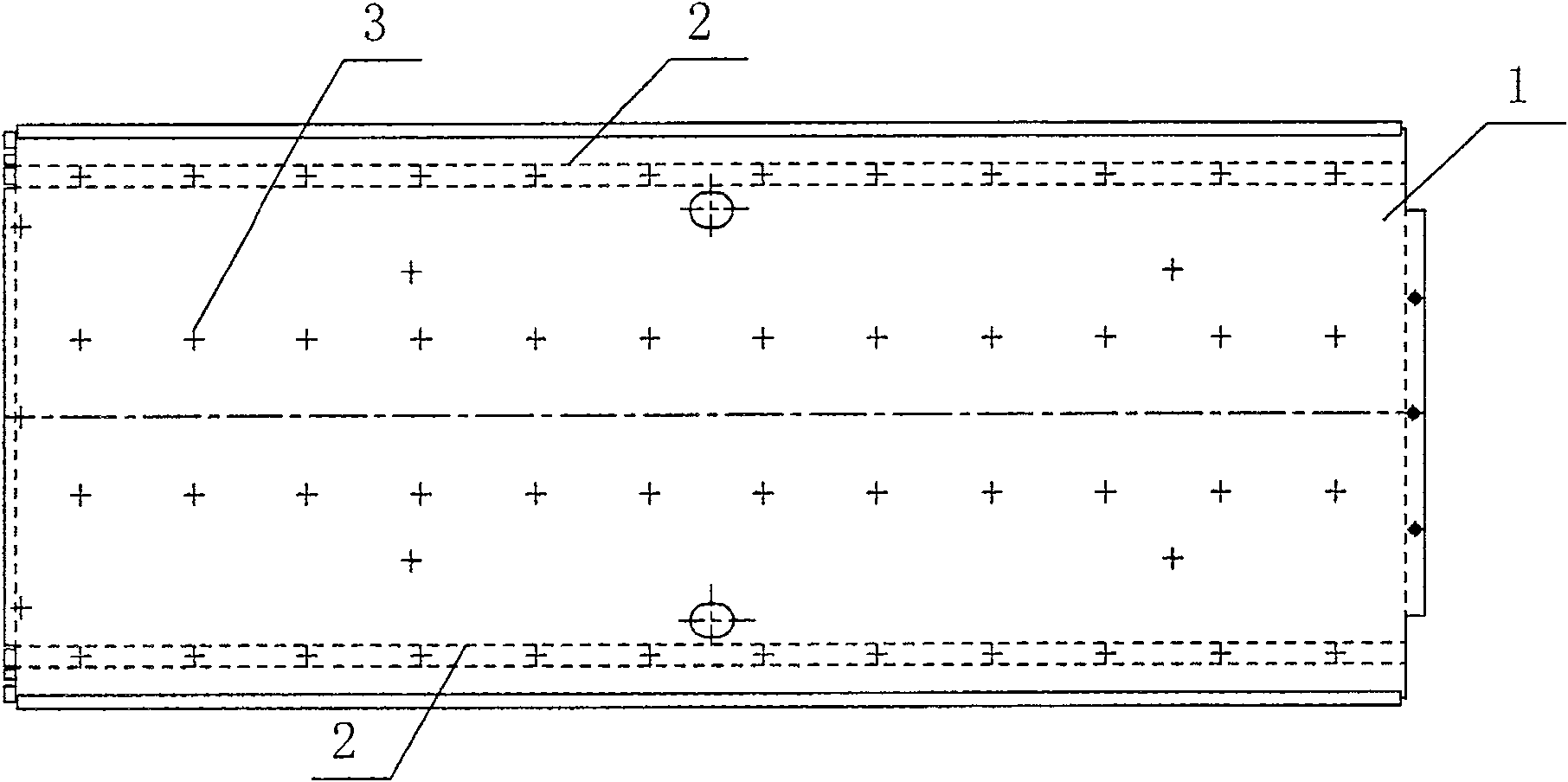

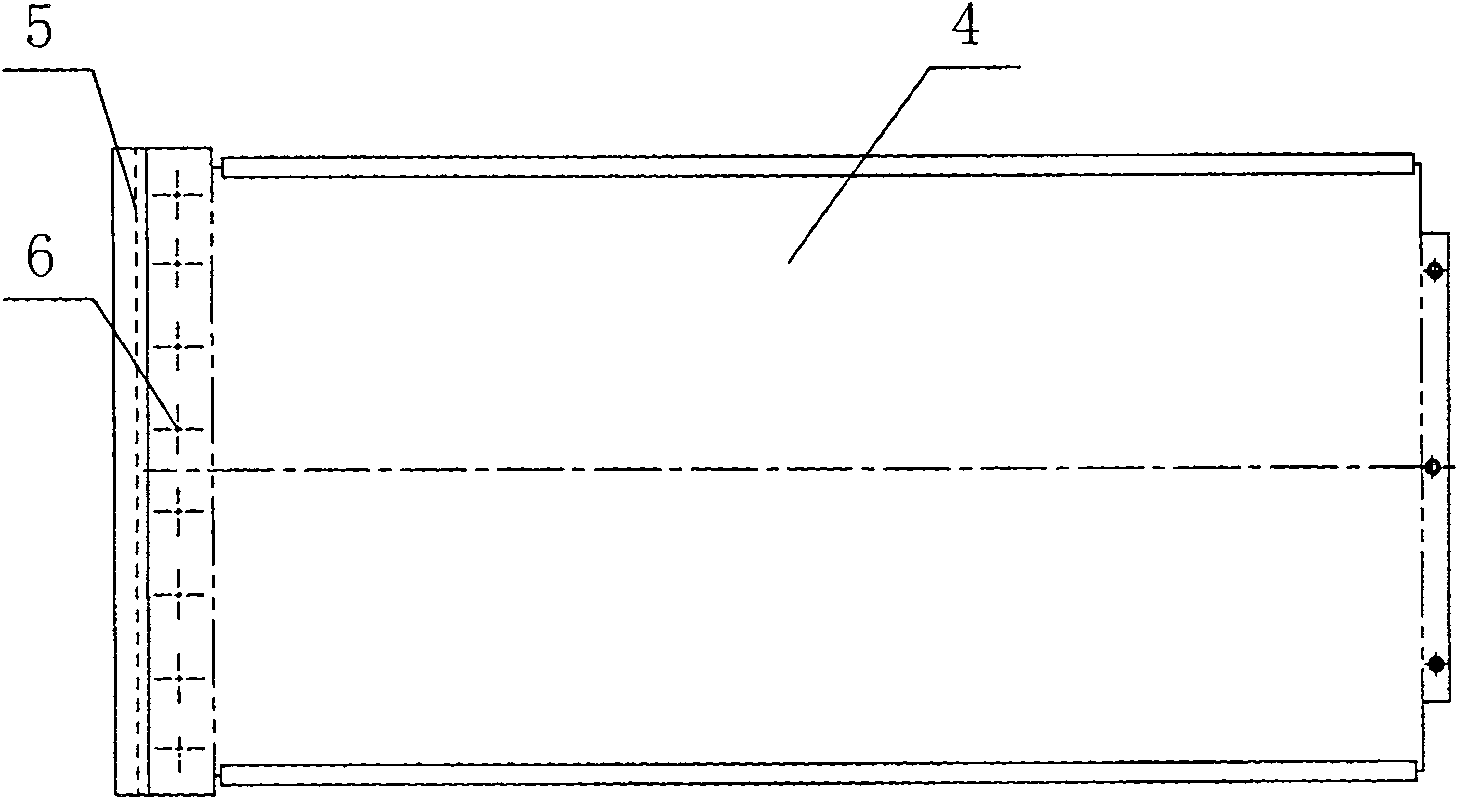

[0014] A refrigerator back panel described in the present invention is made of PP hollow board, and PP hollow board is a new type of packaging material, which is non-toxic, tasteless, light in weight, impact-resistant, moisture-resistant, corrosion-resistant, Anti-static, easy processing and other advantages, using it to make the back plate of the refrigerator can not only reduce the cost of the bottom refrigerator, but also benefit the environment.

[0015] The above-mentioned rear panel made of PP hollow board can be specifically: a concave back structure with several creases after being formed by a foaming mold. Since the PP hollow board is different from a metal sheet, it cannot be formed by stretching or stretching. The concave back structure can only be formed through the foaming mold and the foaming process. Controlling the discharge of gas in the foaming process plays an important role in the formation of the concave back structure. The main area of molding, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com