Live air tangent jetting spinning type rosin distillation device and use thereof

A distillation device and spin-type technology, which is applied in the field of rosin processing, can solve the problems of weight-increasing enterprises, high production costs, and low benefits, and achieve the effects of reducing back-mixing, low device investment costs, and reducing rosin distillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

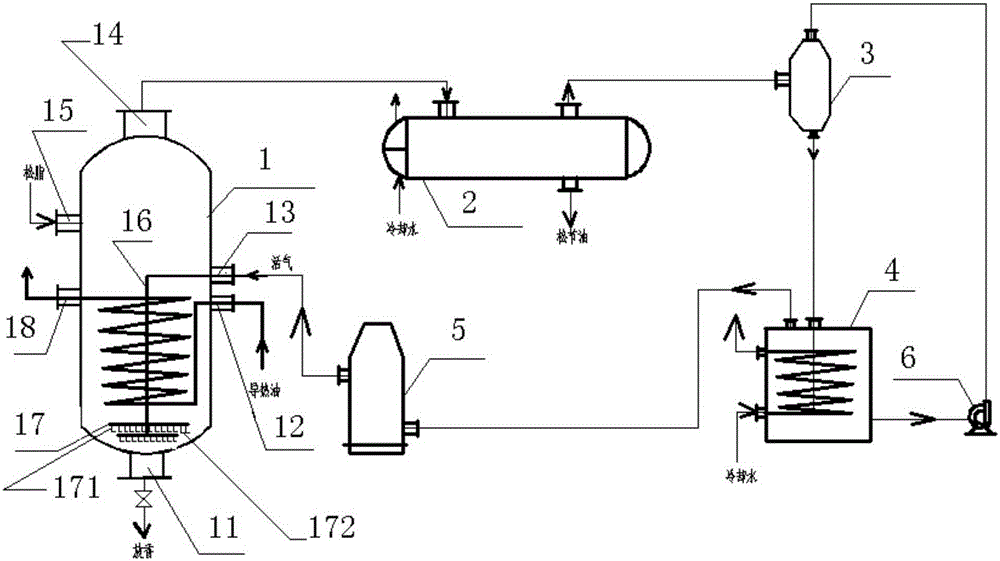

[0041] A system process equipment for distilling rosin by using the active gas tangential spin-type rosin distillation standby device a above, including a rosin distillation device 1, a condensation cooler 2, a water flow vacuum pump 3, a gas-liquid separation tank 4, a gas heating furnace 5, and a liquid circulation pump6.

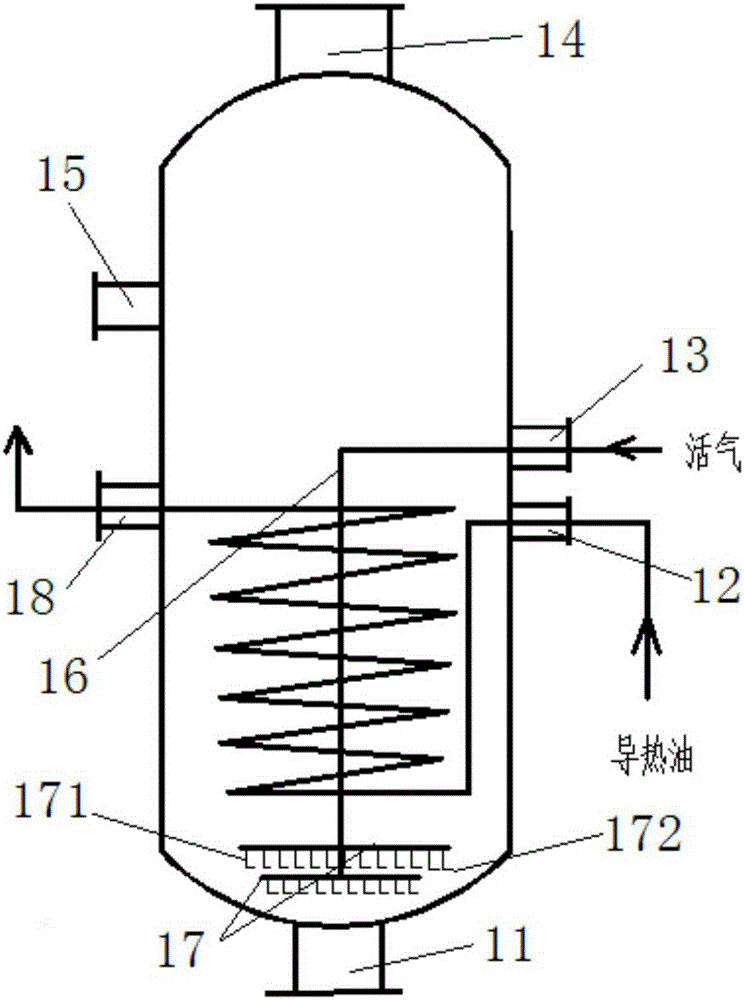

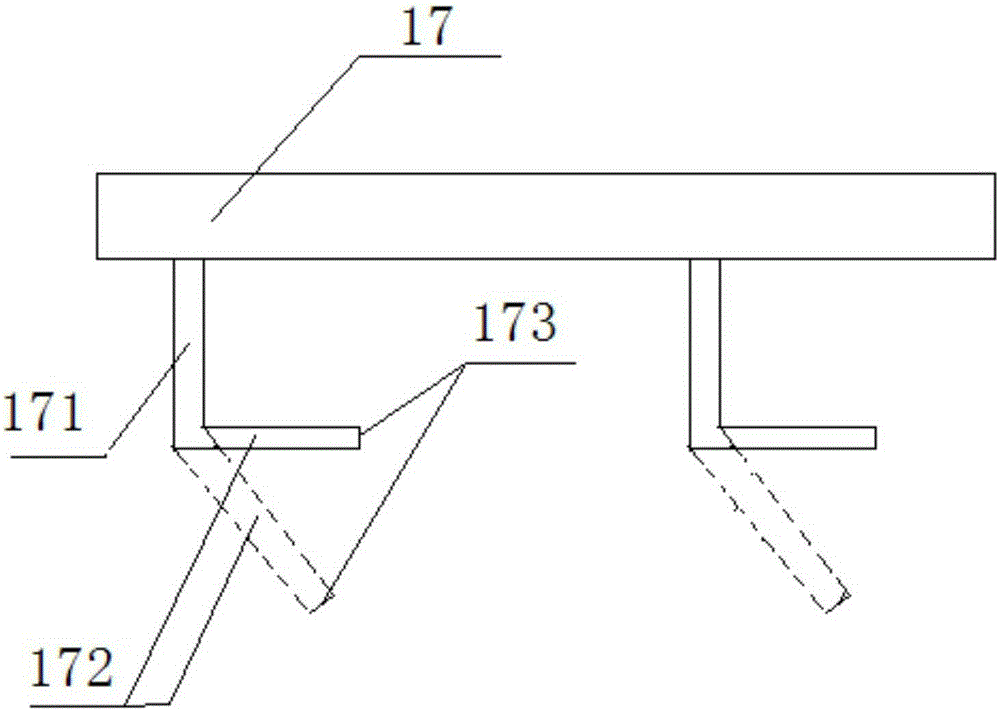

[0042] The net rosin 1000kg (containing 60% of rosin, 40% of turpentine) of melting, filtering and clarification is dropped in the turpentine distillation unit 1, from the entrance of closed air pipe 12, i.e. figure 2 or Figure 4 The arrow in the closed air pipe 12 is directed from the outside of the turpentine distillation device 1 to the interior of the turpentine distillation device 1, and the heat transfer oil is introduced into the port initially entering the turpentine distillation device 1 to heat the rosin in the turpentine distillation device 1, and the heat transfer oil flows in the closed air pipe 12 , flows out from the trachea outlet 18. ...

Embodiment 2

[0044] A system process equipment for distilling rosin by using the active gas tangential spin-type rosin distillation backup device b above, including a rosin distillation device 1, a condensation cooler 2, a water flow vacuum pump 3, a gas-liquid separation tank 4, a gas heating furnace 5, and a liquid circulation pump6.

[0045] The net rosin 1000kg (containing rosin 60%, turpentine 40%) of melting, filtering and clarification is dropped in the turpentine distillation unit 1, from the entrance of closed air pipe 12, i.e. figure 2 or Figure 4 The arrow in the closed air pipe 12 is directed from the outside of the turpentine distillation device 1 to the interior of the turpentine distillation device 1, and the heat transfer oil is introduced into the port initially entering the turpentine distillation device 1 to heat the rosin in the turpentine distillation device 1, and the heat transfer oil flows in the closed air pipe 12 , flows out from the trachea outlet 18. The sup...

Embodiment 3

[0047] A system process equipment for distilling rosin by using the active gas tangential spin-type rosin distillation backup device c, including a rosin distillation device 1, a condensation cooler 2, a water flow vacuum pump 3, a gas-liquid separation tank 4, a gas heating furnace 5, and a liquid circulation pump6.

[0048] The net rosin 1000kg (containing rosin 60%, turpentine 40%) of melting, filtering and clarification is dropped in the turpentine distillation unit 1, from the entrance of closed air pipe 12, i.e. figure 2 or Figure 4 The arrow in the closed air pipe 12 is directed from the outside of the turpentine distillation device 1 to the interior of the turpentine distillation device 1, and the heat transfer oil is introduced into the port initially entering the turpentine distillation device 1 to heat the rosin in the turpentine distillation device 1, and the heat transfer oil flows in the closed air pipe 12 , flows out from the trachea outlet 18. The superheat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com