Refining method for desulphurizing and deodorizing crude sulphate turpentine

A technology of sulfate turpentine and a refining method, which is applied in the refining field of crude sulfate turpentine, can solve the problems of complicated operation, high cost, large pollution and the like, and achieves the effects of time-saving operation, low cost and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In 100mL (about 87g) sulfur content, add 2.01g active ingredient content to be 46.5%wt p-menthane hydroperoxide (equivalent to 2.3% of raw material quality, the actual consumption of oxygenant and The ratio of the theoretical value is 1:1.15), stirring, heating to 110°C, and keeping the temperature for 9h;

[0030] Add 150 mL of distilled water to the reaction solution, continue to stir for 10 minutes, let the reaction solution stand for stratification, and remove the aqueous solution; directly carry out steam distillation on the organic layer, and collect the distillate with the outlet temperature of the distillation head at 96°C, 97°C, and 98°C respectively. parts, the resulting volumes were 16.5mL, 15mL, and 49.5mL, respectively, and the remaining residue was 10mL;

[0031] The mass volume fraction (ie content) of sulfur in each fraction and still raffinate was measured with a microcomputer sulfur and chlorine analyzer, and the results were 317.99mg / L, 150.40mg / L, 30...

Embodiment 2

[0035] The proportioning of embodiment 2, 3, reaction conditions and operation method etc. are identical with embodiment 1, just in embodiment 2 and embodiment 3, p-menthane hydroperoxide in embodiment 1 is replaced by pinane hydrogen Peroxide and p-cymene hydroperoxide as reagents for oxidative desulfurization of crude sulfate turpentine.

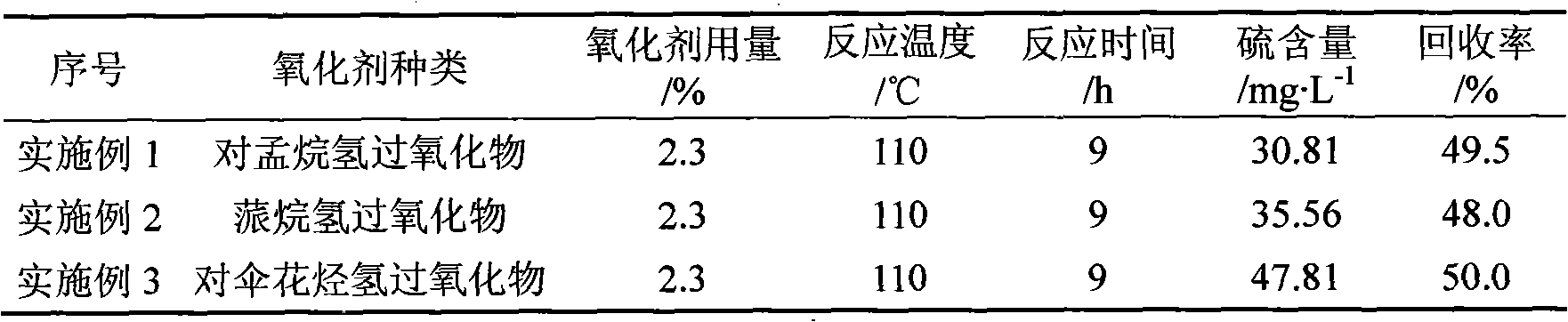

[0036] The reaction conditions and results of Examples 1-3 are listed in Table 1.

[0037] Table 1 Desulfurization and deodorization reaction conditions and effects of CST

[0038]

[0039] Here, rate of recovery=(volume of fraction volume / raw raw material crude sulfate turpentine collected by distillation)×100

[0040] The raw materials CST used in Examples 1 to 3 are the same, and the amount of oxidizing agent refers to the ratio of the actual amount added to the theoretically calculated amount, where the theoretically calculated amount refers to the amount of oxygen required to completely oxidize the sulfur contained in the raw mate...

Embodiment 4~12

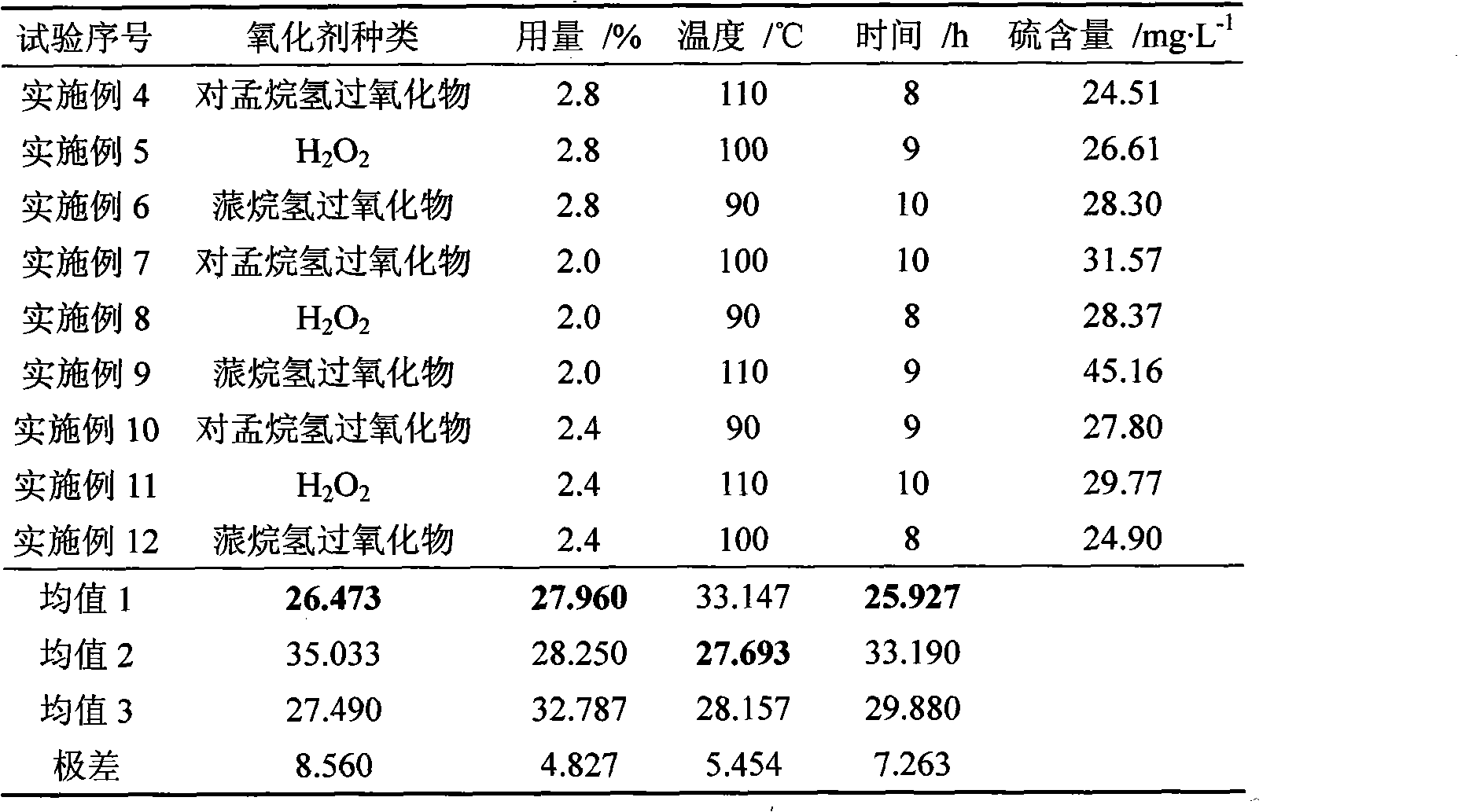

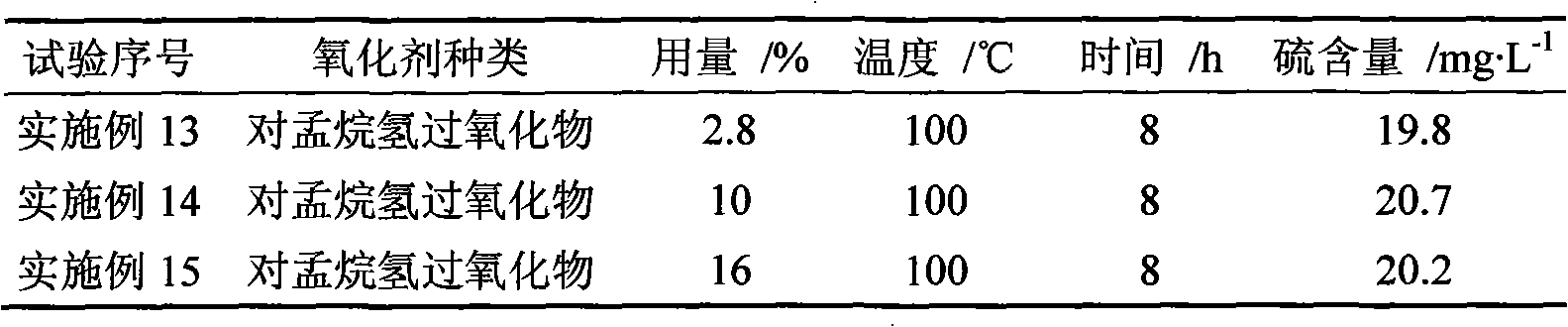

[0043] Embodiment 4~12 is to select oxidant type, oxidant consumption, reaction temperature, reaction time as 4 factors of orthogonal test, then respectively get 3 different values as 3 level values of orthogonal test, respectively correspond to: pair menthane hydroperoxide, H 2 o 2 , Pinane hydroperoxide; 2.8, 2.4, 2.0; 110°C, 100°C, 90°C; 8h, 9h, 10h. which added H 2 o 2 This reaction factor is to compare with the oxidation effect of some oxidizing agents in use today. The reaction conditions and effects of Examples 4-12 are listed in Table 2.

[0044] Table 2 CST desulfurization and deodorization reaction orthogonal test conditions and effects

[0045]

[0046] The results in Table 2 show that this process can greatly reduce the sulfur content in the raw material sulfate turpentine, the minimum can reach below 20mg / L, and hardly feel obvious stench, and the color of turpentine also changes from original yellow to colorless and transparent .

[0047] In terms o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com