Separation method of middle-layer resin liquid

A separation method and fat liquid technology, applied in the field of rosin production, can solve the problems of low grade rosin products, pollution of the working environment, and small processing capacity, and achieve the effects of low production cost, small environmental pollution, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

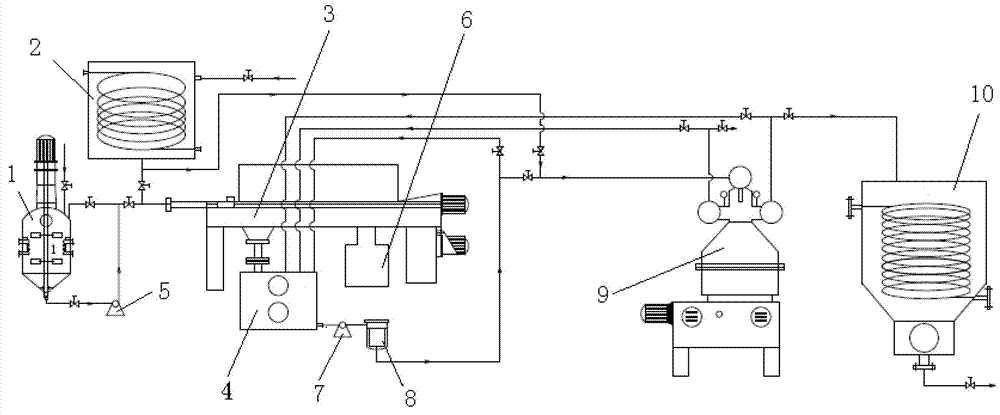

Image

Examples

Embodiment 1

[0030] Throw one ton of the middle layer fat liquid, the middle layer fat liquid contains 25% water, contains 10% solid residue, adds 200KG of turpentine, and heats to 70°C while stirring at 60 rpm. The flow rate of the first pump into the decanter centrifuge is controlled at 600-650 kg / hour to realize the coarse separation of fat liquid and solid suspended matter; the main motor speed of the decanter centrifuge is 3000 rpm, and the auxiliary motor speed is 1400 rpm .

[0031] The fat liquid after coarse separation is heated to 80°C, and is pumped into the feed port of the disc centrifuge by the second pump for three-phase fine separation of fat liquid, water and fine slag, and the flow rate is controlled at 500-550 kg / Hours, the speed of the disc separator is 6500 rpm, the separated fat liquid is 807.5KG, the water content is 0.2%, and the actual recovery rate is as high as 94.8%.

Embodiment 2

[0033] Throw one ton of middle layer fat liquid, the middle layer fat liquid contains 24.8% water, 9.2% solid residue, add 250KG turpentine, heat to 70°C while stirring at 65 rpm, the flow rate pumped into the decanter centrifuge by the first pump The control is at 800-850 kg / h to realize the coarse separation of fat liquid and suspended solids; the main engine speed of the decanter centrifuge is 3600 rpm, and the auxiliary motor speed is 1500 rpm.

[0034] The fat liquid after coarse separation is heated to 80°C, and is pumped into the feed port of the disc centrifuge by the second pump, and the three-phase fine separation of fat liquid, water and fine slag is carried out, and the flow rate is controlled at 600-650 kg / hour, the speed of disc separator is 7000 rpm, and after separation, 890KG of net fat liquid is obtained, with a water content of 0.15%, and the actual recovery rate is 96.8%.

Embodiment 3

[0036] Throw one ton of middle layer fat liquid, the middle layer fat liquid contains 24.0% water, 9.0% solid residue, add 250KG turpentine, heat to 70°C while stirring at 70 rpm, the flow rate pumped into the decanter centrifuge by the first pump Control at 950-1000 kg / h to realize coarse separation of fat liquid and suspended solids; the main engine speed of the decanter centrifuge is 400 rpm, and the auxiliary motor speed is 2000 rpm.

[0037] The fat liquid after coarse separation is heated to 80°C, and is pumped into the feed port of the disc centrifuge by the second pump, and the three-phase fine separation of fat liquid, water and fine slag is carried out, and the flow rate is controlled at 750-800 kg / Hours, the speed of the disk separator is 7500 rpm, and after separation, 900KG of net fat liquid is obtained, with a water content of 0.10%, and the actual recovery rate is 97.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com