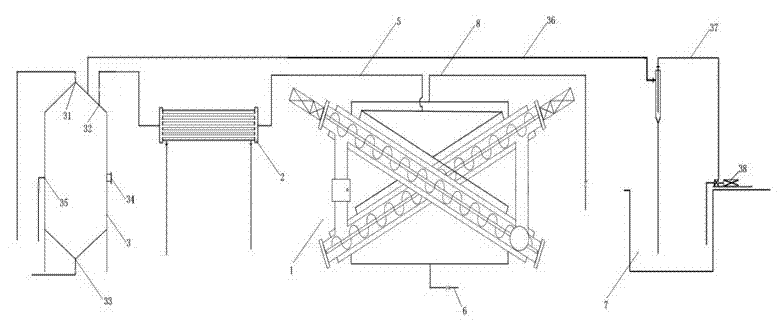

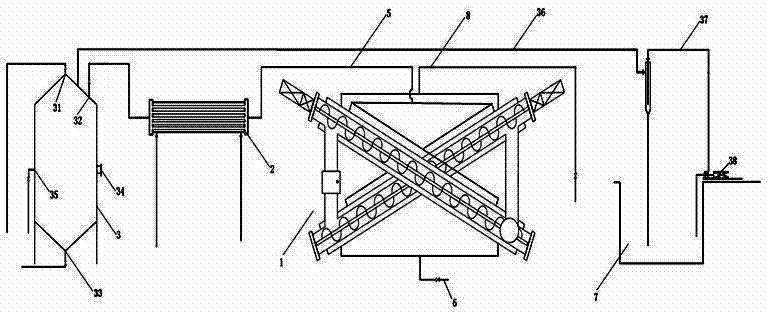

Slag evaporating system for extracting turpentine oil from molten slag

A technology of turpentine and steamed slag, applied in the industrial field, can solve problems such as waste of resources and environmental pollution, and achieve the effects of saving resources, improving economic benefits, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

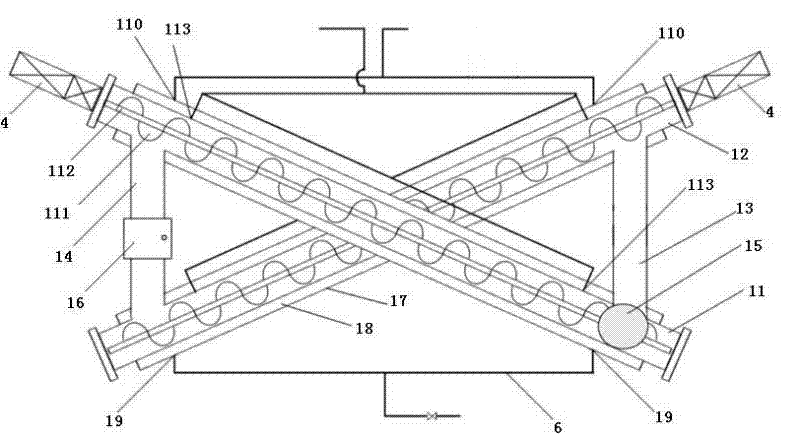

[0015] Embodiment: The slag steaming tanks 11 and 12 of the present invention are made of stainless steel, the tank sleeve 17 is welded on the outer wall of the slag steaming tank, the steam chamber 5 is not connected to the inner cavity of the slag steaming tank, and the molten slag is placed in the inner cavity of the slag steaming tank. The steam enters the steam chamber 18 without interfering with each other; the slag steaming motor 4 is set on the upper end of each slag steaming tank to drive the shaft 112 to rotate, and the spiral impeller 111 pushes the molten slag to move from bottom to top; the slag inlet 15 and the slag outlet 16 places are equipped with doors, which are opened when loading and removing slag, and closed when cooking; in order to let the steamed turpentine out of the steaming slag tank as soon as possible, and thoroughly cook the pine slag, each steaming slag tank is equipped with a door at the upper and lower sections. The turpentine oil outlet hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com