Energy-saving and clean production method for distilling rosin and process equipment

A clean production and turpentine technology, which is applied in the field of rosin processing, can solve the problems of unrealized industrial production and achieve the effects of saving phase change heat, enhancing heat transfer and mass transfer, and saving cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

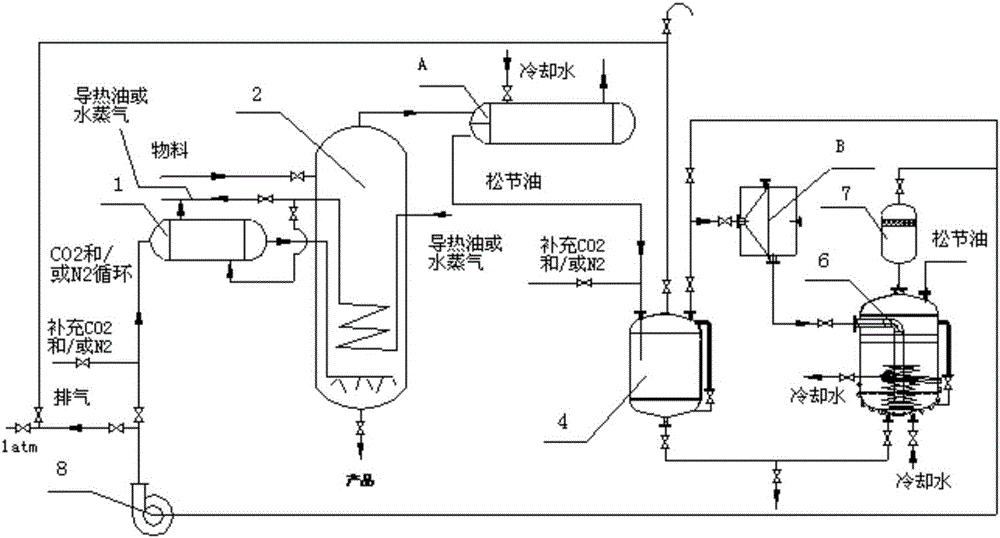

Image

Examples

Embodiment 1

[0030] Pass the circulating active gas into the circulating active gas preheater 1 for preheating. 2 Proceed to preheat to 100°C. Then the turpentine liquid obtained after rosin melting, filtering and clarification is sent into distiller 2 for distillation, and 6000kg of the rosin liquid is dropped into. The indirect heating medium of the distiller is heat conduction oil, and the temperature of the medium is 360°C. circulating gas N 2 The volume flow into the still is 280m 3 / h, the temperature is 100°C, and the pressure is 0.06MPa. The net turpentine liquid is distilled under reduced pressure in the distiller to steam the turpentine, the distillation temperature is 180° C., the vacuum degree is 93.33 kPa, and the distillation time is 30 min; the mixture of turpentine steam and non-condensable gas comes out from the top of the distiller 2 and enters the condenser A. After the turpentine is condensed, it enters the solvent storage tank 4 for gas-liquid separation, and the t...

Embodiment 2

[0032] Pass the circulating active gas into the circulating active gas preheater 1 for preheating. 2 Preheat to 150°C. Then the turpentine liquid obtained after rosin melting, filtering and clarification is sent into distiller 2 for distillation, and 6000kg of the rosin liquid is dropped into. The indirect heating medium of the distiller is water vapor, and the temperature of the medium is 360°C. circulating gas N 2 The volume flow into the still is 150m 3 / h, the temperature is 150°C, and the pressure is 0.06MPa. The net turpentine liquid is distilled under reduced pressure in the distiller to steam the turpentine, the distillation temperature is 190°C, the vacuum is 53.33kPa, and the distillation time is 45min; the mixture of turpentine steam and non-condensable gas comes out from the top of the distiller 2 and enters the condenser A. After the turpentine is condensed, it enters the solvent storage tank 4 for gas-liquid separation, and the turpentine condensate and non-c...

Embodiment 3

[0034] Pass the circulating active gas into the circulating active gas preheater 1 for preheating. 2 Proceed to preheat to 200°C. Then the turpentine liquid obtained after rosin melting, filtering and clarification is sent into distiller 2 for distillation, and 6000kg of the rosin liquid is dropped into. The indirect heating medium of the distiller is water vapor, and the temperature of the medium is 360°C. circulating gas N 2 The volume flow into the still is 280m 3 / h, the temperature is 200°C, and the pressure is 0.04MPa. The net turpentine liquid is distilled under reduced pressure in the distiller to steam the turpentine, the distillation temperature is 200° C., the vacuum degree is 73.33 kPa, and the distillation time is 35 min; the mixture of turpentine steam and non-condensable gas comes out from the top of the distiller 2 and enters the condenser A. After the turpentine is condensed, it enters the solvent storage tank 4 for gas-liquid separation, and the turpentin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com