Automatic slag splashing control method and system for converter

A control method and slag splashing technology, which are applied in the field of converter slag splashing protection, can solve the problems of affecting the rhythm of steelmaking production, increasing the nitrogen amount of slag splashing, and unstable furnace maintenance, so as to shorten the slag splashing time, reduce erosion, reduce The effect of saving nitrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

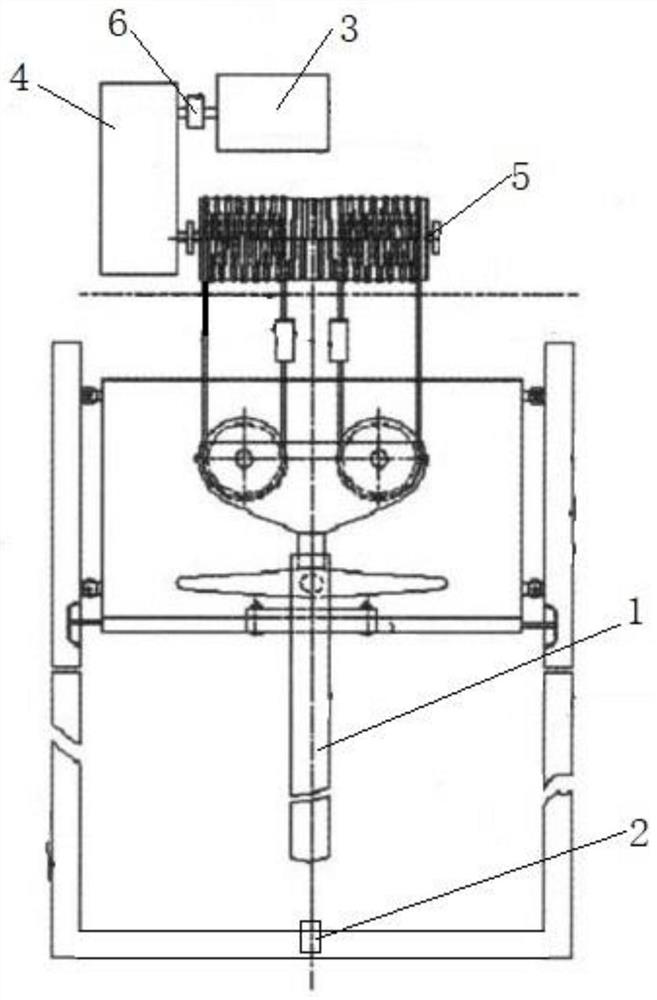

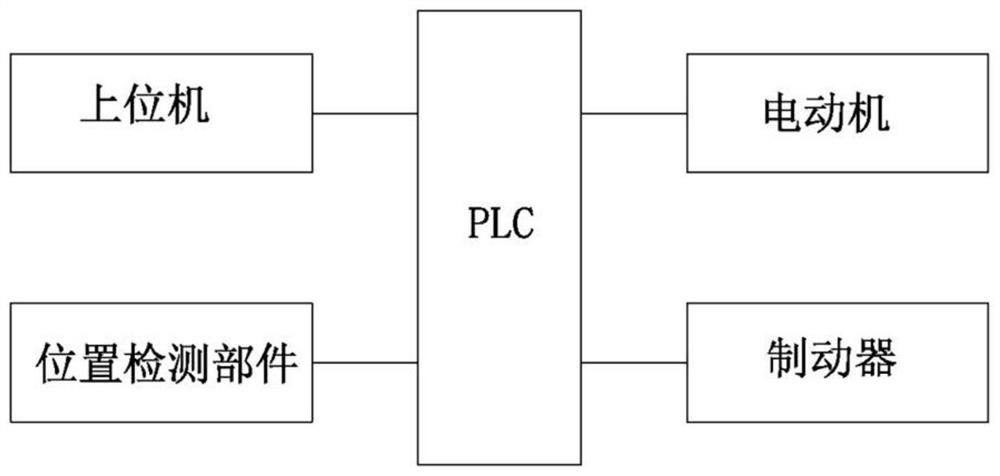

Image

Examples

Embodiment 1

[0037] 1) When the end-point oxygen content in molten steel is greater than 500ppm and less than or equal to 900ppm, the end-point carbon content is greater than 0.02% and less than or equal to 0.06%, and the yield of residual manganese is greater than 30% and less than or equal to 40%, the state of the final slag is poor , for dilute slag.

[0038] 2) Add the slagging agent into the converter through the high-level silo. Specifically, add 400-500 kg of magnesia carbon balls to the converter first to play the role of deoxidation, and then add 800-500 kg of light-burned dolomite on both sides of the converter intersection 1000kg and raw dolomite 800~1000kg, so that the accumulation of slag adjustment material is more flat, and because the price of raw dolomite is relatively low, it can be used together with lightly burned dolomite, which can not only promote the rapid melting of lime, but also increase the alkalinity and viscosity of slag , reduce the erosion of slag to the lin...

Embodiment 2

[0043] 1) When the end point oxygen content in molten steel is greater than 300ppm and less than or equal to 500ppm, the end point carbon content is greater than 0.06% and less than or equal to 0.1%, and the yield of residual manganese is greater than 40% and less than or equal to 45%, the final slag is in good condition , is normal slag.

[0044] 2) Add the slag adjusting agent into the converter through the high-level silo. Since the viscosity of the slag is normal, the amount of slag adjusting material that needs to be added is less than that of thin furnace slag, and the purpose of slag adjusting can be achieved. Specifically, to the converter Add 0-300kg of magnesium carbon balls firstly, and then add 300-500kg of light-burned dolomite and 300-500kg of raw dolomite at the same time on both sides of the converter crossing.

[0045] 3) Since the final slag is normal, the amount of added slag adjustment material is less than that of dilute slag, and the low-high-low-low gun ...

Embodiment 3

[0049] 1) When the end-point oxygen content in molten steel is less than or equal to 300ppm, the end-point carbon content is greater than 0.1%, and the yield of residual manganese is greater than 45% and less than or equal to 50%, the final slag state is relatively viscous and is viscous slag.

[0050] 2) Since the slag is sticky, there is no need to add slag adjustment material.

[0051] 3) Since the final slag is relatively sticky, no slag adjustment material is added, and there is little slag splashing material in the furnace, and it can fully react without too much stirring, so choose the high-low-low gun position, and lower it step by step from high to low Slag splashing, specifically, the gun position is pressed down step by step from high to low from 1400mm, and then pressed down to 1200mm after 120 seconds, and then pressed down to the end gun position of 1000mm in about 170 seconds. The stirring in the furnace is appropriate, and the slag splashing part is the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com