Mineral wool pulling force detection apparatus

A technology of tension detection and mineral wool, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

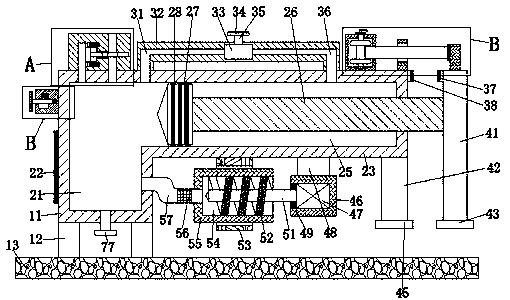

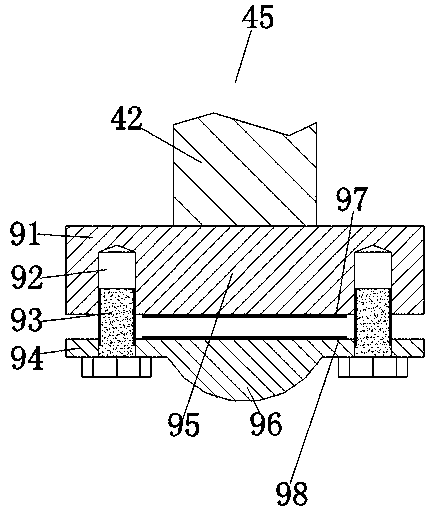

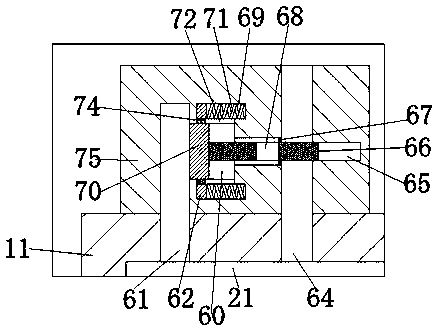

[0019] Such as Figure 1-Figure 5 As shown, a mineral wool tension detection device of the present invention includes a frame structure I11, a test device arranged on the frame structure I11, and an upper end surface of the frame structure I11 near the left end surface The tension protection device and the switch device arranged on the left end surface of the first frame structure 11, the test equipment includes a gas compression chamber I21 arranged in the frame structure I11, and the frame structure I11 is close to A frame structure II23 is fixedly arranged on the right end surface of the upper side end surface, and a tension device is fixedly arranged on the upper side end surface of the frame structure II23 close to the right end surface, and the frame structure II23 is provided with a The gas compression chamber I21 is connected to the gas compression chamber II25, the gas compression chamber II25 is provided with a pneumatic block 27 that can slide left and right, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com