Patents

Literature

51results about How to "Good hole making effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparing method of nanometer silicon-carbon composite lithium-ion battery negative electrode material

ActiveCN106784707APromote absorptionAlleviate volume effectMaterial nanotechnologyCell electrodesCarbon compositesBall mill

The invention provides a preparing method of a nanometer silicon-carbon composite lithium-ion battery negative electrode material. A composite of porous silicon and graphite and a microwave drying method are adopted. The preparing method comprises the following steps of 1, proportionally mixing and ball-milling micrometer silicon, low-melting-point organic matter, carbon sources and a ball milling auxiliary into a ball-milled mixture, and drying the ball-milled mixture for drying pelletizing to obtain a precursor in which micrometer silicon, the low-melting-point organic matter and the carbon sources are evenly distributed; 2, conducting heating treatment on the precursor to make the low-melting-point organic matter molten out to obtain a precursor material in which silicone with a porous structure and the carbon sources are evenly distributed; 3, conducting high temperature sintering on the precursor material under the protection of inert atmosphere to obtain a carbon-covering porous silicon material; 4, proportionally mixing the carbon-covering porous silicon material with a graphite material to obtain the nanometer silicon-carbon composite lithium-ion battery negative electrode material. According to the nanometer silicon-carbon composite lithium-ion battery negative electrode material, the raw materials are rich in sources, low in cost and simple in process, and expansion of a silicon material in the charging and discharging processes is overcome, so that the material has an excellent rate capability and cycle performance.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

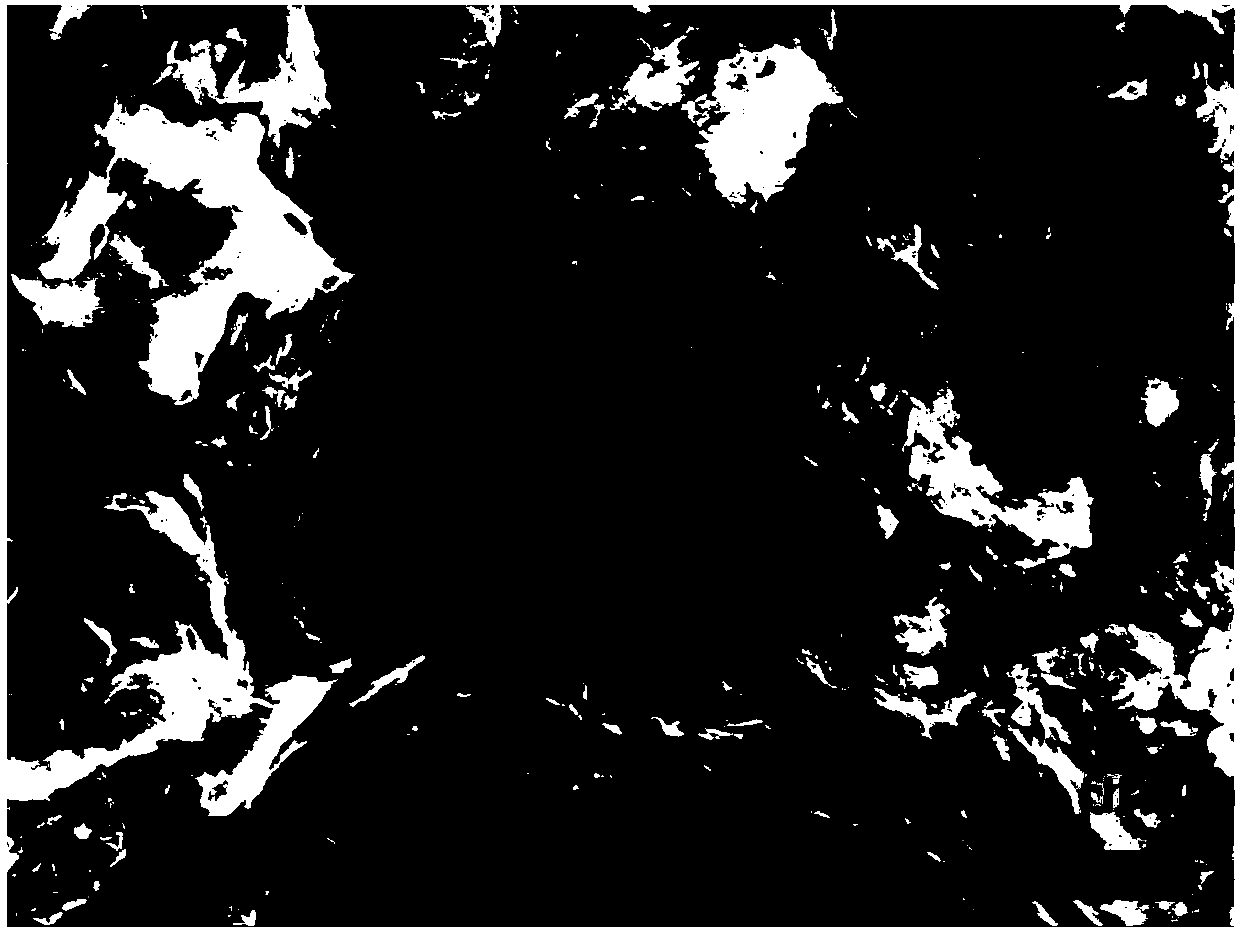

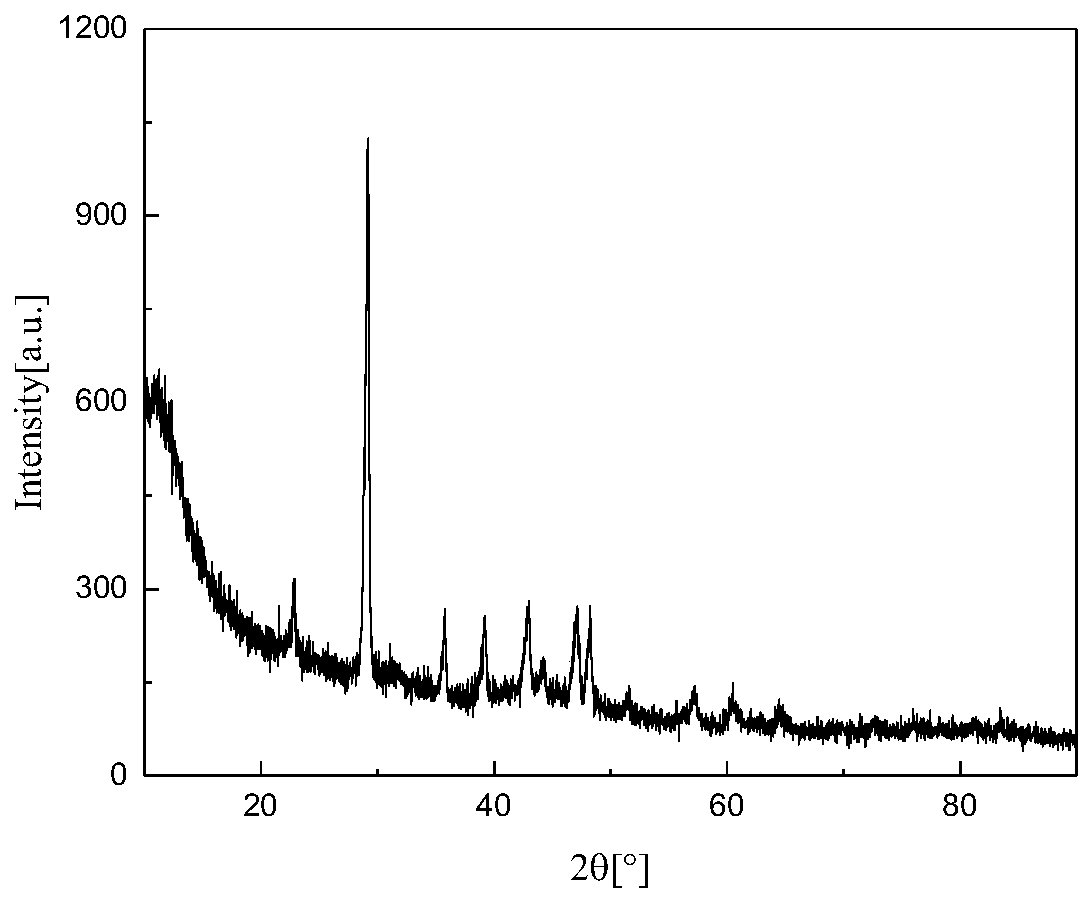

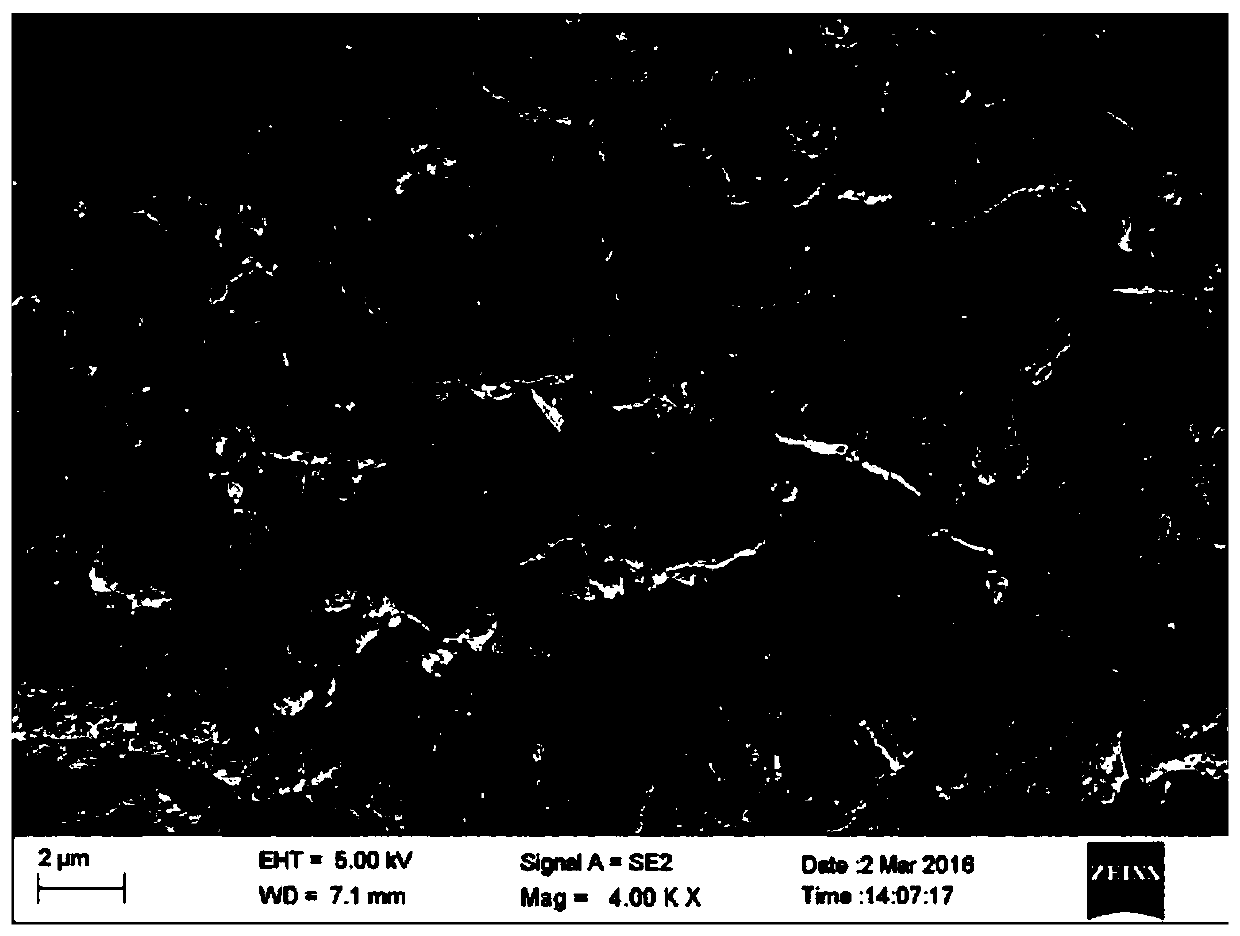

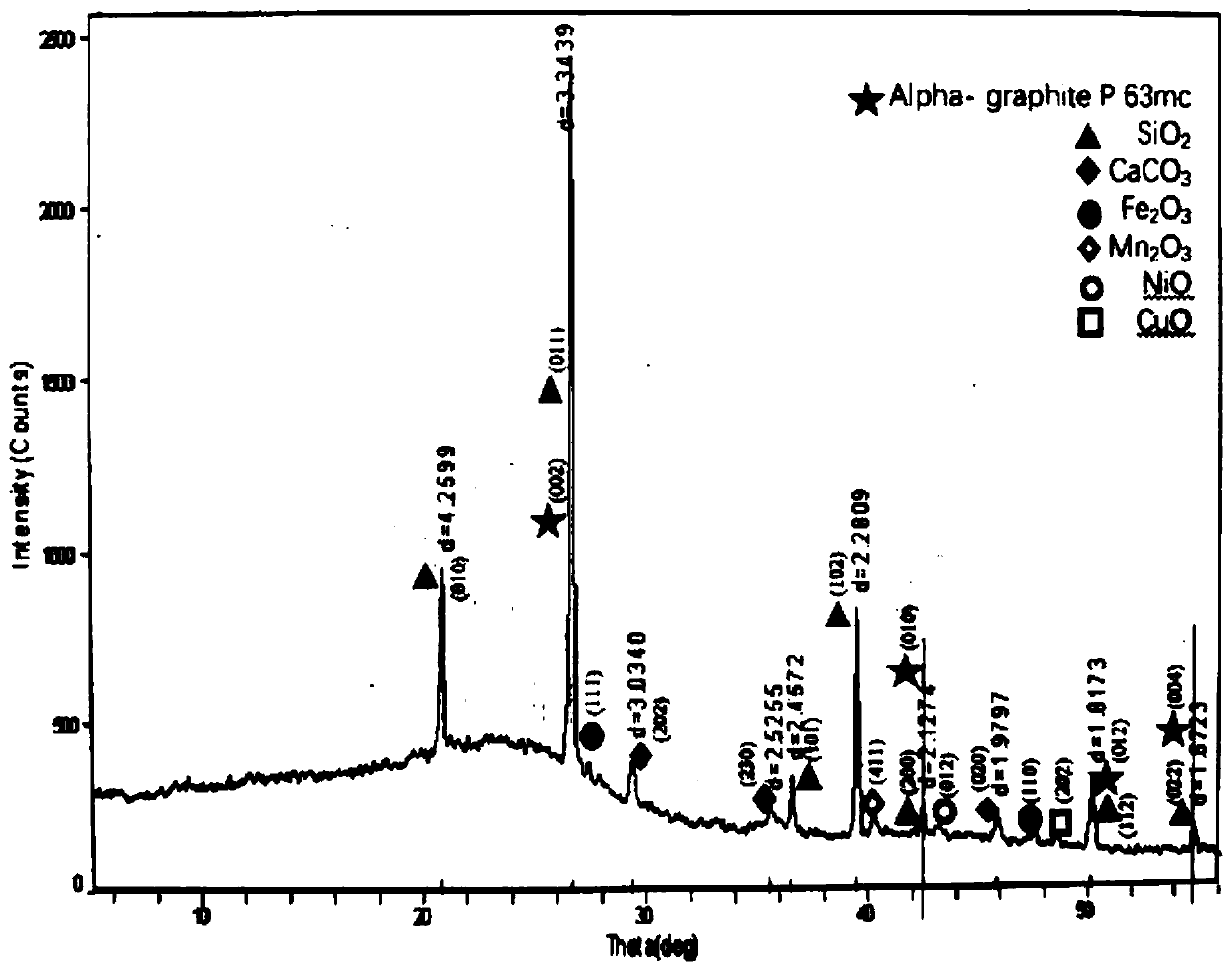

Asphalt-based nanoporous carbon material, negative material thereof, and lithium ion battery

InactiveCN104300150AHas a porous structureLarge specific surface areaMaterial nanotechnologyCell electrodesNanoporous carbonSodium-ion battery

The invention discloses an asphalt-based nanoporous carbon material, a negative material thereof, and a lithium ion battery. The asphalt-based nanoporous carbon material is prepared by mainly using 0.1-10g of asphalt, 3-50g of anhydrous aluminum trichloride, 100-400ml of anhydrous carbon tetrachloride and 200-500ml of a reaction terminating agent, and the amounts of the above raw materials can be freely adjusted in proportion. The asphalt-based nanoporous carbon material is prepared by mainly using asphalt, anhydrous aluminum chloride, anhydrous carbon tetrachloride and the reaction termination agent, and asphalt and anhydrous carbon tetrachloride undergo a Friedel-Crafts crosslinking reaction through a nanometer pore forming technology, so the obtained asphalt-based carbon material has a porous structure and a high specific surface area, and the negative material prepared by using the asphalt-based nanoporous carbon material has the characteristics of strong electrolyte imbibition and retention ability, good processing performance, low price and the like, and can greatly improve the cycle performances of the lithium ion battery.

Owner:HENAN ZHONGLIAN GAOKE NEW ENERGY

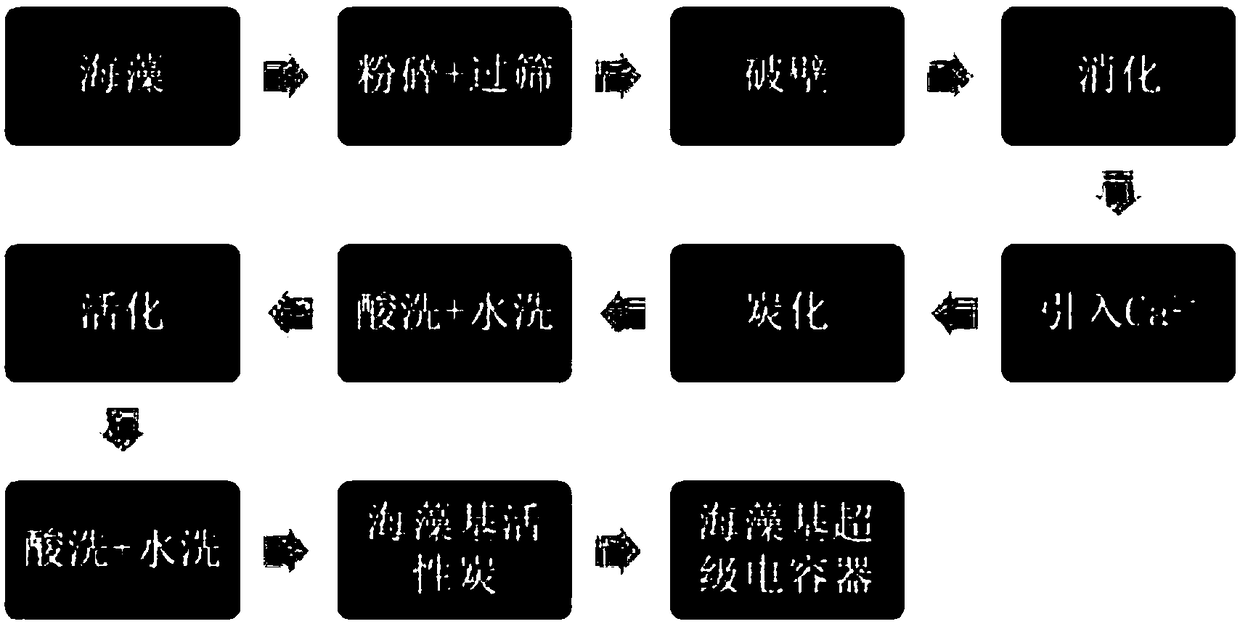

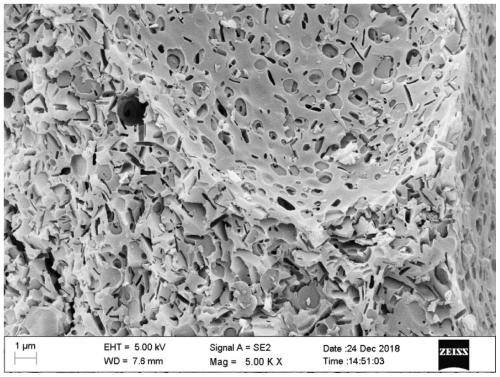

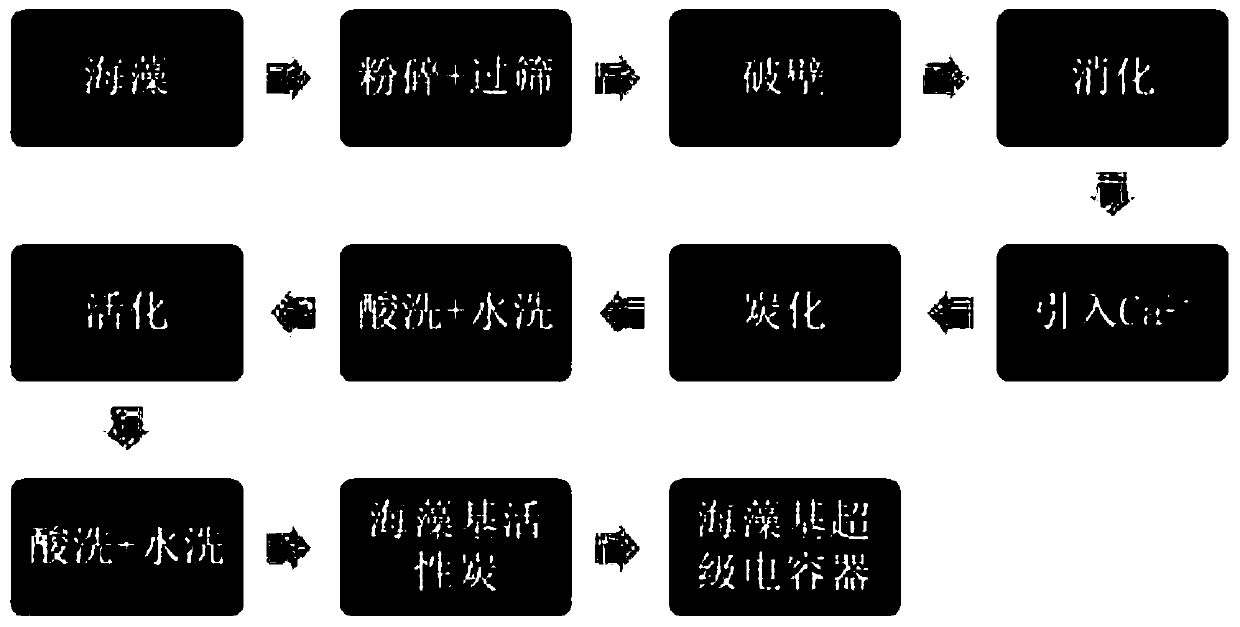

Preparation method of alga-based active carbon precursor for super capacitor

ActiveCN108101051AHelps to create poresDeveloped spatial network structureCarbon compoundsHybrid capacitor electrodesCross-linkDigestion

The invention discloses a preparation method of an alga-based active carbon precursor for a super capacitor. The method mainly comprises the following steps: ultrasound and swelling and other methodsare firstly utilized for carrying out cell wall breaking of alga raw materials, so that alginate in pectin of cell walls and between cells is dissolved; a digestion process is further carried out, under the heating condition with alkali, alginates which are not dissolved in water are converted into water soluble alkali metals and extracted; a cross-linking agent is introduced, and precipitation ofpolymers is formed; washing and filtering steps are carried out, in order to discharge a large amount of inorganic salts, pigments and other impurities which are dissolved in water along with water,and the precursor is obtained. The precursor is carbonized and activated in order to obtain the active carbon material with reasonable pore structure, abundant channels, and massive specific surface area, in order to substantially improve capacity and electrochemical performance of the super capacitor with extremely good industrial application prospects.

Owner:SHANDONG UNIV

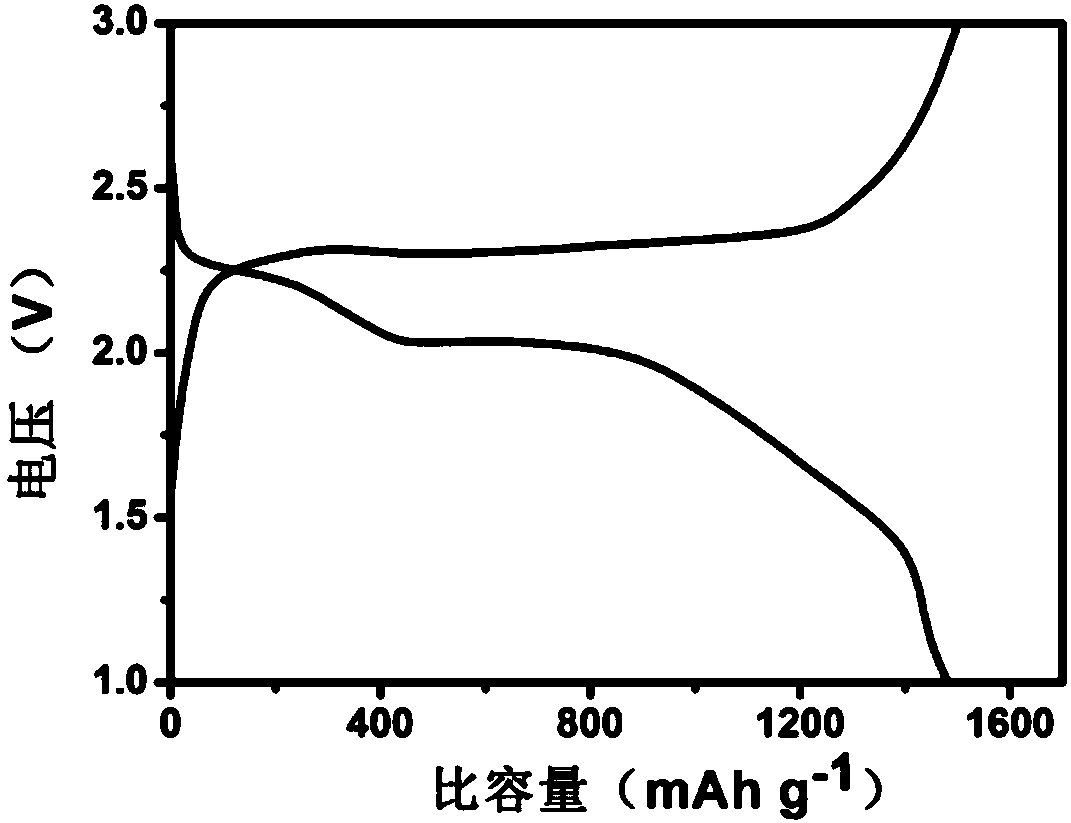

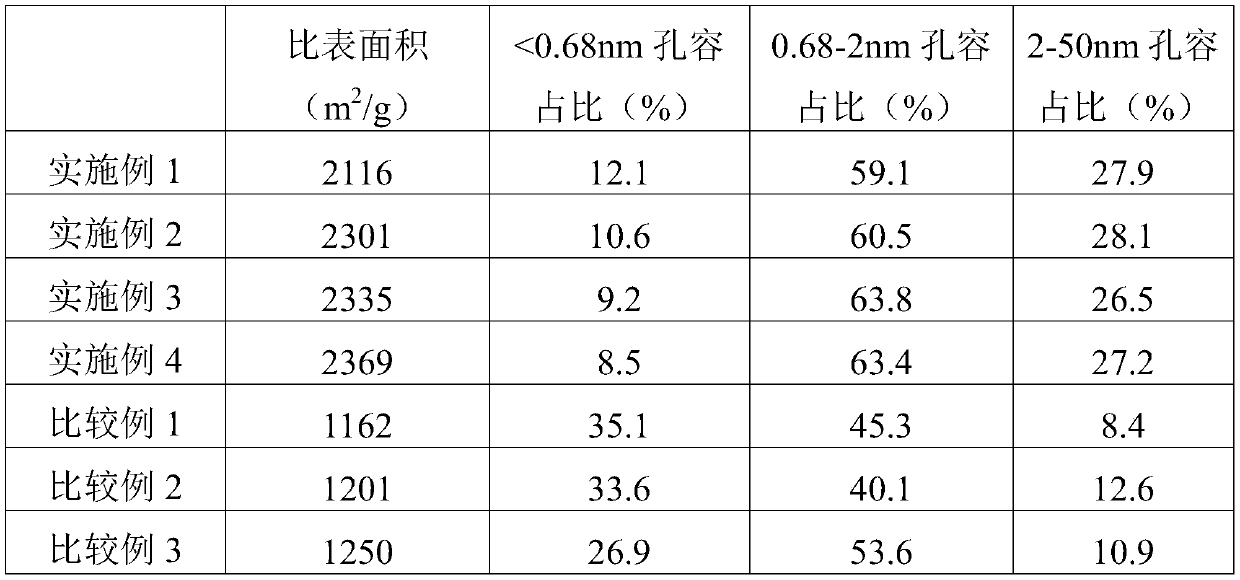

Porous carbon material, preparation method thereof, porous carbon/sulfur composite material, battery positive electrode material, lithium sulfur battery and application of lithium sulfur battery

The invention provides a porous carbon material, a preparation method thereof, a porous carbon / sulfur composite material, a battery positive electrode material, a lithium sulfur battery and application of the lithium sulfur battery, and belongs to the technical field of a battery energy material. The preparation method of the porous carbon material, provided by the invention, comprises the following steps of adding an organic ligand, a metal salt, a carbon source and a surfactant into a solvent, performing solvothermal reaction to obtain a MOFs@C composite material, and performing thermal treatment on the MOFs@C composite material to obtain the porous carbon material. According to the method, the MOFs material used as a pore formation agent and the carbon source are sintered at a high temperature to prepare the porous carbon material, metal ions of the MOFs materials under the high temperature are vaporized so that pores are formed in the carbon materials, the prepared porous carbon material structure is relatively rich and is large in pore capacity and has a hierarchical porous structure, the structure strength is also superior to that of a conventional porous carbon material, theporous carbon material is suitable for loading of high-sulfur quantity, and the cycle property and the energy density of the battery can be greatly improved.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD

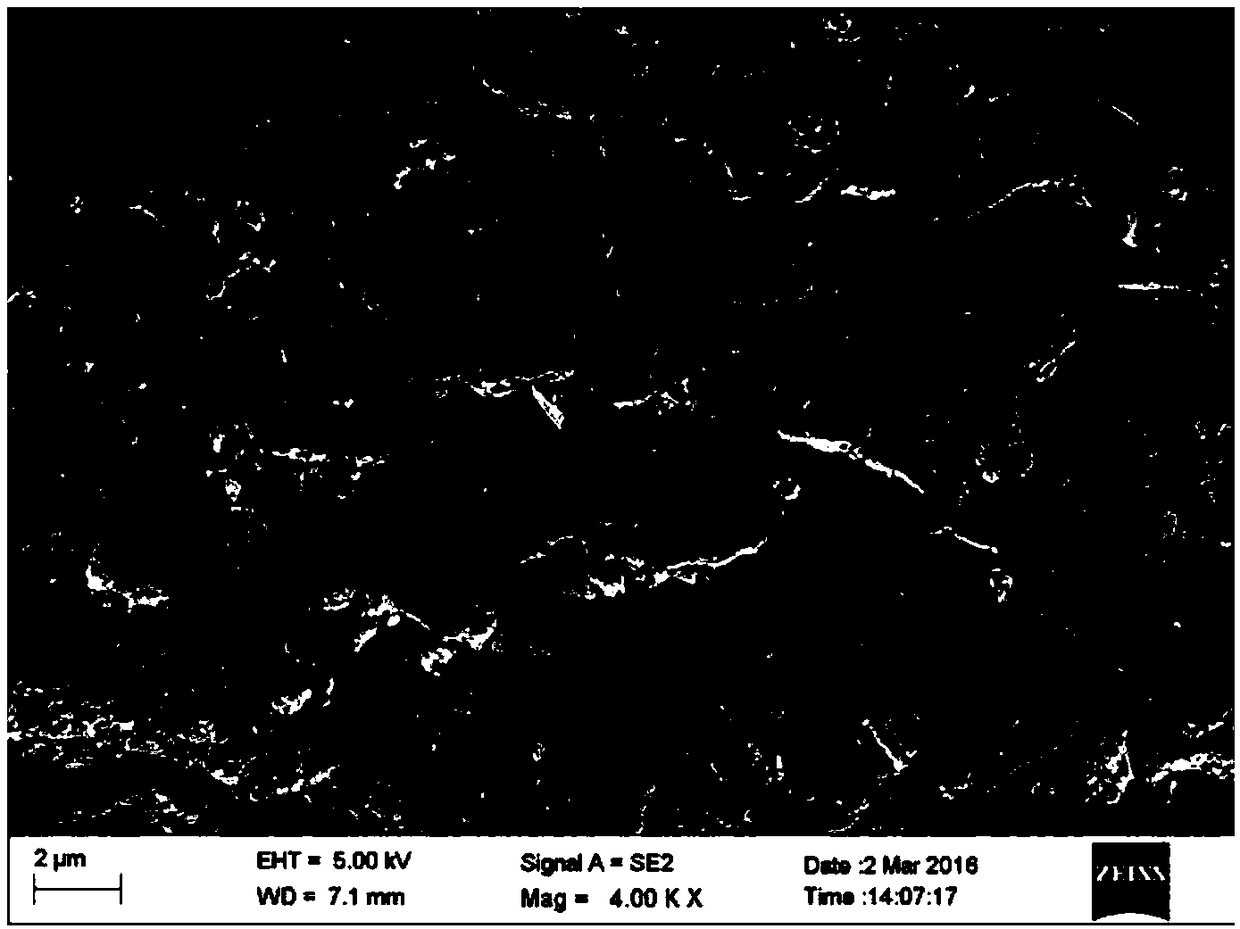

Preparation method of porous graphene/carbon nano tube lithium sulfur anode material

ActiveCN107768637ASuppression cascadingLarge specific surface areaMaterial nanotechnologyCell electrodesPorous grapheneMicrosphere

The invention provides a preparation method of a porous graphene / carbon nano tube lithium sulfur anode material. The method comprises the steps of introducing silicon dioxide microspheres as a template, mixing with a carbon nano tube dispersion liquid, dropwise adding a sodium ascorbate solution, using hydrofluoric acid for soaking for 5 to 7 days, and obtaining a porous graphene / carbon nano tube;grinding with a sulfur elementary substance, using a hydrothermal reaction kettle for heating for 10 to 15h at 140 to 160 DEG C under the argon protection, and obtaining a sulfur / porous graphene / carbon nano tube. The material prepared by the invention adopts the porous graphite / carbon nano tube composite material as a frame so as to form a three-dimensional conductive network structure, so that sulfur can be stored, and a battery performance is improved.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

Low-cost high-activity catalytic type desulphurization active coke and preparation method thereof

ActiveCN104028218AImprove desulfurization effectReduce usageOther chemical processesDispersed particle separationPyrolusiteWater vapor

The invention provides a low-cost high-activity catalytic type desulphurization active coke. The low-cost high-activity catalytic type desulphurization active coke is a material which is activated, extruded and formed by mainly components comprising carbonization soft coal and pyrolusite; the percentage of weight of manganese is not less than 1.6%; the saturated sulphur capacity of the desulphurization active coke is 140-181mg / g; the specific surface area is 319-363m<2> / g; the iodine value is 344-393mg / g. The preparation method of the low-cost high-activity catalytic type desulphurization active coke comprises the following steps: firstly carbonizing smoke, crushing the pyrolusite and the soft coal carbonization material into powder, adding the soft pyrolusite powder into the soft coal carbonization material powder and uniformly mixing, then adding water to mix till the material is free of powder aggregate, adding coal tar, fully kneading and then extruding, forming and drying, causing the dried material to be subjected to activation reaction under the conditions with N2 protection and water vapor, finally cooling the material along with a furnace to room temperature under the N2 protection to obtain the low-cost high-activity catalytic type desulphurization active coke. By virtue of the low-cost high-activity catalytic type desulphurization active coke, the problems of low desulfuration capacity, regeneration frequency, large use amount and high operation cost of the currently-used desulfuration active coke can be solved.

Owner:SICHUAN UNIV

High-strength light ceramic filler

InactiveCN101020606AIncrease Al2O3 contentHigh compressive strengthSustainable biological treatmentCeramicwarePorosityChemical composition

The high strength light ceramic filler is prepared with clay 60-78 wt%, black earth 8-15 wt%, calcium carbonate 8-15 wt%, talcum 3-10 wt% and rice bran powder for the rest. Chemically, it consists of silica 50-60 wt%, alumina 13-20 wt%, calcium oxide 3-8 wt% and magnesia 10-16 wt% except impurity. It has high compression strength, long service life, low impurity content, high whiteness and high porosity.

Owner:杨剑

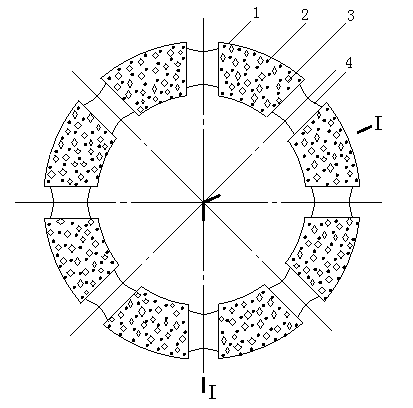

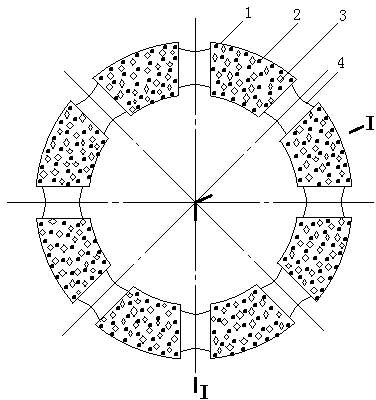

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

InactiveCN103015903AManufacturing Method AdvantagesEnhance the edge effectDrill bitsAdhesiveGraphite

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

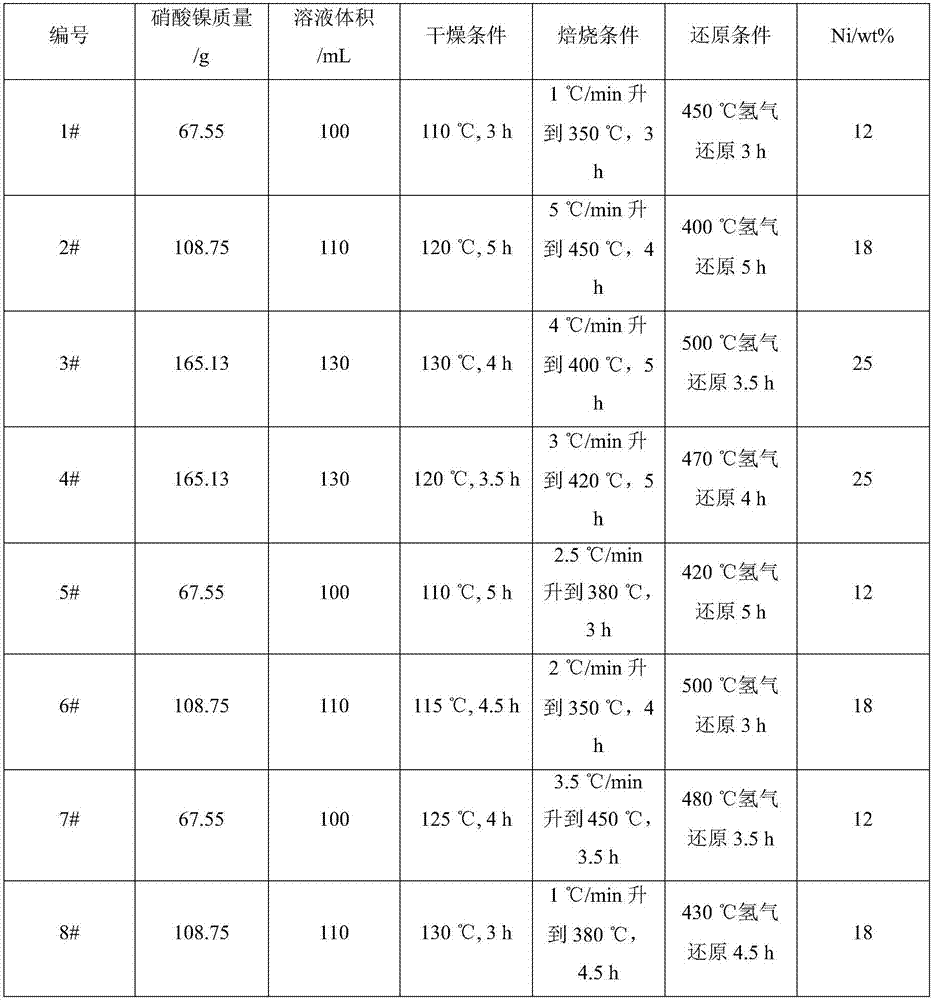

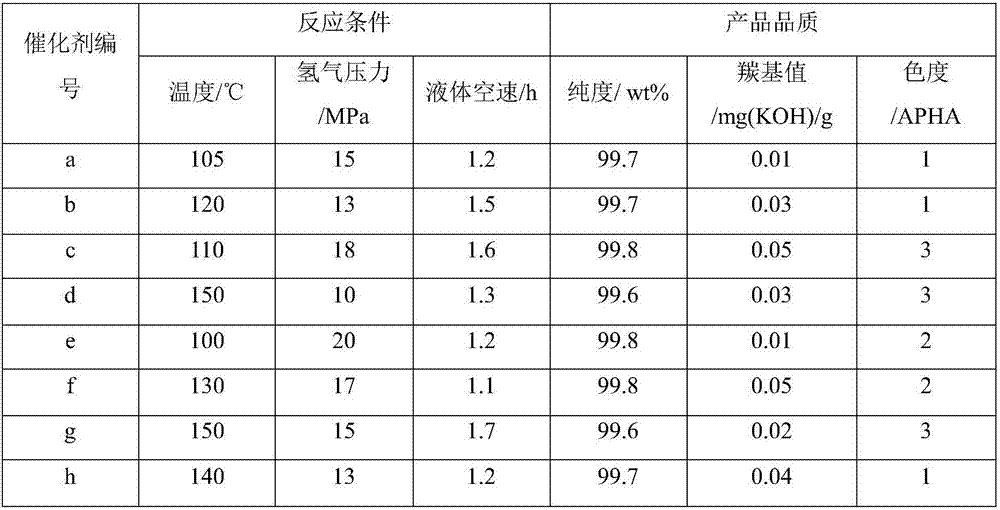

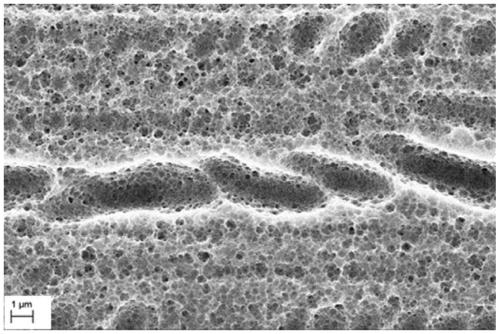

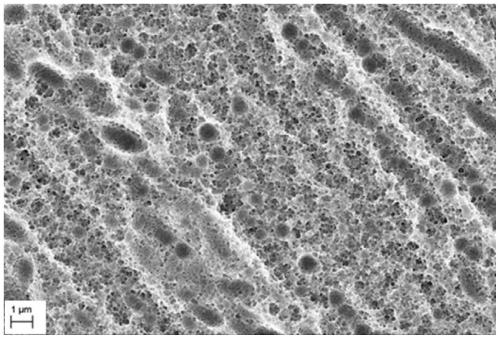

Large-size diesel oil particulate filter with low pressure drop and low expansion coefficient and preparation method thereof

ActiveCN108439967ASmall pressure dropSmall expansion coefficientGas treatmentDispersed particle filtrationAdhesiveThermal expansion

The invention discloses a large-size diesel oil particulate filter with low pressure drop and a low expansion coefficient and a preparation method thereof. The filter is prepared from the following raw materials: an inorganic component, a graphene precursor, starch, polymer resin and an adhesive, wherein the inorganic component is prepared from the following components by mass: 30 to 50 percent oftalcum, 5 to 30 percent of kaolin, 10 to 25 percent of aluminum oxide, 5 to 30 percent of hydrated alumina and 5 to 25 percent of silicon dioxide; the amounts of the graphene precursor, the starch and the polymer resin respectively account for 2 to 15 percent, 5 to 10 percent and 5 to 15 percent of the mass of the inorganic component; the amount of the adhesive is 2 to 10 percent of the total mass of the inorganic component, the graphene precursor, the starch and the polymer resin. The filter provided by the invention can be used for purifying automobile tail gases, in particular to particulate matters in tail gases of diesel vehicles, so that the problems of high pressure drop and high thermal expansion coefficient in an existing filter are solved; meanwhile, the problem of lower qualification rate in the preparation process of the filter is solved, the production cost is reduced, and the production efficiency is improved.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

Light heat insulation and hydrophobic glass bead used for construction and preparation method of light heat insulation and hydrophobic glass bead

ActiveCN106587640AImprove water resistanceImprove water absorptionGlass shaping apparatusAbsorption rateVolume density

The invention provides a light heat insulation and hydrophobic glass bead used for construction. The light heat insulation and hydrophobic glass bead comprises, by mass, 60%-80% of clayed perlite production tailings, 5%-25% of expanded perlite micro powder, 0.5%-2.0% of fluorite powder, 0.5%-5.0% of pure alkali, 0.3%-1% of green silicon carbide dust collection powder, 0.5%-1% of quicklime powder and 8%-12% of water glass. The invention further provides a preparation method of the light heat insulation and hydrophobic glass bead used for construction, and the light heat insulation and hydrophobic glass bead used for construction has the beneficial effects of being small in volume density, good in heat insulation performance and low in water absorption rate and is wide in application prospect.

Owner:XINYANG KEMEI NEW MATERIALS

Aluminum oxide carrier, and preparation method and application

ActiveCN106861766ACrystallization intactEvenly dispersedCatalyst carriersOrganic compound preparationPore diameterChemistry

An aluminum oxide carrier is characterized by having a pore volume from 0.6mL / g to 1.1mL / g, a specific surface area from 200m<2> / g to 300m<2> / g, 50%-60% of pores with pore diameters more than 60nm, 25%-35% of pores with pore diameters from 30nm to 45nm and 10%-15% of pores with pore diameters from 8nm to 12nm. The aluminum oxide carrier has a multi-level pore channel structure.

Owner:SHANXI UNIV

Transparent freshness-preserving film capable of prolonging freshness-preserving time of fruits and vegetables and preparation process of transparent freshness-preserving film

The invention discloses a transparent freshness-preserving film capable of prolonging the freshness-preserving time of fruits and vegetables and a preparation process of the transparent freshness-preserving film. The transparent freshness-preserving film is characterized by being prepared from, by weight, 1000-1200 parts of polyethylene, 100-120 parts of kaolin, 4-30 parts of sodium alginate, 16-150 parts of chitosan, 300-600 parts of dioctyl phthalate, 2-8 parts of ultraviolet light absorbent, 20-50 parts of polysulfonyldiphenylene phenyl phosphonate, 2-30 parts of antibacterial agents, 100-200 parts of beeswax and 10-30 parts of silicon dioxide, wherein the dioctyl phthalate serves as plasticizer. The transparent freshness-preserving film and the preparation method thereof have the advantages that the technology is good in holemaking effect, simple in process and low in product cost. By adding an appropriate number of inorganic particles, the film weight is increased, the transparency of the film is improved, meanwhile, the strength and softness of the film are further improved, the film can have a better freshness-preserving effect, the selling cycle is prolonged, the loss and consumption are lowered, and thereby the operation cost of a supermarket is lowered.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

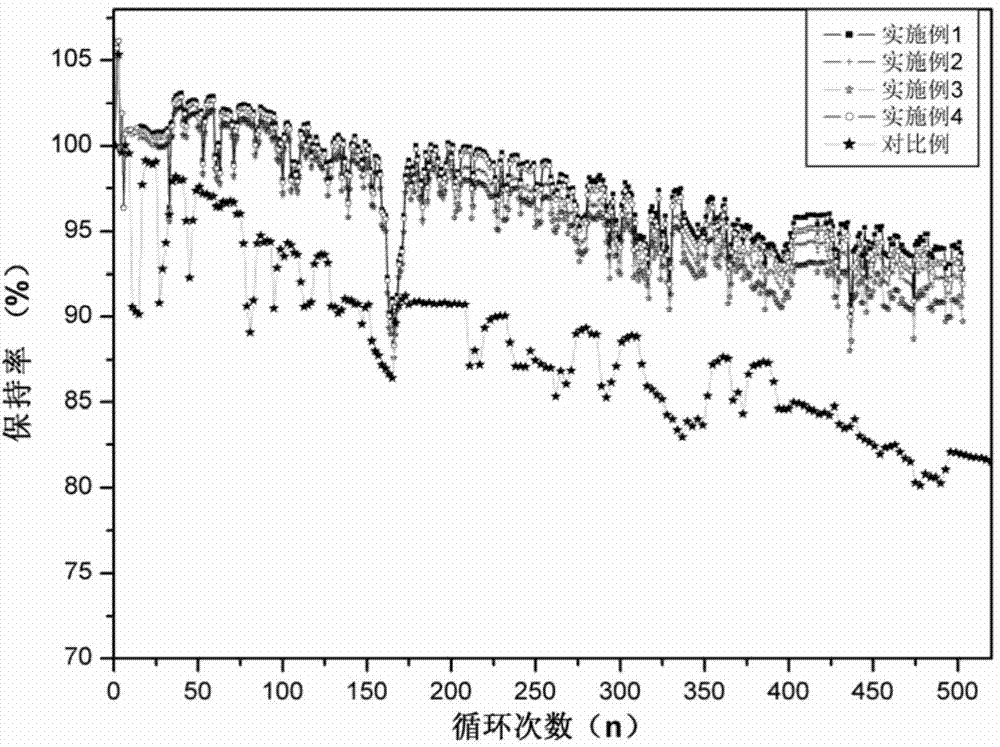

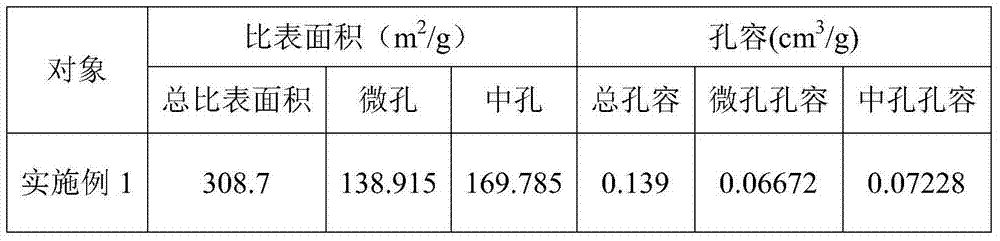

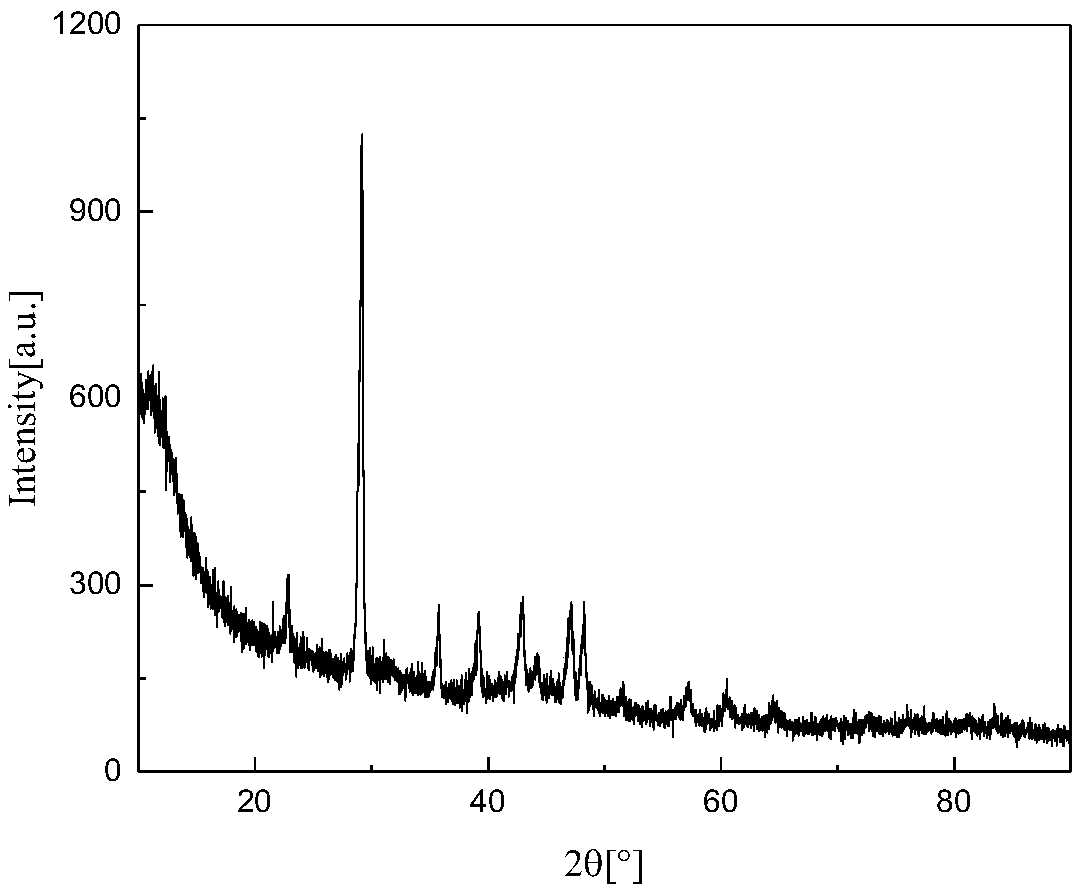

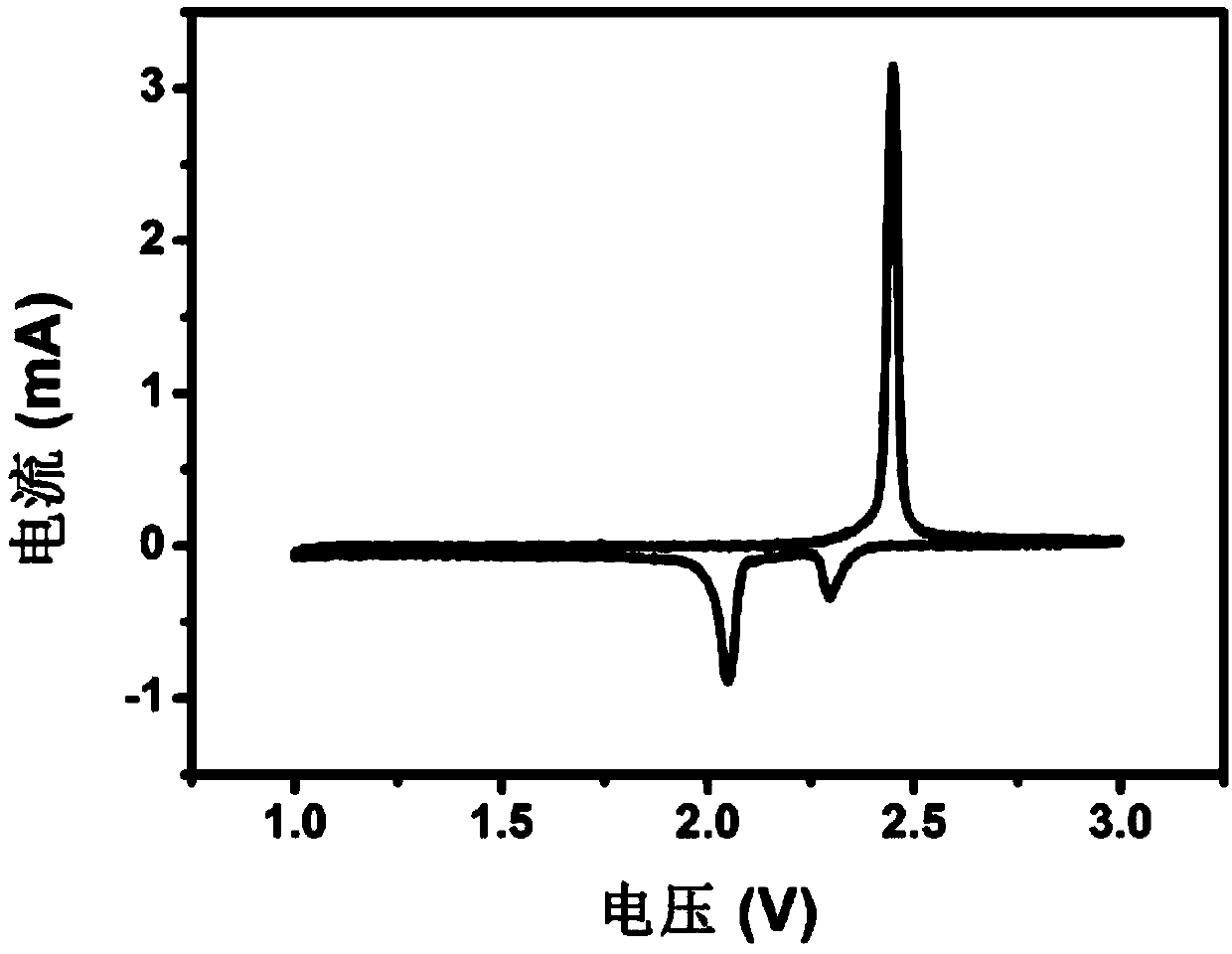

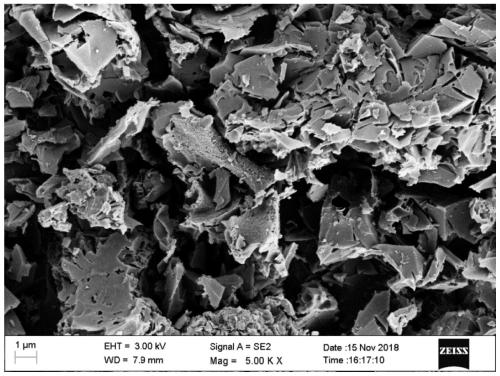

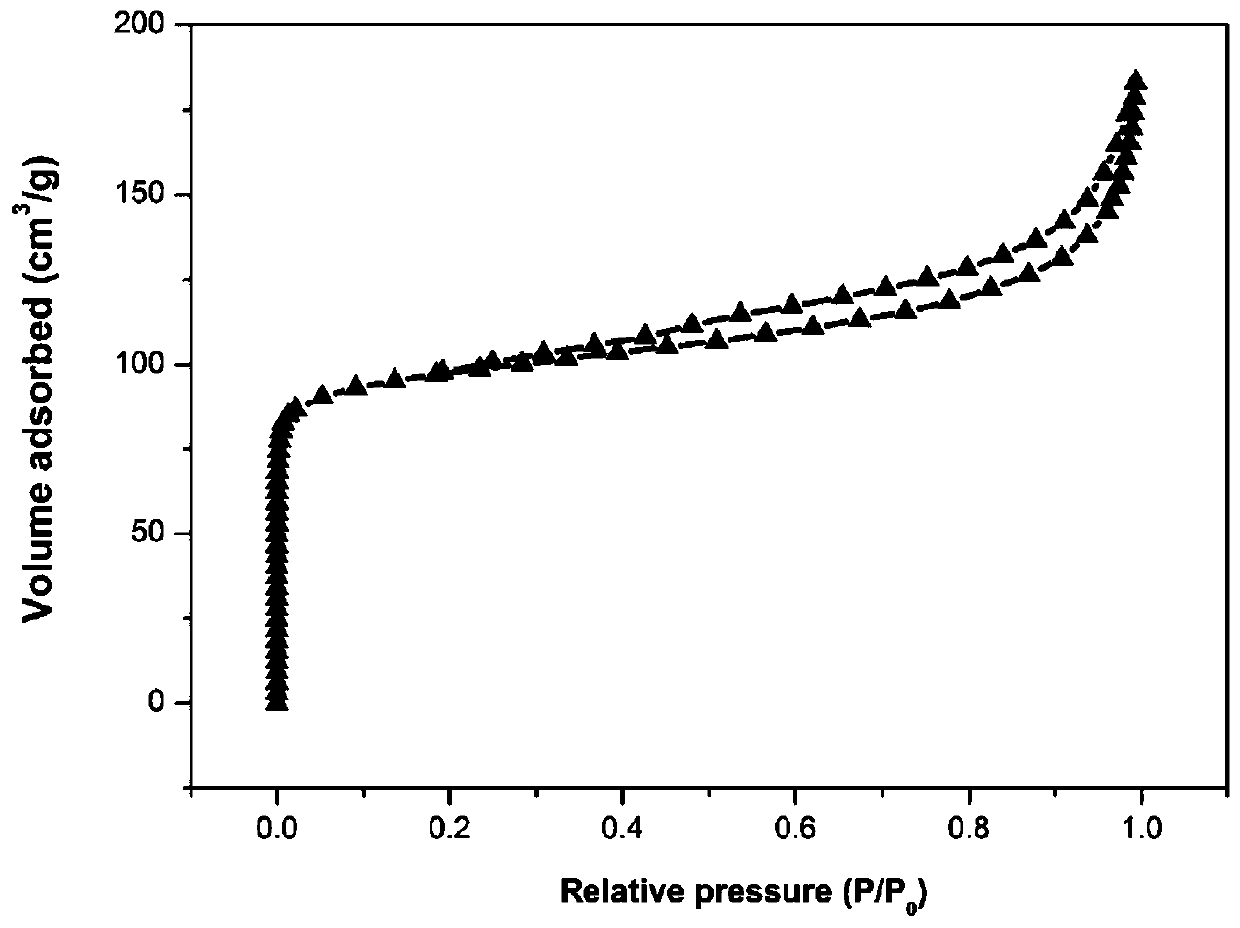

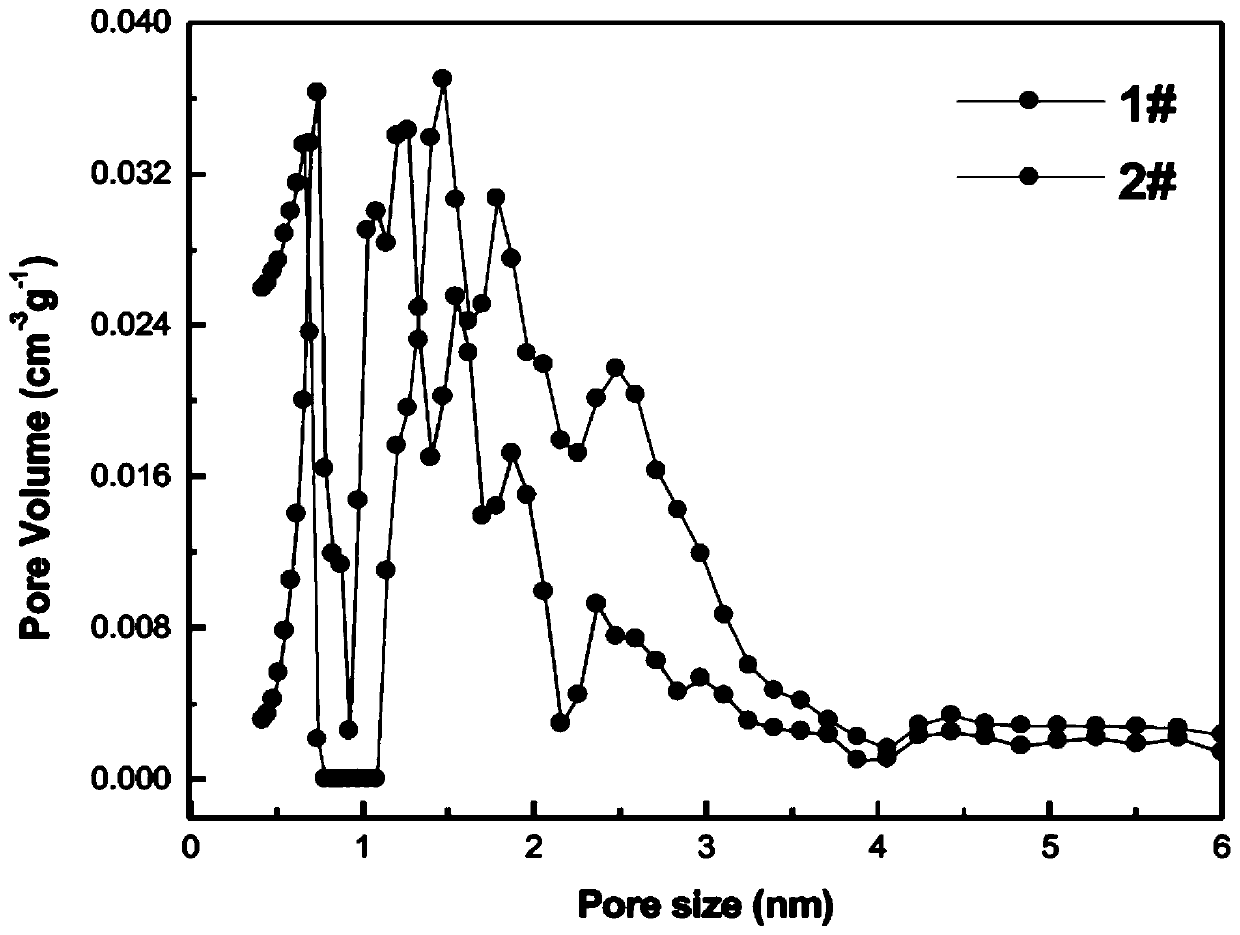

Alginate-based porous carbon as well as preparation method and application thereof

ActiveCN111153403AMany poresHigh specific surface areaCarbon compoundsHybrid capacitor electrodesTube furnaceCapacitance

The invention relates to alginate-based porous carbon as well as a preparation method and application thereof. The preparation method comprises the following specific steps: putting alginate or a calcium-modified alginate precursor into a tubular furnace, introducing protective gas into the tubular furnace, heating to carry out carbonization; washing and drying the carbonization product, impregnating the carbonization product in a chemical activator solution; after impregnation, heating the carbonization product to activate the carbonization product in a protective atmosphere, and after activation, washing to obtain the alginate-based porous carbon. The obtained porous carbon is uniform and consistent in morphology, rich in pores, large in specific surface area and reasonable in micro-pore, mesopore and macro-pore distribution. A super capacitor electrode prepared by the porous carbon is excellent in performance and good in cycling stability.

Owner:SHANDONG UNIV

A kind of preparation method of seaweed-based activated carbon precursor for supercapacitor

ActiveCN108101051BDeveloped spatial network structureWell-developed pore structureCarbon compoundsHybrid capacitor electrodesCross linkerCell wall

Owner:SHANDONG UNIV

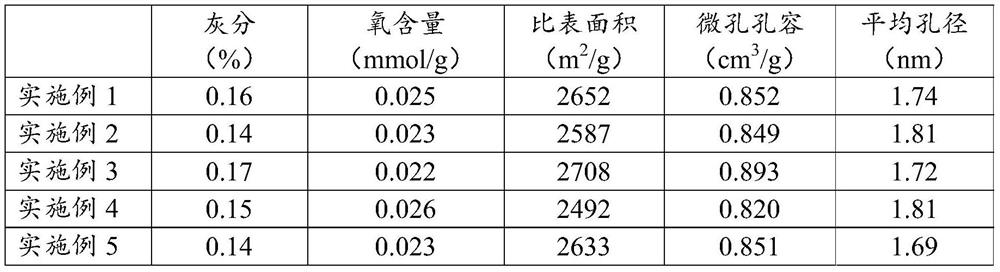

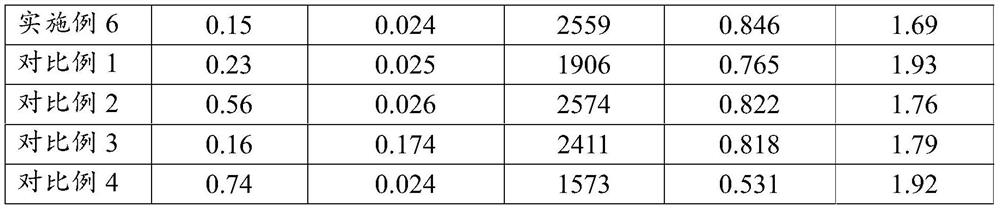

Process method for producing high-quality organic system supercapacitor active carbon

InactiveCN110357094ALarge specific surface areaGood hole making effectCarbon compoundsHybrid capacitor electrodesWater vaporCarbonization

The invention provides a process method for producing high-quality organic system supercapacitor active carbon. The process method comprises: 1) washing a coconut shell carbonization material 3 times,drying to obtain a drying material, crushing the drying material to achieve a particle size of 50-80 [mu]m, adding the crushed material to a metal oxide suspension, stirring for 20 min in a high-pressure stirring kettle to obtain a mixture, placing the mixture in an activation furnace introduced with an inert gas, pre-activating, heating at a heating rate of 10-15 DEG C / min to an activation temperature of 600 DEG C, and maintaining for 50 min to obtain a pre-activated material; 2) heating the pre-activated material to a temperature of 850-950 DEG C, introducing a mixed gas of water vapor andoxygen, and carrying out an activation reaction for 120 min to obtain an activated material; and 3) reducing the temperature of the activation furnace to 600-800 DEG C, introducing carbon dioxide gas,carrying out a reaction, naturally cooling to a room temperature under an inert atmosphere, soaking in an acid solution, washing with pure water to achieve a neutral state, and drying to obtain the supercapacitor active carbon. According to the present invention, the prepared active carbon has characteristics of high specific surface area, reasonable pore size distribution and the like.

Owner:北海艾米碳材料技术研发有限公司

Preparation method of carbon material for supercapacitor, carbon material and application of carbon material

PendingCN111943192AReduce the impactImprove electrochemical performanceCarbon compoundsHybrid capacitor electrodesCapacitanceSlag

The invention provides a preparation method of a carbon material for a supercapacitor, the carbon material and application of the carbon material, and the preparation method of the carbon material forthe supercapacitor comprises the following steps: step 102, pretreating a certain amount of raw coal and gasified slag enriched carbon, then performing uniform mixing with a certain amount of co-activator, and carrying out high-temperature activation treatment; and step 104, mixing the first product obtained after high-temperature activation treatment with a certain amount of an acid-alcohol mixed solution, performing heating and stirring, and carrying out suction filtration, washing and drying after the reaction is finished for later use. According to the preparation method, the raw materials are cheap and easy to obtain, the process is simple and controllable, the operation conditions are mild, industrial production can be achieved, and the carbon material prepared through the preparation method has the characteristics of being high in specific surface area, high in specific capacitance, small in internal resistance and the like.

Owner:TAIYUAN UNIV OF TECH

Method for preparing gasoline vehicle particle catcher by using fumed silica

The invention relates to the technical field of exhaust pollutant post-treatment of gasoline vehicles, and particularly relates to a method for preparing a low-pressure drop and low-expansion coefficient cordierite gasoline vehicle exhaust particle catcher by using fumed silica. The method comprises the following steps: (1) mixing inorganic raw materials by a dry method, and adding a binder; (2) kneading; (3) practicing; (4) extruding, microwaving and drying; (5) cutting and sintering; (6) punching holes, blocking the holes and then putting the holes into a kiln for back burning. The fumed silica material is adopted as the raw material catcher, the pore-forming effect is remarkable, and the micro-pore connectivity is good, so that the pressure drop and the thermal expansion coefficient ofthe catcher can be reduced; meanwhile, the fumed silica can replace common silica, thereby not only achieving the function of serving as an inorganic component, but also achieving the pore-forming effect and reducing the adding amount of the organic pore-forming agent; the use of the fumed silica not only can meet the use requirements, but also reduces the production cost and improves the production efficiency.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

Transparent preservative film for preserving agricultural product with micropores and preparation technology thereof

The invention discloses a transparent preservative film for preserving agricultural product with micropores and preparation technology thereof. The preservative film is characterized by comprising: by weight, 1000-1200 parts of polyethylene, 100-120 parts of calcium carbonate, 3-30 parts of sodium alginate, 15-150 parts of chitosan, 300-600 parts of dicapryl phthalate, 2-8 parts of ultraviolet ray absorber, 20-50 parts of polysulfonyldiphenylene phenyl phosphonate, 1.5-30 parts of antibacterial agent, and 200-300 parts of beeswax, wherein dicapryl phthalate is a plasticizer. The preparation technology has good effect on making holes, and has simple process and low product cost. The film weight is increased by adding moderate inorganic particles, and the transparency of the film is increased, further the intensity and softness of the film are increased, which makes the preservative film has good preservation effect. So that the sale period is prolonged, the spoilage is reduced, and the operating cost of supermarket is reduced.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

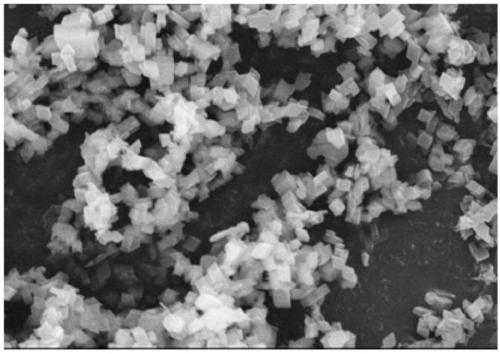

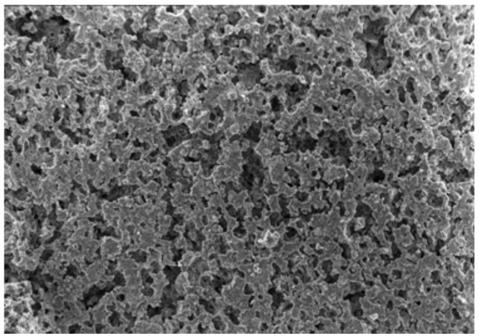

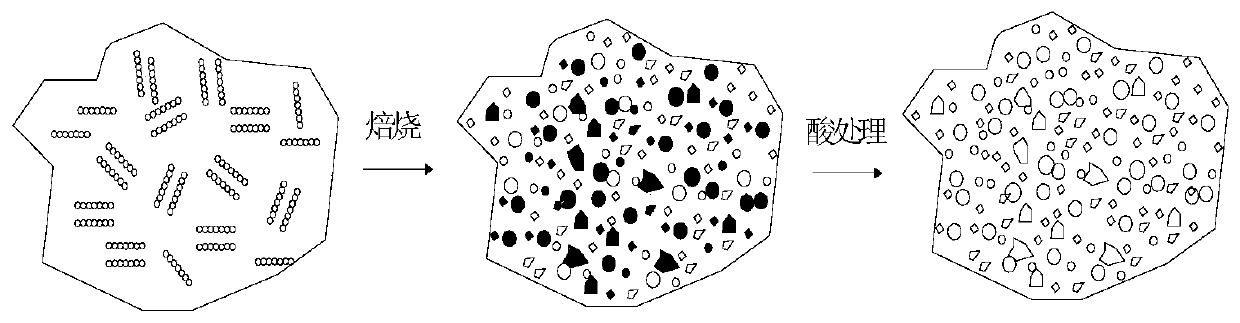

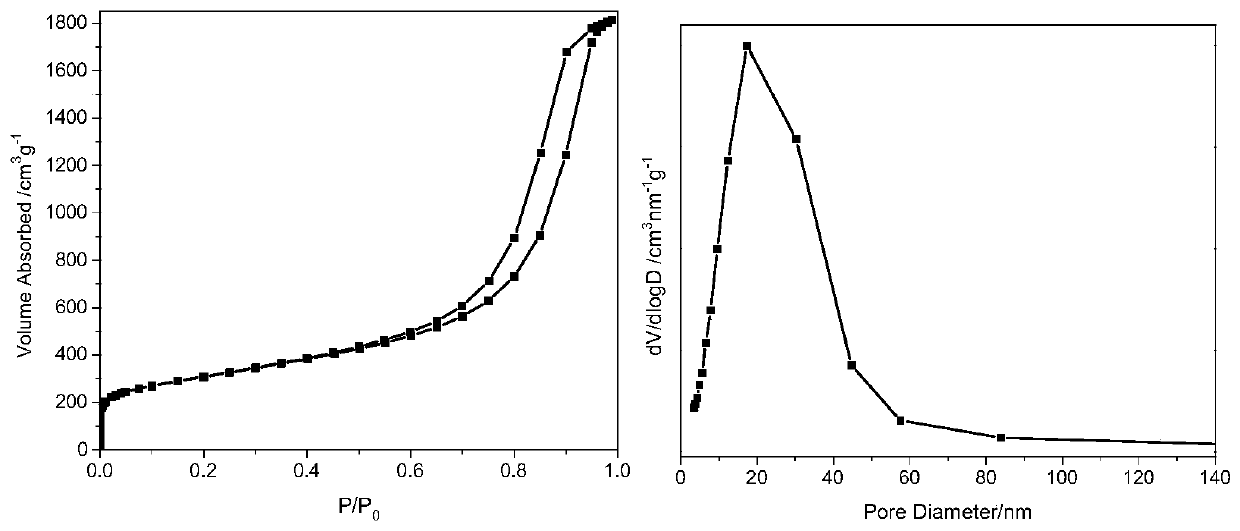

In-situ nitrogen-doped porous carbon material and preparation method thereof

ActiveCN111517323APlay the role of auxiliary hole makingGood hole making effectCarbon preparation/purificationMeth-Porous carbon

The invention relates to a preparation method of an in-situ nitrogen-doped porous carbon material, belonging to the technical field of material science. According to the method, magnesium-aluminum hydrotalcite synthesized in situ serves as an auxiliary pore forming agent, phenols or methyl substituted phenols, formaldehyde and nitrogen-containing monomers are copolymerized, a nitrogen-doped carbonprecursor is generated through a one-pot hydrothermal method, and then high-temperature roasting and acid treatment are carried out to prepare the porous carbon material. The specific surface area, pore size distribution and nitrogen doping amount of the nitrogen-doped porous carbon are regulated and controlled by controlling the molar ratio of phenolic aldehyde, the dosage of nitrogen-containingpolymeric monomers, the ratio of magnesium-aluminum to a phenol polymeric monomers and hydrothermal reaction conditions; and the prepared material is high in carbon residue rate and narrow in pore size distribution range. The method can avoid usage of hydrofluoric acid, and is high in operability and friendly to environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

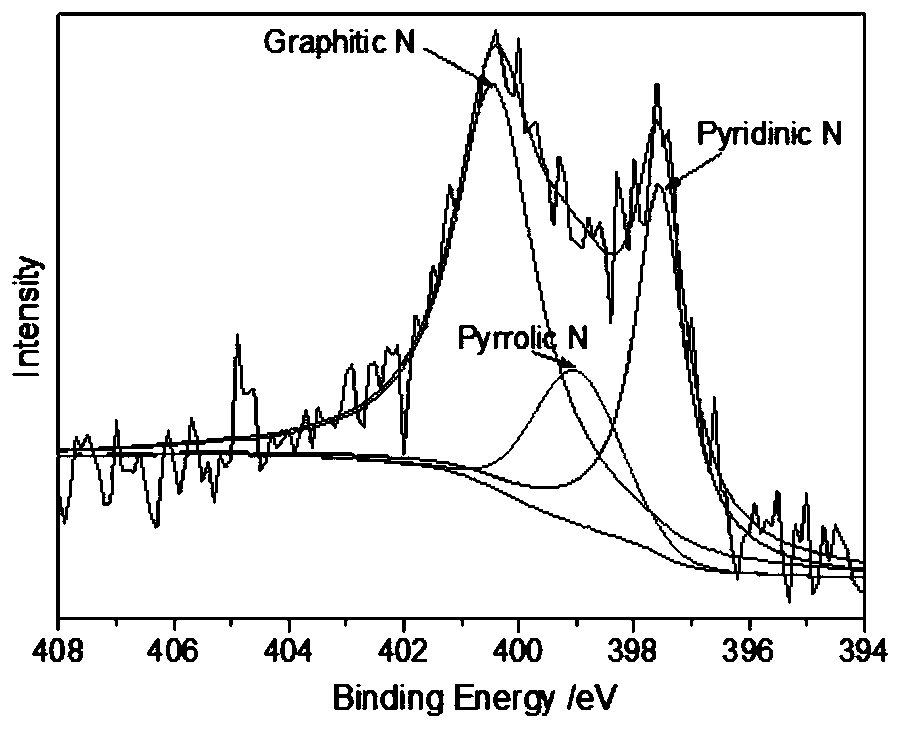

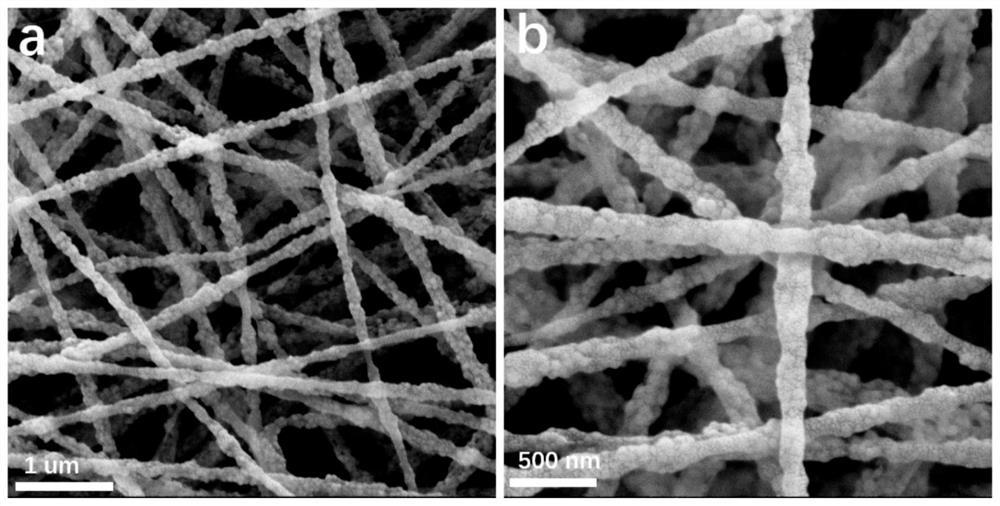

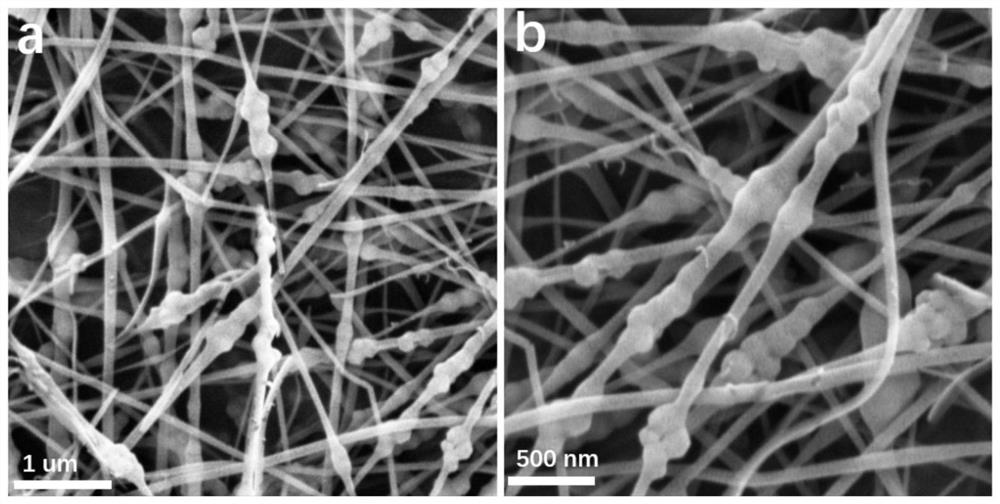

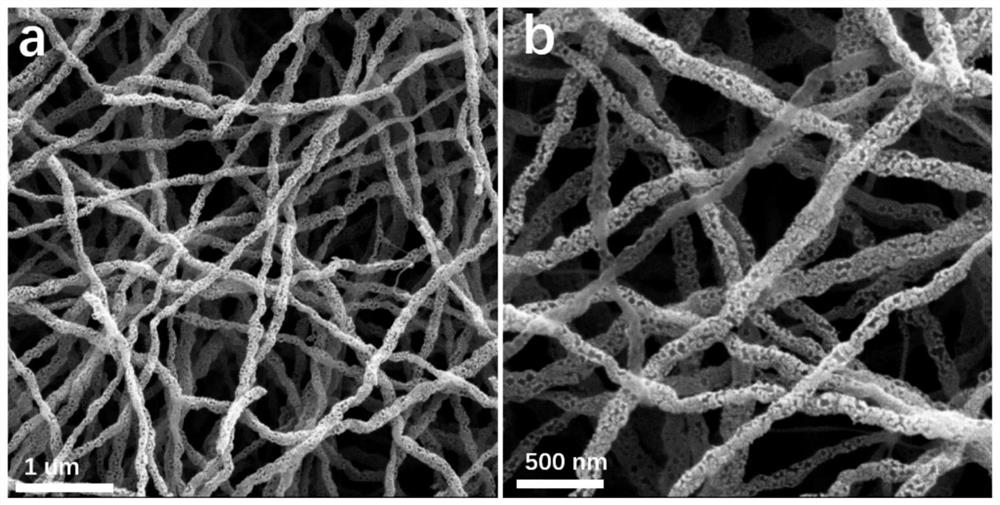

Preparation method of defective nanofiber carbon carrier coupled iron monatomic catalyst

ActiveCN114032576AGood hole making effectImprove catalytic performanceElectrolytic organic productionElectrodesPtru catalystMetal-organic framework

The invention relates to a preparation method of a defective nanofiber carbon carrier coupled iron monatomic catalyst, and belongs to the field of new energy nanomaterials and the technical field of catalysis. The invention aims to solve the problem of low CO2RR reaction activity caused by low specific surface area of the existing catalyst. According to the main scheme, a one-dimensional nanofiber material is prepared from a Fe-doped metal organic framework, polyacrylonitrile and N, N-dimethylformamide through an electrostatic spinning reaction, then Fe single atoms are prepared through high-temperature heat treatment under the protective atmosphere and are loaded on a nitrogen-doped carbon carrier, then under the assistance of diaminonitrile, unstable pyridine nitrogen and pyrrole nitrogen in a carbon skeleton are removed through secondary heat treatment at the temperature of 1,100 DEG C, the carbon-carrier-loaded Fe monatomic catalyst with the intrinsic defects is obtained, and the prepared carbon-carrier-loaded Fe monatomic nanofiber material with the intrinsic defects has high catalytic activity and stability and can be applied to an electrode material for electrocatalytic CO2 reduction reaction.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation methods of polycrystalline silicon wafer texturing liquid and black silicon material and application of polycrystalline silicon wafer texturing liquid and black silicon material in accelerating LeTID recovery of PERC battery

ActiveCN111040766AEasy to useTexturing time is shortFinal product manufactureSurface treatment compositionsPolycrystalline siliconHydrogen fluoride

The invention provides preparation methods of a polycrystalline silicon wafer texturing liquid and a black silicon material and application of the polycrystalline silicon wafer texturing liquid and the black silicon material in accelerating LeTID recovery of a PERC battery. The polycrystalline silicon wafer texturing liquid is prepared from HF (Hydrogen Fluoride), Mn(NO3)2, poly(N-vinylacetamide)and water. By adopting the polycrystalline silicon wafer texturing liquid, a damaged layer does not need to be removed before texturing, a polycrystalline silicon wafer can be directly immersed into the polycrystalline silicon wafer texturing liquid for etching, rapid texturing is realized in a relatively mild environment, the etched polycrystalline silicon wafer can be used for preparing a solarcell after being cleaned for removal of impurities, the use is convenient, and the texturing time is short. The invention also provides a preparation method and application of the black silicon material. The black silicon material has the characteristic of accelerating LeTID recovery when being used for a polycrystalline silicon PERC battery processing technology, can improve the power generationefficiency of the battery, and is beneficial to the popularization and application of the polycrystalline silicon PERC battery.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Honeycomb ceramic carrier for diesel engine soot particle purifying DPF

InactiveCN108675823AHigh apparent porosityHigh mechanical strengthExhaust apparatusSilencing apparatusPorosityMicrowave

The invention discloses a honeycomb ceramic carrier for a diesel engine soot particle purifying DPF (diesel particulate filter). The honeycomb ceramic carrier comprises a main body material, a splicing material and a hole sealing material. A preparation method of the honeycomb ceramic carrier comprises the following steps: preparing main body mud; carrying out extrusion molding on the main body mud, drying the extruded and molded mud, cutting the dried mud to form square blocks, and sintering the square blocks by a vacuum induction furnace to form a honeycomb monomer; carrying out height cutting processing on the honeycomb ceramic monomer, bonding the cut honeycomb ceramic monomer by splicing mud to form a spliced honeycomb ceramic body, carrying out microwave drying until the splicing mudis completely dried, carrying out outer circle processing, covering the sidewall of the spliced honeycomb ceramic body with the splicing mud to form an outer skin layer, and carrying out microwave drying until the outer skin layer is completely dried; and carrying out crossing interval hole sealing on the end surface of the obtained honeycomb ceramic with the hole sealing mud, carrying out microwave drying, and baking the dried honeycomb ceramic at 600 DEG C to obtain the honeycomb ceramic carrier for the diesel engine soot particle purifying DPF. The honeycomb ceramic carrier for the dieselengine soot particle purifying DPF has the advantages of high porosity, large specific surface area, high refractory temperature and high mechanical strength.

Owner:李维地

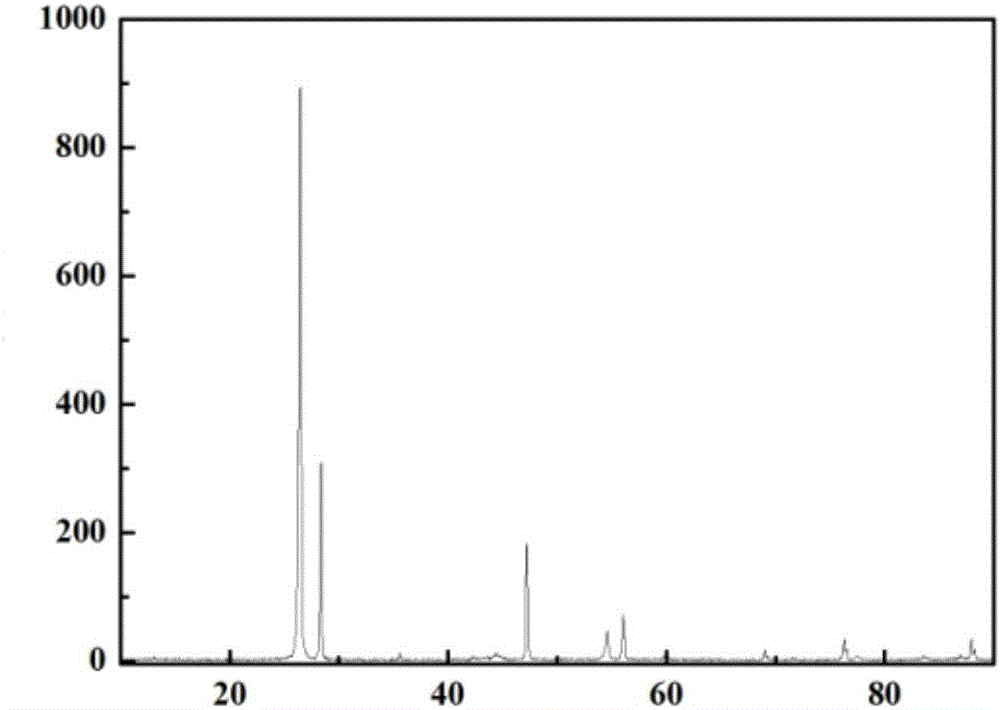

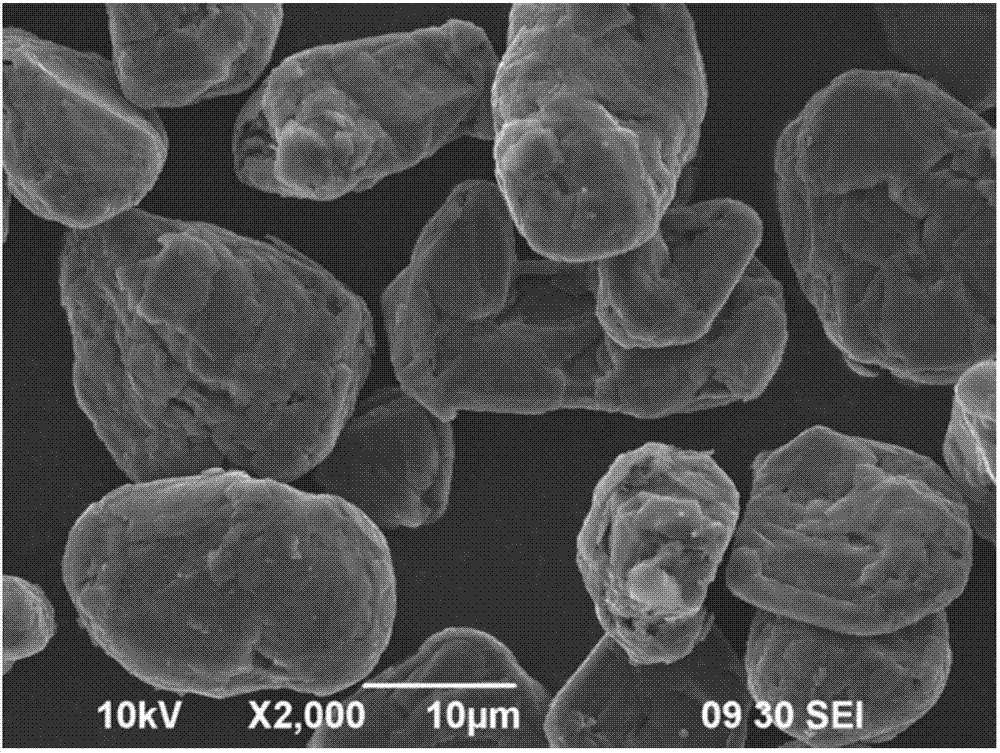

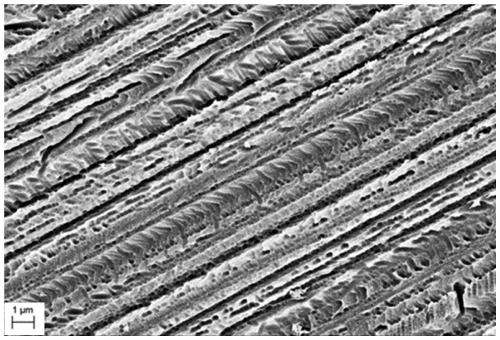

Method for preparing ceramic bond super-hard abrasive tool

ActiveCN101913122BGood hole making effectGood air hole adjustabilityGrinding devicesSpherical granuleTemperature control

The invention relates to a method for preparing a ceramic bond super-hard abrasive tool, which comprises the following steps of: mixing ceramic bond, super-hard abrasive (diamond and cubic boron nitride), filler (common abrasive such as corundum, silicon carbide and the like) and pore-forming agent, adding temporary bond into the mixture, uniformly filling the mixture into a molding mold, moldingthe mixture under the pressure of 60 to 200MPa, and preparing the ceramic super-hard abrasive tool with pores by the processes of drying, roasting, surface treatment, adhesion, modification and shaping treatment and detection. The ceramic super-hard abrasive tool comprises the following components in part by weight: 40 to 75 parts of super-hard abrasive, 30 to 10 parts of filler, 30 to 15 parts of ceramic bond, 3 to 10 parts of temporary bond and 5 to 15 parts of pore-forming agent, wherein the pore-forming agent is macromolecular resin spherical granules (one of acrylic resin, polyimide resin and solid phenolic resin); and the roasting is step temperature-controlled burning. The ceramic super-hard abrasive tool has the advantages of good pore-forming effect, good pore adjustability, novelty and environmental protection, no toxin or harm, and convenience for use and popularization.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

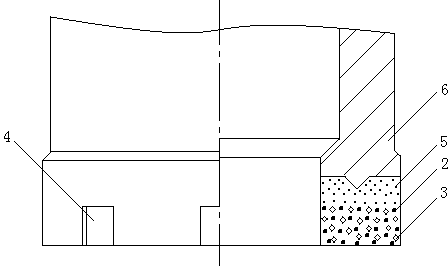

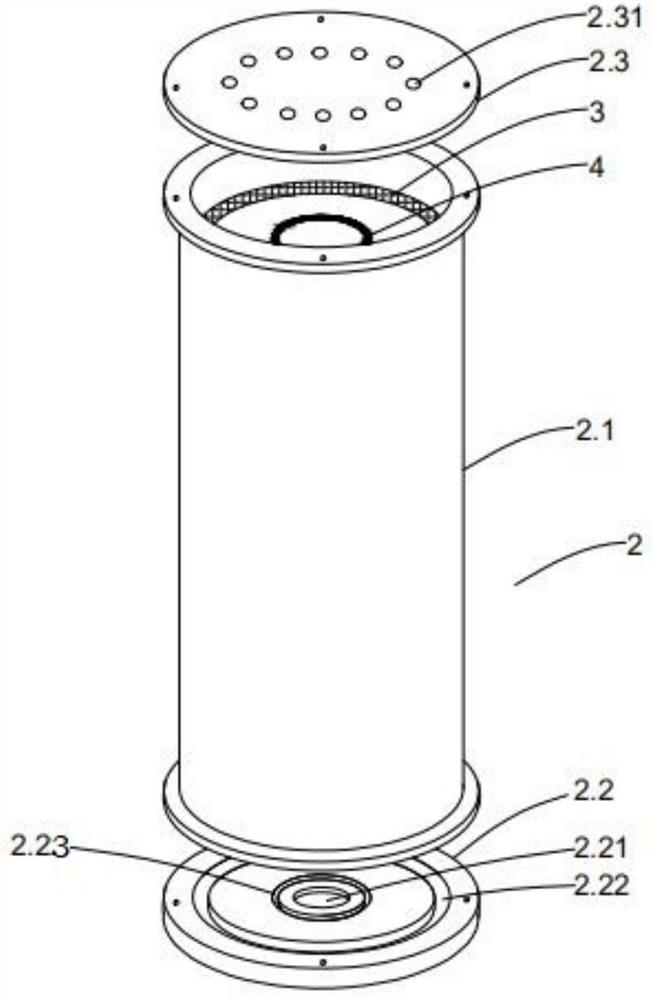

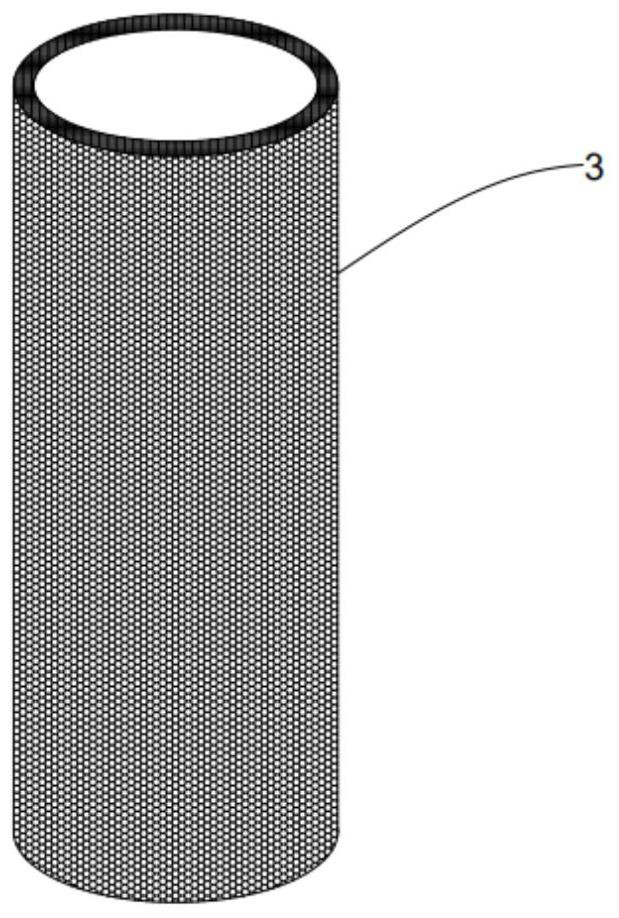

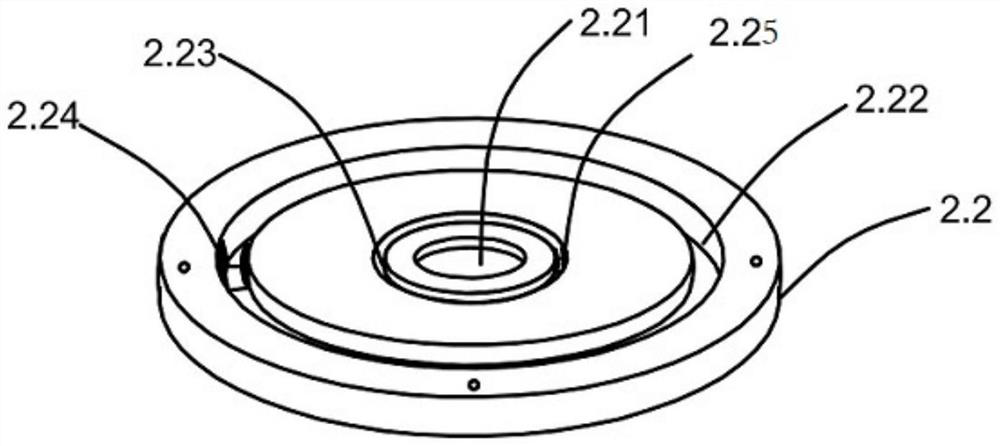

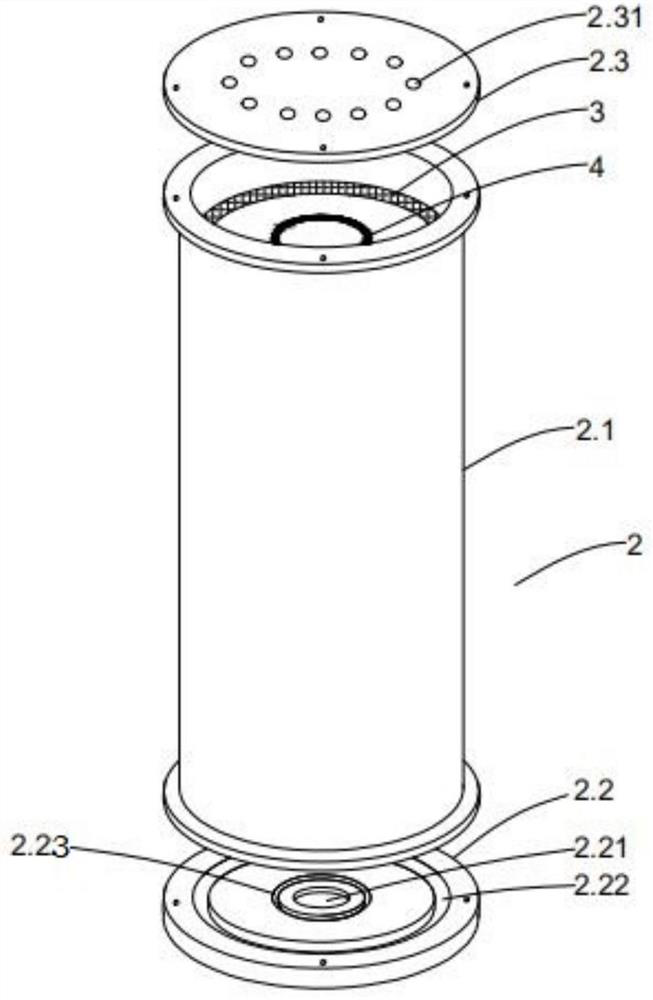

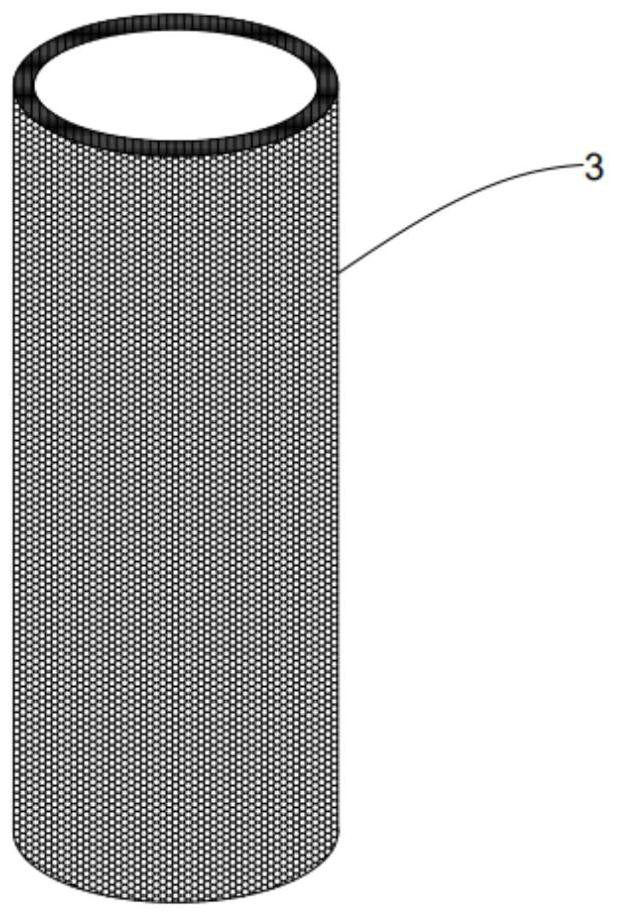

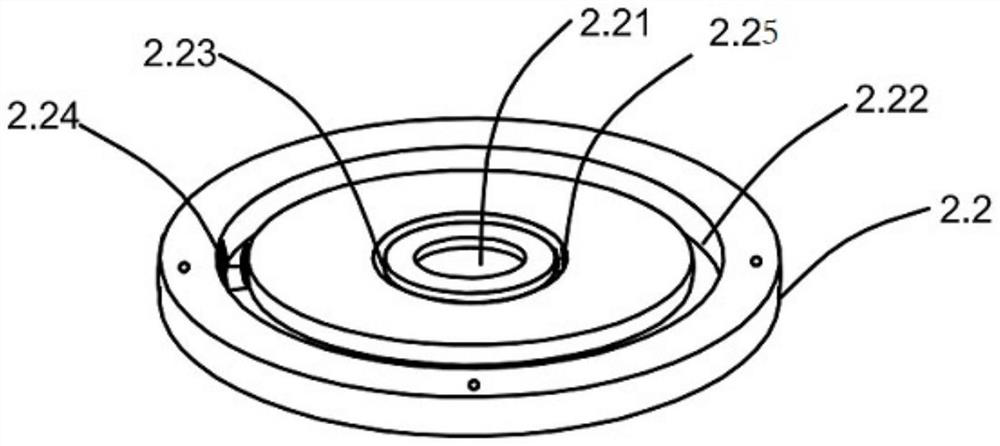

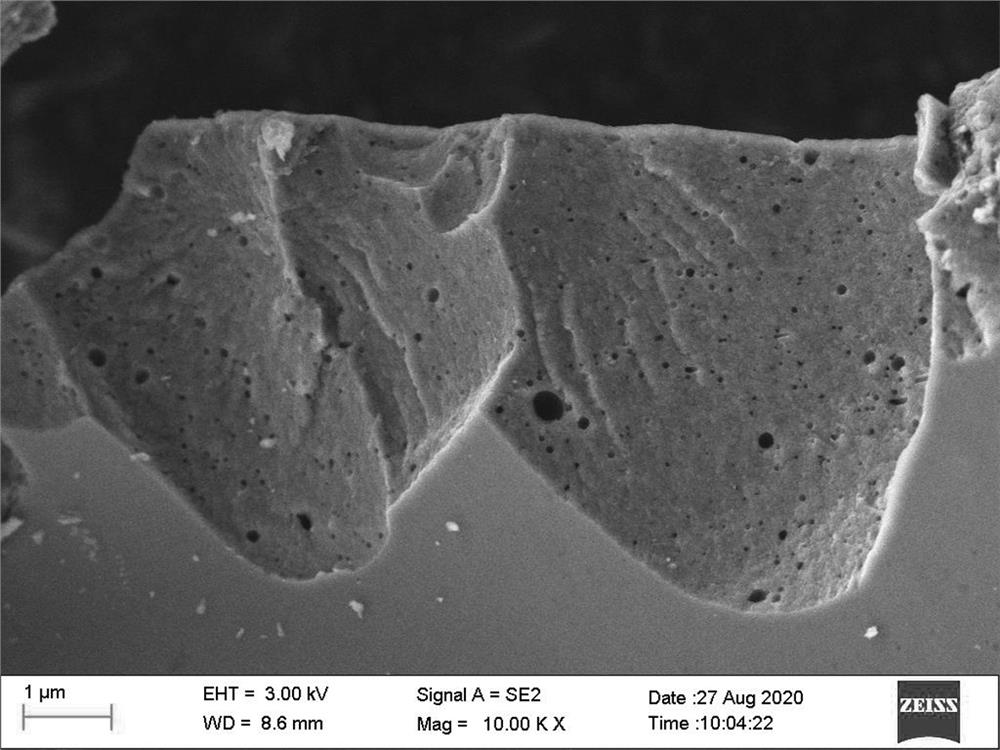

Electrolysis column, electrolysis impurity removal device and impurity removal method for nickel plating liquid electrolysis impurity removal

ActiveCN111647937AImprove adsorption capacityGood removal effectCellsElectrolysisElectrically conductive adhesive

The invention discloses an electrolysis column, electrolysis impurity removal device and impurity removal method for nickel plating liquid electrolysis impurity removal. The electrolysis column comprises a shell, a cathode and an anode. The cathode and the anode are arranged in the shell. The cathode comprises a base material. The base material is plastic of a porous mesh-shaped structure. The surface of the plastic is coated with an electric conduction adhesive layer. The surface of the electric conduction adhesive layer is electroplated with a metal layer. The electrolysis impurity removal device comprises a water pump, an electric controller, an electrolytic bath and a purification tank. The electrolysis column is detachably connected in the electrolytic bath. The input end of the waterpump communicates with an electroplating tank. The output end of the water pump communicates with a water inlet of the electrolysis column. The cathode and the anode of the electrolysis column are both electrically connected with the electric controller. The device further comprises the purification tank. The electrolytic bath is provided with an overflow opening communicating with the purification tank. The purification tank is provided with a water outlet. The water outlet communicates with the electroplating tank. The impurity removal method includes the step of electrolysis impurity removal and the step of impurity recycling and has the characteristics of being simple, feasible and good in impurity removal effect.

Owner:佛山亚特表面技术材料有限公司

A kind of electrolytic column for electrolytic decontamination of nickel plating solution, electrolytic decontamination device and decontamination method

ActiveCN111647937BImprove adsorption capacityGood removal effectCellsMetallurgyElectrically conductive adhesive

The invention discloses an electrolytic column for electrolytic removal of impurities in a nickel plating solution, an electrolytic removal device and a method for removing impurities. The electrolytic column includes a casing, a cathode and an anode arranged in the casing, the cathode includes a base material, and The base material is a plastic with a porous network structure, the surface of the plastic is coated with a conductive adhesive layer, and the surface of the conductive adhesive layer is electroplated with a metal layer; the electrolytic cleaning device includes a water pump, an electric controller, an electrolytic tank and a purification tank, the electrolytic tank is detachably connected with an electrolytic column, the input end of the water pump is connected with the electroplating tank, the output end of the water pump is connected with the water inlet of the electrolytic column, and the cathode and anode of the electrolytic column are connected with the electrolytic column. The controller is electrically connected, the device also includes a purification tank, the electrolytic tank is provided with an overflow port connected to the purification tank, the purification tank is provided with a water outlet, and the water outlet is connected to the electroplating tank; the impurity removal method The method includes an electrolytic impurity removal step and an impurity recovery step, and has the characteristics of simple operation and good impurity removal effect.

Owner:佛山亚特表面技术材料有限公司

Preparation method of hydrophobic porous carbon material

ActiveCN112408360AAvoid wastingAvoid it happening againCarbon preparation/purificationPotassium persulfateOXALIC ACID DIHYDRATE

The invention relates to a preparation method of a hydrophobic porous carbon material, which belongs to the field of carbon materials, and is characterized by comprising the following steps: pre-emulsifying raw materials organic silicon, styrene, acrylate, an emulsifier and deionized water, dropwisely adding potassium peroxodisulfate to perform emulsion polymerization to obtain styrene-acrylic latex SSAL, and blending the SSAL with an oxalic acid solution to obtain a resin matrix PSO; and carbonizing PSO at high temperature to obtain a hydrophobic porous carbon material. According to the method, oxalic acid is used as an activating agent, and a specific adding step is matched, so that the pore-forming effect is guaranteed, and meanwhile, energy waste and waste liquid generation are avoided.

Owner:山东利特纳米技术有限公司

A low-cost high-activity catalytic desulfurization active coke and its preparation method

ActiveCN104028218BImprove desulfurization effectReduce usageOther chemical processesDispersed particle separationPyrolusiteWater vapor

Owner:SICHUAN UNIV

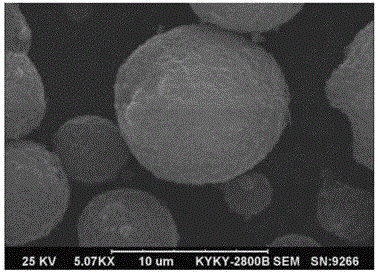

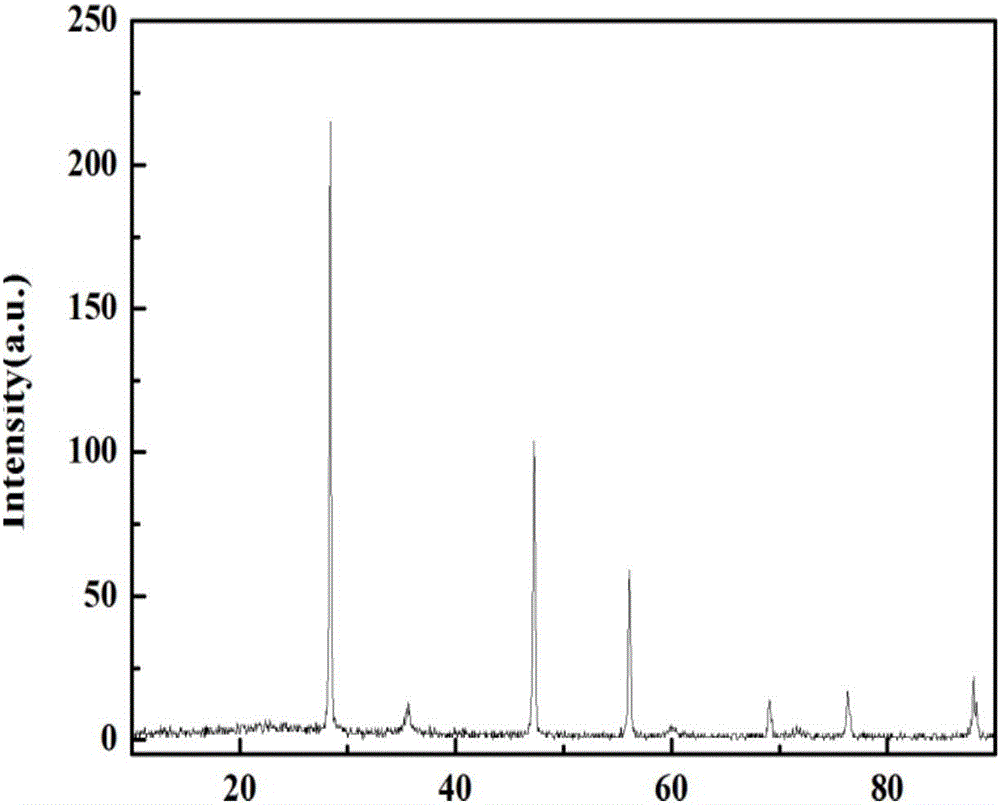

A kind of pitch-based mesoporous spherical activated carbon and preparation method thereof

The invention belongs to the technical field of activated adsorption materials and preparation methods thereof and in particular relates to asphalt-based mesoporous spherical activated carbon and a preparation method thereof. The invention mainly solves the technical problems such as complex preparation method, low production efficiency, high energy consumption and instable product quality existing in the conventional spherical activated carbon. With the adoption of the technical scheme, the invention discloses asphalt-based mesoporous spherical activated carbon and a preparation method thereof, wherein the diameter of the activated carbon is 0.1-0.6mm, the strength is 90-95 percent, the specific surface area is 600-1500m<2> / g, the ash content is less than 1000ppm, the mesoporous rate is 50-85 percent, and the average particle size is 2-3.5nm. The invention has the advantages of simple preparation method, high production efficiency, low energy consumption and stable product quality.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

A kind of preparation method of mesoporous ceramic

ActiveCN107021783BEfficient coatingIncrease microporosityCeramic materials productionCeramicwarePorosityMetal framework

The invention discloses a preparation method of mesoporous ceramic. The mesoporous ceramic is prepared by taking a traditional pore-forming agent clad with an organic metal framework compound as a novel ceramic pore-forming agent, wherein the organic metal framework compound is a coordination polymer, has a three-dimension porous structure and is a high-stability mesoporous material taking metal ions as connection points; meanwhile, the surface of the traditional pore-forming agent is subjected to polydopamine membrane cladding treatment to improve the complexation of the metal ions on the surface of the traditional pore-forming agent, thereby realizing the high-efficient cladding of the organic metal framework compound. The novel pore-forming agent has good pore-forming capability equal to that of the traditional pore-forming agent, and also endows traditional ceramic pores with multidimensional mesoporous structures, the micropore performance of ceramic is obviously improved, and a prepared ceramic product is higher in porosity and more uniform; in addition, the metal ions can be converted into metal or metal compounds in a sintering process, so as to further improve the comprehensive performance of a ceramic body.

Owner:安徽省亚欧陶瓷有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com