Alginate-based porous carbon as well as preparation method and application thereof

An alginate and porous carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as low efficiency, uneven product structure distribution, incomplete reaction, etc., and achieve rich resources and pore capacitance characteristics. Excellent, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

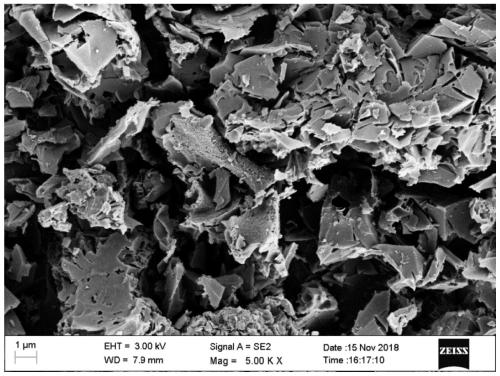

[0061] This example relates to a method for preparing a calcium-modified soluble alginate-based porous carbon precursor, including the following steps:

[0062] Step 1: Dissolve 50g of sodium alginate in 3000ml of deionized water, and stir thoroughly with an electric mixer to obtain an aqueous solution of sodium alginate.

[0063] In step 2, 36 g of calcium lactate was dissolved in 1000 ml of deionized water, and after manual stirring, an aqueous solution of calcium lactate was obtained.

[0064] Step 3: In a constant temperature water bath at 50°C, under the conditions of electrically stirring the solution obtained in Step 1 at a rate of 2000 r / min, slowly add the solution obtained in Step 2 into the solution in Step 1, keep stirring electrically and heat for 6 hours;

[0065] In step 4, the product obtained in step 3 is fully dried and crushed, and then sieved with an 80-mesh sieve to obtain a calcium-modified soluble alginate-based porous carbon precursor for supercapacitor...

Embodiment 2

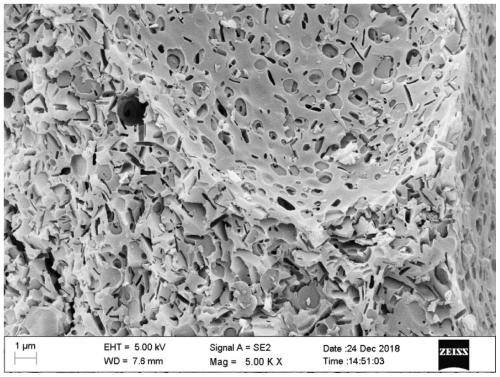

[0067] This example relates to a method for preparing a calcium-modified soluble alginate-based porous carbon precursor, including the following steps:

[0068] Step 1: Dissolve 50g of sodium alginate in 3000ml of deionized water, and stir thoroughly with an electric mixer to obtain an aqueous solution of sodium alginate.

[0069] In step 2, 18 g of calcium lactate was dissolved in 1000 ml of deionized water, and after manual stirring, an aqueous solution of calcium lactate was obtained.

[0070] Step 3, under the conditions of electric stirring the solution obtained in step 1 in a constant temperature water bath at 50°C at a rate of 2000 r / min, slowly add the solution obtained in step 2 into the solution in step 1, keep electric stirring and heat for 6 hours;

[0071] In step 4, the product obtained in step 3 is fully dried and crushed, and then sieved with an 80-mesh sieve to obtain a calcium-modified soluble alginate-based porous carbon precursor for supercapacitors.

Embodiment 3

[0073] This example relates to a method for preparing a calcium-modified soluble alginate-based porous carbon precursor, including the following steps:

[0074] Step 1: Dissolve 50g of sodium alginate in 3000ml of deionized water, and stir thoroughly with an electric mixer to obtain an aqueous solution of sodium alginate.

[0075] In step 2, 6 g of calcium lactate was dissolved in 1000 ml of deionized water, and after manual stirring, an aqueous solution of calcium lactate was obtained.

[0076] Step 3, under the conditions of electric stirring the solution obtained in step 1 in a constant temperature water bath at 50°C at a rate of 2000 r / min, slowly add the solution obtained in step 2 into the solution in step 1, keep electric stirring and heat for 6 hours;

[0077] In step 4, the product obtained in step 3 is fully dried and crushed, and then sieved with an 80-mesh sieve to obtain a calcium-modified soluble alginate-based porous carbon precursor for supercapacitors.

PUM

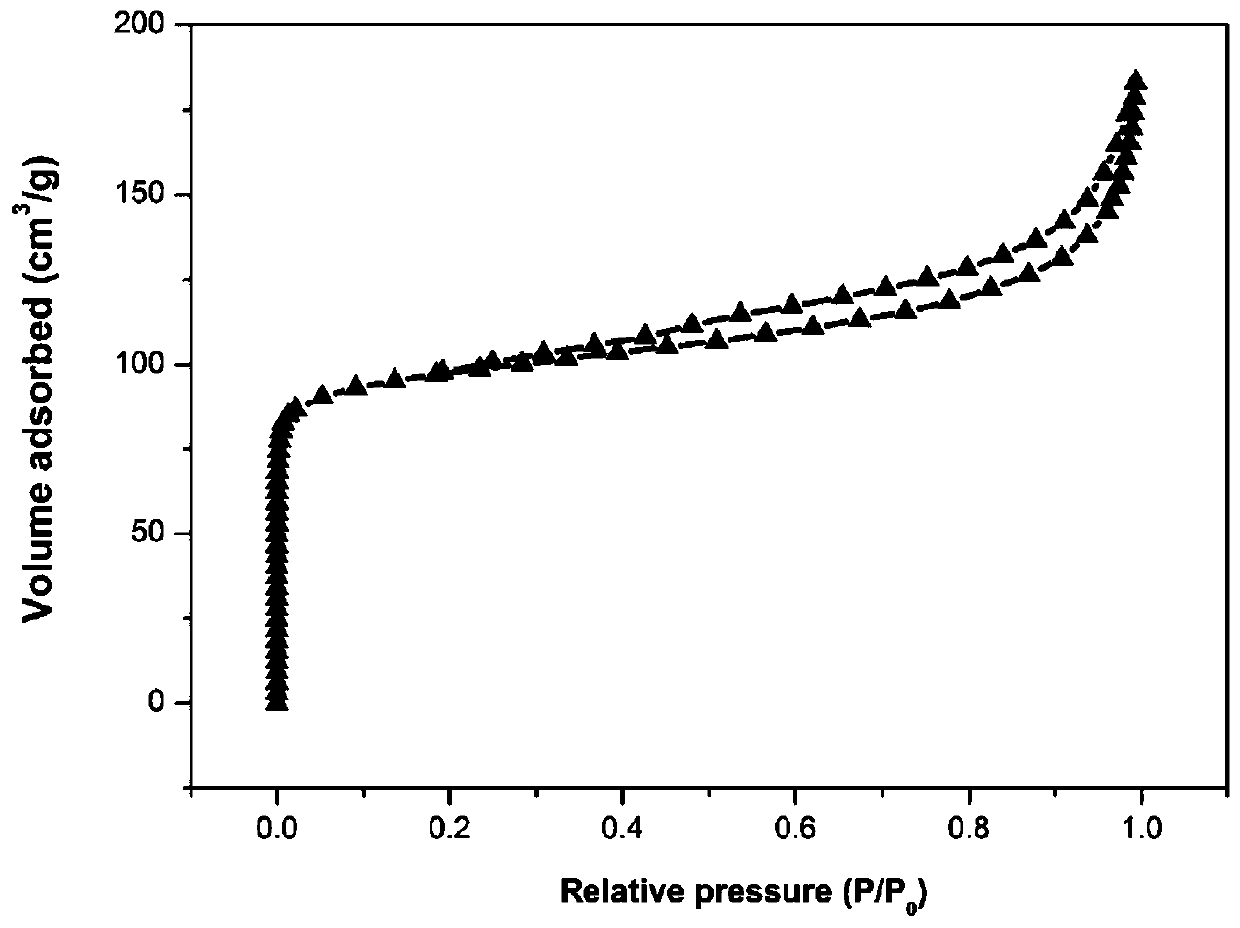

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Micropore average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com