Preparation method of defective nanofiber carbon carrier coupled iron monatomic catalyst

A nanofiber and carbon carrier technology, applied in the field of catalysis and new energy nanomaterials, can solve the problems of low CO2RR reaction activity and low specific surface area of the catalyst, and achieve the effect of improving the catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The electrospinning method was used to prepare the iron single atom anchored in the nanofiber carbon support material.

[0055] Concrete preparation steps are as follows:

[0056] 1) Add 0.3 g of Fe-doped MOF into 3.55 mL of N,N-dimethylformamide, and stir ultrasonically to form a dispersion.

[0057] 2) Add 0.3 g of polyacrylonitrile into the above dispersion liquid, stir for 24 hours and ultrasonically homogenize.

[0058] 3) The above mixed solution was transferred to a needle tube for electrospinning, and the voltage between the positive and negative electrodes was selected as 17kV to obtain Fe-doped metal organic framework nanofibers coated with polyacrylonitrile.

[0059] 4) Pre-oxidize the above materials in a muffle furnace at 220° C. for 2 hours.

[0060] 5) The above materials were reacted at 900° C. for 2 h under the condition of Ar as protective gas.

[0061] 6) Mix the above materials in 1M HNO 3 The solution was washed once, and dried under vacuum at 8...

Embodiment 2

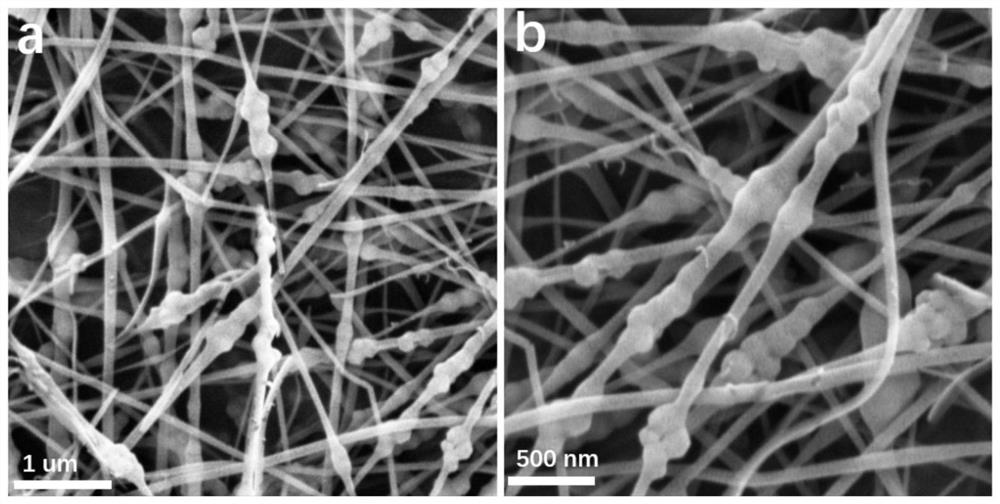

[0064] The steps in Example 2 are similar to those in Example 1, and the other reaction conditions remain unchanged, except that the amount of Fe-doped metal-organic framework in step 1) is changed to 0.5 g, and the amount of polyacrylonitrile in step 2) is changed to 0.25 g, and other reaction conditions remain unchanged. figure 2 The SEM image of the Fe-doped metal-organic framework nanofibers coated with polyacrylonitrile was obtained for Example 2, as can be seen from the figure figure 1 The homogeneously coated nanofibers are no longer seen, indicating that the amount of metal-organic framework and polyacrylonitrile added has a great influence on the prepared fiber structure.

Embodiment 3

[0066] The steps in Example 3 are similar to those in Example 1, and other reaction conditions remain unchanged, except that the heat treatment temperature in step 7) is changed to 900°C. Figure 9 Obtain the linear cyclic voltammogram (LSV) of sample under argon and carbon dioxide gas saturation for embodiment 3, electrolyte is the KHCO of 0.5M 3 solution, the scan window is 0 to -1V (vs. RHE), and the scan speed is 5mV / s. compared to Figure 8 It can be seen that, compared with the LSV curve of the sample treated at 1100 °C, the LSV curve obtained by the second heat treatment at 900 °C is lower in current density, indicating that the temperature of the second heat treatment has a great influence on the activity of the catalyst.

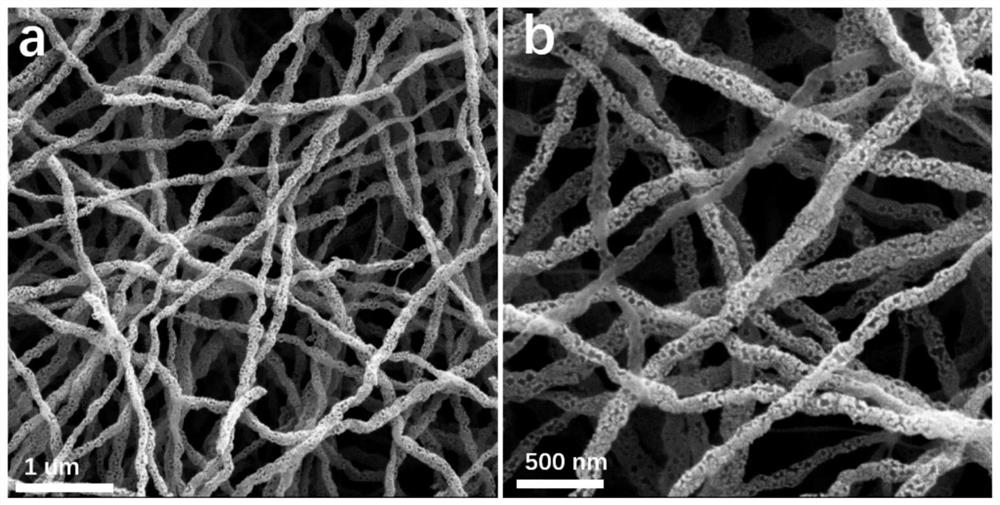

[0067] The morphology of the obtained carbon support-coupled iron single-atom catalyst nanofibers with defects was characterized by scanning electron microscopy.

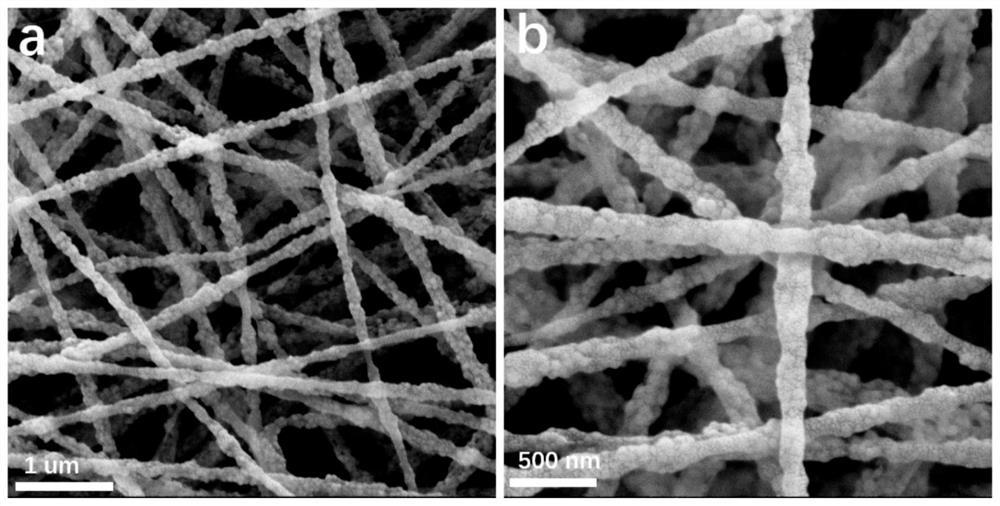

[0068] figure 1 It is the SEM image of the polyacrylonitrile-coated Fe-doped metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com