Preparing method of nanometer silicon-carbon composite lithium-ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problem that the agglomeration of nanomaterials is difficult to disperse uniformly, it is difficult to overcome the first efficiency, and the chemical vapor deposition is difficult to coat. Silicon materials and other problems, to achieve the effect of low price, excellent pore-making effect and rich source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

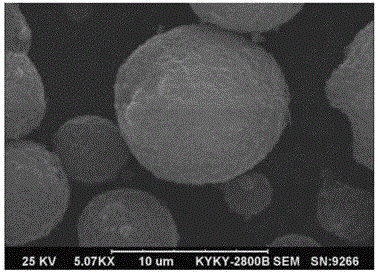

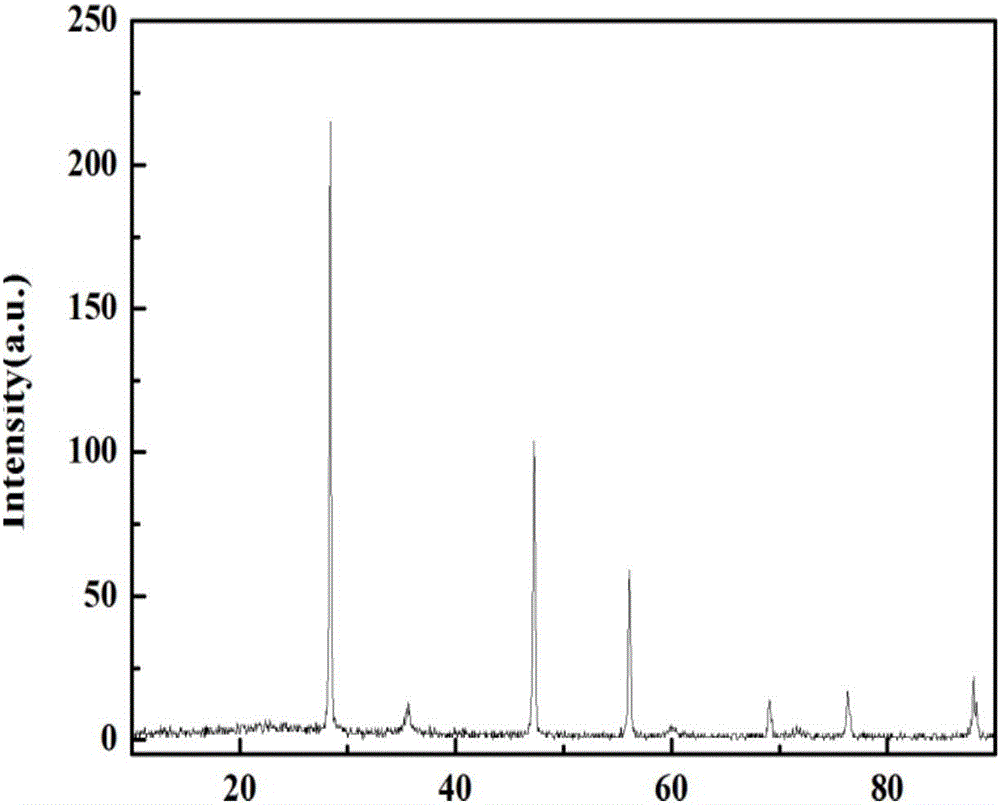

[0031] Put 40g of polycrystalline silicon with a purity of 99.999%, 20g of paraffin wax, 20g of glucose, and 100g of ethanol in a ball milling tank device, control the ball milling speed to 400 rpm, and after 40 hours of ball milling, dry and granulate to obtain a precursor. Place it in an oven at 150°C for 10 hours to melt out the paraffin in the particles to obtain the precursor material. Under the protection of nitrogen, the precursor material is subjected to high-temperature sintering treatment, and the heating rate during high-temperature sintering treatment is controlled at 10°C / min. 1100°C, sintering time is 5h, the carbon-coated porous silicon material is obtained, and the XRD of carbon-coated porous silicon carbon is shown in the attached figure 1 , SEM see attached figure 2, weighed 5g of carbon-coated porous silicon material after sintering, and 95g of mesophase carbon microspheres, and mixed them in a V-type machine for 4 hours to obtain anode materials for nano-s...

Embodiment 2

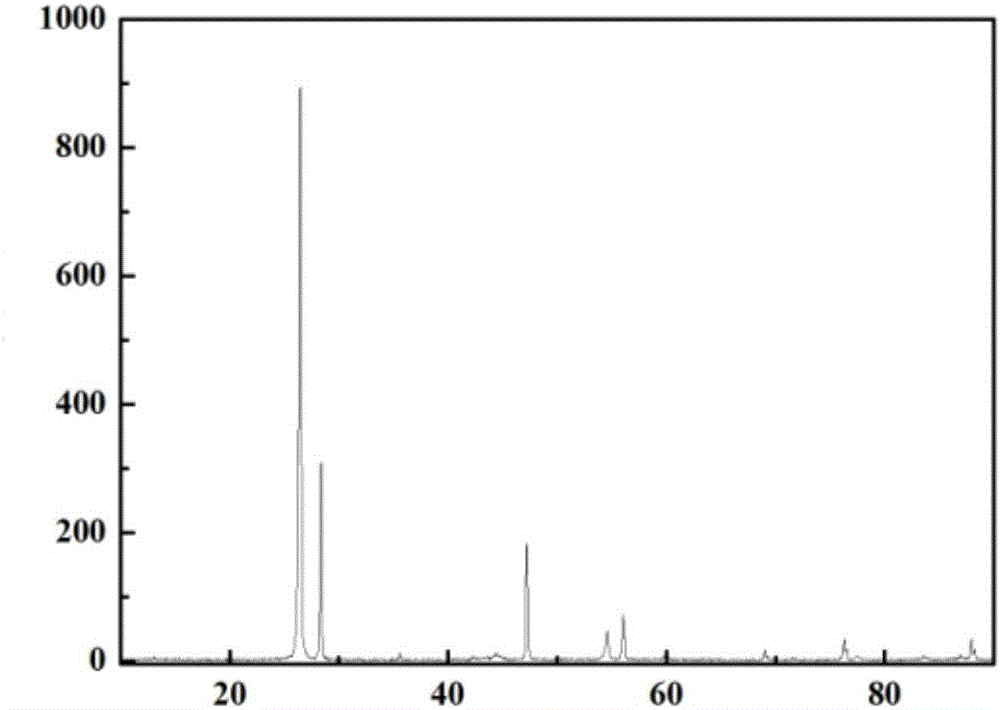

[0035] Put 20g of polycrystalline silicon with a purity of 99.999%, 40g of paraffin wax, 10g of glucose, and 100g of ethanol in a ball mill tank, and after ball milling at 400 rpm for 40 hours, dry and granulate to obtain precursor 1, and place the precursor in an oven at 150°C After 24 hours, the paraffin in the particles was melted to obtain the precursor material. Under the protection of nitrogen, the precursor material was sintered at a high temperature. The heating rate was 5°C / min, the sintering temperature was 1100°C, and the sintering time was 5h to obtain porous silicon carbon. Materials, carbon-coated porous silicon carbon XRD see appendix figure 1 , SEM see attached figure 2 , weighed 5g of the sintered material, 95g of mesophase carbon microspheres, and mixed them in a V-type machine for 4 hours to obtain a nano-silicon-carbon composite lithium-ion battery negative electrode material XRD test. image 3 .

[0036] Its charging capacity is 446mAh / g, and its initia...

Embodiment 3

[0038] Put 20g of monocrystalline silicon with a purity of 99.999%, 40g of naphthalene, 10g of glucose, and 100g of ethanol in a ball mill tank, and after ball milling at 400 rpm for 40 hours, dry and granulate to obtain a precursor. Put it in the oven for 24 hours, melt the paraffin in the particles to obtain the precursor material, under the protection of nitrogen, carry out high-temperature sintering treatment on the precursor 2, the heating rate is 10°C / min, the sintering temperature is 1100°C, and the sintering time is 5h, and the porous Silicon carbon material, carbon-coated porous silicon carbon XRD see appendix figure 1 , SEM see attached figure 2 , weighed 5g of sintered material, 95g of artificial graphite, and mixed it in a V-type machine for 4 hours to obtain a nano-silicon-carbon composite lithium-ion battery negative electrode material. XRD test is shown in the appendix image 3 .

[0039] Its charging capacity is 440mAh / g, and its first-time efficiency is 89%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com