Preparation method of porous graphene/carbon nano tube lithium sulfur anode material

A technology of porous graphene and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of active material sulfur loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

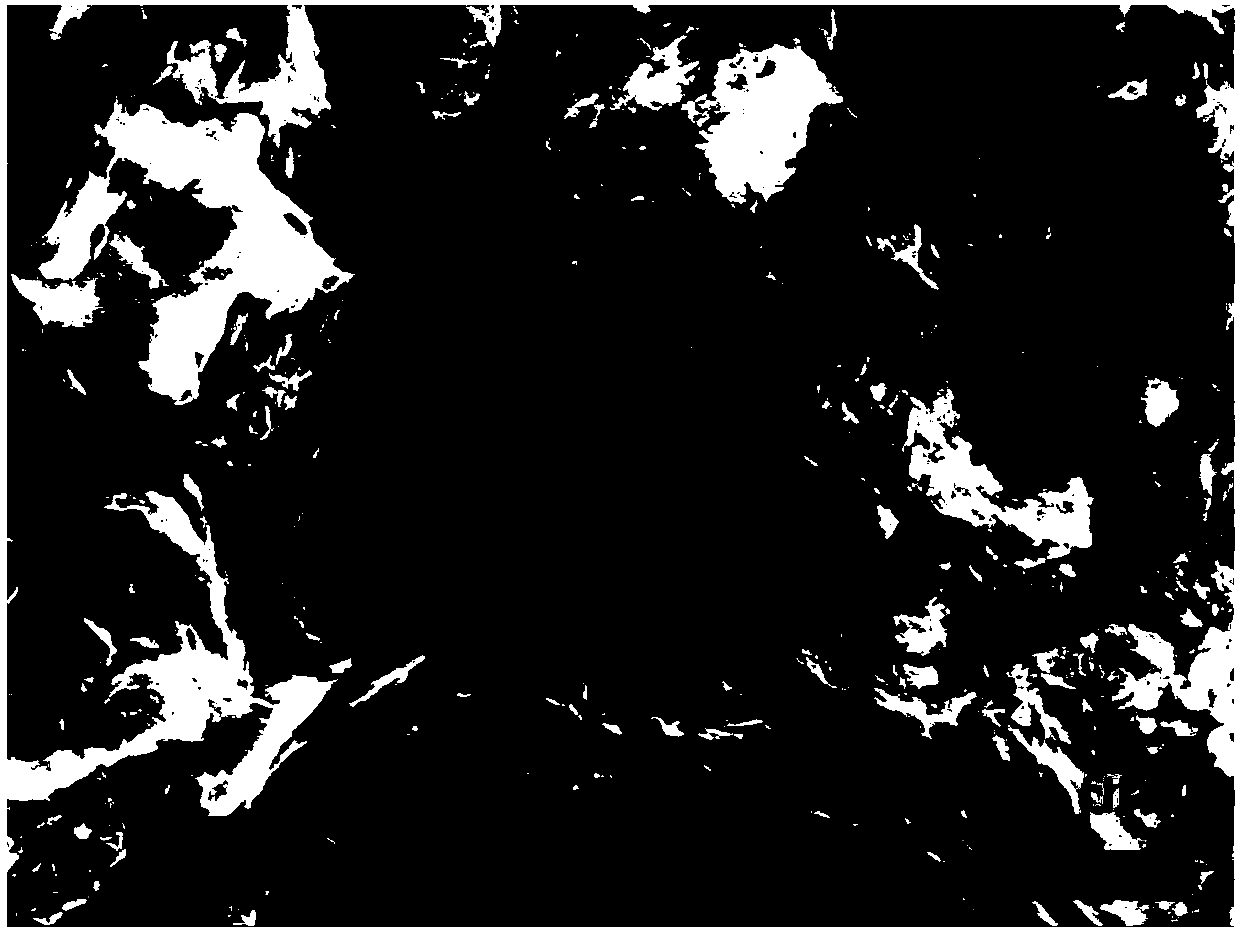

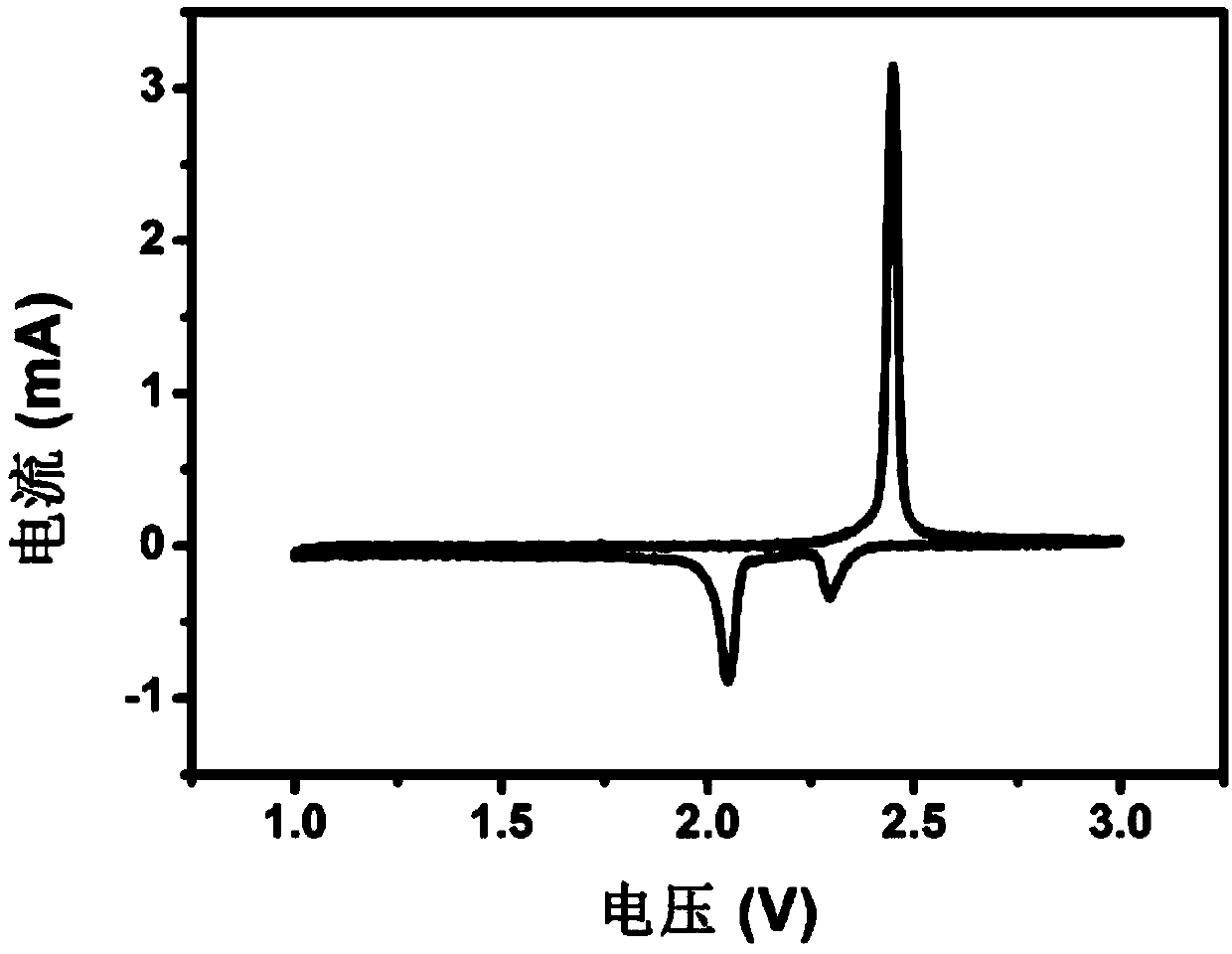

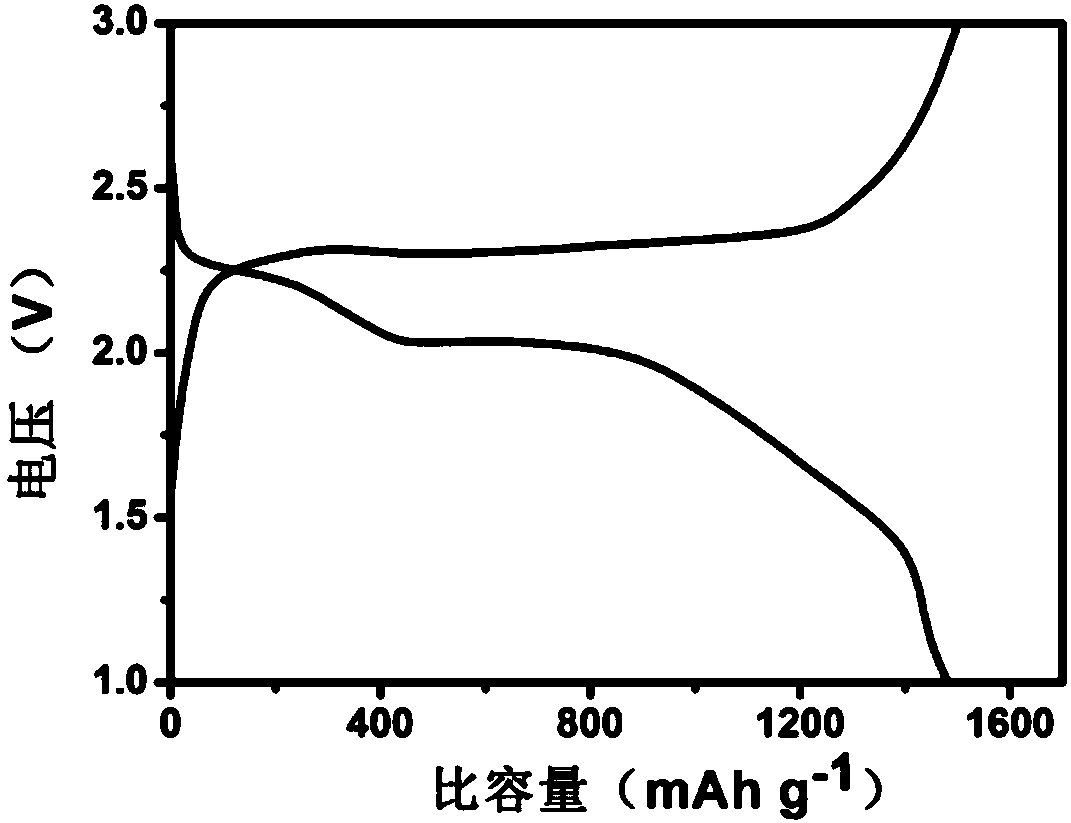

Image

Examples

Embodiment 1

[0021] 1) Preparation of monodisperse silica microspheres: mix ethyl orthosilicate and absolute ethanol, the volume ratio of ethyl orthosilicate and absolute ethanol is 1:20.4; in addition, deionized water, concentrated ammonia water and Mix absolute ethanol, the volume ratio of deionized water, concentrated ammonia water and absolute ethanol is 1:3.5:16.8.

[0022] 2) Mix and react the two groups of solutions in step 1) for 24 hours with magnetic stirring to obtain monodisperse silica microspheres with a diameter of 200-300 nm. After drying, add deionized water to prepare a water dispersion with a mass percentage concentration of 50 mg / mL. Liquid A.

[0023] 3) Prepare graphene oxide: mix graphite and sodium nitrate, add concentrated sulfuric acid ice bath and stir; then add potassium permanganate, remove ice bath and titrate deionized water, pour hydrogen peroxide, graphite, sodium nitrate and potassium permanganate The mass ratio is 2.5:1:6.3, and the volume ratio of conce...

Embodiment 2

[0032] 1) Preparation of monodisperse silica microspheres: mix ethyl orthosilicate and absolute ethanol, the volume ratio of ethyl orthosilicate and absolute ethanol is 1:20.4; in addition, deionized water, concentrated ammonia water and Mix absolute ethanol, the volume ratio of deionized water, concentrated ammonia water and absolute ethanol is 1:3.5:16.8.

[0033] 2) Mix and react the two groups of solutions in step 1) for 24 hours with magnetic stirring to obtain monodisperse silica microspheres with a diameter of 200-300 nm. After drying, add deionized water to prepare a water dispersion with a mass percentage concentration of 50 mg / mL. Liquid A.

[0034] 3) Prepare graphene oxide: mix graphite and sodium nitrate, add concentrated sulfuric acid ice bath and stir; then add potassium permanganate, remove ice bath and titrate deionized water, pour hydrogen peroxide, graphite, sodium nitrate and potassium permanganate The mass ratio is 2.5:1:6.3, and the volume ratio of conce...

Embodiment 3

[0040] 1) Preparation of monodisperse silica microspheres: mix ethyl orthosilicate and absolute ethanol, the volume ratio of ethyl orthosilicate and absolute ethanol is 1:20.4; in addition, deionized water, concentrated ammonia water and Mix absolute ethanol, the volume ratio of deionized water, concentrated ammonia water and absolute ethanol is 1:3.5:16.8.

[0041] 2) Mix and react the two groups of solutions in step 1) for 24 hours with magnetic stirring to obtain monodisperse silica microspheres with a diameter of 200-300 nm. After drying, add deionized water to prepare a water dispersion with a mass percentage concentration of 50 mg / mL. Liquid A.

[0042] 1) Prepare graphene oxide: mix graphite and sodium nitrate, add concentrated sulfuric acid ice bath and stir; then add potassium permanganate, remove ice bath and titrate deionized water, pour hydrogen peroxide, graphite, sodium nitrate and potassium permanganate The mass ratio is 2.5:1:6.3, and the volume ratio of conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com