Aperture-controllable honeycomb three-dimensional porous MXene and general synthesis method thereof

A three-dimensional porous, synthetic method technology, applied in the field of nanomaterials, can solve the problems of reducing specific surface area, porosity and ion permeability, restricting efficient utilization of surface and interface, restricting application and processing performance, etc., to suppress stacking and agglomeration, Excellent processing characteristics and structural stability, effect with general purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

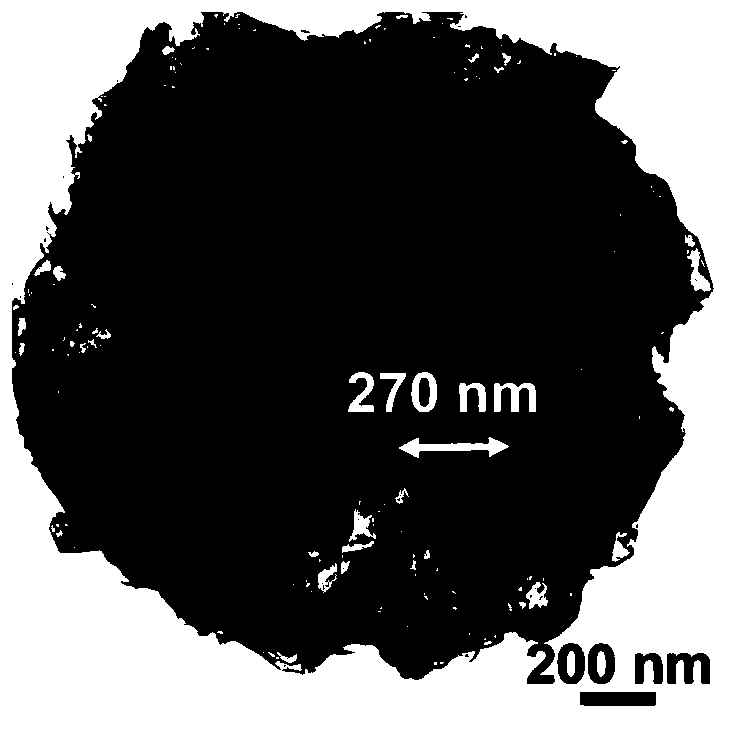

[0025] 1) Disperse MXene and polystyrene nanospheres with a particle size of 260nm in ethanol (the mass ratio of MXene to polystyrene nanospheres is 1:0.01), and ultrasonically disperse for 30min to prepare MXene concentration of 20mg mL -1 precursor solution.

[0026] 2) Utilize an ultrasonic atomizer to atomize the precursor solution obtained in step 1) into aerosol droplets with a size of about several microns.

[0027] 3) Ar gas is used as the carrier gas, and the carrier gas flow rate is 0.1L h -1 , the aerosol droplets obtained in step 2) were blown into a tube furnace with a preset temperature of 400 °C, and pyrolyzed for 1 min to obtain a honeycomb three-dimensional porous MXene structure. The obtained honeycomb three-dimensional porous MXene particle is a three-dimensional structure particle with an average size of about 3.5 μm, assembled by three-dimensional close cross-linking of MXene, and a honeycomb porous morphology with an inner diameter of 260 nm, and its spe...

Embodiment 2

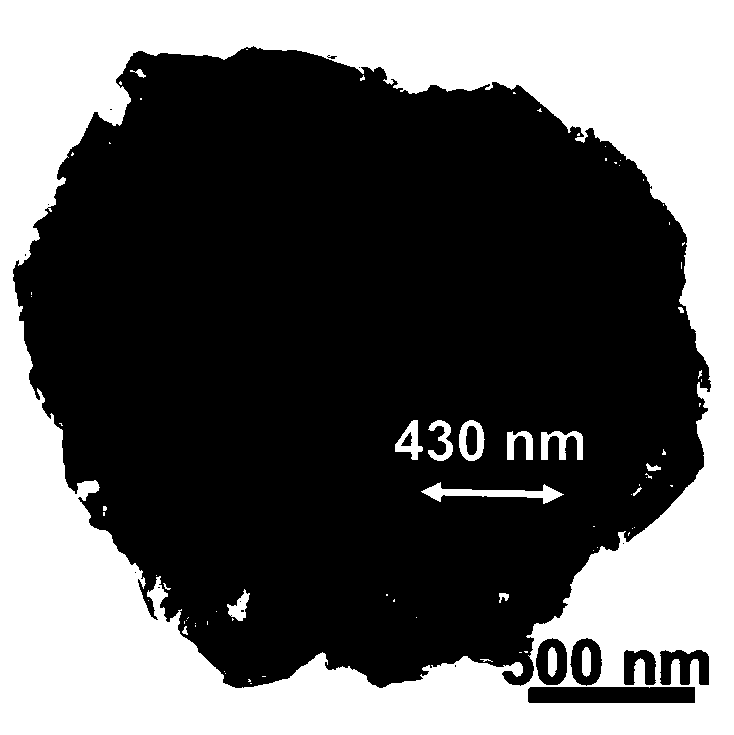

[0029] 1) Disperse MXene and polystyrene nanospheres with a particle size of 430nm (the mass ratio of MXene to polystyrene nanospheres is 1:1) in water, and ultrasonically disperse for 30min to prepare MXene with a concentration of 10mg mL -1 precursor solution.

[0030] 2) Utilize an ultrasonic atomizer to atomize the precursor solution obtained in step 1) into aerosol droplets with a size of about several microns.

[0031] 3) Ar gas is used as the carrier gas, and the carrier gas flow rate is 2L h -1 , the aerosol micro-droplets mentioned in 2) were blown into a tube furnace with a preset temperature of 600°C for pyrolysis, and the pyrolysis time was 30s to obtain a honeycomb three-dimensional porous MXene structure. The obtained honeycomb three-dimensional porous MXene particle is a three-dimensional structure particle with an average size of about 3.5 μm, assembled by three-dimensional tight cross-linking of MXene, and a honeycomb porous morphology with an inner diameter ...

Embodiment 3

[0033] 1) Disperse MXene and polystyrene nanospheres with a particle size of 800nm (the mass ratio of MXene to polystyrene nanospheres is 1:100) in water, and ultrasonically disperse for 60min to prepare MXene with a concentration of 0.5mg mL -1 precursor solution.

[0034] 2) Utilize an ultrasonic atomizer to atomize the MXene precursor solution obtained in step 1) into aerosol droplets with a size of about several microns.

[0035] 3) Ar gas is used as the carrier gas, and the carrier gas flow rate is 5L h -1 , the aerosol droplets obtained in step 2) were blown into a tube furnace with a preset temperature of 800°C for pyrolysis, and the pyrolysis time was 10s to obtain a honeycomb three-dimensional porous MXene structure. The obtained honeycomb three-dimensional porous MXene particle is a three-dimensional structure particle with an average size of about 3.5 μm, assembled by three-dimensional close cross-linking of MXene, and a honeycomb porous morphology with an inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com