MXene nanotube and general synthesis method thereof

A synthesis method and nanotube technology, applied in the field of nanomaterials, can solve the problems of affecting and limiting the macroscopic performance and processing performance of MXene, and achieve the effects of good economy, simple and controllable preparation method, and inhibition of lamination and agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

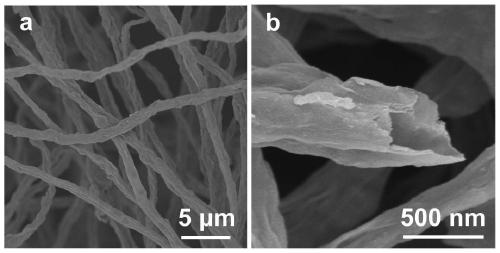

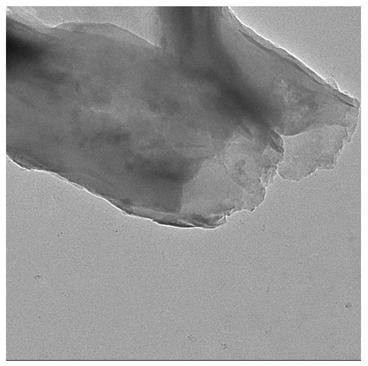

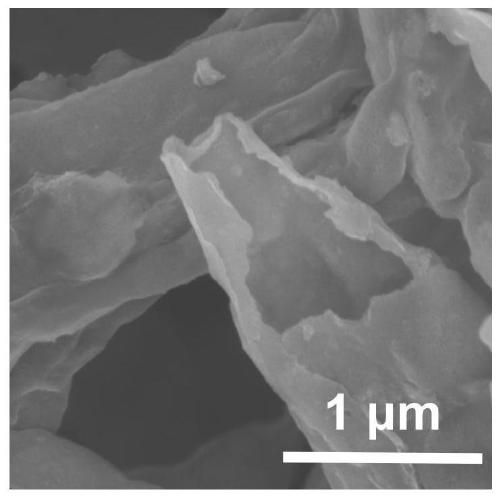

Image

Examples

Embodiment 1

[0029] (1) Disperse MXene in N,N-dimethylformamide under normal temperature and pressure conditions to prepare 4ml with a concentration of 10mgmL -1 of the dispersion.

[0030] (2) Dissolve polyacrylonitrile in the MXene dispersion prepared in step (1) at 50°C and mix evenly, wherein the concentration of polyacrylonitrile in the mixed solution is 100 mg mL -1 .

[0031] (3) Dissolve polymethyl methacrylate in N,N-dimethylformamide at 60°C to form a concentration of 200mg mL -1 homogeneous solution.

[0032] (4) Put the mixed solution in step (2) into syringe A, put the solution in step (3) into syringe B, and use an electrospinning machine to carry out coaxial electrospinning. The mixed solution described in step (2) is the outer layer solution, and the advancing speed is 1.0mlh -1 , the solution described in step (3) is the inner layer solution, and the advancing speed is 0.8ml h -1 , the positive voltage is 18kv, the negative voltage is -2.5kv, the spinning distance is ...

Embodiment 2

[0035] (1) Disperse MXene in N,N-dimethylformamide under normal temperature and pressure conditions to prepare 4ml with a concentration of 40mgmL -1 of the dispersion.

[0036] (2) Dissolve polyacrylonitrile in the MXene dispersion prepared in step (1) at 55°C and mix evenly, wherein the concentration of polyacrylonitrile in the mixed solution is 110 mg mL -1 .

[0037] (3) Dissolve polymethyl methacrylate in N,N-dimethylformamide at 70°C to form a concentration of 225mg mL -1 homogeneous solution.

[0038] (4) Put the mixed solution in step (2) into syringe A, put the solution in step (3) into syringe B, and use an electrospinning machine to carry out coaxial electrospinning. The mixed solution described in step (2) is the outer layer solution, and the advancing speed is 1.1mlh -1 , the solution described in step (3) is the inner layer solution, and the advancing speed is 0.9ml h -1 , the positive voltage is 20kv, the negative voltage is -2.5kv, the spinning distance is ...

Embodiment 3

[0041] (1) Disperse MXene in N,N-dimethylformamide under normal temperature and pressure conditions to prepare 4ml with a concentration of 60mgmL -1 of the dispersion.

[0042] (2) Dissolve polyacrylonitrile in the MXene dispersion prepared in step (1) at 60°C and mix evenly, wherein the concentration of polyacrylonitrile in the mixed solution is 120mg mL -1 .

[0043] (3) Dissolve polymethyl methacrylate in N,N-dimethylformamide at 75°C to form a concentration of 250mg mL -1 homogeneous solution.

[0044] (4) Put the mixed solution in step (2) into syringe A, put the solution in step (3) into syringe B, and use an electrospinning machine to carry out coaxial electrospinning. The mixed solution described in step (2) is the outer layer solution, and the advancing speed is 1.2mlh -1 , the solution described in step (3) is the inner layer solution, and the advancing speed is 1.0ml h -1 , the positive voltage is 22kv, the negative voltage is -2.5kv, the spinning distance is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com