Equipment inhibiting generation of dioxin in incineration flue gas and use method of equipment

A technology for generating equipment and flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve the problems of increasing the operation consumption of back-end induced draft fans, collection and transportation of small micro-powder, collection and transportation of micro-powder, etc. problems, to achieve a good effect of comprehensive utilization of resources, reduce acid gas content, and inhibit the formation of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

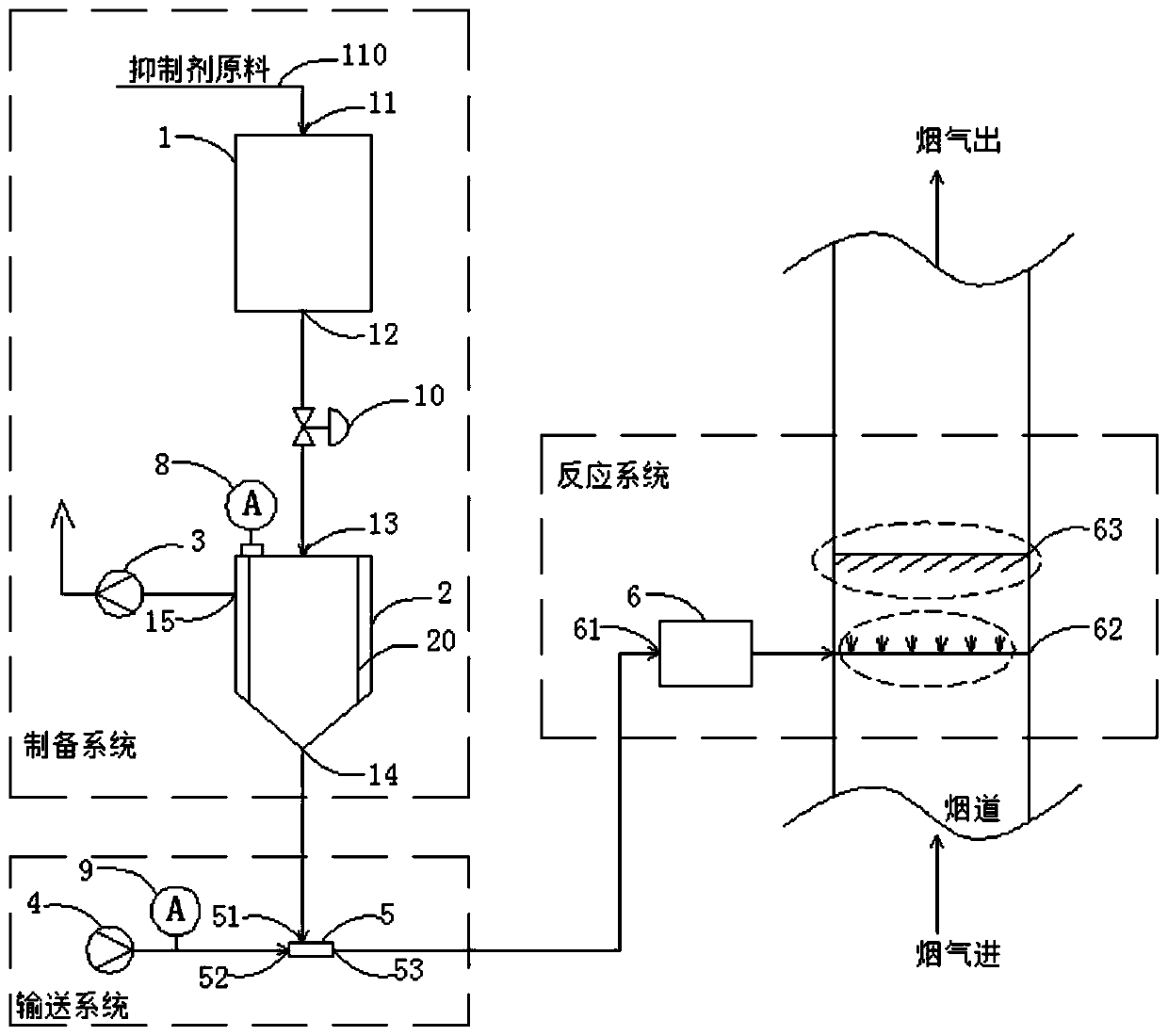

[0032] Such as figure 1 The shown device for suppressing the generation of dioxin in the flue gas of incineration includes a micropowder inhibitor preparation system, a micropowder inhibitor delivery system and a reaction system.

[0033] Adopting a waste incinerator in the form of a circulating fluidized bed with a processing capacity of 400 tons per day, the flue gas volume under stable operating conditions reaches 250,000 Nm per hour. After the flue gas passes through the economizer and the air preheater to recover the heat of the flue gas, the flue gas enters the flue gas purification process section, and the purified flue gas meets the standard and is discharged. The device for suppressing the generation of dioxins in the flue gas of incineration is installed downstream of the economizer, and is used to suppress the re-formation of dioxins in the incineration process and flue gas cooling process without affecting the recovery of flue gas heat.

[0034] The micropowder in...

Embodiment 2

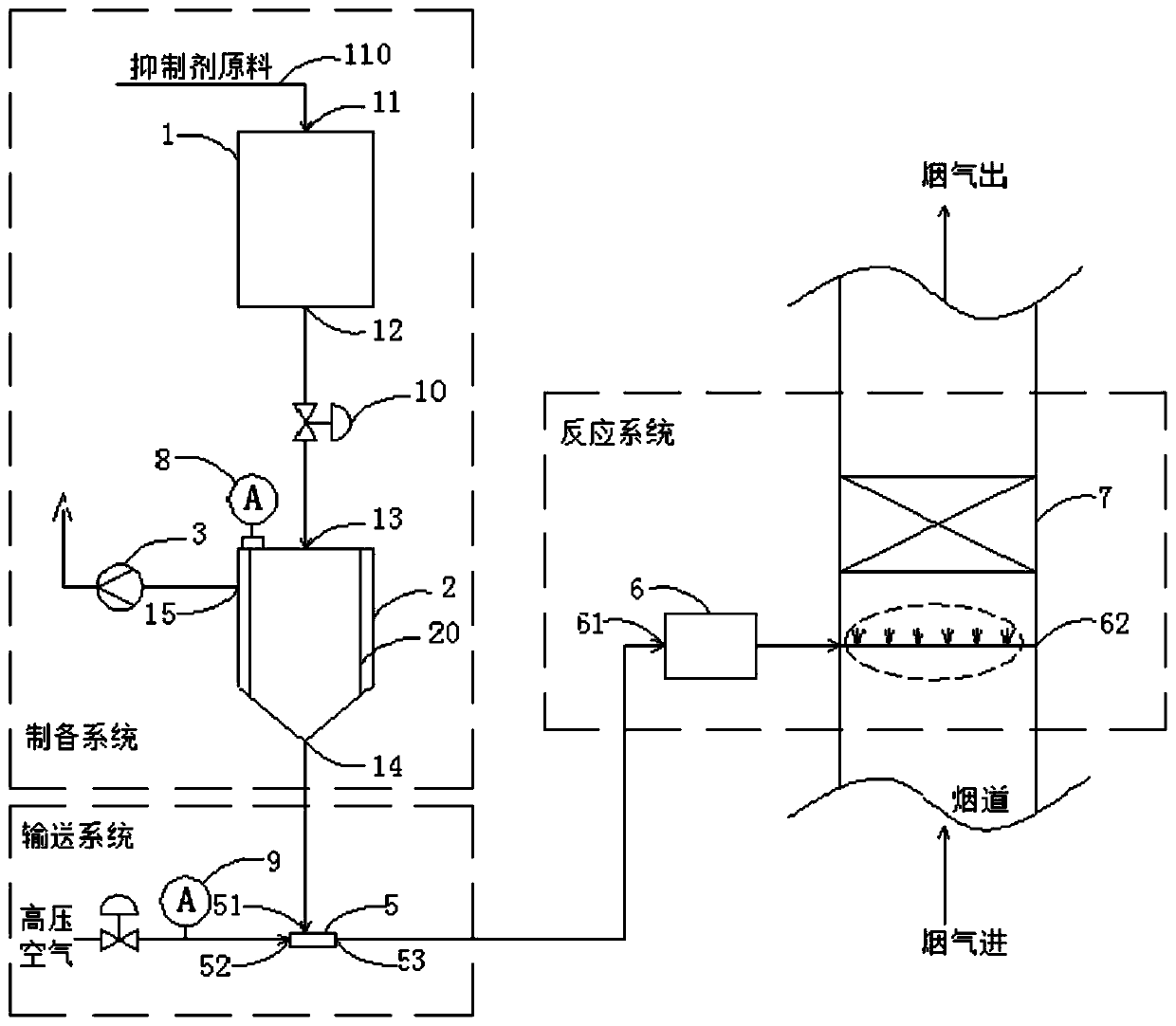

[0048] Such as figure 2 Compared with Example 1, the shown device for suppressing the generation of dioxins in the flue gas of incineration: the Roots blower 4 is changed to high-pressure air and valves are added; when the deflector 63 is not installed, the packing is added Layer 7, other structures and process conditions are the same as those in Embodiment 1.

[0049] The high-pressure air comes from the utility part of the factory, and the delivery gas inlet 52 of the gas-solid mixing device 5 is connected to the utility pipeline. control.

[0050] A layer of filler layer 7 is arranged in the reaction system. The filler material of the filler layer 7 is inorganic ceramics, the opening ratio of which is about 85%, and the thickness of the filler layer 7 is 100mm. The micropowder inhibitor is sprayed into the flue through the gas-solid injection device 62, fully mixed and reacted with the flue gas, flows through the packing layer 7, and then reduces the concentration of chl...

Embodiment 3

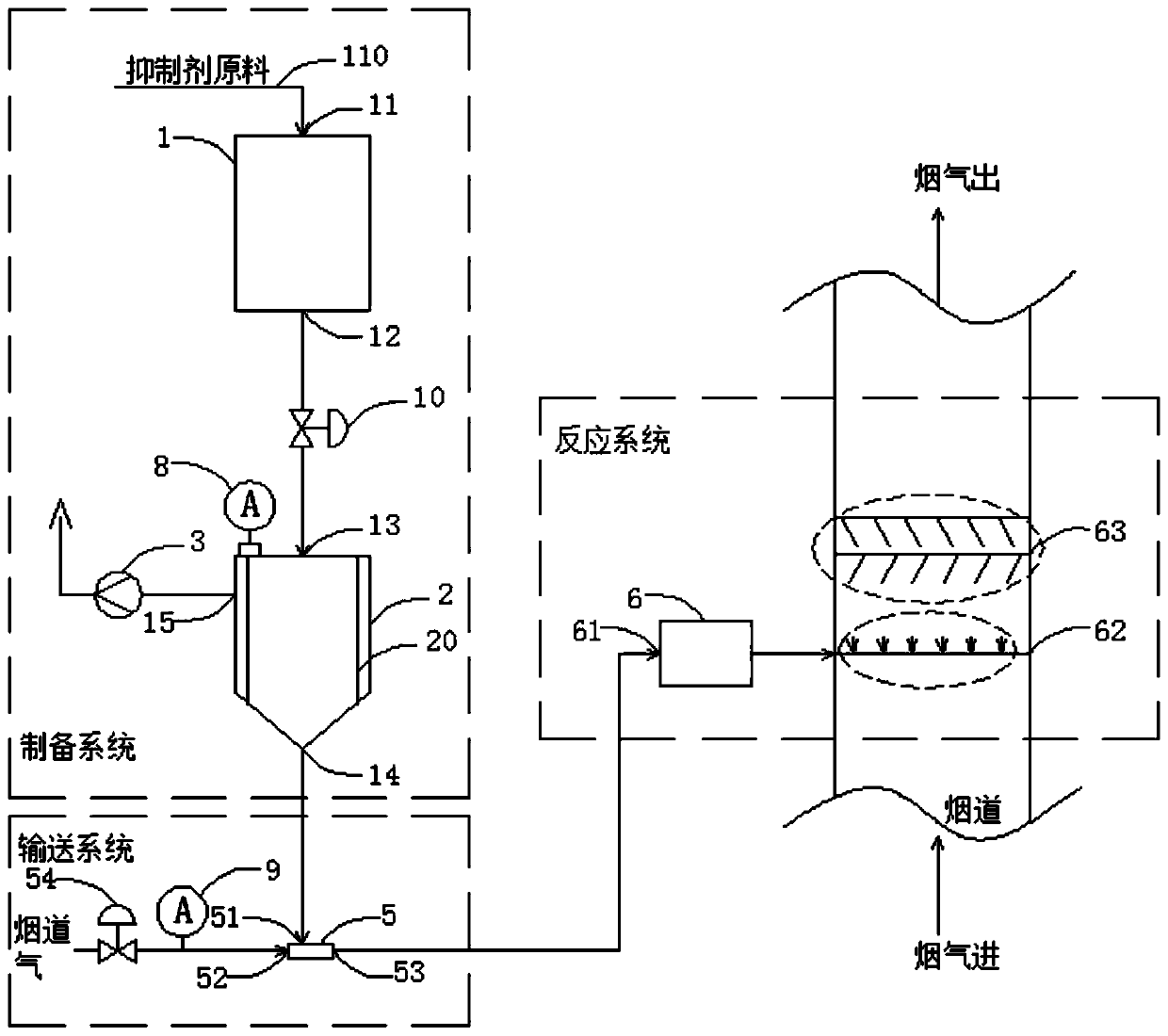

[0054] Such as image 3 Compared with Example 1, the shown device for suppressing the generation of dioxin in the flue gas of incineration: the Roots blower 4 is changed to flue gas and a regulating valve 54 is added, and two layers of deflectors 63 with different angles are installed , other structures and processing conditions are the same as in Example 1.

[0055] The flue gas of the micropowder inhibitor conveying system comes from the gas in the flue that has been pressurized after the reaction of the sprayed inhibitor. The conveying gas inlet 52 of the gas-solid mixing device 5 is connected to the flue gas pipeline. In order to ensure the stability of the process operation, connect A regulating valve 54 is added on the official road, and the regulating valve 54 is controlled by the measuring instrument 9 .

[0056] Two layers of deflectors 63 are set in the reaction system. In order to meet the ideal flow state of the flue gas in the flue, a layer of deflectors 63 is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com