Large-size diesel oil particulate filter with low pressure drop and low expansion coefficient and preparation method thereof

A low expansion coefficient, particle filter technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problems of low pass rate, high pressure drop and high thermal expansion coefficient, etc., to improve production efficiency and good thermal conductivity , good micropore connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

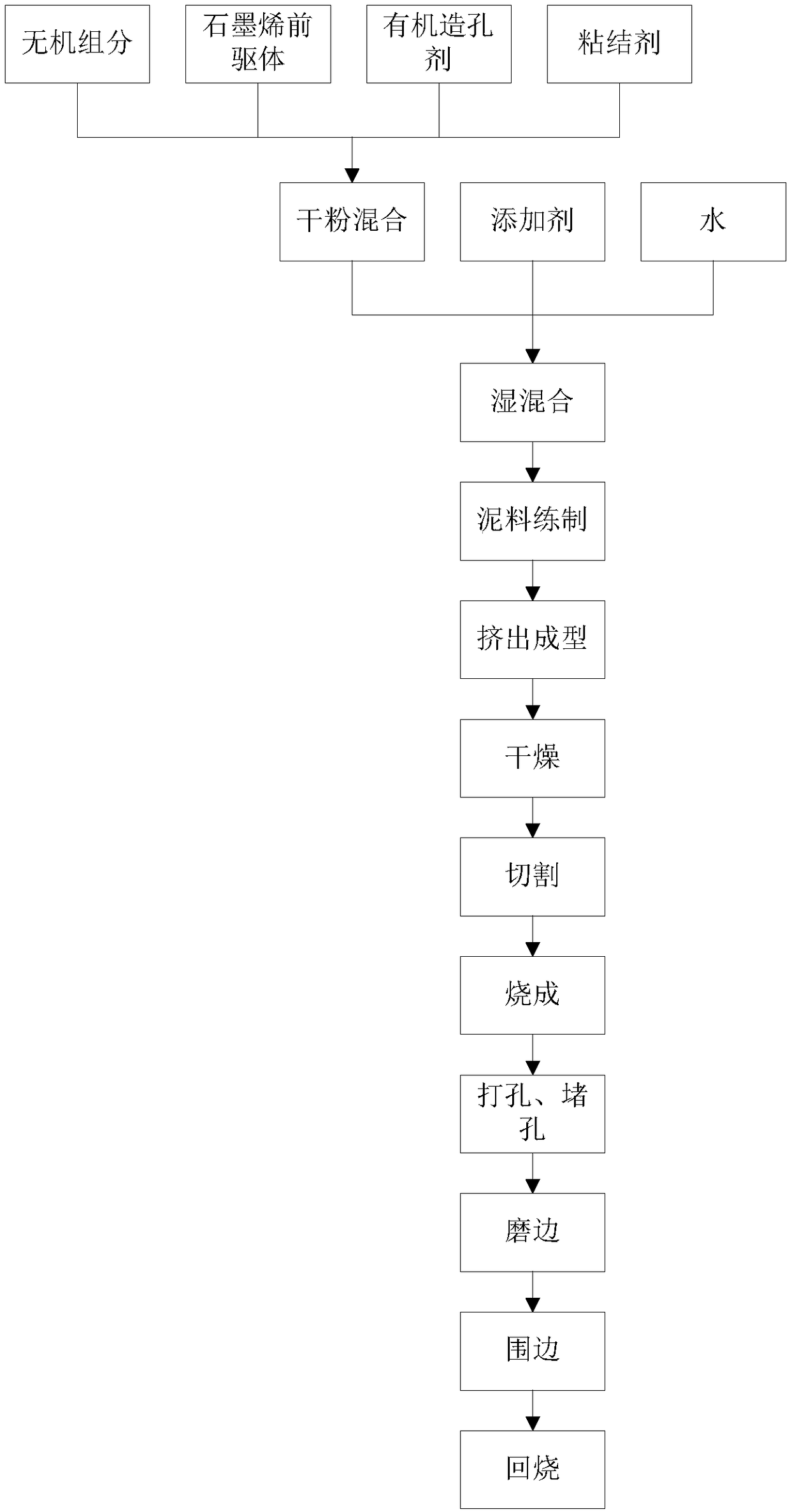

[0038] A method for preparing a diesel particulate filter, comprising the steps of:

[0039] (1) adopt dry method to mix the talc of 34.13% by weight, the kaolin a of 7.89% by weight, the kaolin b of 7.89% by weight, the alumina of 20.05% by weight, the hydrated alumina of 20.05% by weight, the silicon dioxide of 10% by weight, The graphene precursor of 10% by weight, the starch of 8% by weight, the polymer resin of 7% by weight and the binding agent of 5% by weight, prepare the homogeneous mixture with close packing, wherein graphene precursor, starch and polymer The amount of resin added is added on the basis of inorganic components, and the amount of binder added is added on the basis of total mixed components; (2) the powder that has been mixed is placed in a kneading machine and 30% of the total powder is added. The water of % weight was kneaded for 7 minutes, and the additive of 1% by weight was added and kneaded for 10 minutes, and the addition of additive was to add on t...

Embodiment 2

[0041] A method for preparing a diesel particulate filter, comprising the steps of:

[0042] (1) adopt dry method to mix the talc of 34.13% by weight, the kaolin a of 7.89% by weight, the kaolin b of 7.89% by weight, the alumina of 20.05% by weight, the hydrated alumina of 20.05% by weight, the silicon dioxide of 10% by weight, The graphene precursor of 7% by weight, the starch of 8% by weight, the polymer resin of 10% by weight and the binding agent of 5% by weight are prepared to have a close-packed homogeneous mixture, wherein the graphene precursor, starch and polymer The amount of resin added is added on the basis of inorganic components, and the amount of binder added is added on the basis of total mixed components; (2) the powder that has been mixed is placed in a kneading machine and 30% of the total powder is added. The water of % weight was kneaded for 7 minutes, and the additive of 1% by weight was added and kneaded for 10 minutes, and the addition of additive was t...

Embodiment 3

[0044] A method for preparing a diesel particulate filter, comprising the steps of:

[0045] (1) adopt dry method to mix the talc of 34.13% by weight, the kaolin a of 7.89% by weight, the kaolin b of 7.89% by weight, the alumina of 20.05% by weight, the hydrated alumina of 20.05% by weight, the silicon dioxide of 10% by weight, The graphene precursor of 4% by weight, the starch of 8% by weight, the polymer resin of 13% by weight and the binding agent of 5% by weight, obtain the homogeneous mixture with tight packing, wherein graphene precursor, starch and polymer The amount of resin added is added on the basis of inorganic components, and the amount of binder added is added on the basis of total mixed components; (2) the powder that has been mixed is placed in a kneading machine and 30% of the total powder is added. The water of % weight was kneaded for 7 minutes, and the additive of 1% by weight was added and kneaded for 10 minutes, and the addition of additive was to add on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com