Process method for producing high-quality organic system supercapacitor active carbon

A supercapacitor and organic system technology, applied in chemical instruments and methods, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problems of small number of micropores, insufficient specific surface area of activated carbon, hindering the performance of supercapacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

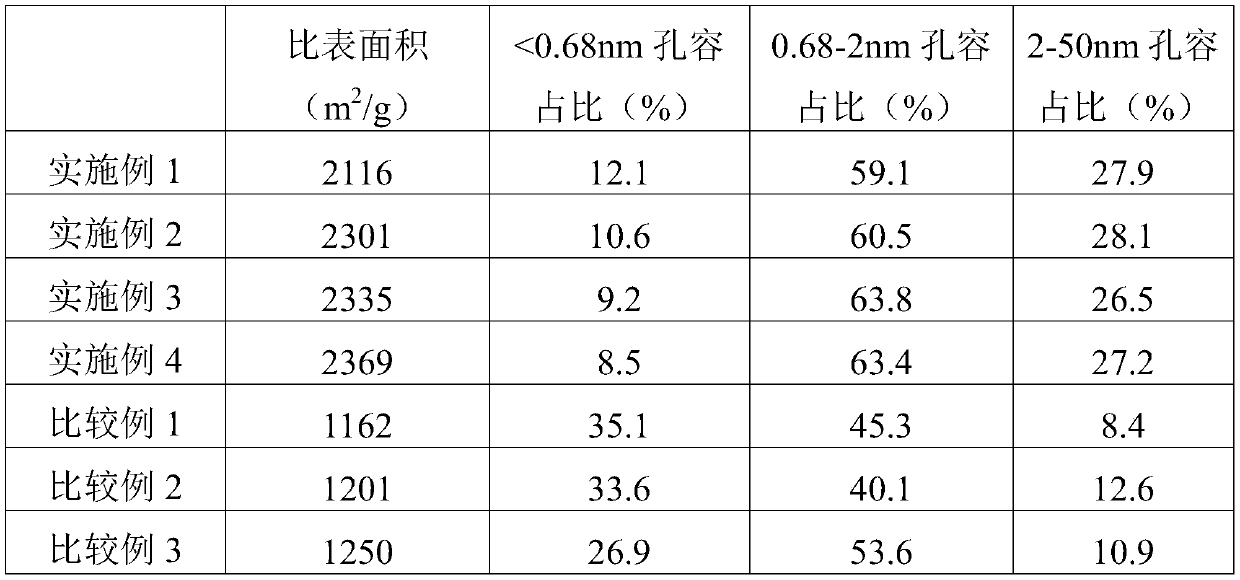

Embodiment 1

[0023] A process for producing high-quality organic supercapacitor activated carbon, comprising the following steps:

[0024] 1) Wash the coconut shell carbonized material for 3 times, dry it to obtain the dried material, grind the dried material to 80 μm, add it to the metal oxide suspension, and stir it in a high-pressure stirring tank for 20 minutes to obtain the mixture. The mixture is pre-activated in an activation furnace with an inert gas, heated to an activation temperature of 600°C at a heating rate of 10°C / min, and kept for 50 minutes to obtain a pre-activated material;

[0025] 2) The temperature of the pre-activated material was raised to 950°C, and then a mixed gas of water vapor and oxygen was introduced to carry out the activation reaction for 120 minutes to obtain the activated material;

[0026] 3) Reduce the temperature of the activation furnace in step 2) to 800°C, pass in carbon dioxide gas to react for 360 minutes, naturally cool to room temperature under ...

Embodiment 2

[0029] A process for producing high-quality organic supercapacitor activated carbon, comprising the following steps:

[0030] 1) Wash the coconut shell carbonized material 3 times with clarified lime water, dry it to obtain the dried material, grind the dried material to 50 μm, add it to the suspension of nano-zinc oxide and aluminum oxide, and stir in a high-pressure stirring tank After 20 minutes, the mixed material was obtained, and the mixed material was placed in an activation furnace with an inert gas for pre-activation, and the temperature was raised to an activation temperature of 600 °C at a heating rate of 10 °C / min, and kept for 50 min to obtain a pre-activated material;

[0031] 2) The temperature of the pre-activated material was raised to 850°C, and then a mixed gas of water vapor and oxygen was introduced to carry out the activation reaction for 120 minutes to obtain the activated material;

[0032] 3) Reduce the temperature of the activation furnace in step 2) ...

Embodiment 3

[0035] A process for producing high-quality organic supercapacitor activated carbon, comprising the following steps:

[0036] 1) Dissolving dolomitic lime in water to prepare dolomitic lime water, using the dolomitic lime water to wash the coconut shell carbonized material 3 times, drying to obtain a dried material, crushing the dried material to 60 μm and adding it to the nano-oxidized In the aluminum suspension, stir in a high-pressure stirred tank for 20 minutes to obtain a mixture, place the mixture in an activation furnace with an inert gas for pre-activation, and heat up to an activation temperature of 600°C at a heating rate of 20°C / min. Keep for 50min to obtain the pre-activated material; wherein, the preparation method of the nano-alumina suspension is: configure a sodium polyacrylate solution with a mass fraction of 0.05%, place the nano-alumina powder in the sodium polyacrylate solution, and stir evenly , obtaining the nano-alumina suspension;

[0037] 2) The tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com