Patents

Literature

34results about How to "Manufacturing Method Advantages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

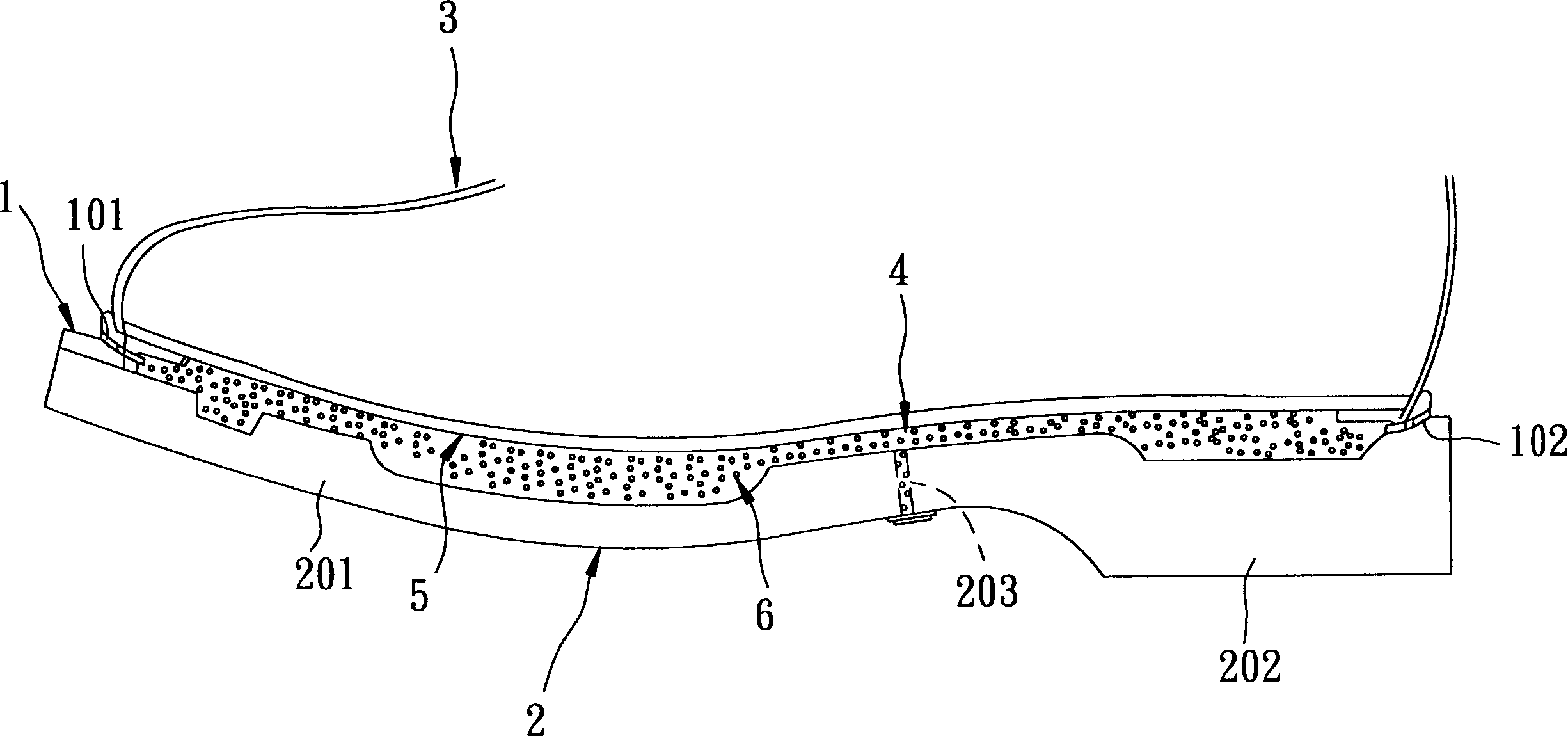

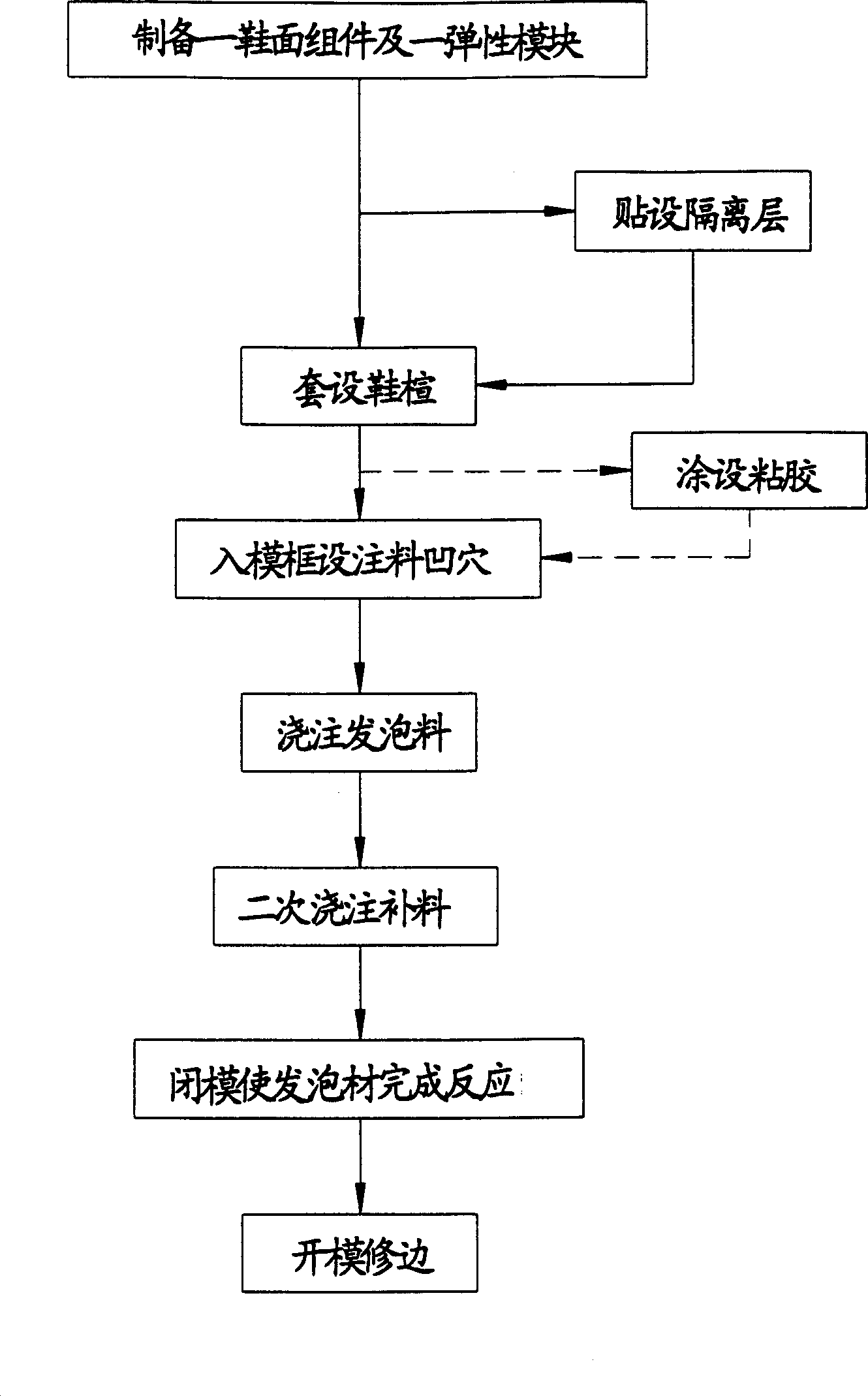

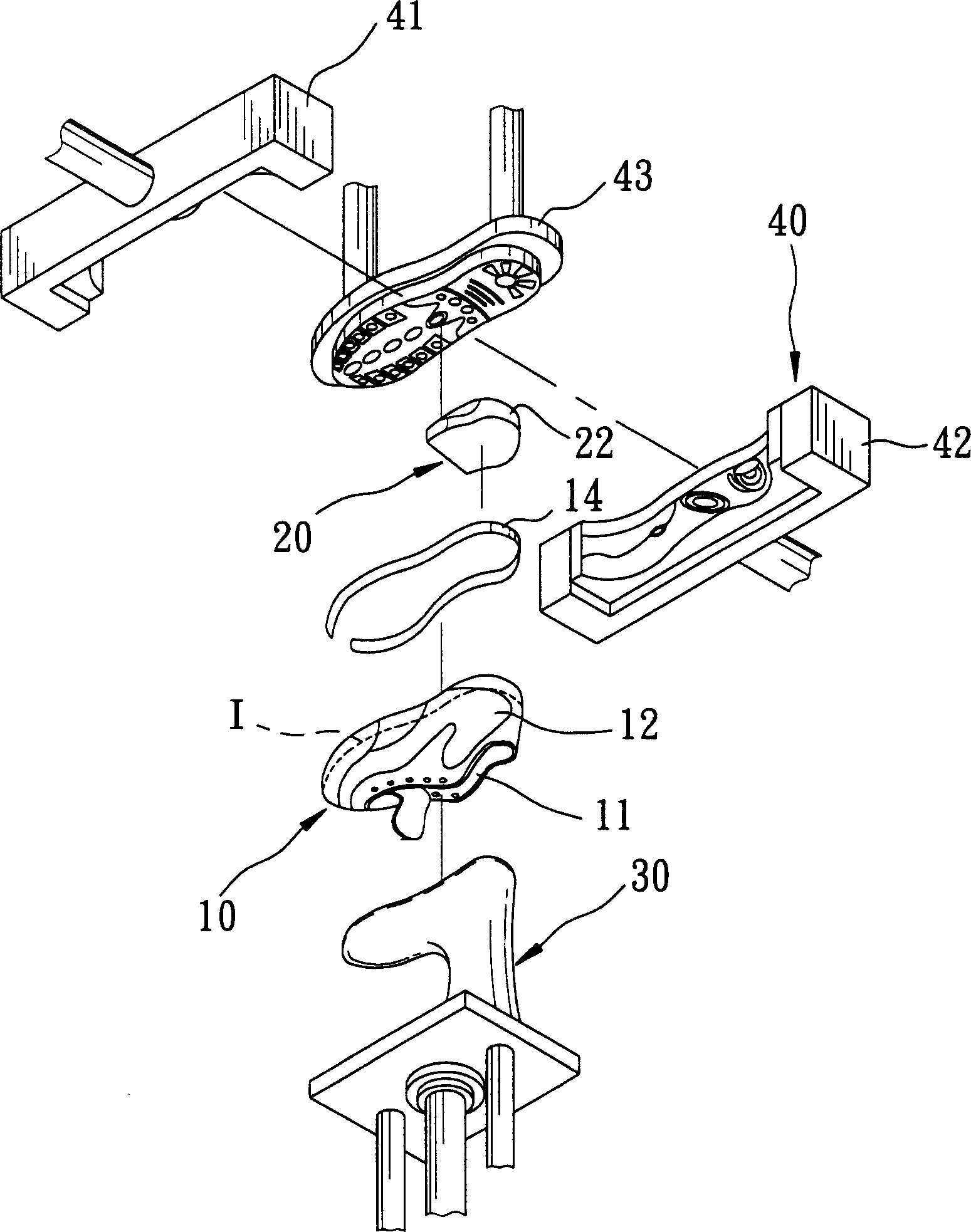

Foamed shoe body formed by integral whole shaping method

InactiveCN1475340AManufacturing Method AdvantagesPrecise flow controlSolesDomestic footwearEngineeringMechanical engineering

A technology for integrally preparing the foamed shoe body includes putting a shoe upper assembly on shoe last and an elastic module in a mould to form an open concave cavity consisting of the bottomsurface of said shoe upper assembly and the inner surface of mould, filling the liquid foaming material in the cavity, closing the mould, and foaming. Its advantages are low cost, and high quality ofproduct.

Owner:纪正贤

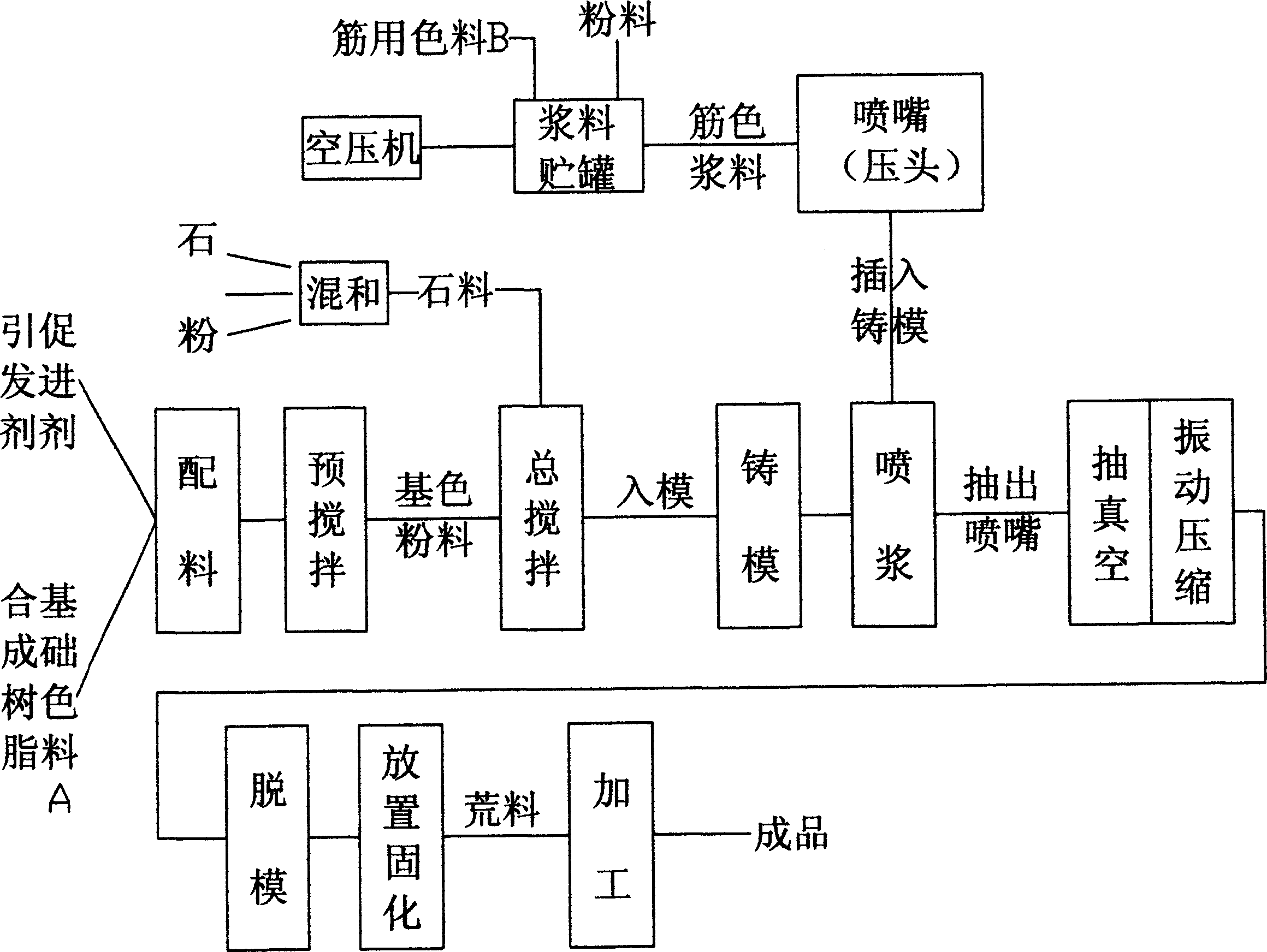

Manufacturing method of colour vein artificial marble

InactiveCN1785627AManufacturing Method AdvantagesMeet different requirementsCeramic shaping apparatusScrapNozzle

A technology for preparing artificial marble with color vein includes such steps as mixing part of stone powder, resin and basic pigment, stirring, pouring the mixture in mould, mixing the rest of stone powder with another pigment for vein, stirring, using compressed air to spray it into the basic material, vacuumizing, pressing while HF vibration, solidifying, demoulding and ageing.

Owner:林志敏

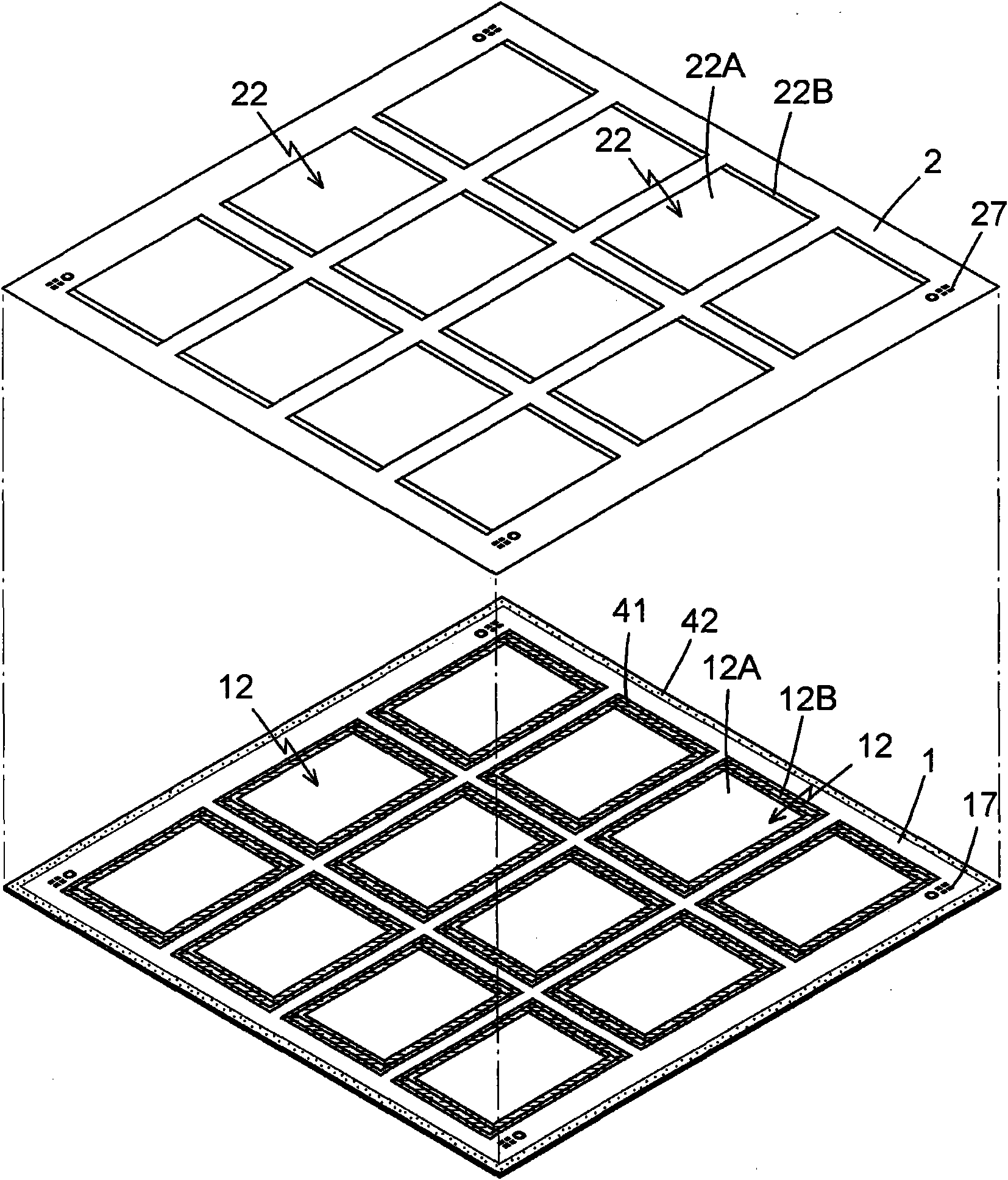

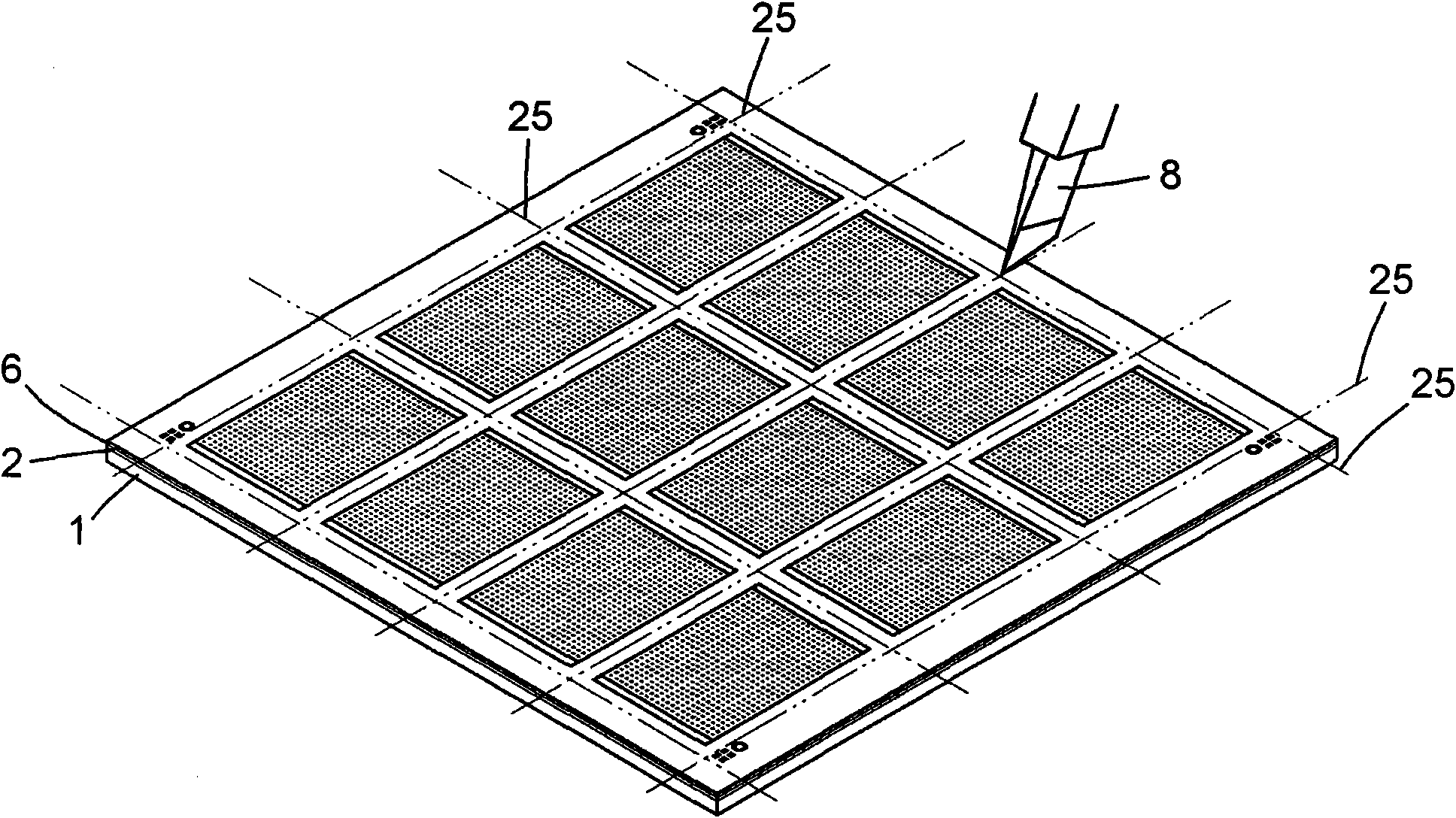

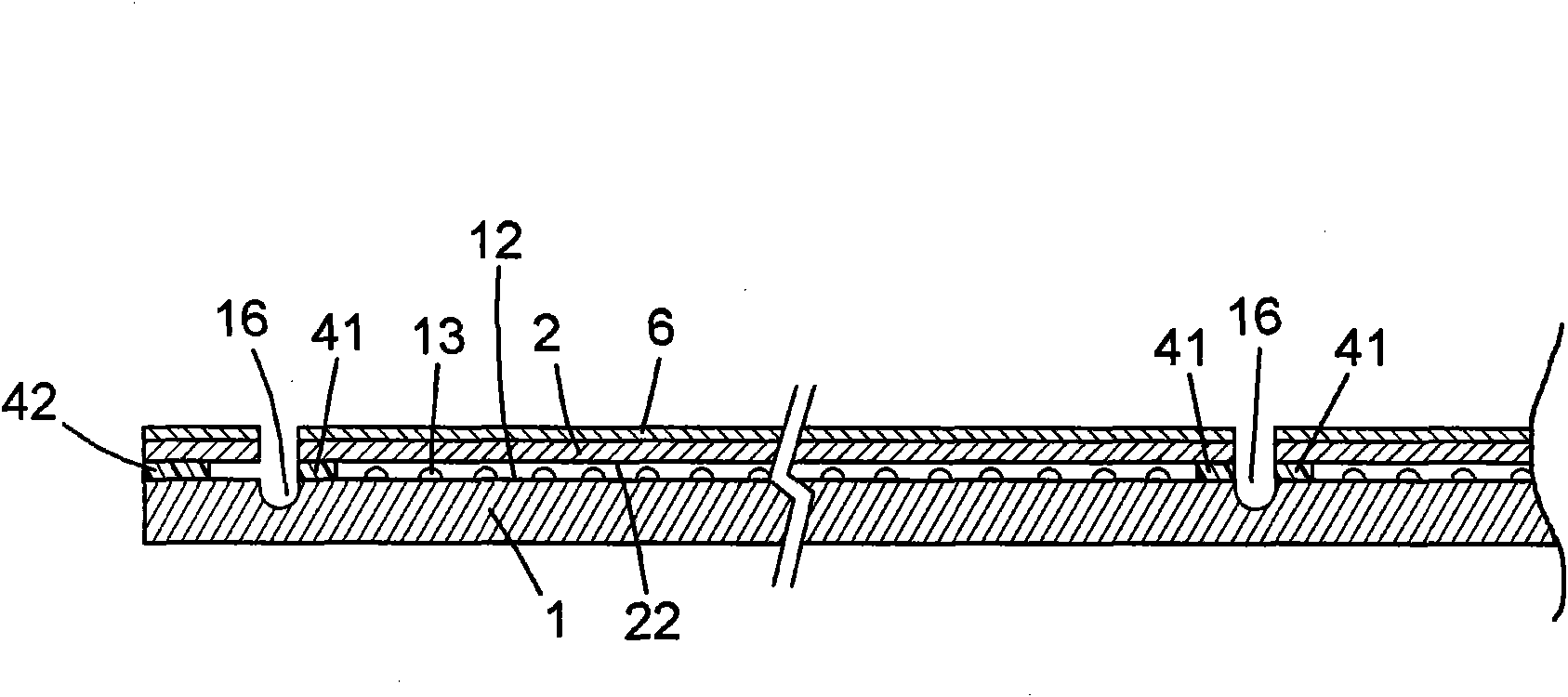

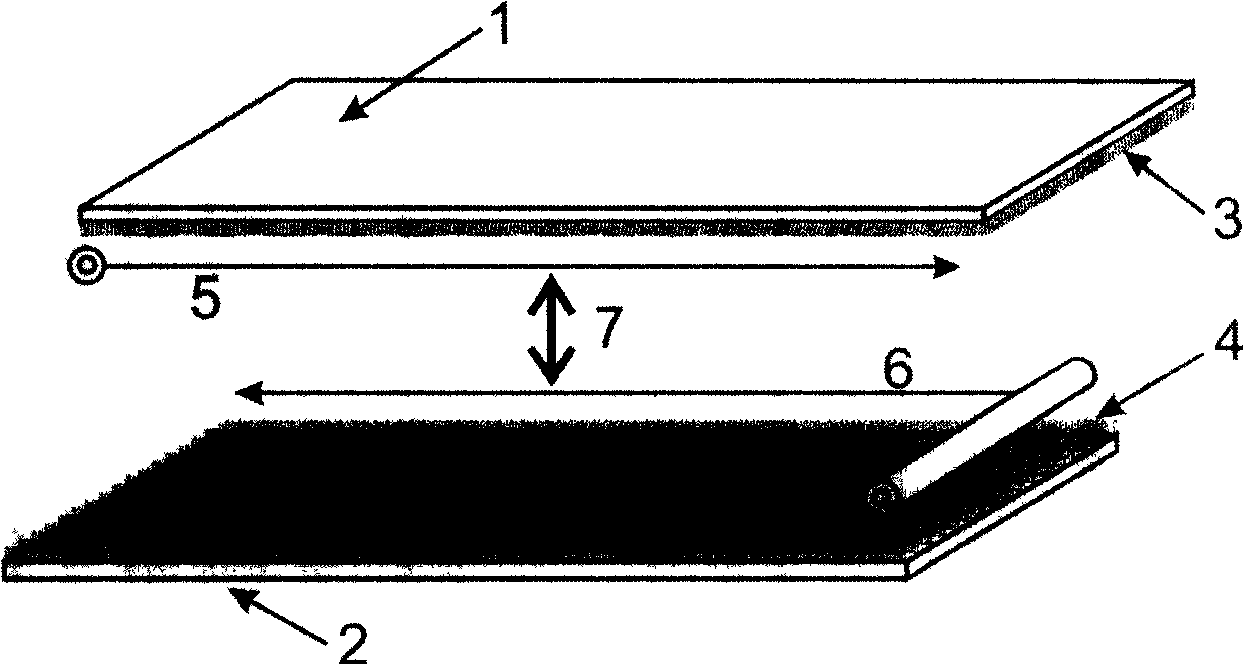

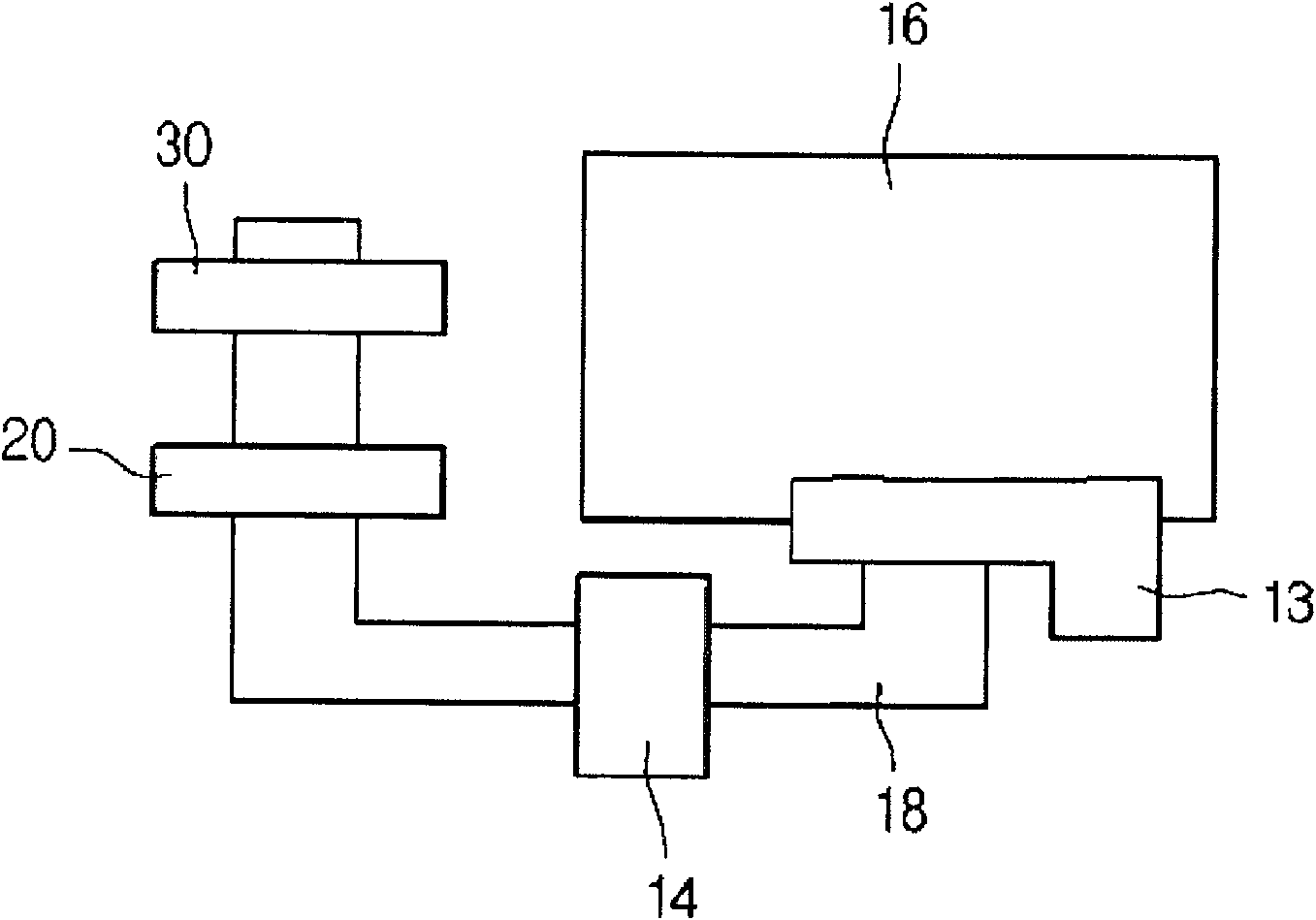

Method for manufacturing touch-control plate

InactiveCN101609379AManufacturing Method AdvantagesImprove qualityInput/output processes for data processingHydrofluoric acidEngineering

The invention relates to a method for manufacturing a touch-control plate, which is characterized by comprising the following steps: (a) selecting a transparent glass plate with larger area and the width larger than that of a base plate layer of a finished touch-control plate product as a base plate layer; (b) taking a rectangular transparent glass plate with area specifications matched with that of the base plate layer and the width larger than that of a panel layer of the finished touch-control plate product as a panel layer; (c) aligning the base plate layer and the panel layer and then overlying the base plate layer and the panel layer and also adhering and overlying two plate bodies of the base plate layer and the panel layer into a combined plate body through each adhering frame positioned on the plate bodies of the base plate layer and the panel layer and sealing frames positioned at the peripheries of the plate bodies; (d) carrying out a thinning manufacture procedure, i.e. the combined plate body of the base plate layer and the panel layer is etched by a hydrofluoric acid solution; (e) carrying out a cutting manufacture procedure; and (f) carrying out splitting operation along grooves of the base plate layer, i.e. the base plate is pressed, split and cut into a plurality of independent finished touch-control plate products along a predetermined cutting line.

Owner:YOUNG FAST OPTOELECTRONICS

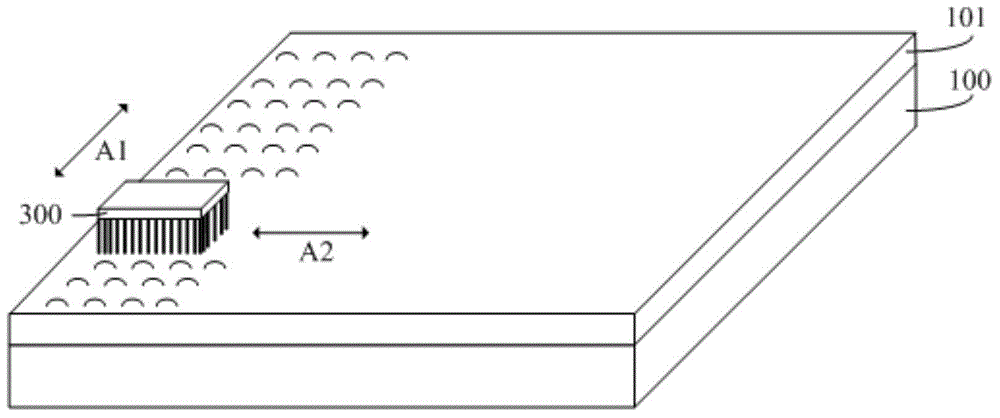

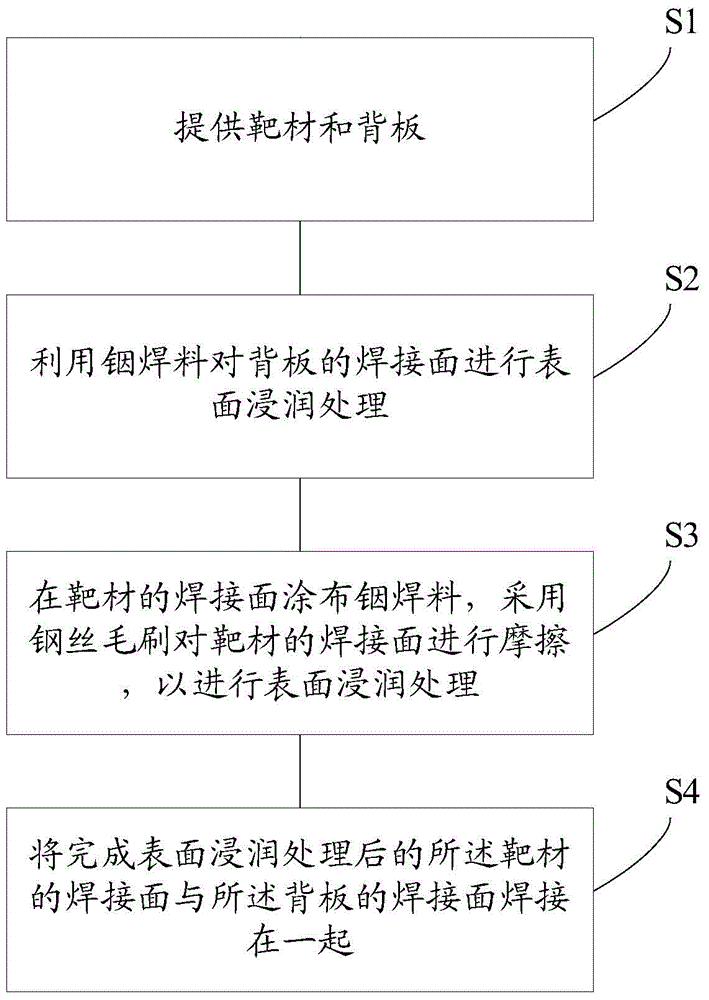

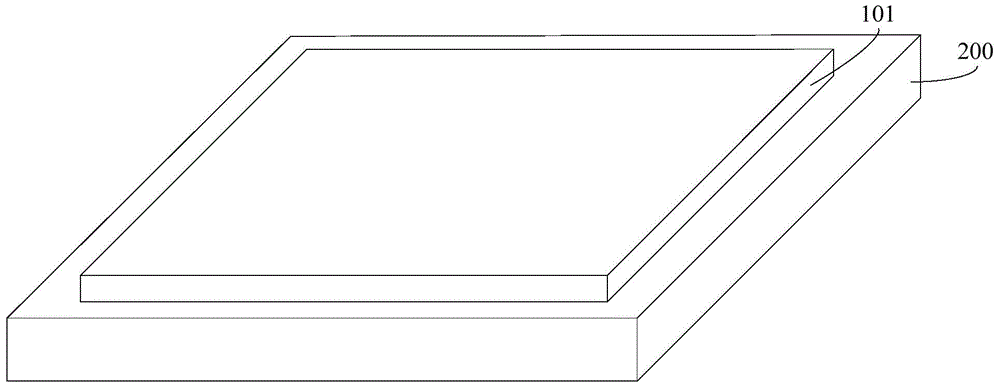

Manufacturing method for target material assembly

InactiveCN105618886AManufacturing Method AdvantagesHigh recovery puritySoldering apparatusIndiumOxide

The invention provides a manufacturing method for a target material assembly. The manufacturing method for the target material assembly includes the steps that surface infiltration treatment is carried out on a welding surface of a back plate through indium solder; a welding surface of a target material is coated with indium solder and is rubbed through a steel wire hairbrush, so that surface infiltration treatment is carried out; and the welding surface, subjected to surface infiltration treatment, of the target material and the welding surface of the back plate are welded together. Through the step of rubbing the welding surface of the target material through the steel wire hairbrush, metal oxide on the welding surface of the target material can be removed, the roughness of the welding surface of the target material is increased, and accordingly the indium solder can fully infiltrate the welding surface of the target material. After the welding surfaces of the target material and the back plate are welded, the bonding performance of the welding surfaces of the target material and the back plate is high, and defects are not prone to occurrence. The target material and the back plate are both infiltrated through the indium solder, the bonding performance of the indium solder is high, the total use amount of the indium solder is smaller compared with that in the prior art, and the recycling purity of the indium solder is improved.

Owner:合肥江丰电子材料有限公司

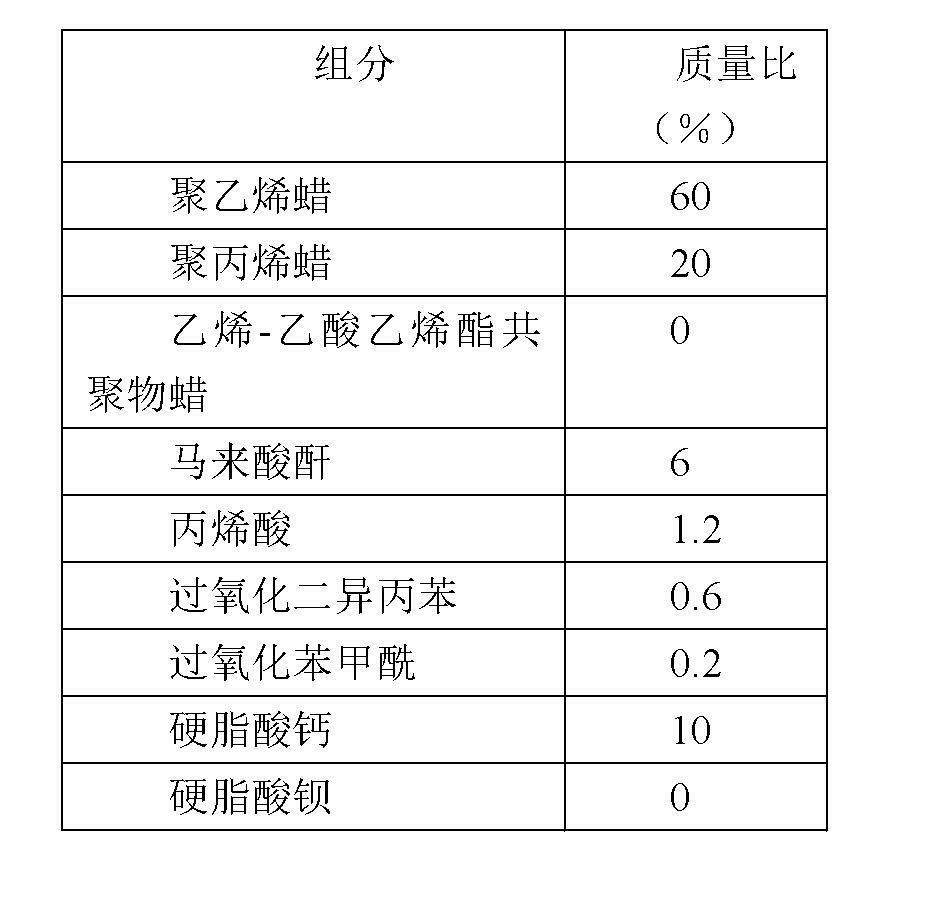

Plastic composite lubricating agent and preparation method thereof

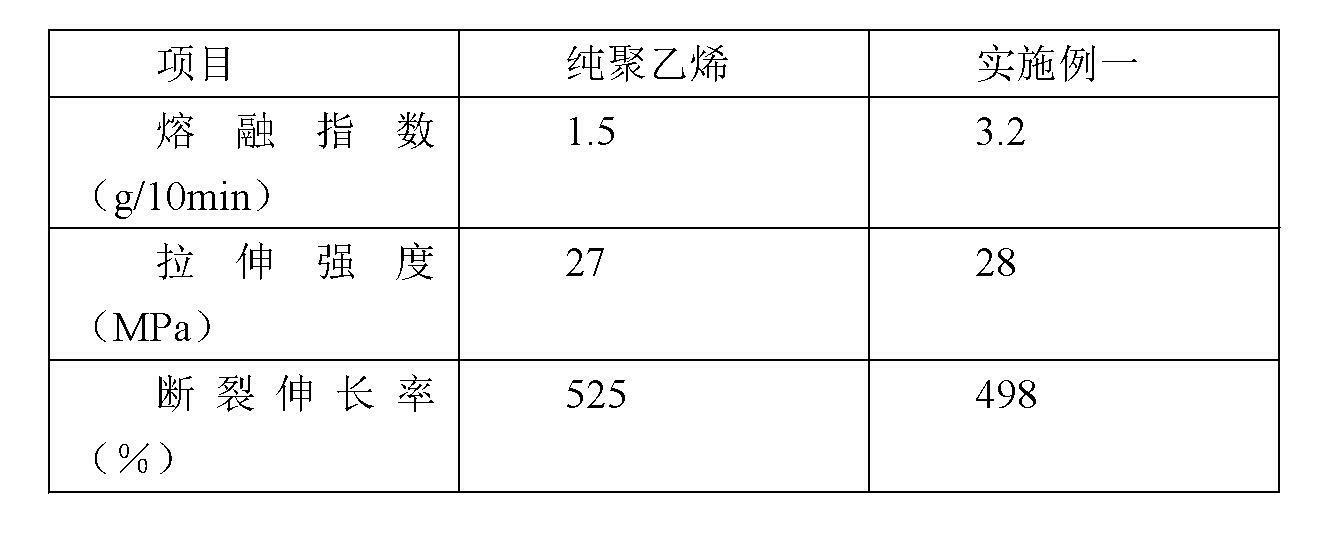

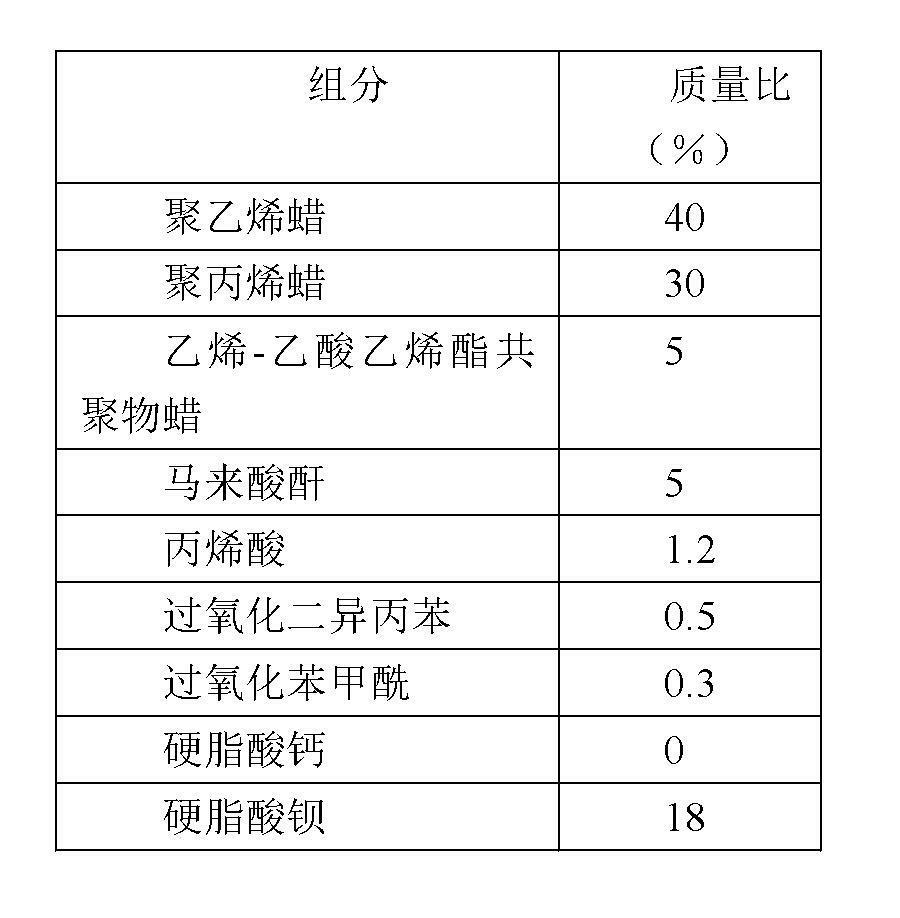

ActiveCN102690440AManufacturing Method AdvantagesFine grainPigment treatment with macromolecular organic compoundsPolymer scienceHeat stability

The invention belongs to the technical field of plastic auxiliaries and specifically relates to a plastic composite lubricating agent and a preparation method thereof. The plastic composite lubricating agent comprises a spherical or near-spherical inorganic powder kernel with lubricating property and a graft-modified polymer wax housing coated on the outer layer. The preparation method comprises the following process steps of: a) performing graft modification: uniformly mixing polymer wax, grafting monomers, an initiator and metal soap, and then performing modification and granulation througha screw extruder; and b) coating powder: using a coating device to coat spherical or near-spherical inorganic powder with the lubricating property in the graft-modified polymer wax. Through optimal selection and improvement of raw materials, optimization of a process and reasonable compounding of all components, the formed composite lubricating agent has good lubricating property inside and outside a full temperature range during plastic processing, and integrates the effects such as heat stability, compatibilization and the like; and the preparation method is favorable for simplifying the formula and process of the modified plastics, and can improve the processing performance of the plastics and lower the cost.

Owner:广州峰华化工科技有限公司

Method of preparing coupler yoke frame

InactiveCN101214602AManufacturing Method AdvantagesReduce heating stepsMetal-working apparatusMechanical pressUltimate tensile strength

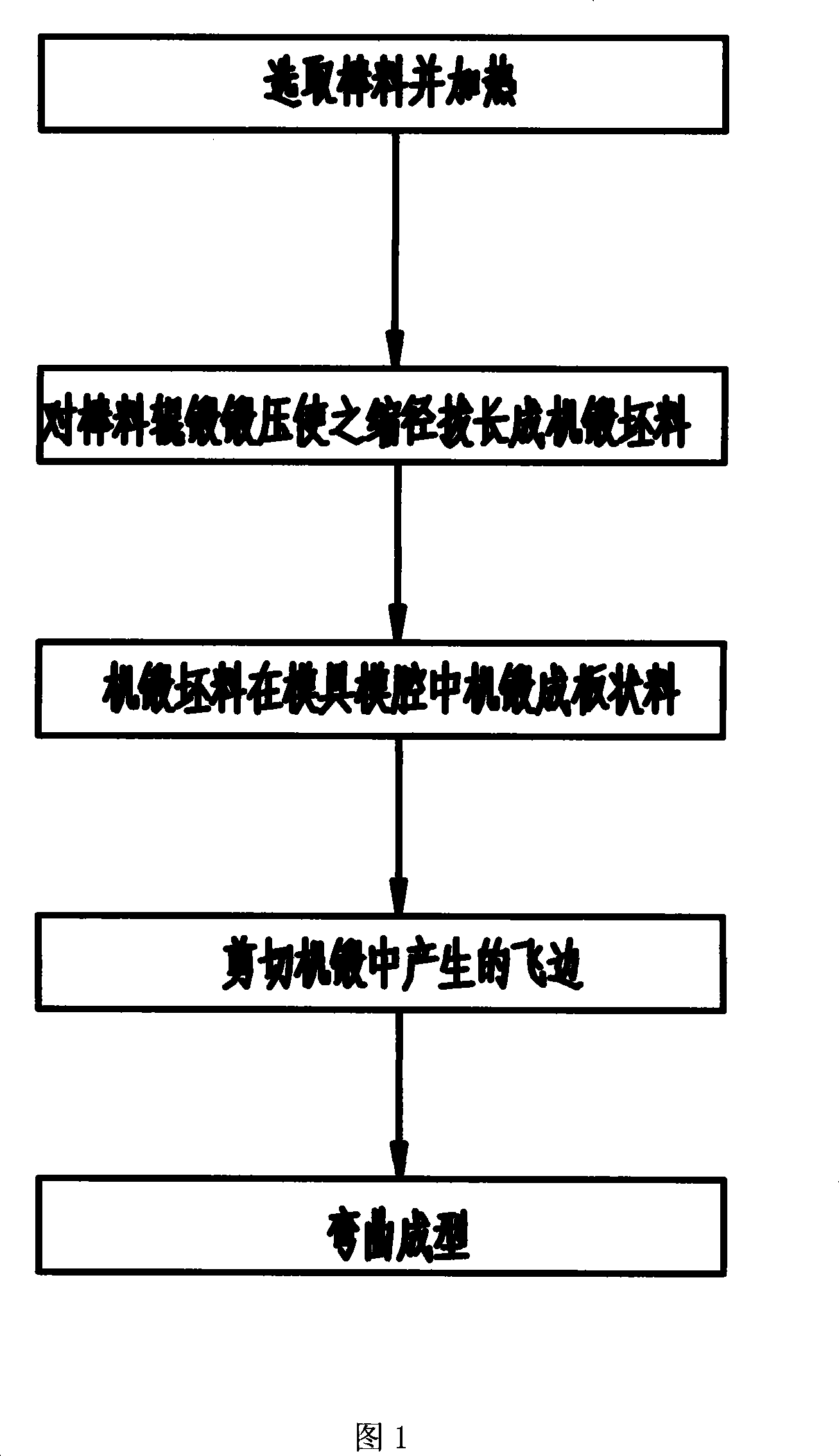

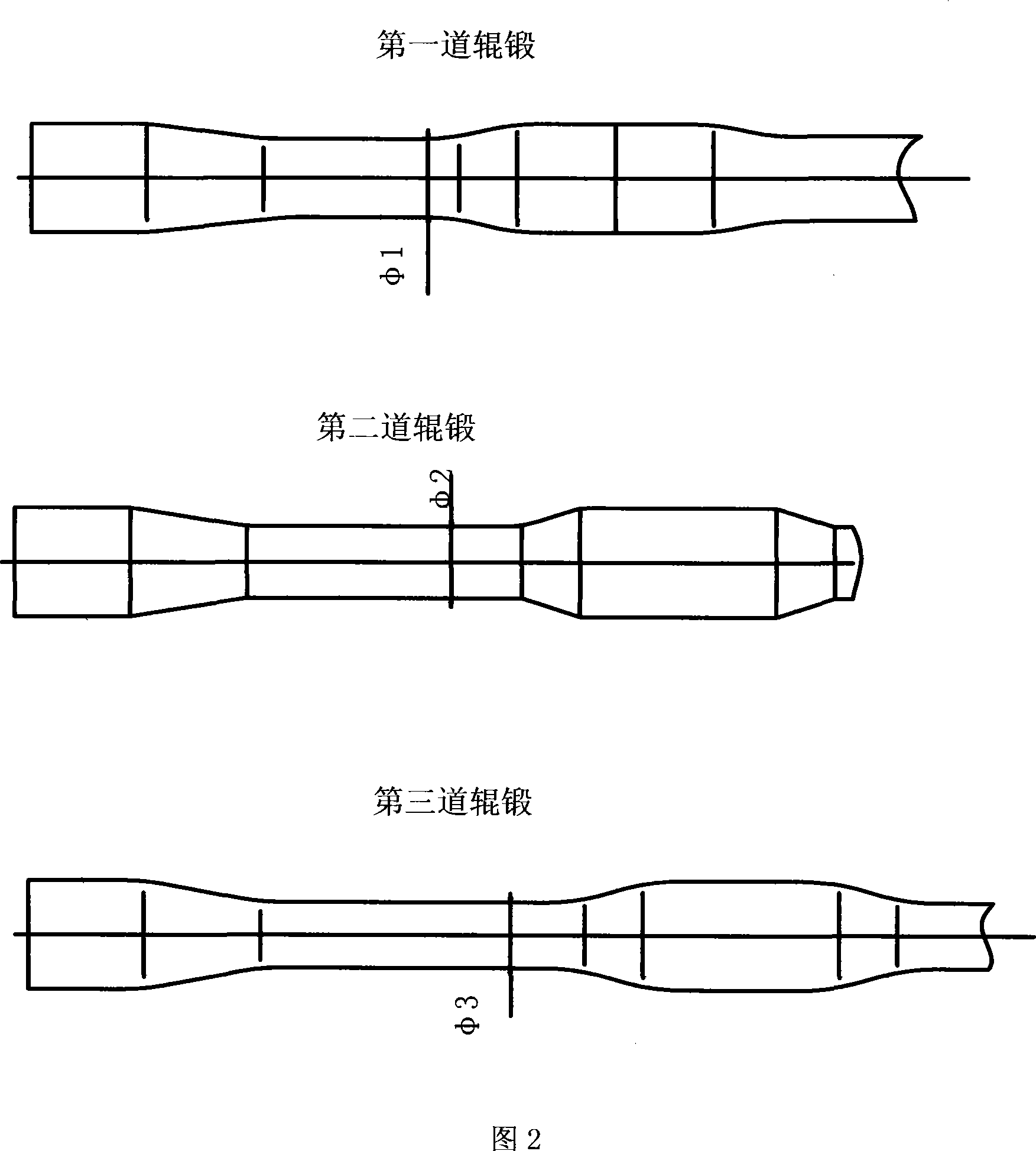

The invention discloses a method for manufacturing a coupler yoke which includes the following technical steps: selecting a rod material and heating to 1200 to 1500 DEG C; forging and pressing on the heated rod material to lead the rod material to contract diameter and draw out to form a mechanical press forging material; a roll forging pressure of a roll forging machine is 300 to 700 tons; mechanical pressing and forging the forged mechanical press forging material in a die cavity to a platy material; the scrap rubbers generated in a cutting mechanical press forging finally heats the platy material to bend and form. Compared with the prior art, the invention adopts roll forging processing on the forging and pressing of the rod material; the roll forging speed has quickened, one time heating can finish the requirement of deformation dimension and the material fell caused by oxidation on the surface of the rod material is fewer and simultaneously adopting the roll forging can realize automatic operation with no needing of a worker or only one worker; thereby greatly reducing the working intensity of the worker ; adopting the roll forging leads the time for the rod material to be forged into the mechanical press forging material in the roll forging to be greatly shortened; thereby the temperature of the rod material is still in the temperature range of the mechanical press forging, thus saving the heating step before the mechanical press forging and simultaneously reducing the energy consumption compared with a free forging of an air hammer.

Owner:曾德文

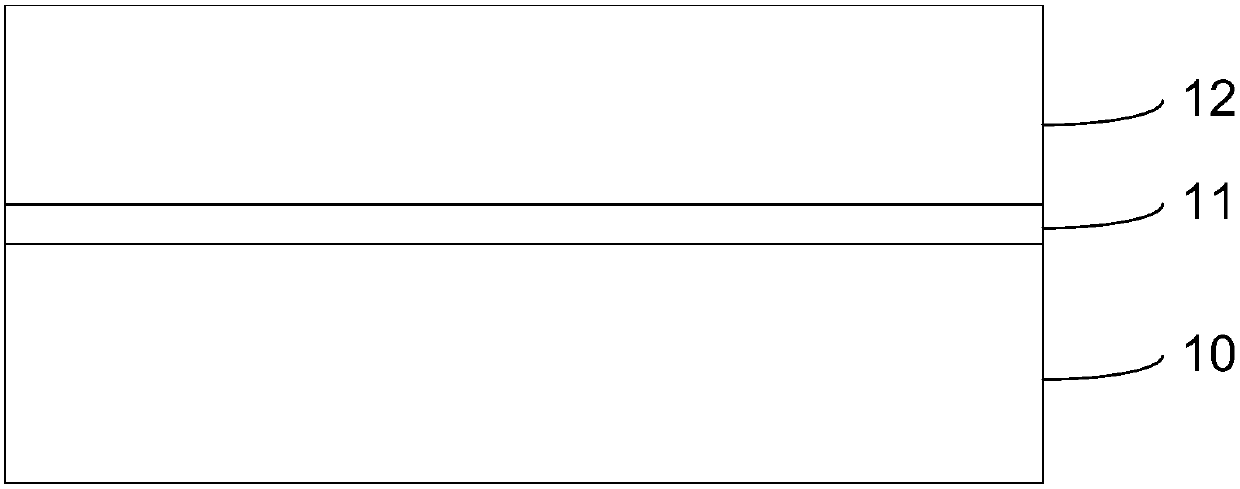

Display panel, display device and manufacturing method of display panel

ActiveCN106298858AManufacturing Method AdvantagesStrong bending resistanceSolid-state devicesSemiconductor/solid-state device manufacturingFilm materialEngineering

The invention provides a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a flexible substrate, a light-emitting device and a protective film layer, wherein the light-emitting device is positioned on one side of the flexible substrate; the protective film layer is positioned on the side, deviating from the light-emitting device, of the flexible substrate; the protective film layer is in direct contact with the flexible substrate; a plurality of bulges are arranged on the side, deviating from the flexible substrate, of the protective film layer. The invention provides a technical scheme that a lower protective film in the prior art is substituted, and the protective film layer is directly formed on the flexible substrate and is in direct contact with the flexible substrate, so that the display panel is thinned while the flexible substrate is protected from scratches; the plurality of bulges are arranged on one side of the protective film layer, so that the bending resistance of the display panel is stronger; on the other hand, the protective film layer adopts a single-layer structure directly formed on the flexible substrate in a printing manner, so that an adhesive material is omitted, the problem of matching between a film material and the adhesive material is not involved, and the restorability of the display panel after the display panel is bent is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

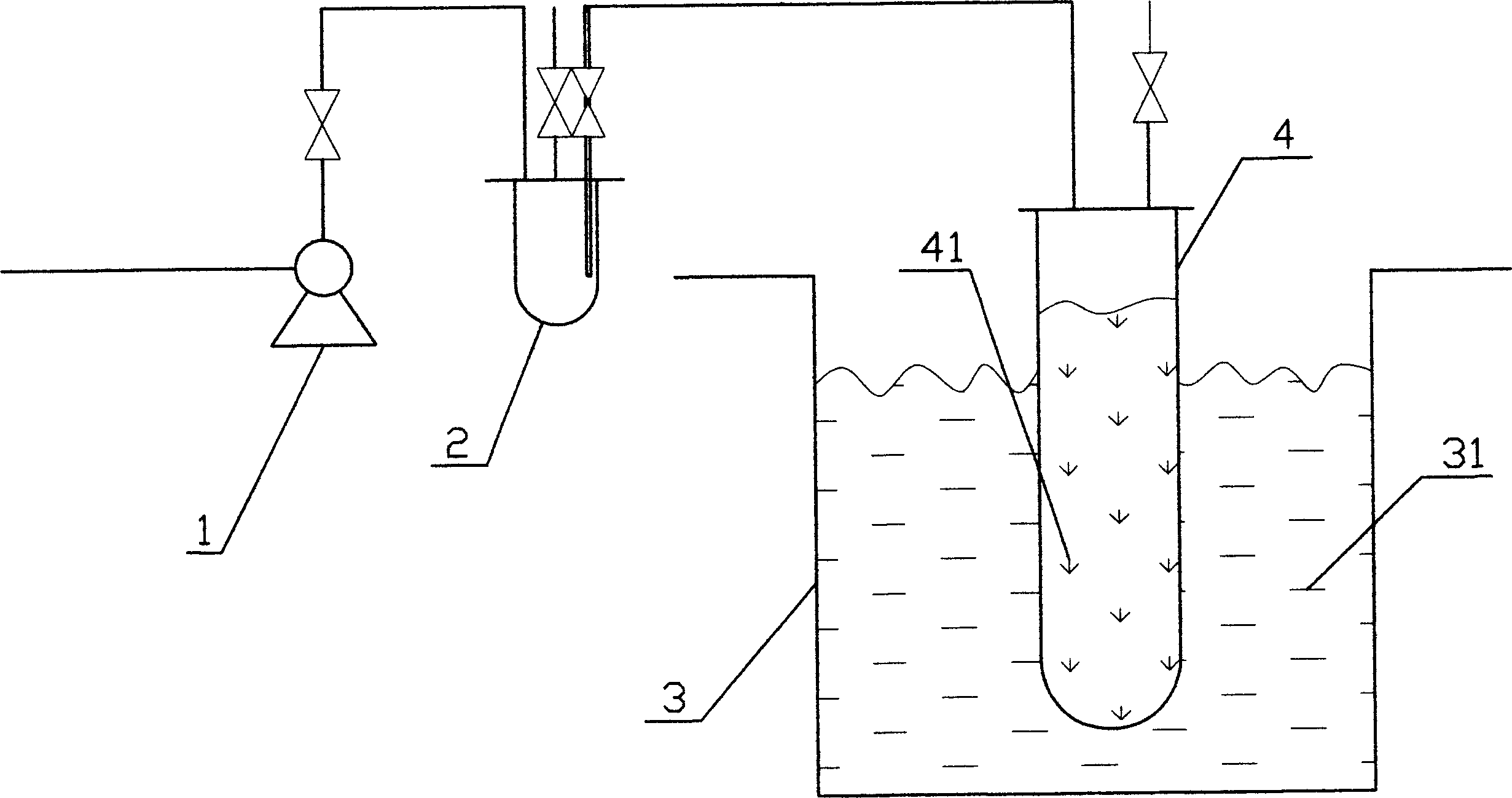

Method for manufacturing drainage bottle

ActiveCN101172394AManufacturing Method AdvantagesGuaranteed absolute airtightnessWound drainsSuction devicesBlow moldingUltrasonic welding

The invention relates to a manufacturing method of a drainage bottle. Firstly, a bottle body with an opening and a bottle cap corresponding to the opening shape are respectively produced through the plastic shaping process, and a continuous and closed weld line according with the shape of the upper edge of the bottle body is arranged on the bottle cap; secondly, the bottle cap is fixed and connected at the upper edge of the bottle body by adopting the ultrasonic welding process, and then the bottle cap is covered above the opening in a sealing way. The adopted injection molding process for manufacturing the bottle body, and the bottle cap is simple, the product quality is greatly improved relative to the blow molding process, and the sand holes or micro-air holes generated in the blow molding process are eliminated. The absolute air tightness at the juncture of the bottle body and the bottle cap can be ensured by adopting the ultrasonic welding, and the air leakage hidden danger possibly existing in the mechanical sealing method can be thoroughly stopped.

Owner:姚荣平 +2

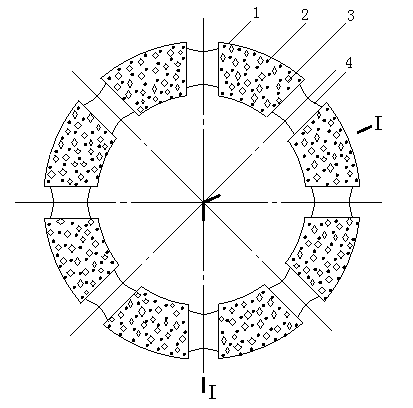

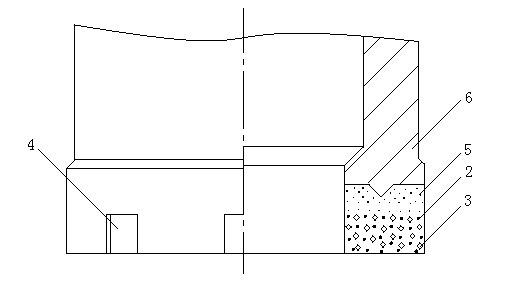

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

InactiveCN103015903AManufacturing Method AdvantagesEnhance the edge effectDrill bitsAdhesiveGraphite

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

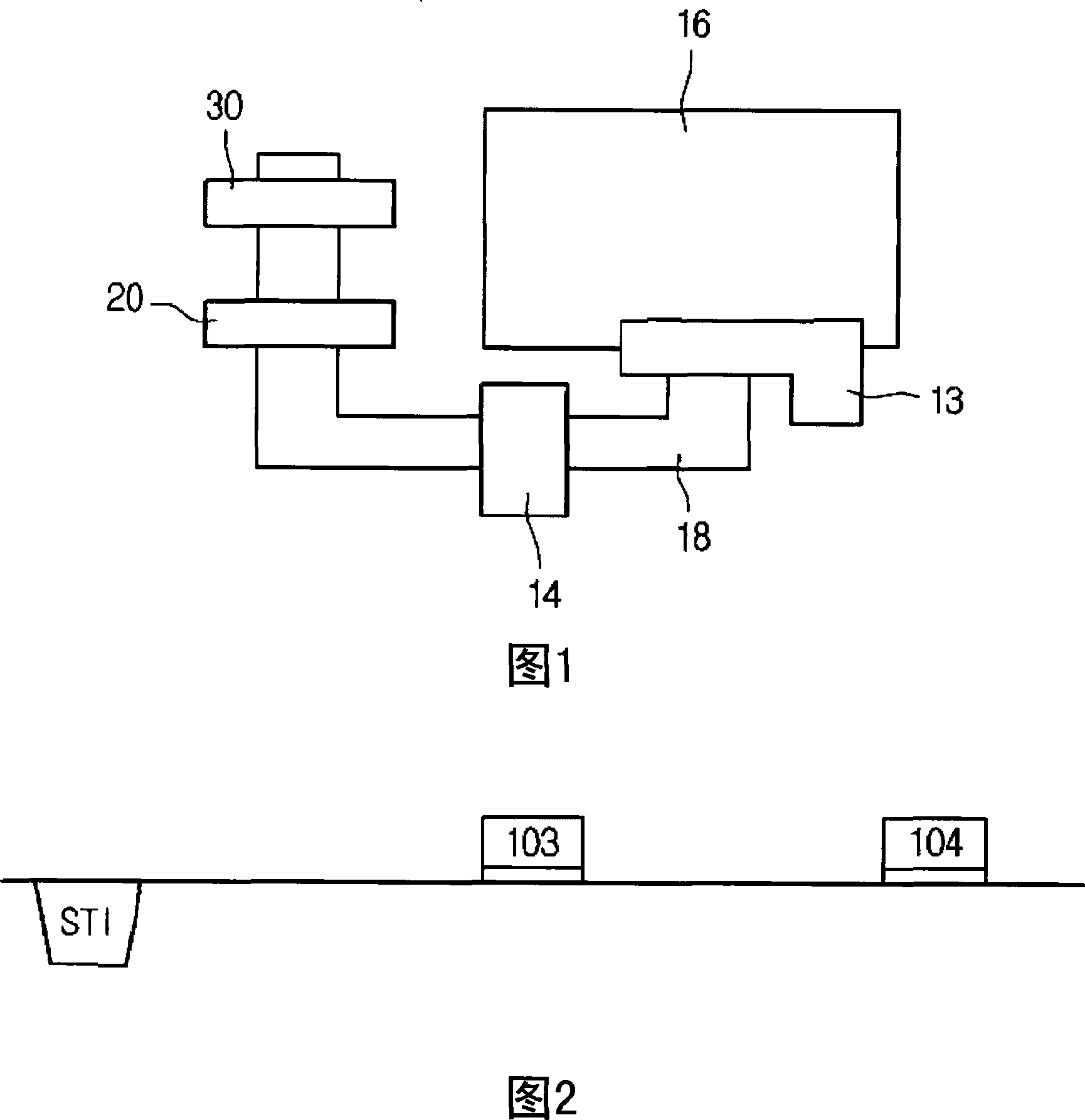

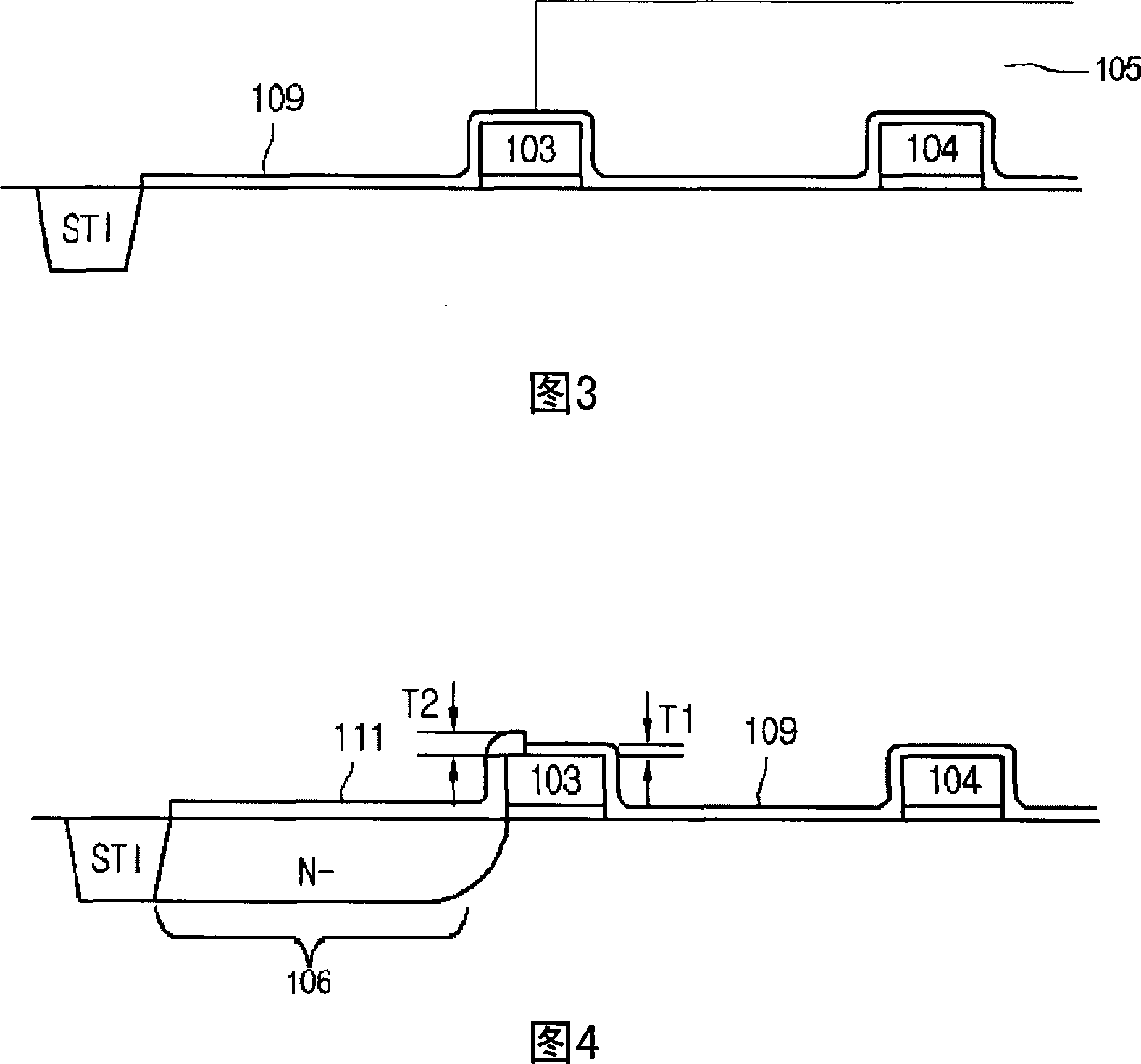

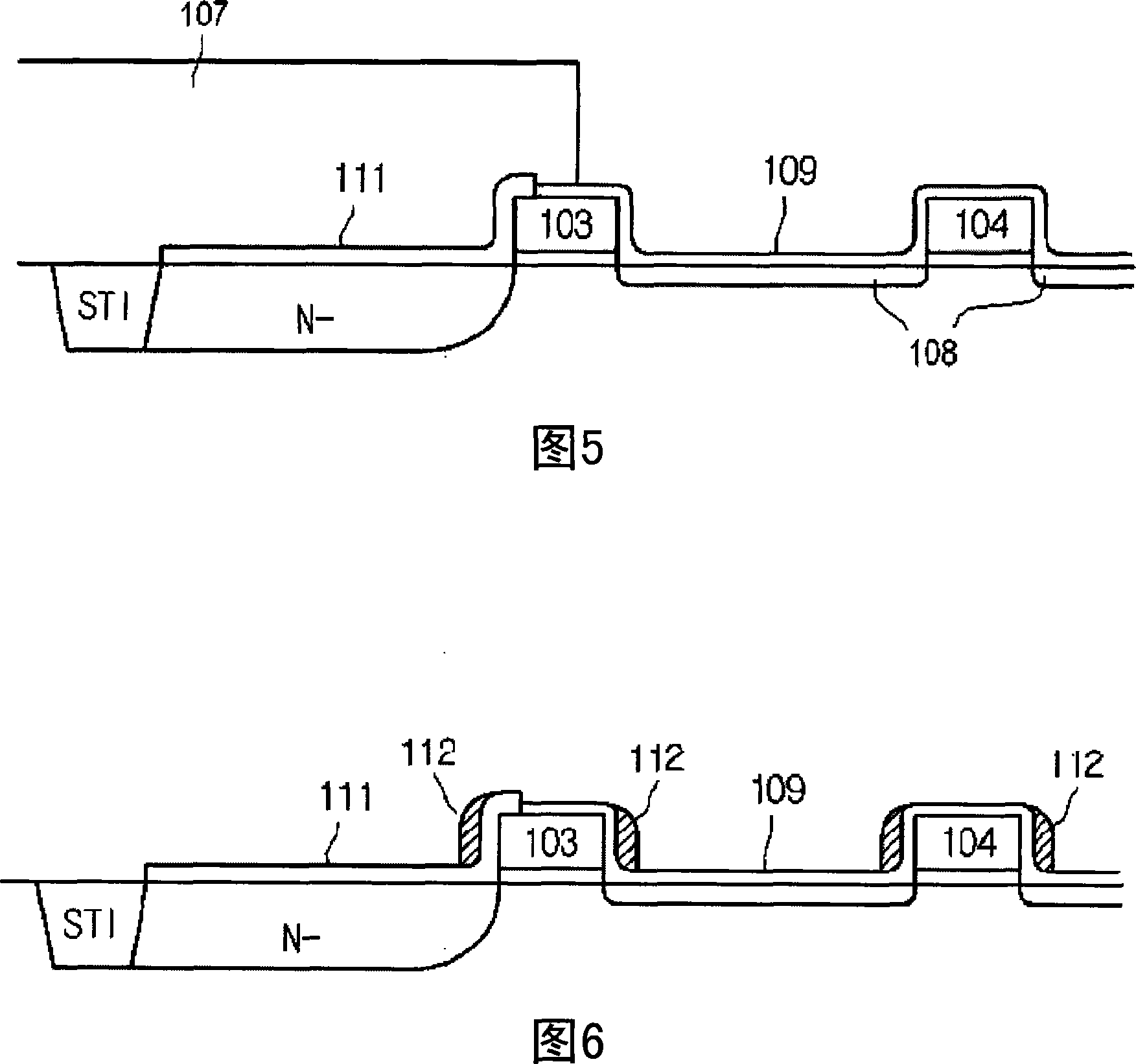

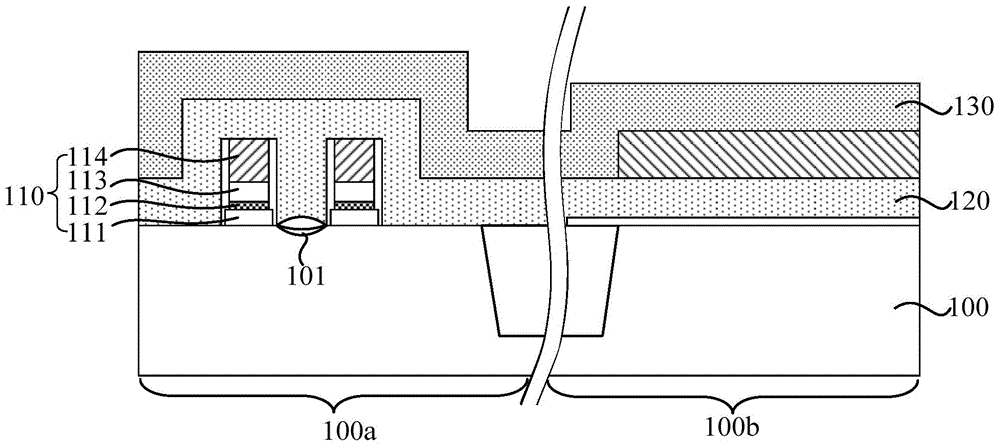

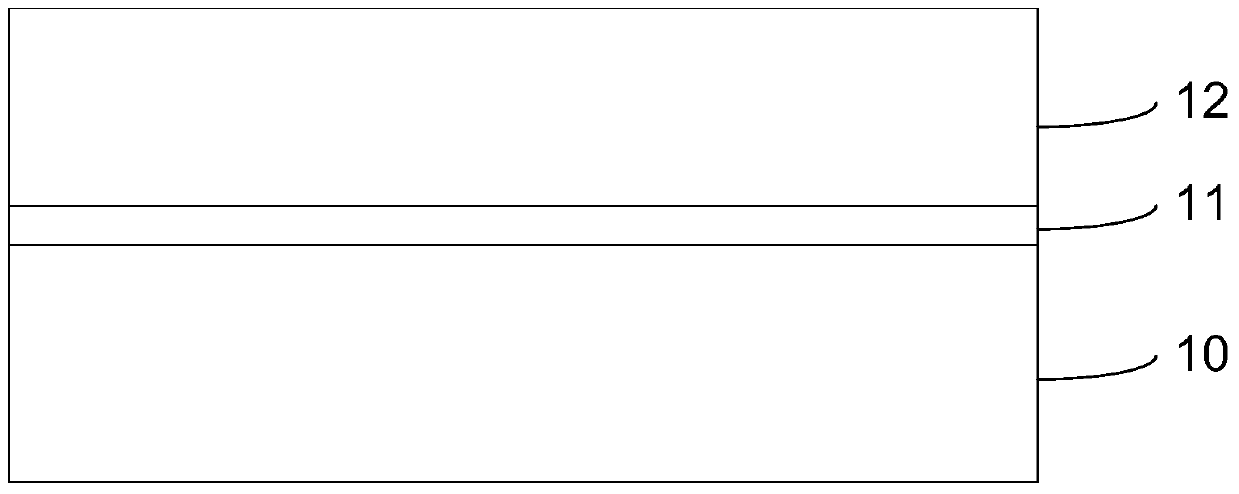

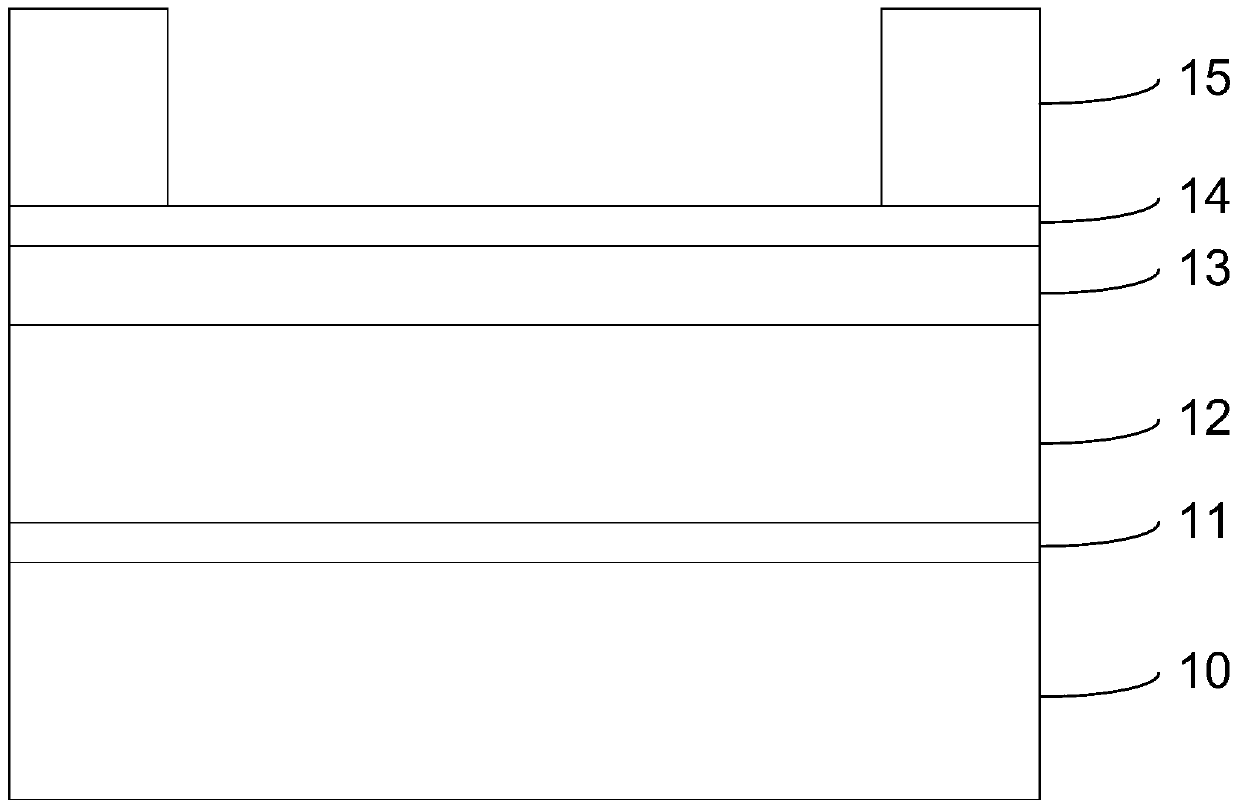

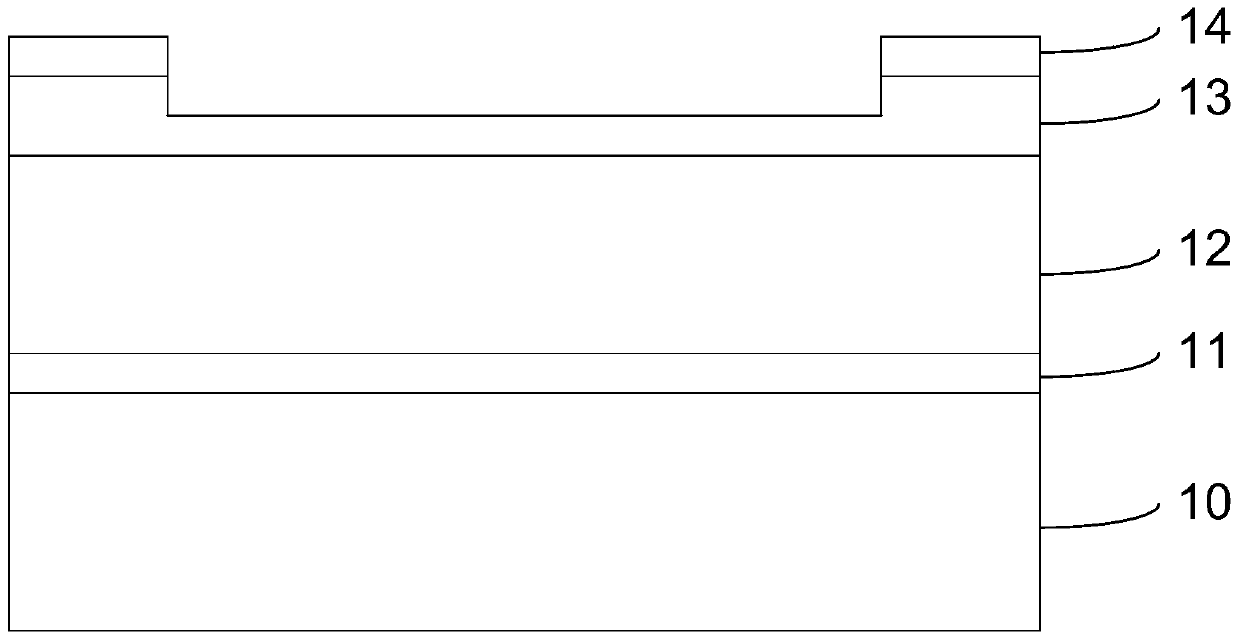

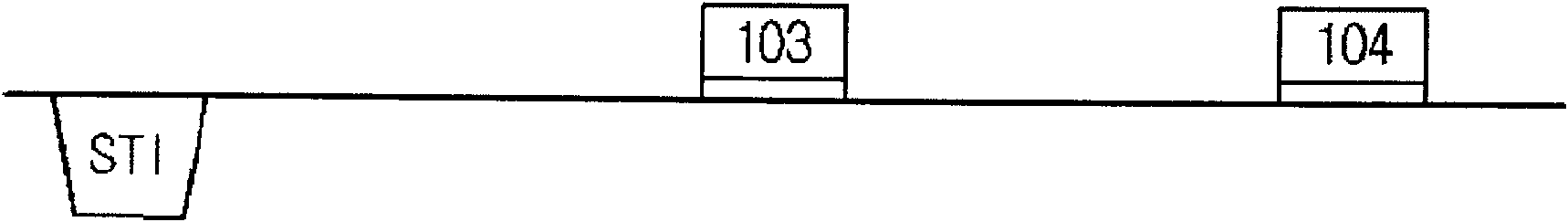

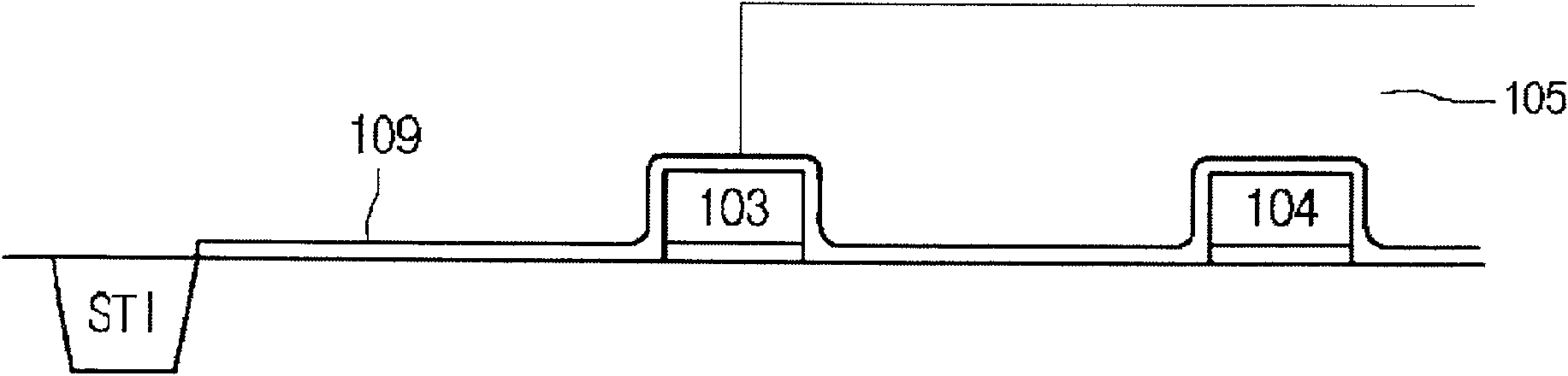

Method for fabricating a CMOS image sensor

InactiveCN101211839AManufacturing Method AdvantagesSolid-state devicesSemiconductor/solid-state device manufacturingCMOSIsolation layer

A method for fabricating a CMOS image sensor may include forming an isolation layer defining an active area on a semiconductor substrate, forming first and second gate electrodes in the transistor area of the semiconductor substrate, forming a photodiode area in the semiconductor substrate at a first side of the first gate electrode, forming an oxide layer over the photodiode area, the oxide layer having a thickness greater than that of the dielectric layer, forming a source / drain extension area in the semiconductor substrate at a second side of the second gate electrode and between the first and second gate electrodes, forming source / drain regions in the transistor area of the semiconductor substrate by ion implantation through the dielectric layer, and forming a complementary ion implantation region in the photodiode area through the oxide layer.

Owner:DONGBU HITEK CO LTD

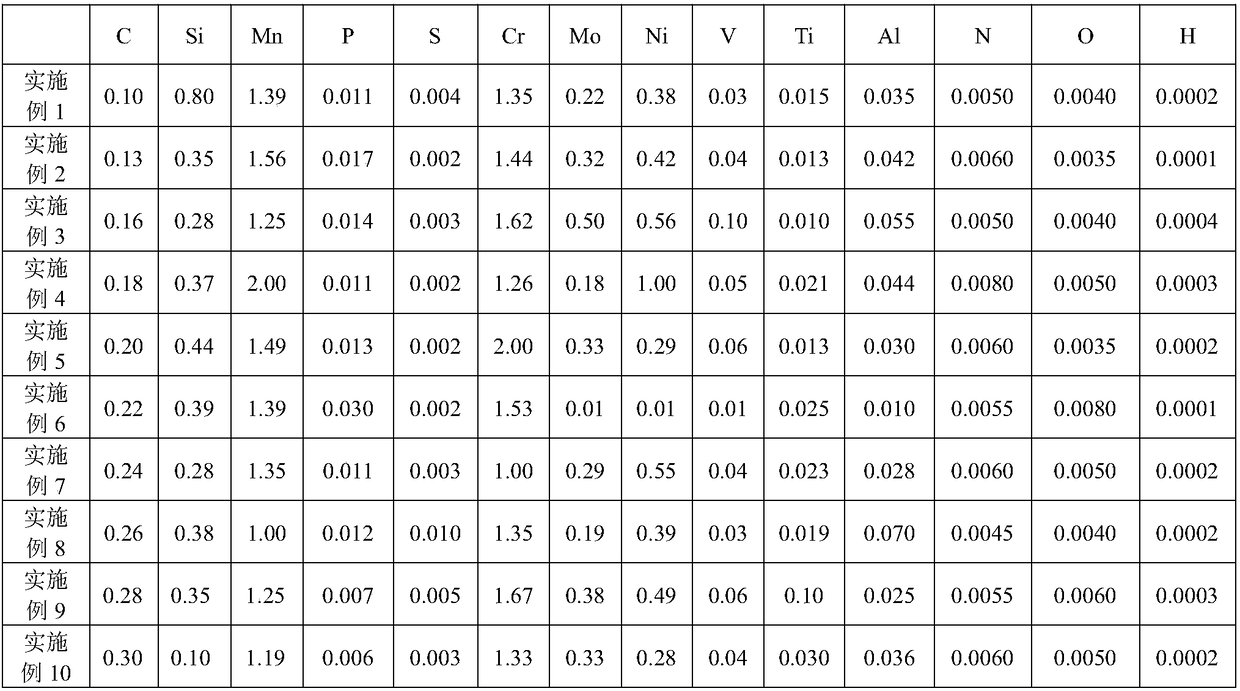

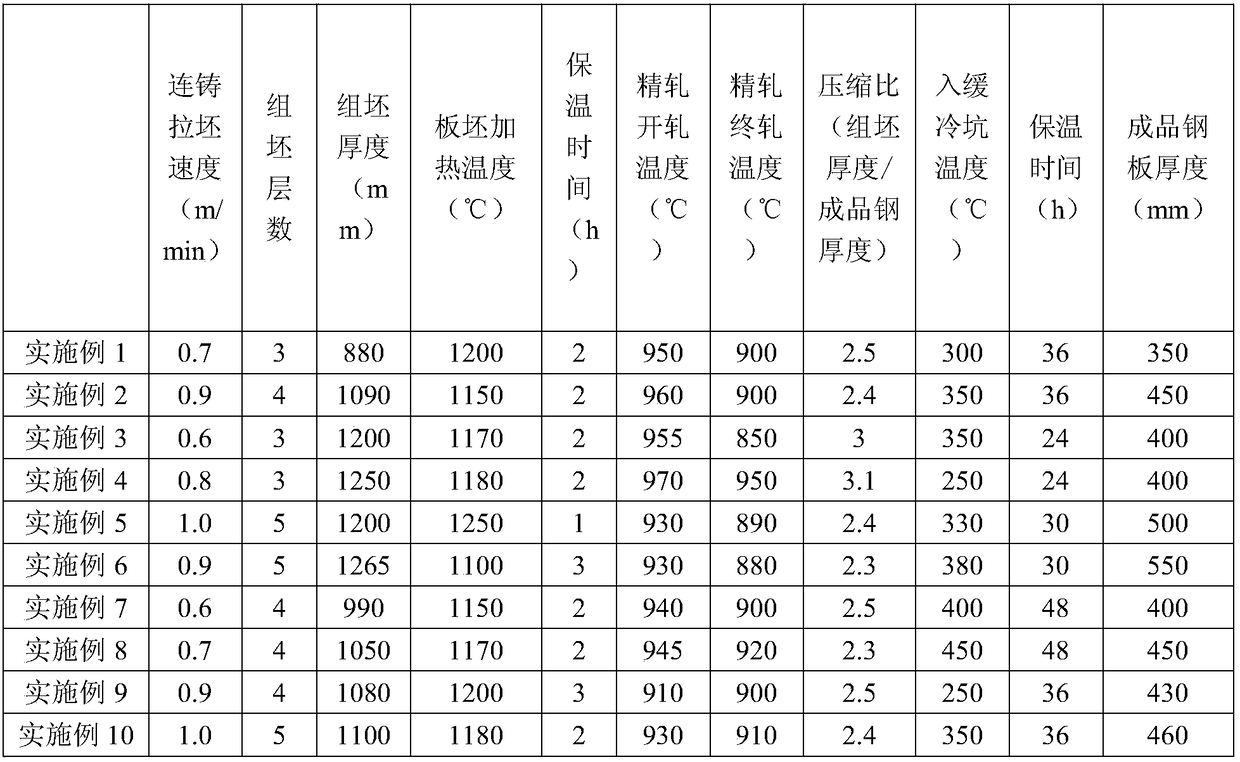

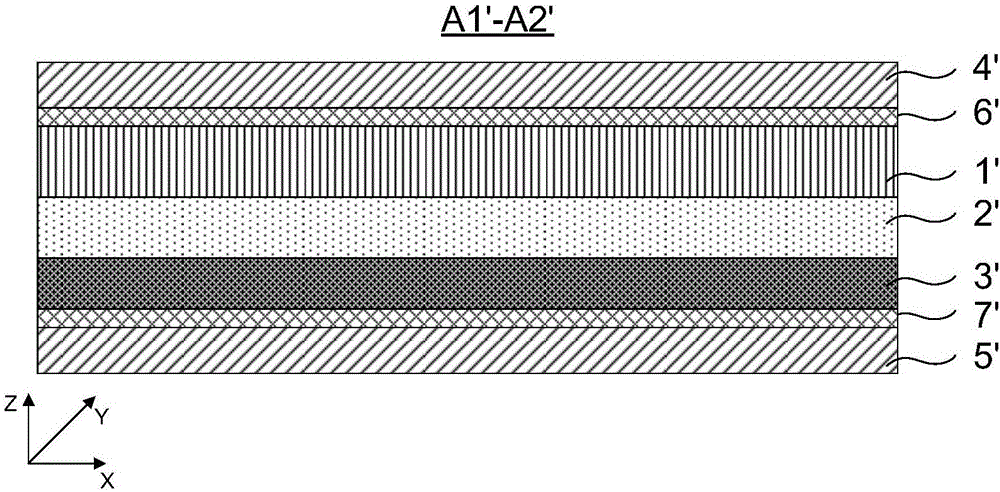

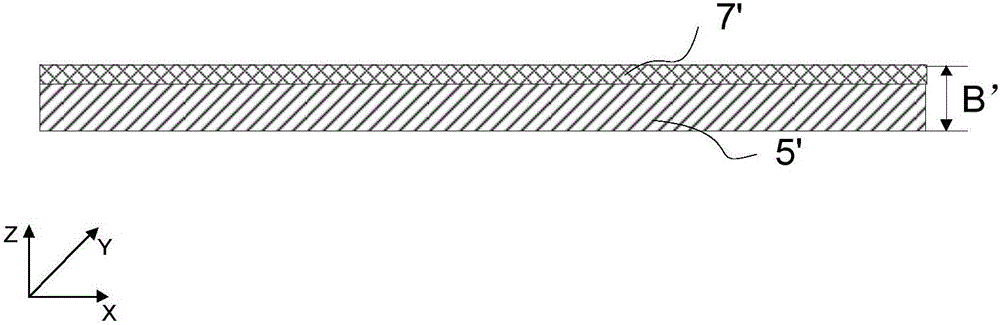

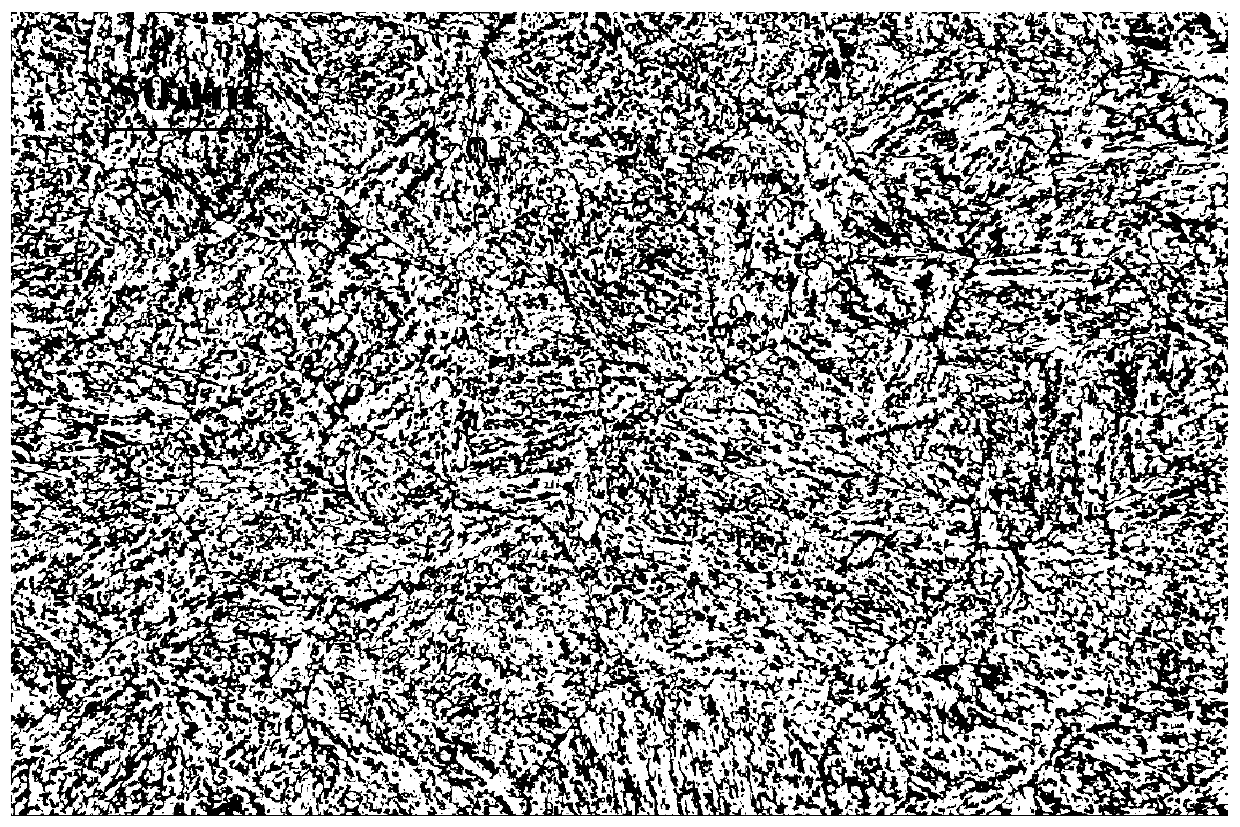

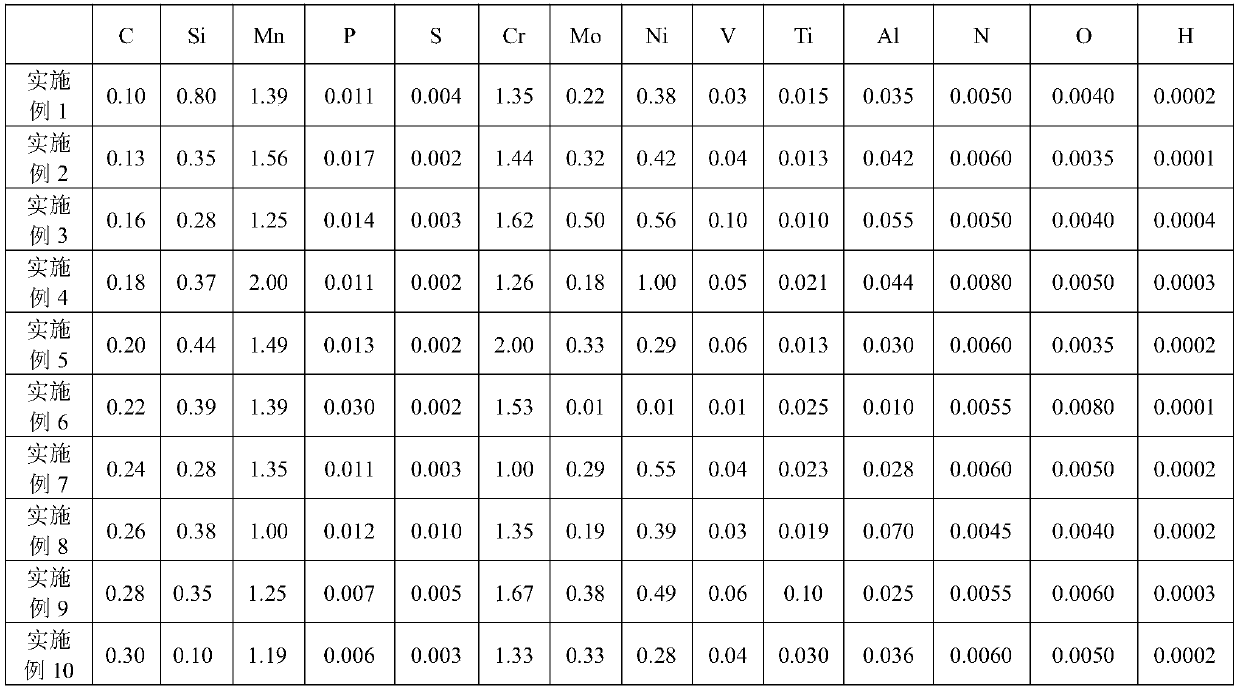

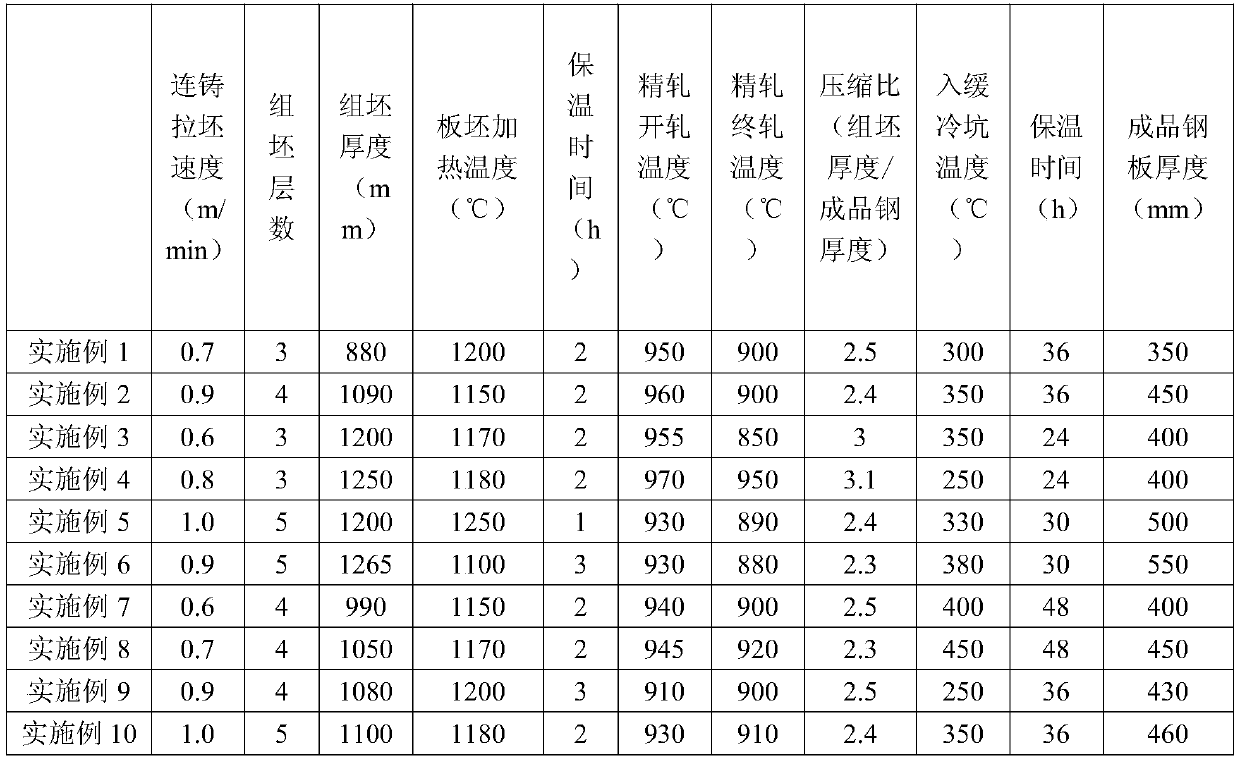

Composite steel plate for plastic mold and manufacturing method of composite steel plate

The invention discloses a composite steel plate for a plastic mold. The composite steel plate is formed by two or more homogeneous billet layers through cladding rolling. The omposite steel plate forthe plastic mold comprises, by mass, 0.10-0.30% of C, 0.10-0.80% of Si, 1.00-2.00% of Mn, 1.00-2.00% of Cr, 0.01-0.50% of Mo, 0.01-1.00% of Ni, 0.01-0.10% of V, 0.01-0.10% of Ti, 0.010-0.070% of Al and the balance Fe and other inevitable impurities. Correspondingly, the invention further discloses a manufacturing method of the composite steel plate for the plastic mold. The composite steel plate for the plastic mold is uniform in thickness and section structure.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

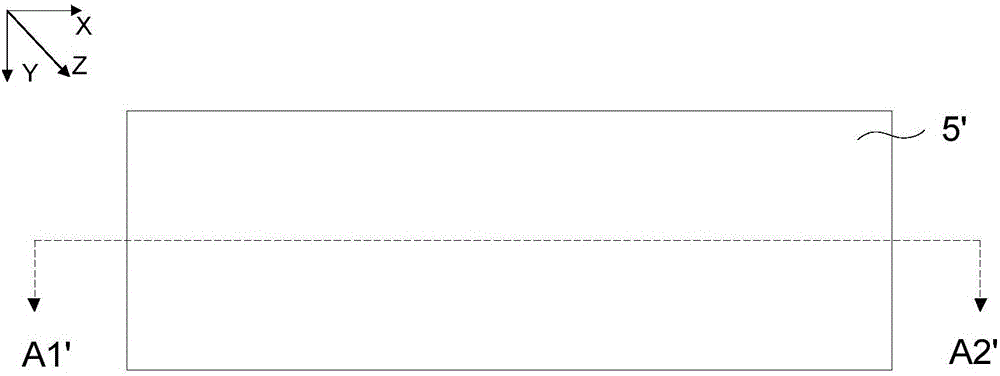

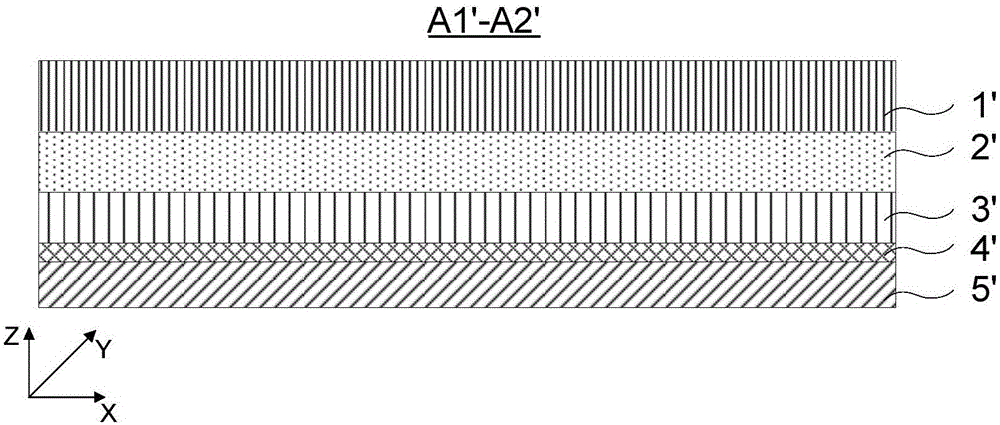

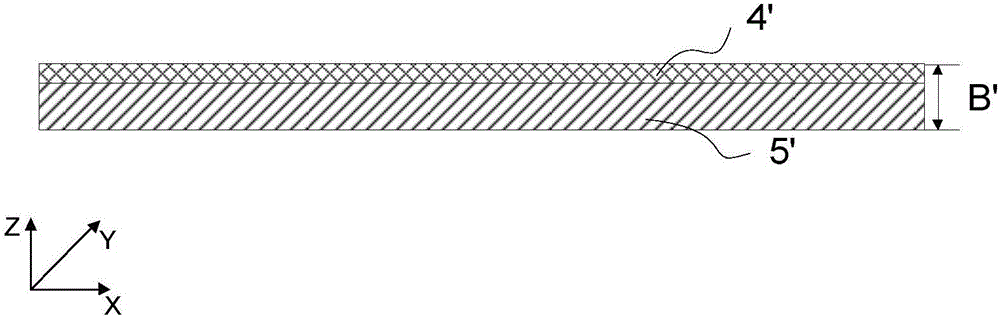

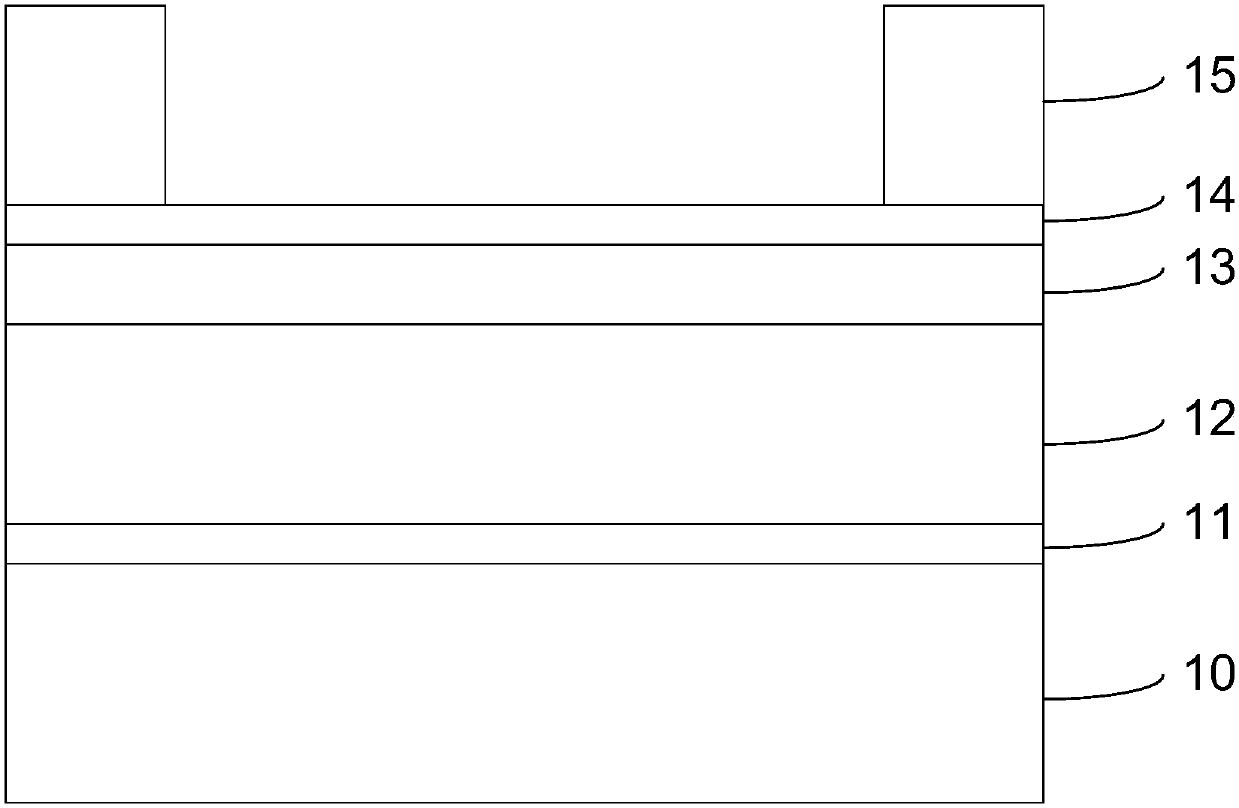

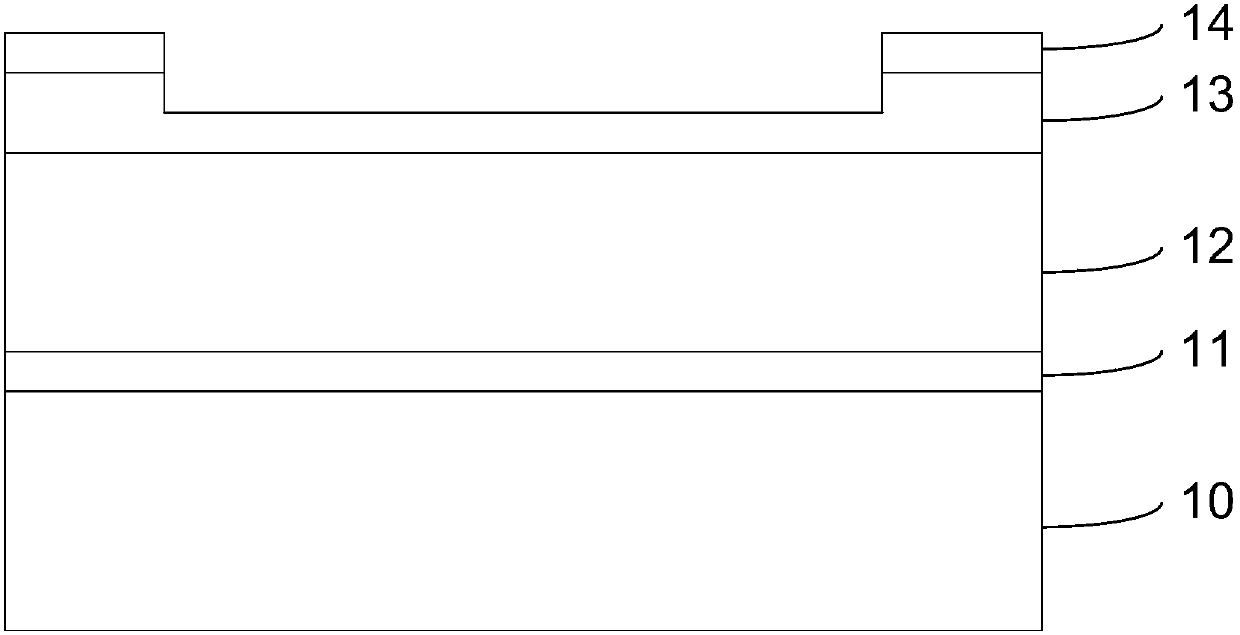

Display panel, display device and manufacturing method of display panel

InactiveCN106654039AManufacturing Method AdvantagesStrong bending resistanceFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention provides a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a flexible substrate, a light-emitting device, a packaging layer and a protection film layer, and is characterized in that the light-emitting device is located at one side of the flexible substrate; the packaging layer is located at the side, which is opposite to the flexible substrate, of the light-emitting device; and the protection film layer is formed on at least one of the side, which is opposite to the light-emitting device, of the flexible substrate and the side, which is opposite to the light-emitting device, of the packaging layer, and the protection film layer is directly contacted with the flexible substrate and / or the packaging layer. According to the invention, the protection film layer is printed on the packaging layer and / or the flexible substrate, and the protection film layer is directly contacted with the packaging layer and / or the flexible substrate, so that a glue material is saved, the display panel is enabled to be thinner while the packaging layer and / or the flexible substrate are / is protected from being scratched, the bending resistance of the display panel is enabled to be higher, and the restoration performance of the display panel after bending is improved at the same time.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

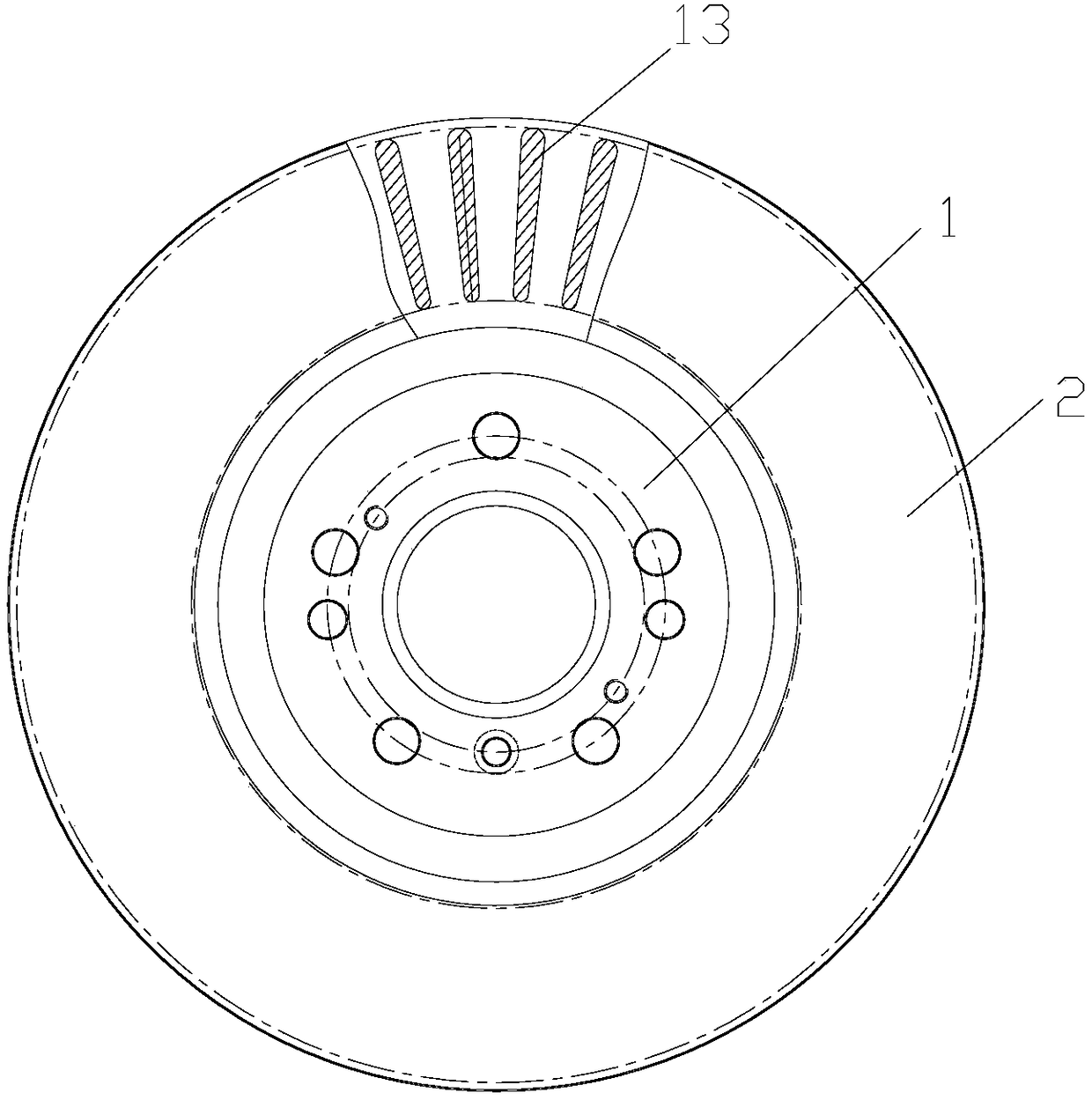

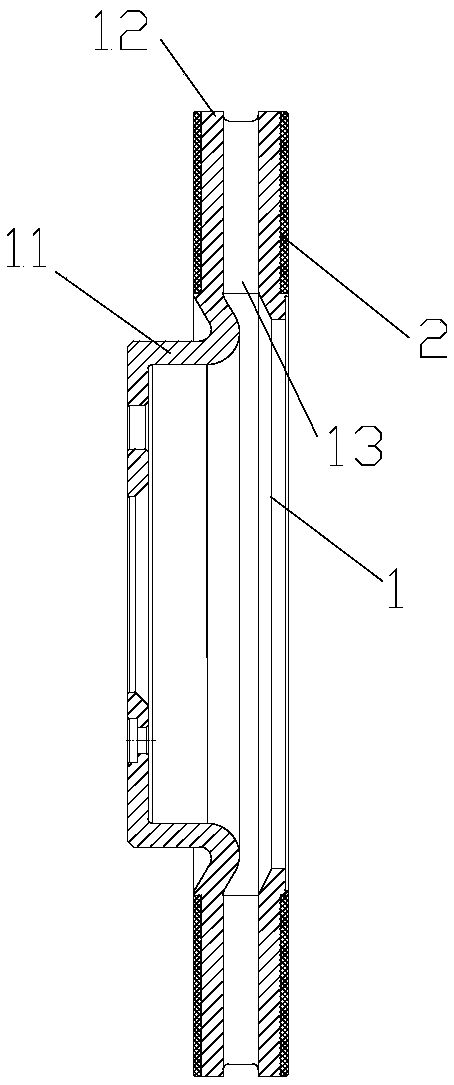

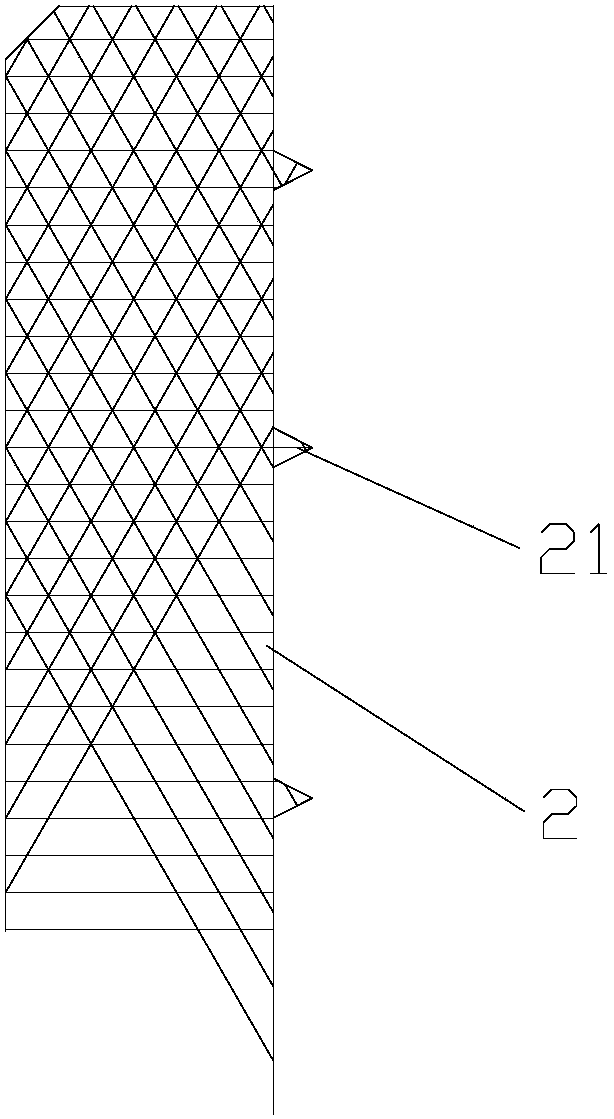

Manufacturing method of vehicle brake disc

InactiveCN109249005AManufacturing Method AdvantagesGive full play to wear resistanceBraking discsFurnace typesCast ironRough surface

The invention relates to the field of vehicle component processing, and provides a manufacturing method of a vehicle brake disc, wherein the brake disc comprises a body disc and two friction rings, the manufacturing method comprises the following steps of: casting two friction rings by adopting a cast iron material; preparing a casting mold and a core mold, wherein the core mold and the two friction rings are respectively fixed in corresponding positions in a mold cavity; pouring molten aluminum alloy into the cavity to form the brake disc; carrying out heat treatment on the brake disc, wherein the inner surface of the friction rings jointed with the body disc is a rough surface, so that the body disc and the friction rings can be embedded into each other. The production method of the invention can be used for manufacturing an aluminum alloy body disk and a cast iron friction ring, and can fully give play to the wear resistance, high friction and high temperature resistance of the castiron by the combination of two materials of cast iron and aluminum alloy, meanwhile, the aluminum alloy material can fully reduce the overall mass of the brake disc, so that the mass of the spring isreduced, and the operation stability of the vehicle is improved.

Owner:GREAT WALL MOTOR CO LTD

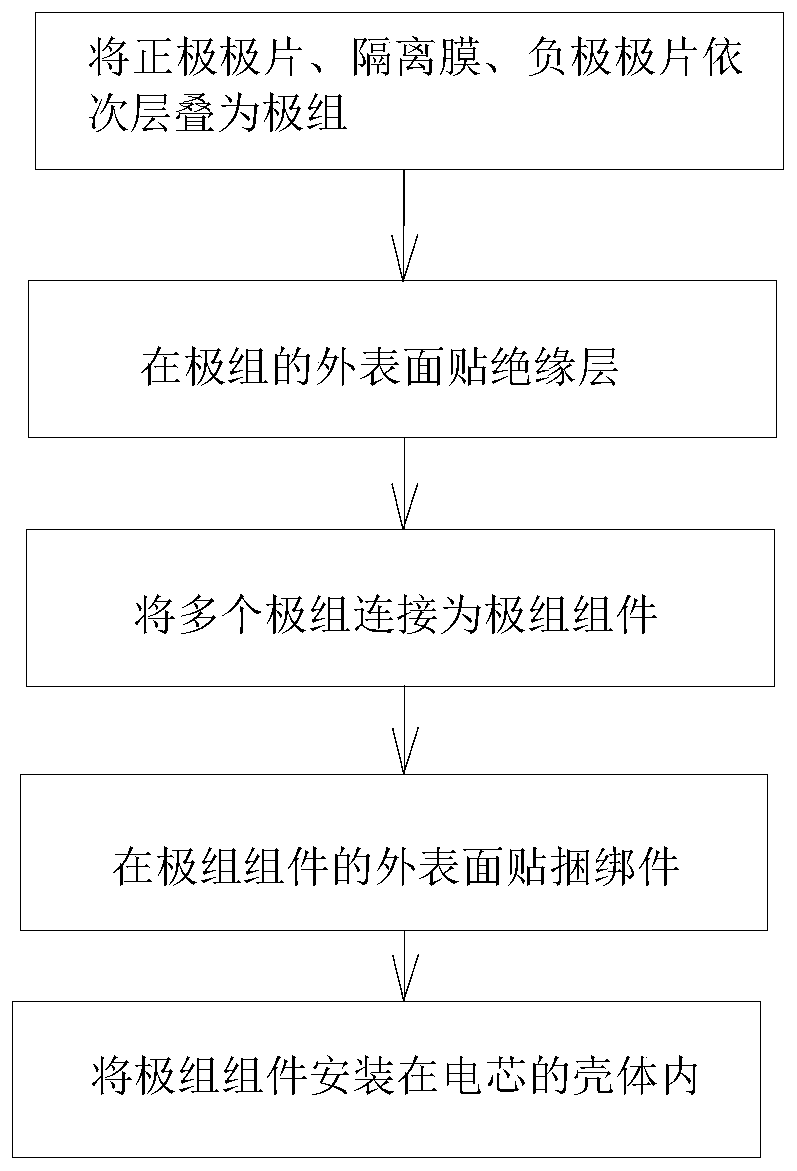

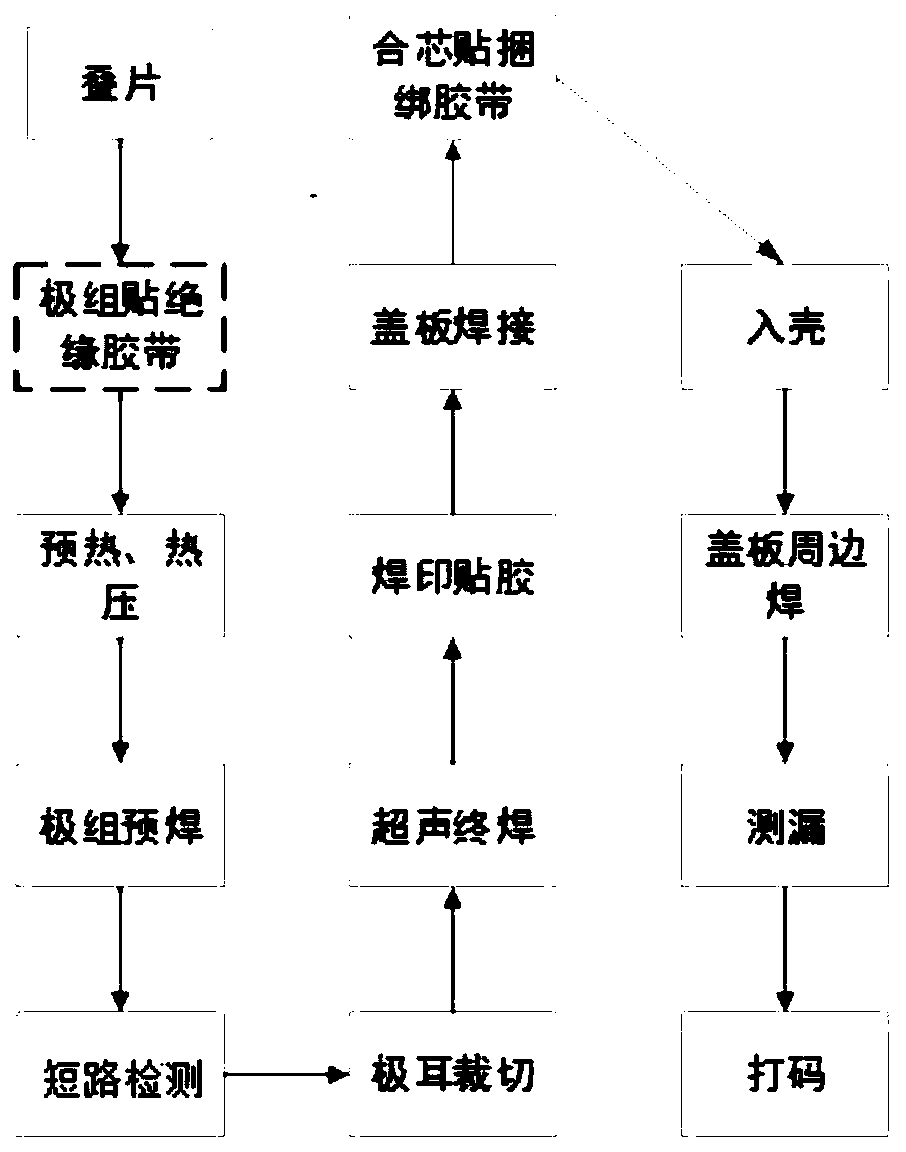

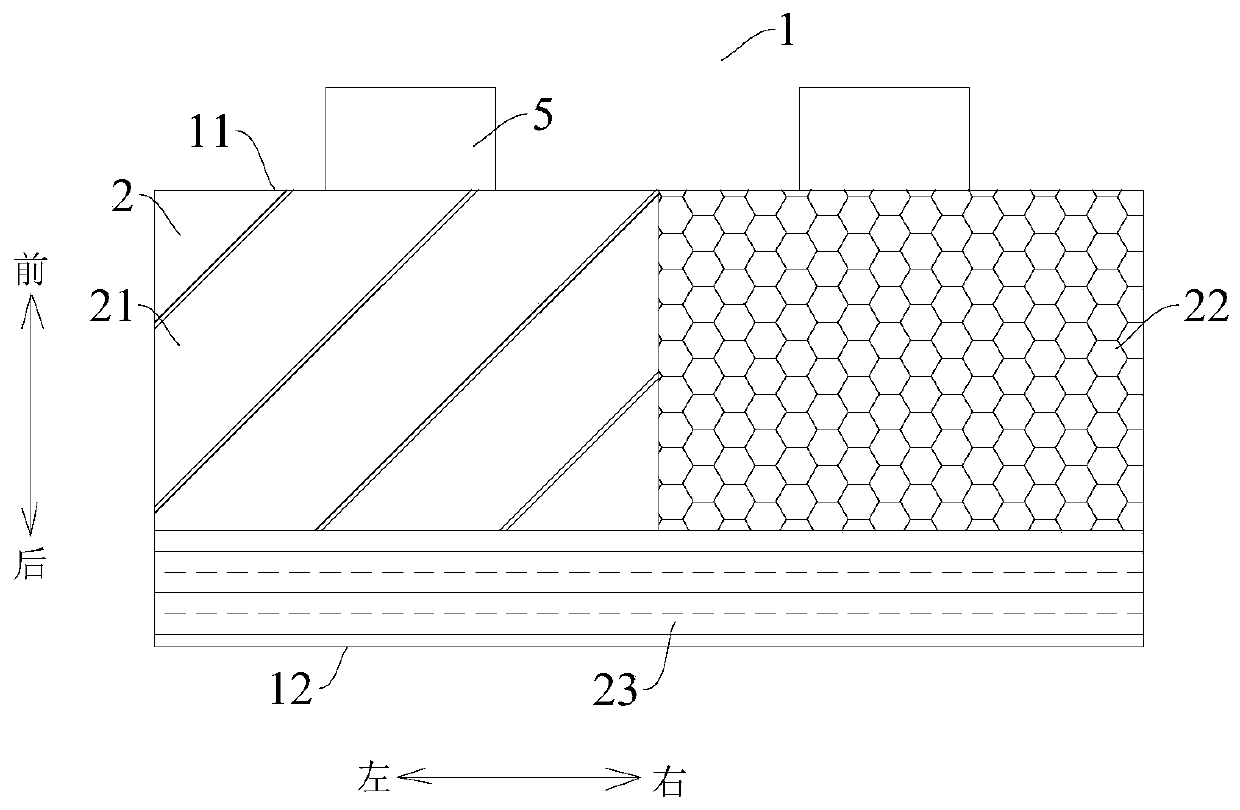

Manufacturing method of cell

ActiveCN110380100AManufacturing Method AdvantagesAvoid short circuitPrimary cell manufactureAssembling battery machinesEngineeringPole piece

The invention provides a manufacturing method of a cell. The manufacturing method of the cell comprises the steps of sequentially laminating a positive pole piece, an isolating film and a negative pole piece into a pole set; attaching an insulating layer to the outer surface of the pole set; connecting a plurality of pole sets into a pole set assembly; attaching binding pieces to the outer surfaceof the pole set assembly; and installing the pole set assembly in a shell of the cell. The cell produced according to the manufacturing method of the invention can prevent the pole pieces from beingseparated or being staggered, and can avoid the short circuit of the cell, thereby being capable of improving the use safety of the cell, and being also capable of improving the smoothness of the cell. In addition, the welding dust can be prevented from getting into the internal part of the pole set after attaching the insulating layer to the outer surface of the pole set.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

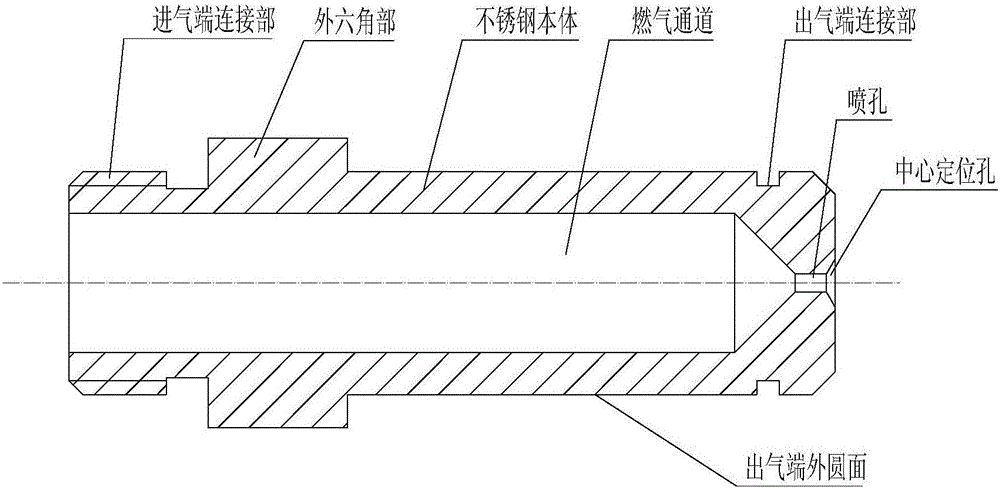

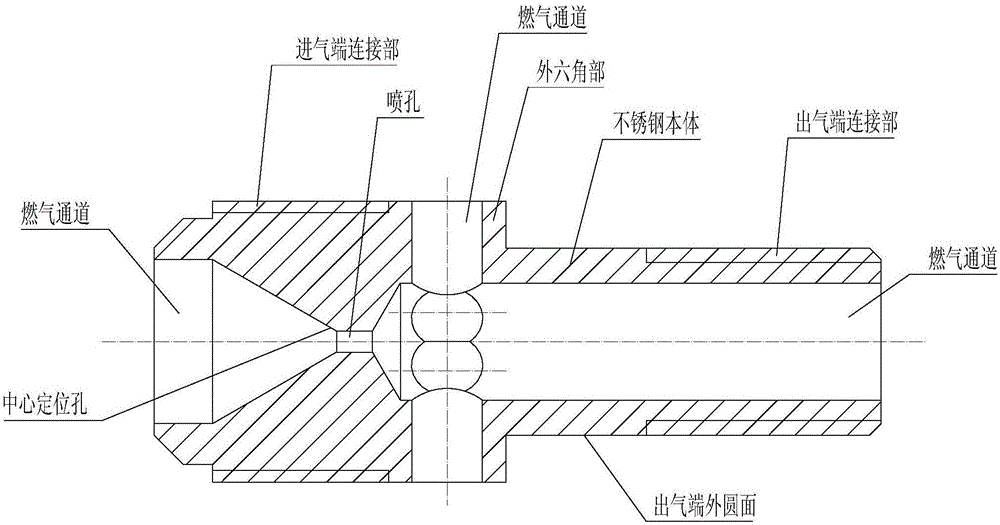

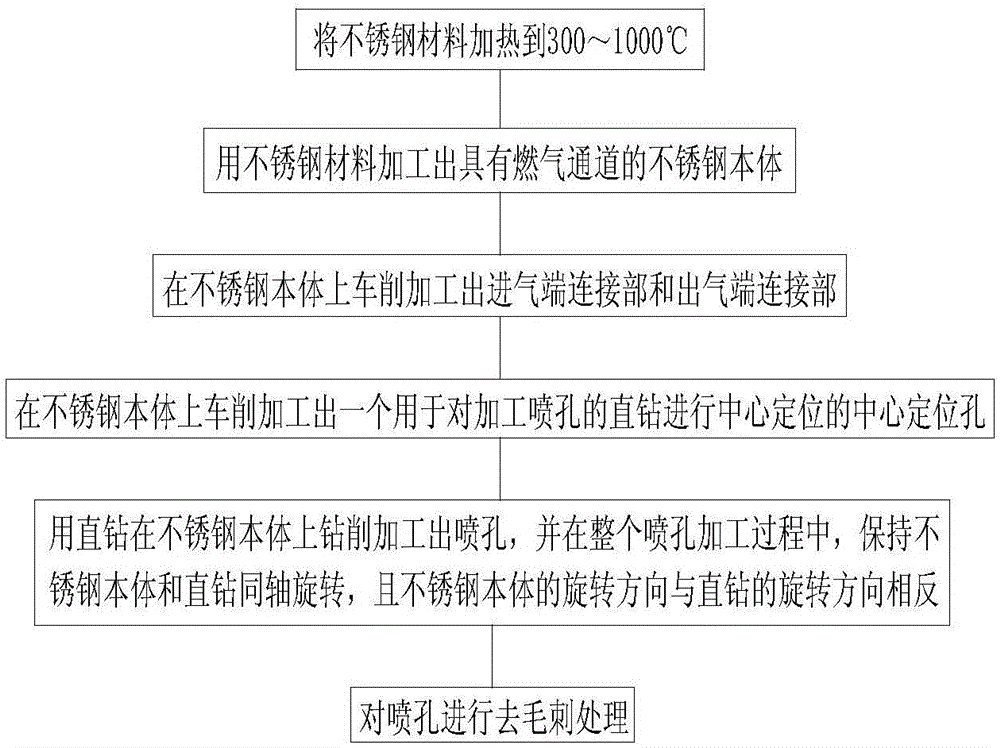

Manufacturing method of stainless steel jet nozzle of gas stove

ActiveCN106736258AManufacturing Method AdvantagesSolve the problem that the nozzle hole is difficult to processDomestic stoves or rangesGaseous fuel burnerDrillGas stoves

The invention relates to a manufacturing method of a stainless steel jet nozzle of a gas stove. The manufacturing method is characterized by comprising the following steps that a stainless steel material is heated to 300-1000 DEG C; a stainless steel jet nozzle body with a gas channel is machined with the stainless steel material; a central positioning hole used for conducting centralized positioning on a straight drill is machined in the stainless steel jet nozzle body, and the straight drill is used for drilling a nozzle hole; the nozzle hole is drilled in the stainless steel jet nozzle body through the straight drill, in the whole nozzle hole drilling process, the stainless steel jet nozzle body and the straight drill keep rotating coaxially, and the rotation direction of the stainless steel jet nozzle body is opposite to that of the straight drill; and an air inlet is formed in the stainless steel jet nozzle body through turning. The manufacturing method has the advantage that the jet nozzle of the gas stove can be manufactured with the stainless steel material.

Owner:胡国定

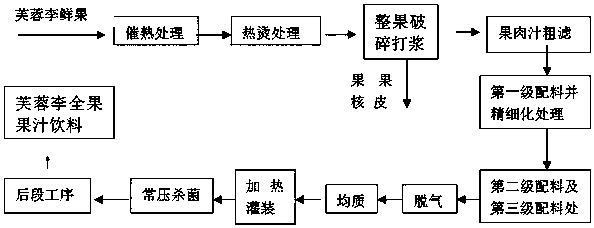

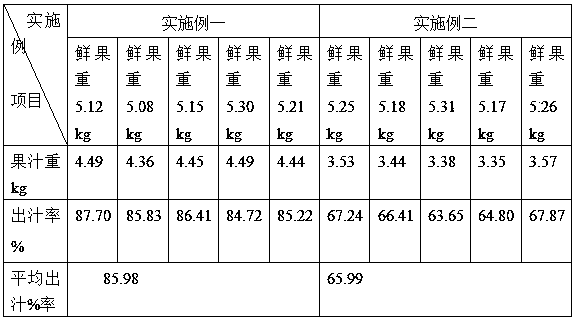

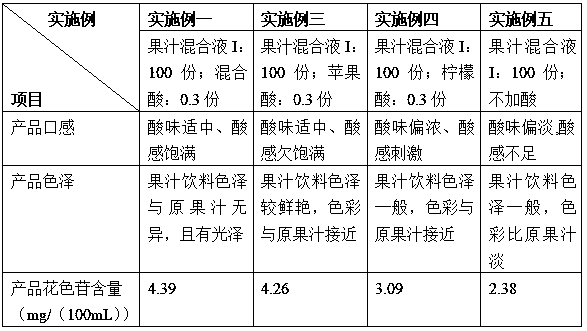

Manufacturing method of Chinese plum whole fruit juice drink

ActiveCN108065152AManufacturing Method AdvantagesIncrease profitSugar food ingredientsFood thermal treatmentThree levelFlavor

The present invention relates to a manufacturing method of Chinese plum whole fruit juice drink and relates to a manufacturing method of purely natural fruit flesh juice drink. The manufacturing method comprises the following main processes of Chinese plum fruit ripening, blanching, whole fruit crushing and beating, fruit flesh and fruit juice rough filtering, blending, fine-treating, re-blending,degassing, homogenizing, pasteurizing, hot filling, etc. The blending process is conducted by using a three-level protective blending technology. The method firstly ripens and softens fruits, then the whole fruits are beaten, utilization rate of the fruits is greatly improved, the three-level protective blending technology is conducted to reduce damages to nutritive substances, the manufacturingmethod can maintain unique color and luster, and fully utilizes fruit own pectin to prepare the purely natural turbid fruit flesh juice drink, and the Chinese plum whole fruit juice drink is excellentin color, fragrance and flavor.

Owner:POMOLOGY RES INST FUJIAN ACAD OF AGRI SCI +1

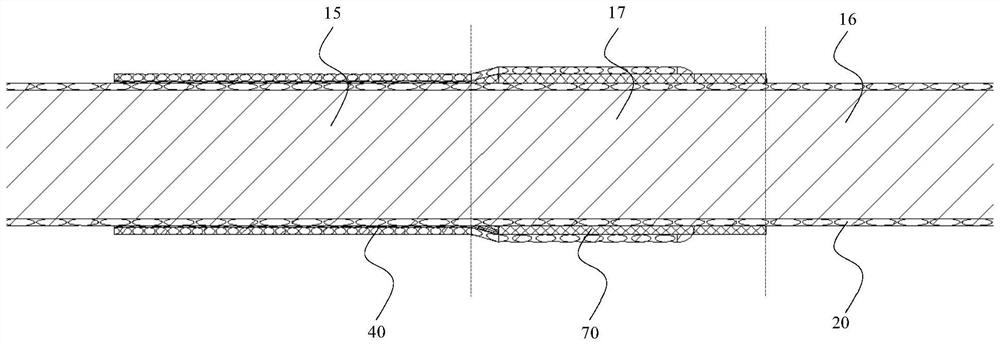

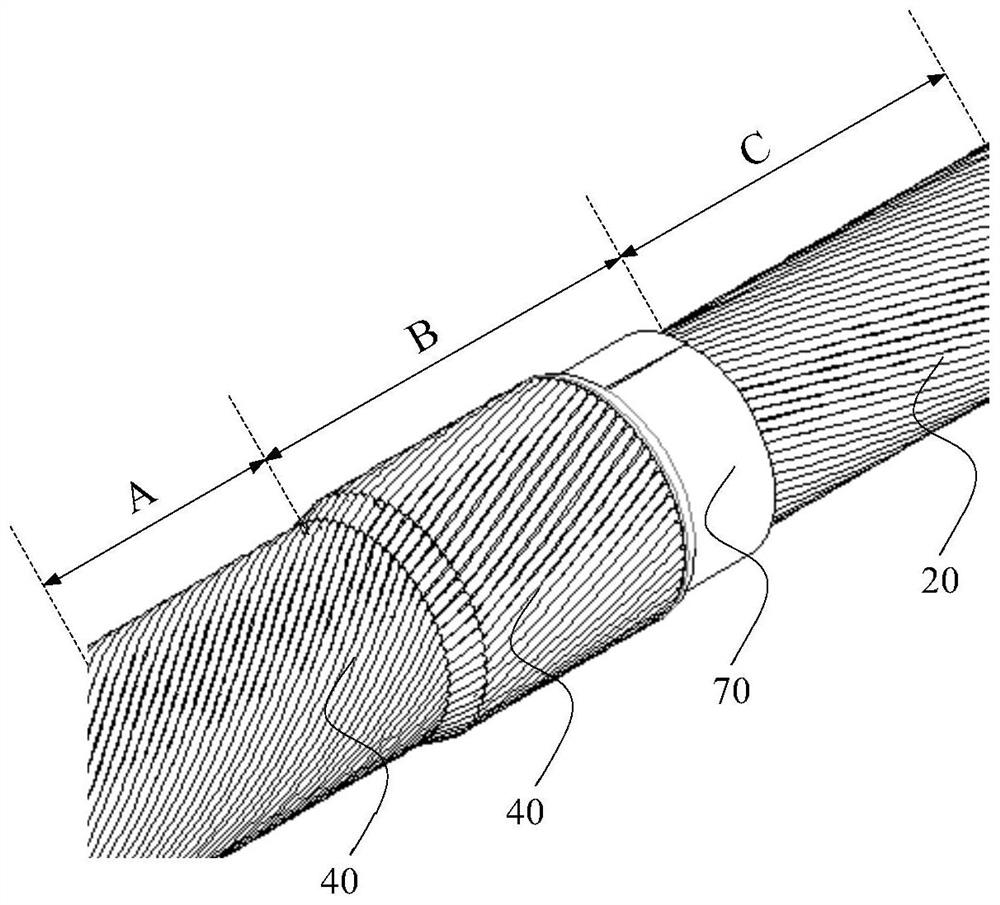

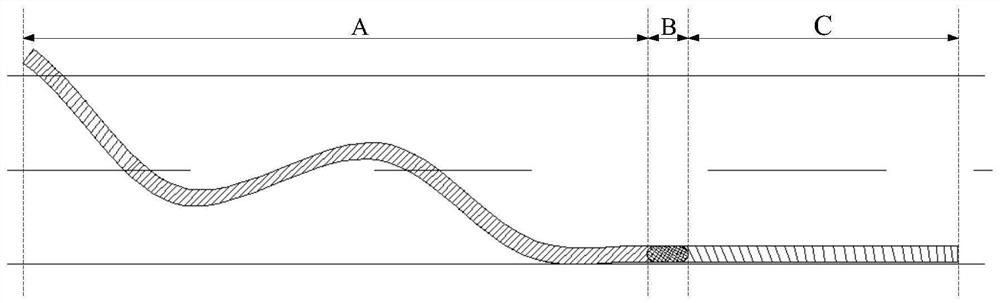

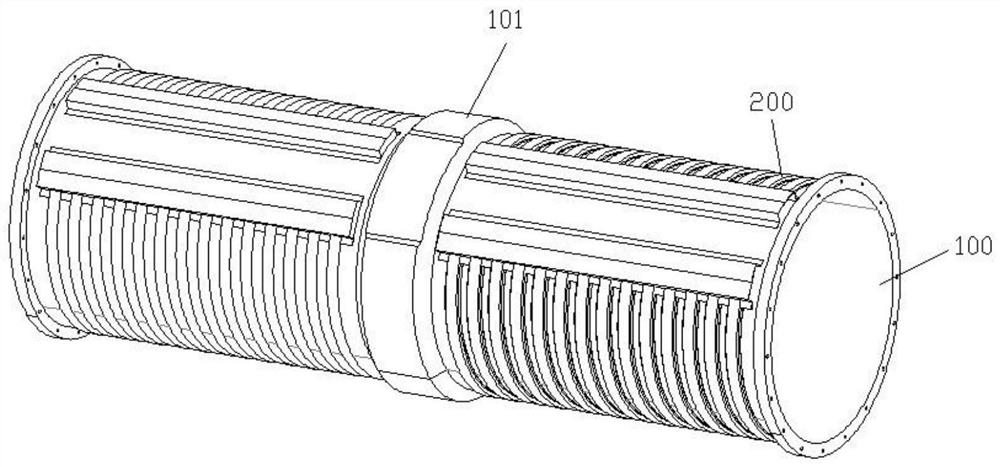

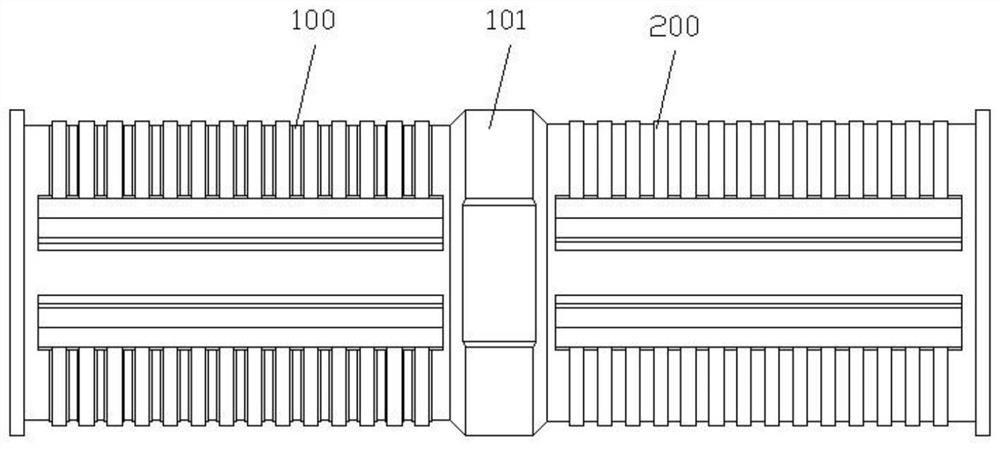

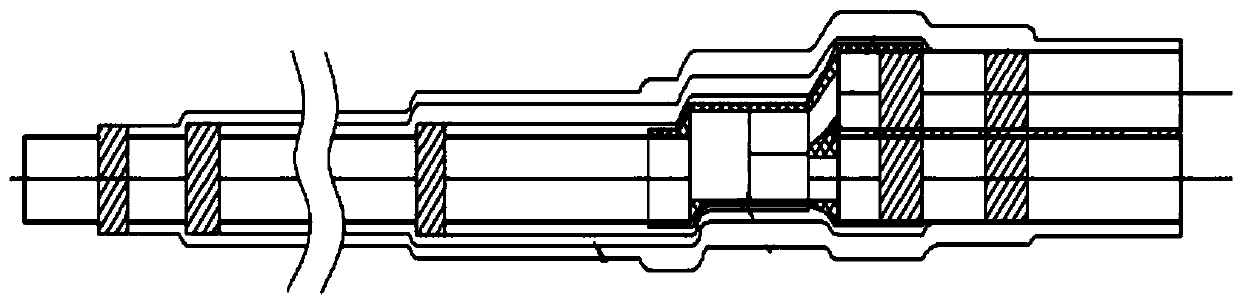

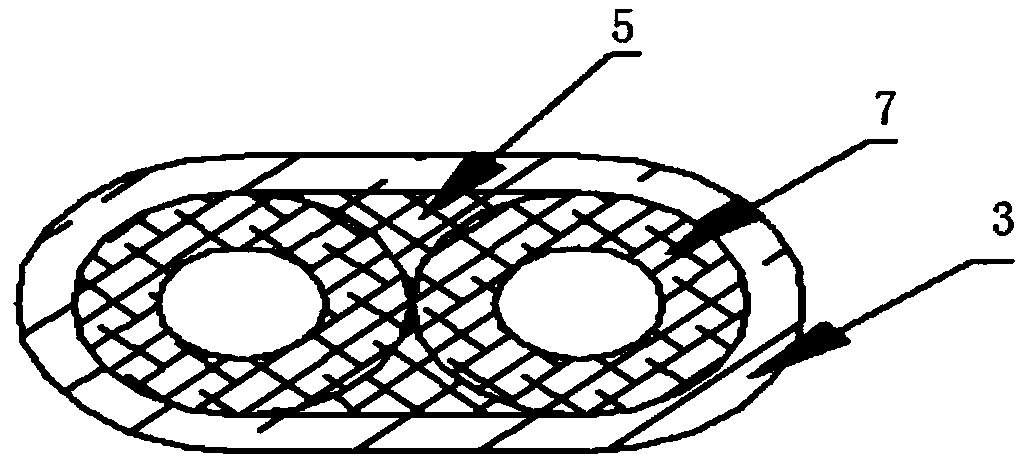

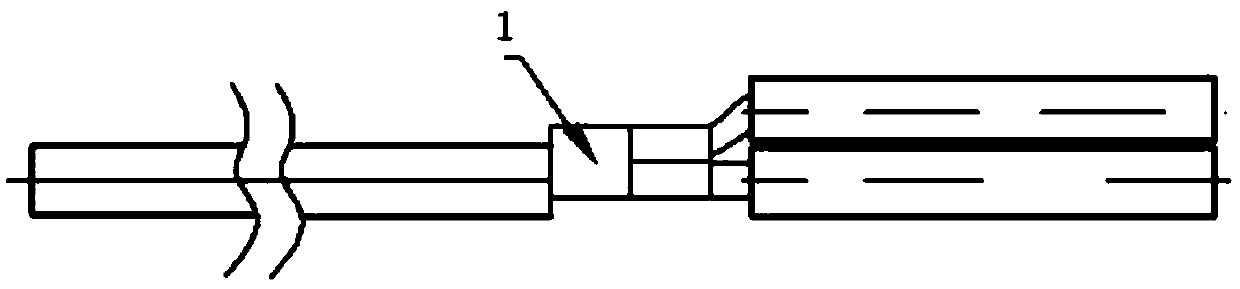

Dynamic and static submarine cable and manufacturing method thereof

ActiveCN113299431AGuaranteed continuityShorten the production cycleCommunication cablesSubmarine cablesStructural engineeringMechanical engineering

The invention provides a dynamic and static submarine cable and a manufacturing method thereof, relates to the technical field of submarine cables, and is used for solving the technical problem that the production period of the dynamic and static submarine cable is relatively long. The dynamic and static submarine cable comprises a continuous cable core, wherein the cable core comprises a dynamic section, a static section and a transition section for connecting the dynamic section and the static section; a first armor layer which sleeves the outer sides of the dynamic section, the static section and the transition section; a transition device which sleeves the outer side of the first armor layer corresponding to the transition section; and a second armor layer arranged outside the first armor layer corresponding to the dynamic section in a sleeving mode, wherein the first end of the second armor layer covers part of the transition device, and the first end of the second armor layer is welded to the peripheral face of the transition device. The dynamic and static submarine cable provided by the invention is used for electric conduction and communication.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

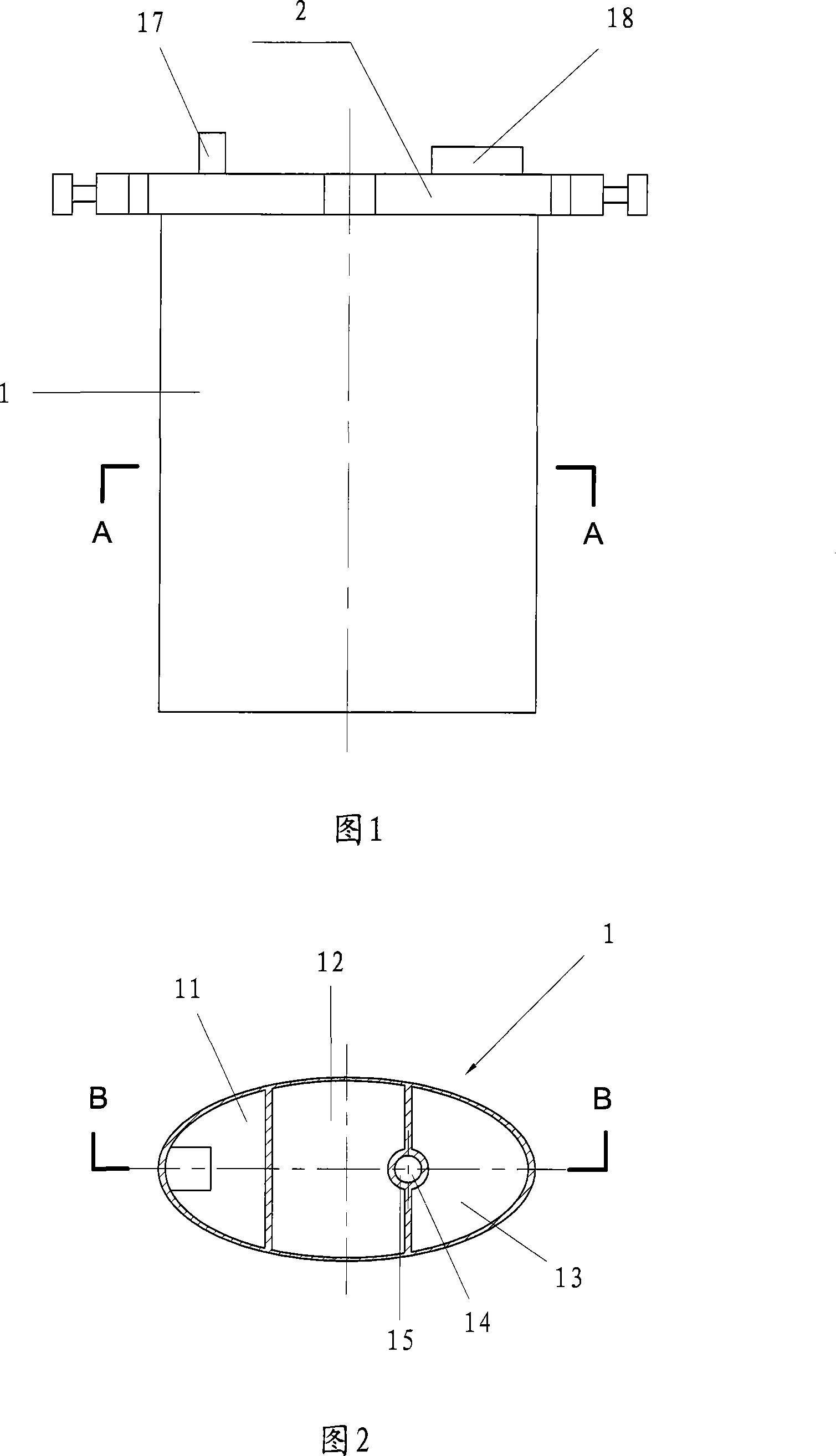

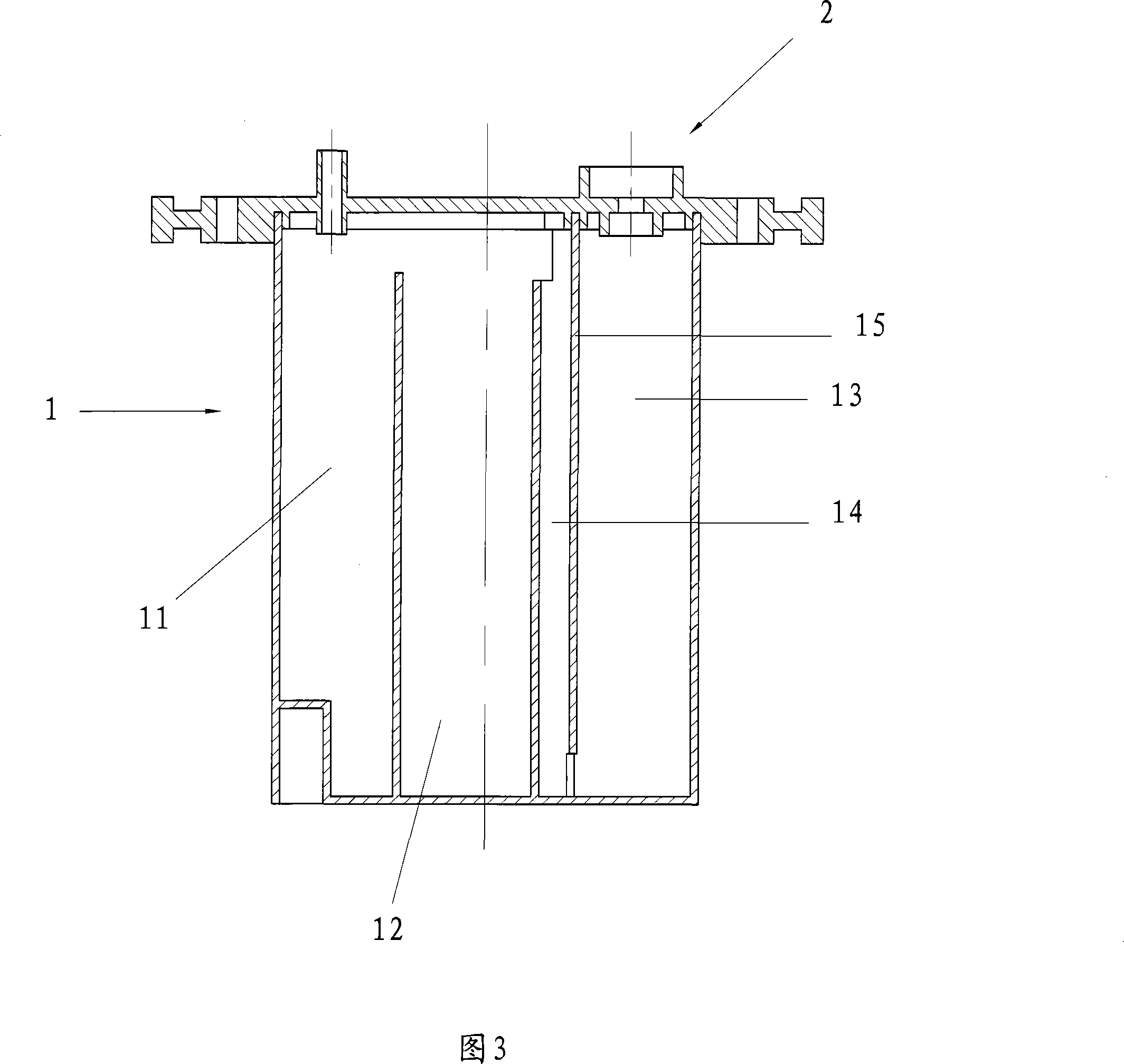

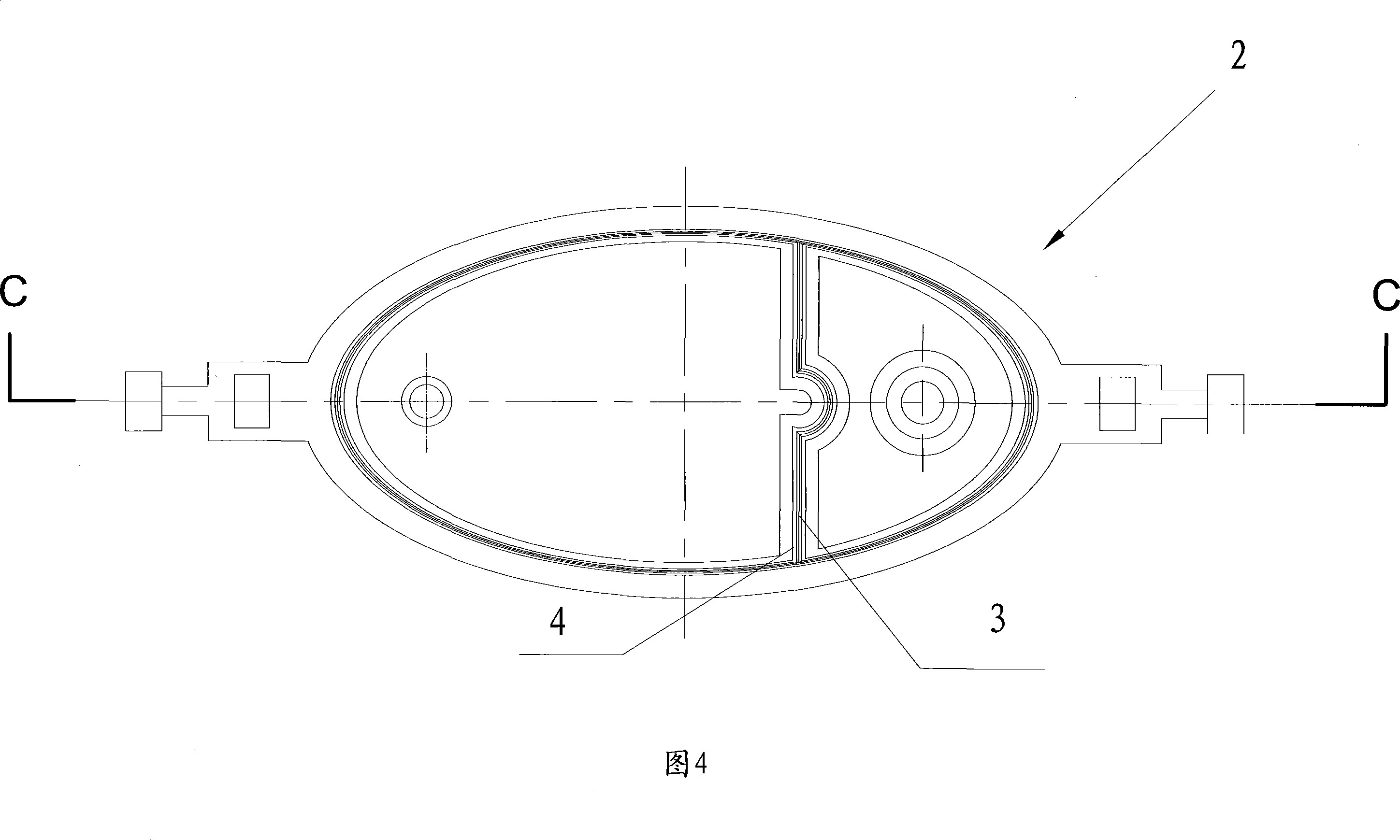

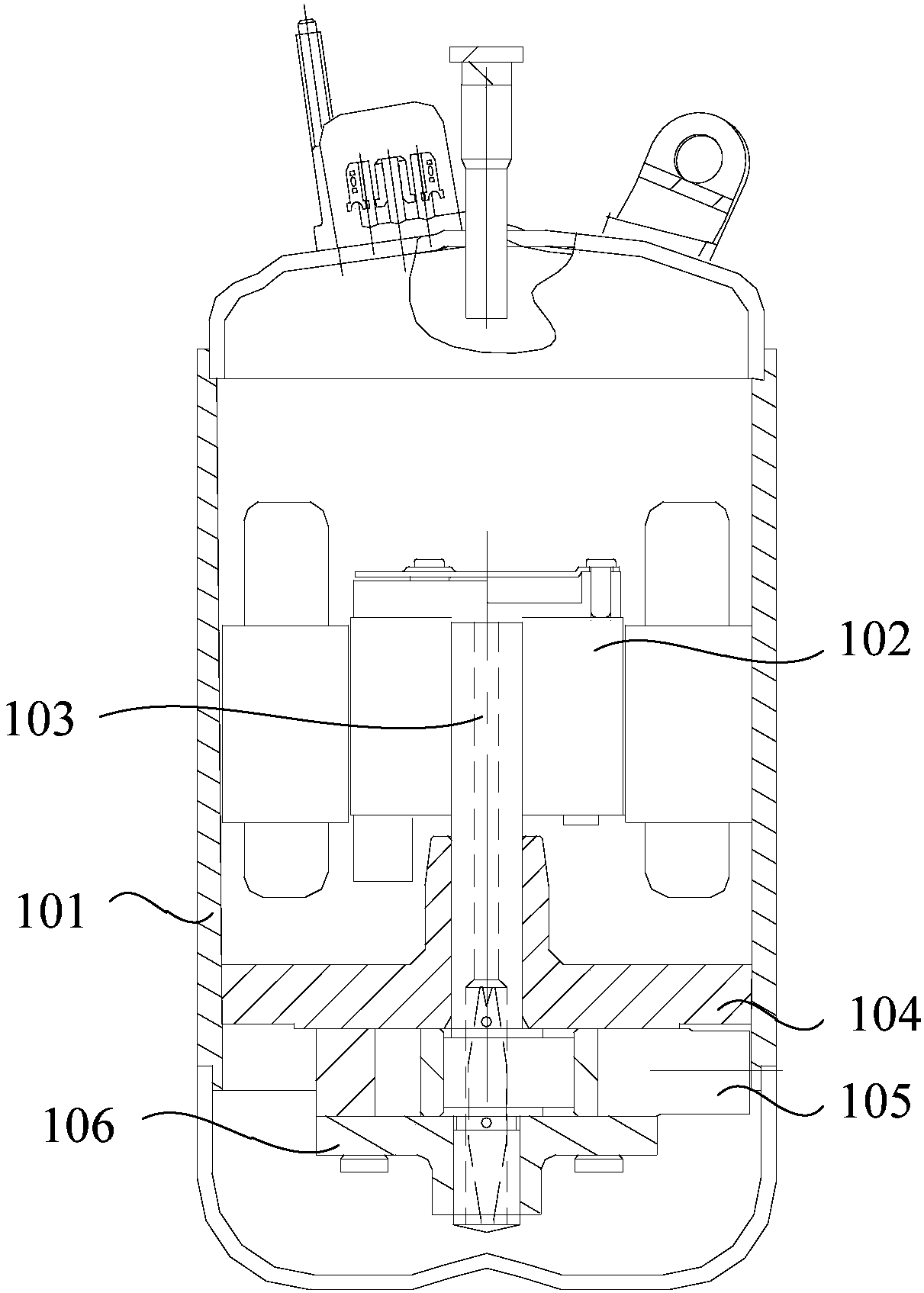

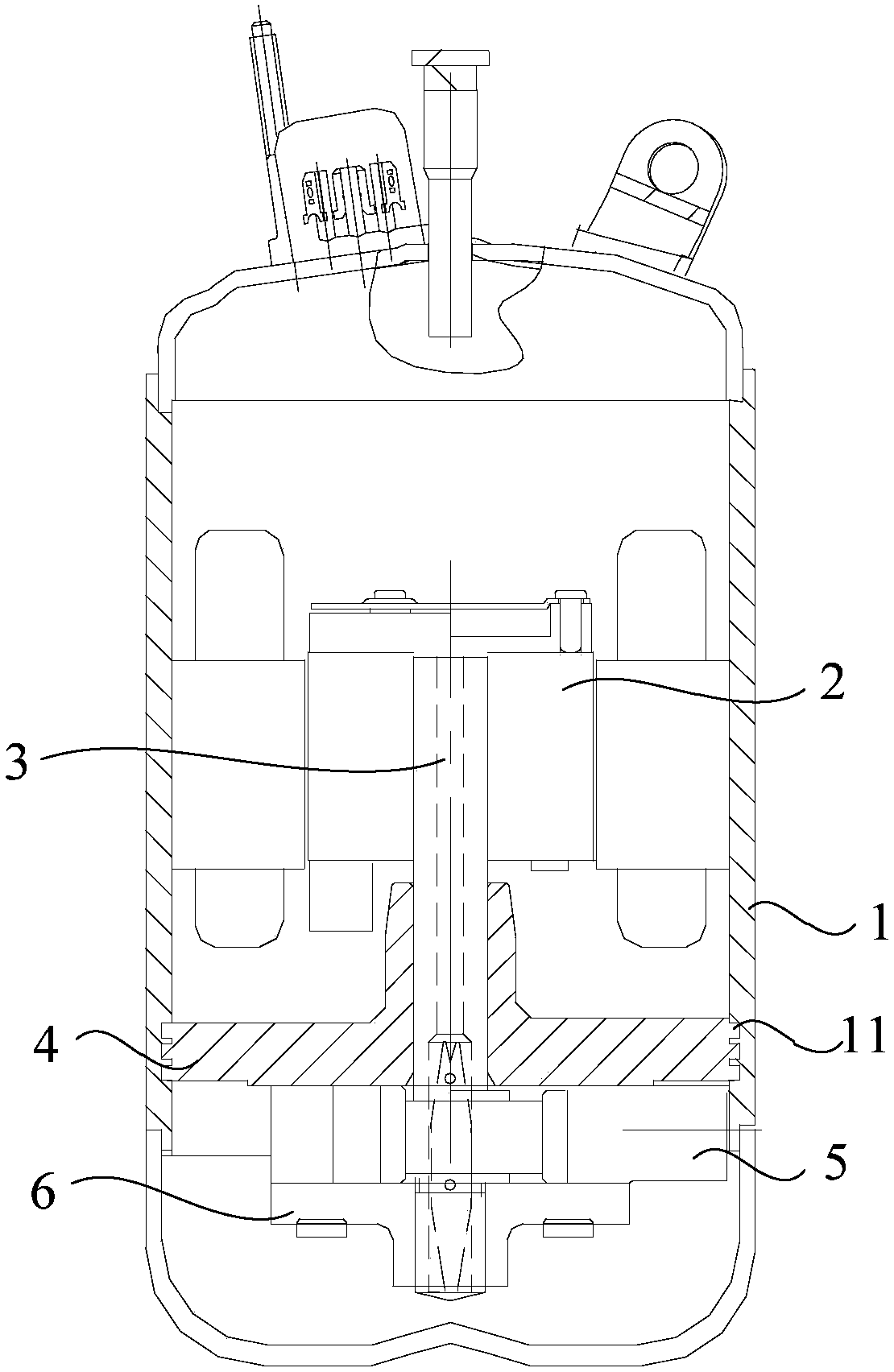

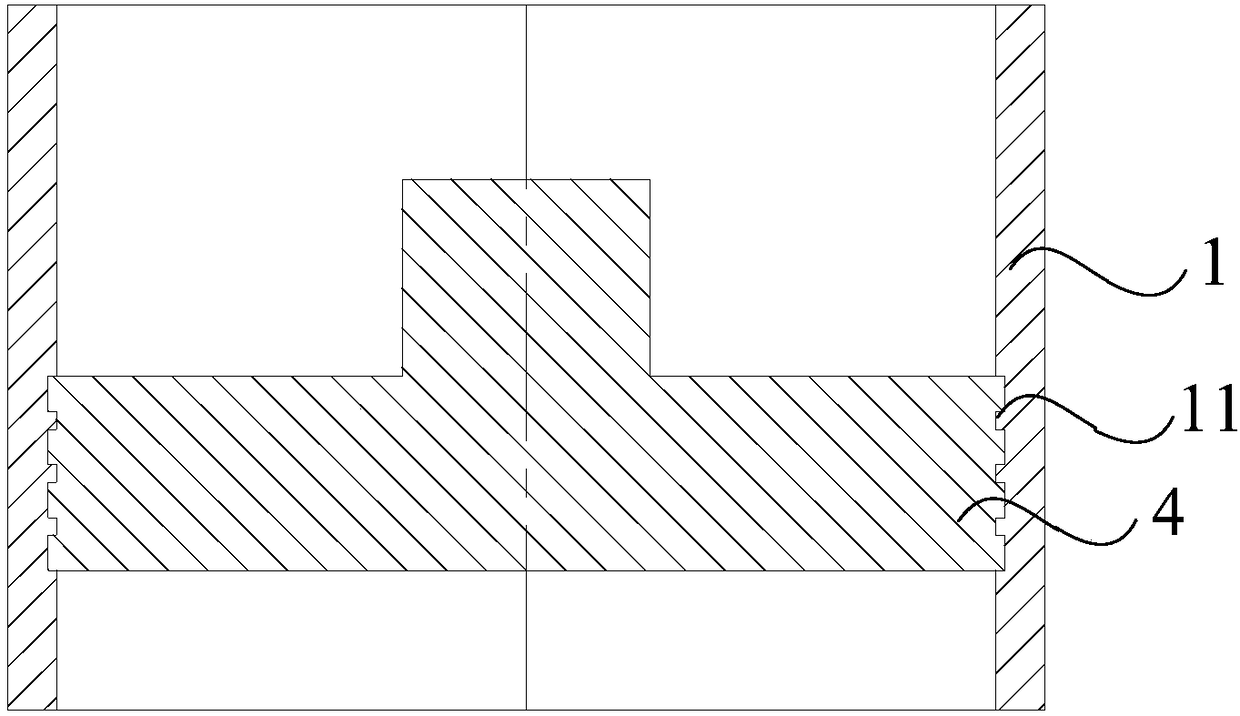

A compressor and a manufacturing method of an upper cylinder head of the compressor

PendingCN109113969AManufacturing Method AdvantagesHigh strengthPositive displacement pump componentsPositive-displacement liquid enginesCylinder headEngineering

The invention provides a compressor and a manufacturing method of an upper cylinder head of the compressor. The compressor includes a shell with the inner surface of the shell being provided with at least one groove surrounding the inner circumference of the shell, a motor assembly, a compression assembly which is placed in the shell and includes an upper cylinder head, a cylinder and a lower cylinder head, and a crankshaft, wherein the cylinder is arranged between the upper cylinder head and the lower cylinder head, the outer surface of the upper cylinder head is provided with at least one protrusion surrounding the outer circumference of the upper cylinder head, and the protrusions correspond to the grooves and are embedded in the corresponding grooves. The invention provides a technicalscheme for enhancing the connection strength between the upper cylinder head and the shell. The inside of the shell is provided with the grooves. When molten metal is poured into an upper cylinder head mold inside the shell, the protrusions matching the grooves are formed. The physical connection at combination parts between the shell and the upper cylinder head is increased through the protrusions and the grooves so as to enhance the strength of connection and fixing. Therefore, the shell and the upper cylinder head can be prevented from being disconnected due to force, and the product yieldis increased.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

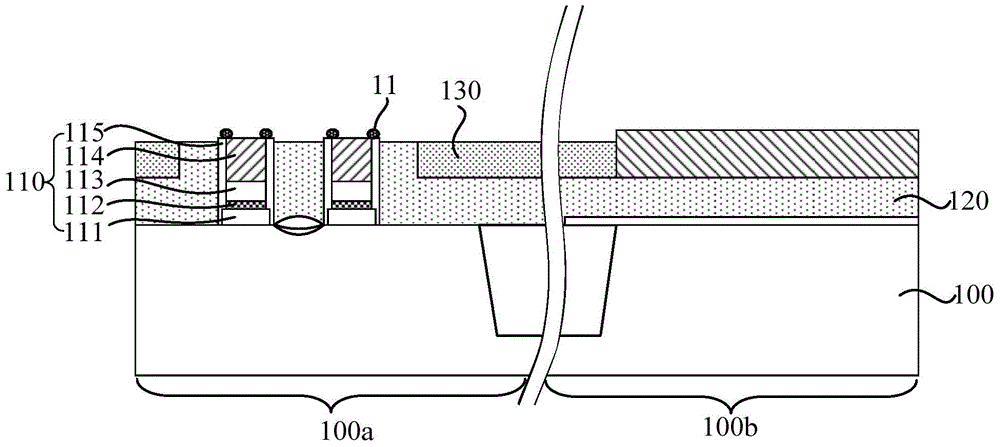

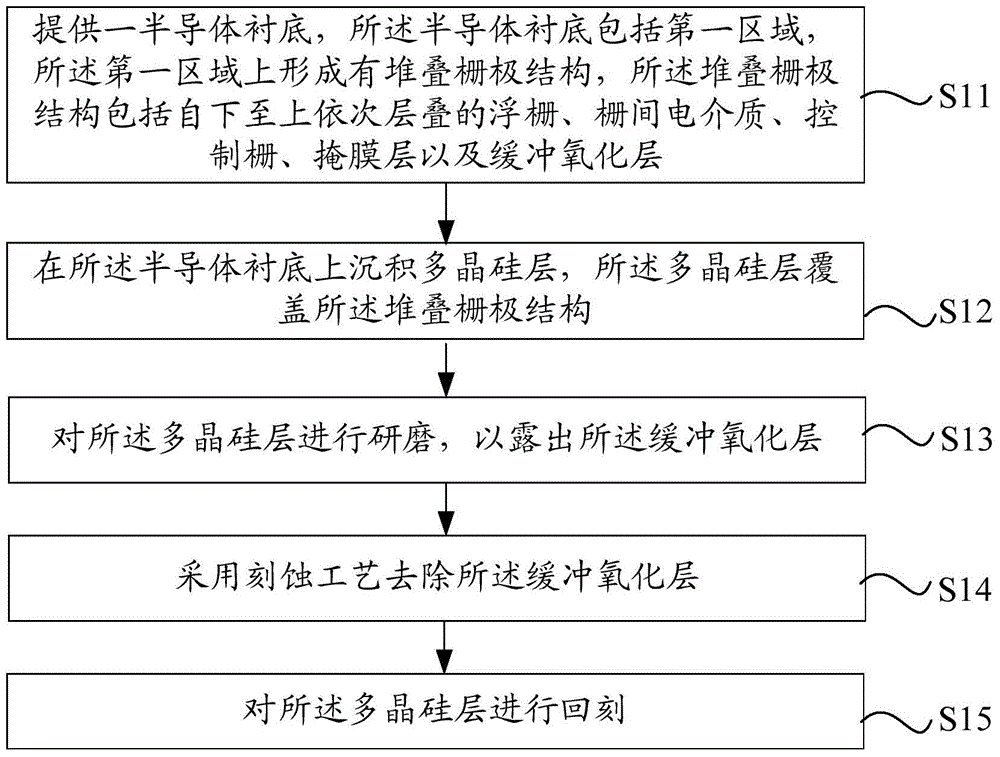

Manufacturing method of semiconductor device

ActiveCN105826178AManufacturing Method AdvantagesAvoid stickingSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricElectrical conductor

The invention discloses a manufacturing method of a semiconductor device. The manufacturing method comprises the steps of providing a semiconductor substrate, wherein the semiconductor substrate comprises a first region, the first region is provided with a stacked gate structure, the stacked gate structure comprises a floating gate, an inter-gate dielectric, a control gate, a mask layer and a buffer oxidation layer which are stacked in sequence form the bottom up, depositing a polycrystalline silicon layer on the semiconductor substrate, wherein the polycrystalline silicon layer covers the stacked gate structure, carrying out grinding on the polycrystalline silicon layer so as to expose the buffer oxidation layer, removing the buffer oxidation layer by adopting an etching process, and carrying out back-etching on the polycrystalline silicon layer. Grinding residues or polycrystalline silicon remains can be prevented from adhering to the control gate by adopting the manufacturing method disclosed by the invention.

Owner:SEMICON MFG INT (SHANGHAI) CORP

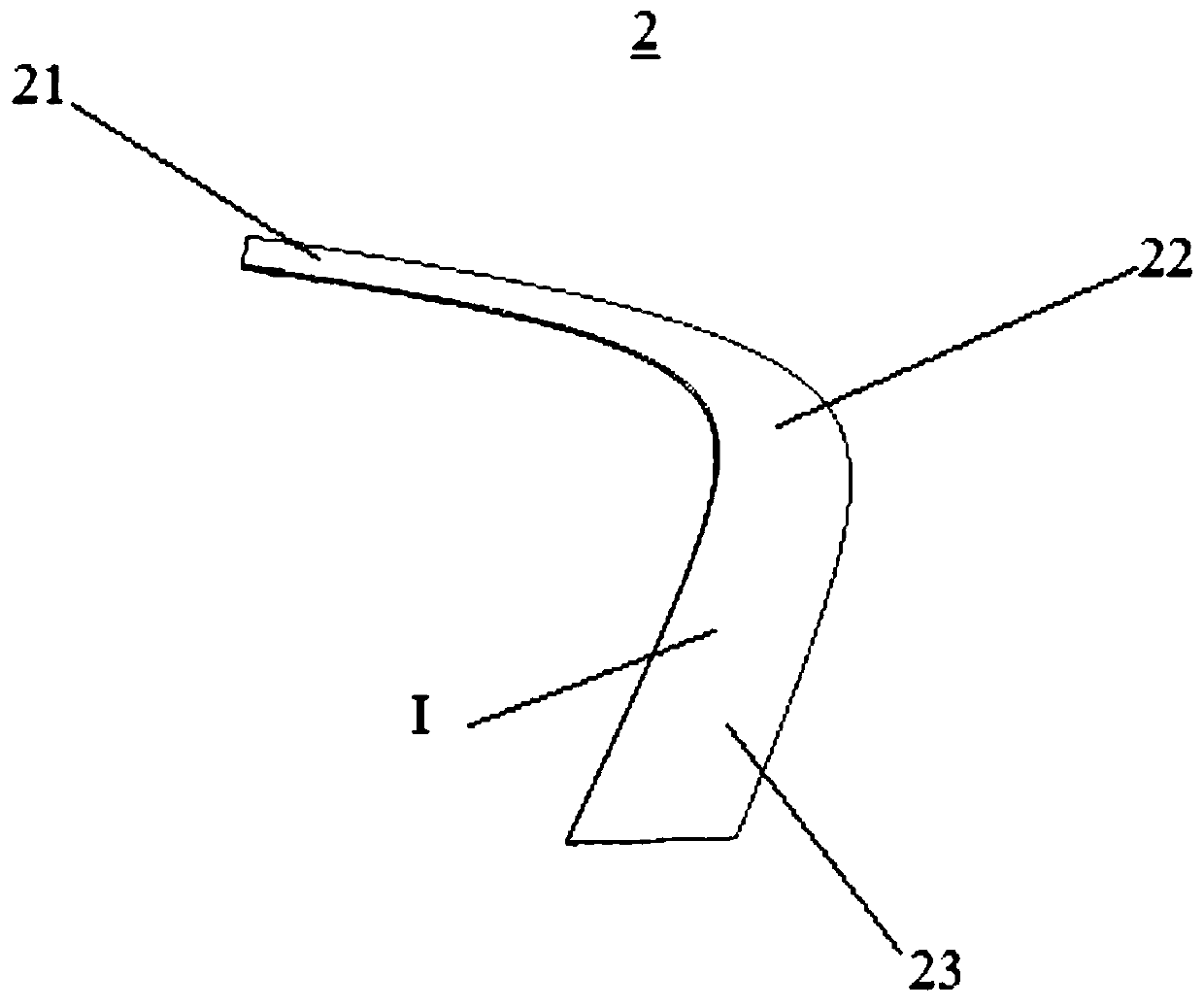

Vehicle door frame panel decorating strip, vehicle door frame panel decorating strip assembly and manufacturing method of vehicle door frame panel decorating strip

PendingCN110271498ASimple structureEasy to manufactureSuperstructure subunitsVehicle sealing arrangementsEngineeringJamb

The invention discloses a vehicle door frame panel decorating strip. The vehicle door frame panel decorating strip at least comprises a first part, a second part and a middle connecting part, and the first part and the second part are mutually and detachably connected through the middle connecting part, wherein the first part is a straight decorating strip which is straight, the second part is a bent decorating strip, the second part at least comprises a first straight part, a second straight part different from the first straight part in direction, and a bent part arranged between the first straight part and the second straight part. In addition, the invention further discloses a vehicle door frame panel decorating strip assembly, which comprises the vehicle door frame panel decorating strip and a vehicle door frame sealing strip connected with the vehicle door frame panel decorating strip. In addition, the invention further discloses a manufacturing method of the vehicle door frame panel decorating strip. The vehicle door frame panel decorating strip is simple in manufacturing process, easy to transport and low in manufacturing and transporting cost.

Owner:QOROS

Semiconductor device manufacturing method

ActiveCN107564849AAvoid corrosionPrevent undercuttingSemiconductor/solid-state device manufacturingEtching rateLow-k dielectric

The invention provides a semiconductor device manufacturing method, and the method comprises the steps: sequentially forming a low-k dielectric layer and a carbon-containing silicide layer on a semiconductor substrate; carrying out the plasma bombardment of the carbon-containing silicide layer, and enabling a part of carbon-containing silicide layer in the thickness direction to be converted intoa first barrier layer; forming a first groove in the first barrier layer and the carbon-containing silicide layer, carrying out the plasma bombardment of the surface of the first groove, and enablinga part of carbon-containing silicide layer in the width direction of the side wall of the first groove to be converted into a second barrier layer, wherein the second barrier layer completely covers the low-k dielectric layer. Because the etching rates of the etching liquid for the first barrier layer, the second barrier layer and the low-k dielectric layer are nearly equal in the forming processof a second groove, the method prevents chemical solution from corroding the surface of the low-k dielectric layer, thereby preventing the undercutting phenomenon, and improving the performances of asemiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

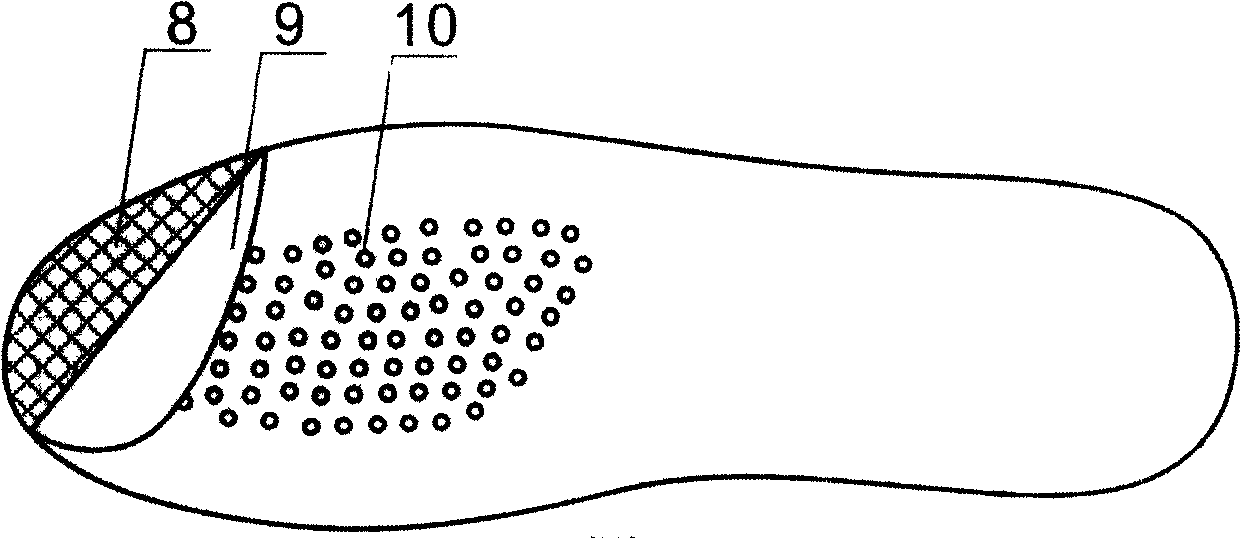

Method for manufacturing comfortable shoes

ActiveCN101243905BManufacturing Method AdvantagesAvoid shockSolesLastingEarthquake resistanceLife quality

The invention relates to a comfortable shoe and the manufacture method. The method comprises the following steps: selecting the shapes and sizes for comforting the feet of people in different area; determining the sole structure with performances of earthquake resistance and shock absorption; selecting the light and soft sole material with good performances of skid resistance, hard fold and wear resistance; distributing the feet pressure evenly on the inner mat made by principle of body physiology tutorial engineering; unifying the comfortable shoe last; ensuring the comfortable temperature and humidity in the intracavity of the shoe by special process treatment and craft processing. The invention also determines the class standard of comfort and the production trace routine of the comfortable shoe, so can ensure good air permeability of the whole footwear upper, the performances of moisture absorption and softness of the inner mat and the performances of earthquake resistance and shock absorption and the breath of the outer sole. The invention adopts new technique to make shoe last, so has the advantages of rapid speed and high precision. The invention also has the advantages of increasing the develop efficiency of the comfortable shoe greatly, ensuring the production quality, meeting the market demand rapid and improving the life quality of people.

Owner:KANGNAI GROUP

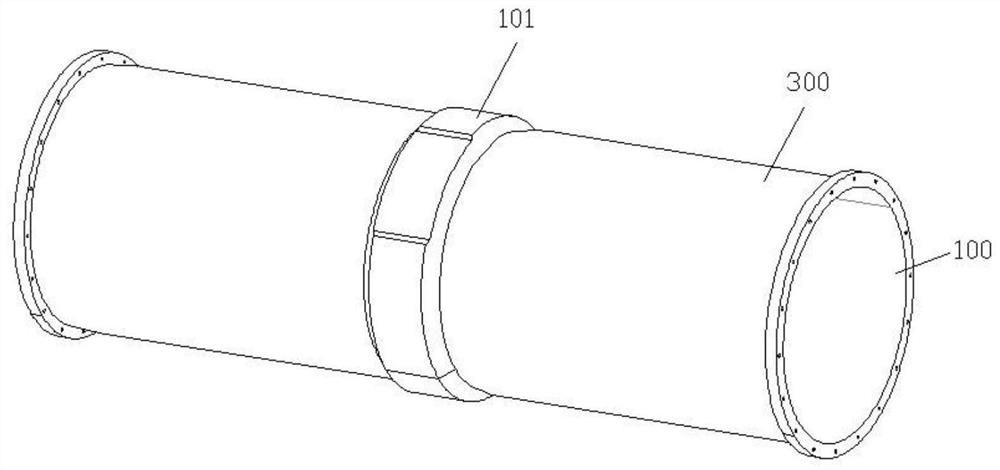

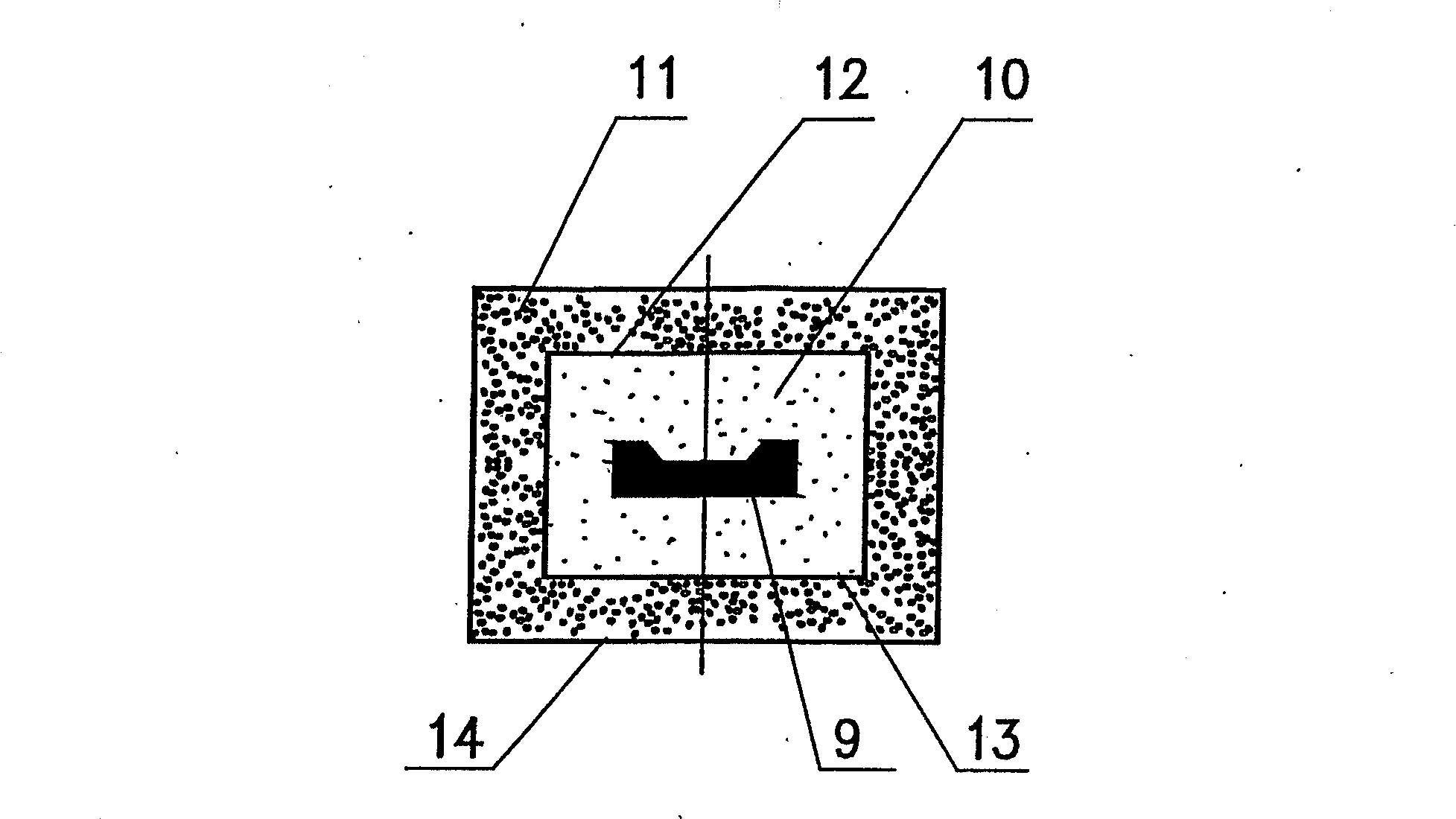

Lightweight thermal insulation device for composite material cylinder and manufacturing method thereof

Owner:TIANJIN ISTAR ADVANCED MATERIAL TECH CO LTD

A kind of composite steel plate for plastic mold and its manufacturing method

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

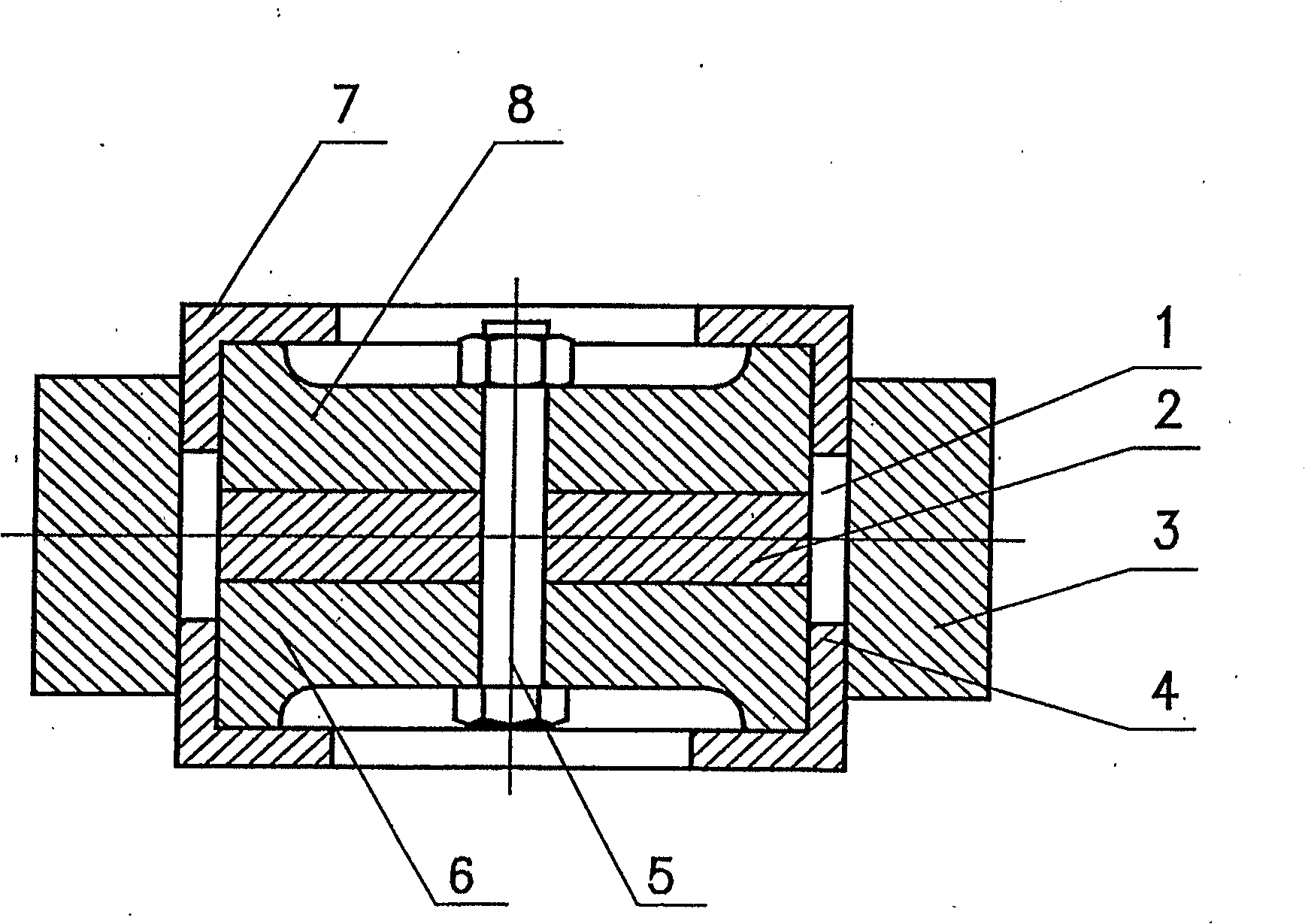

Manufacturing method of lightning-protection cable joint

InactiveCN109616847AManufacturing Method AdvantagesReasonable structural designContact member assembly/disassemblyDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectricityVoltage

The invention relates to a manufacturing method of a lightning-protection cable joint. The manufacturing method comprises the steps of carrying out connecting of a lightning-protection cable branch, processing of the branch connecting position, and overall packaging of the connecting joint. The manufacturing method of the lightning-protection cable joint provided by the invention is reasonable inprocess design, convenient to operate and reliable; and the manufactured lightning-protection cable joint is high in pressure-resistant grade, high in lightning protection effect, stable in connectingsealing performance, capable of preventing from electricity leakage and creepage, high in surface voltage resistance, and capable of effectively improving the voltage resistance level and the breakdown condition of a lightning protection system.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

Manufacturing method of semiconductor device

ActiveCN107564849BManufacturing Method AdvantagesAvoid corrosionSemiconductor/solid-state device manufacturingChemical solutionDevice material

The invention provides a semiconductor device manufacturing method, and the method comprises the steps: sequentially forming a low-k dielectric layer and a carbon-containing silicide layer on a semiconductor substrate; carrying out the plasma bombardment of the carbon-containing silicide layer, and enabling a part of carbon-containing silicide layer in the thickness direction to be converted intoa first barrier layer; forming a first groove in the first barrier layer and the carbon-containing silicide layer, carrying out the plasma bombardment of the surface of the first groove, and enablinga part of carbon-containing silicide layer in the width direction of the side wall of the first groove to be converted into a second barrier layer, wherein the second barrier layer completely covers the low-k dielectric layer. Because the etching rates of the etching liquid for the first barrier layer, the second barrier layer and the low-k dielectric layer are nearly equal in the forming processof a second groove, the method prevents chemical solution from corroding the surface of the low-k dielectric layer, thereby preventing the undercutting phenomenon, and improving the performances of asemiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for fabricating a CMOS image sensor

InactiveCN100590849CManufacturing Method AdvantagesSolid-state devicesSemiconductor/solid-state device manufacturingCMOSIsolation layer

A method for fabricating a CMOS image sensor may include forming an isolation layer defining an active area on a semiconductor substrate, forming first and second gate electrodes in the transistor area of the semiconductor substrate, forming a photodiode area in the semiconductor substrate at a first side of the first gate electrode, forming an oxide layer over the photodiode area, the oxide layerhaving a thickness greater than that of the dielectric layer, forming a source / drain extension area in the semiconductor substrate at a second side of the second gate electrode and between the firstand second gate electrodes, forming source / drain regions in the transistor area of the semiconductor substrate by ion implantation through the dielectric layer, and forming a complementary ion implantation region in the photodiode area through the oxide layer.

Owner:DONGBU HITEK CO LTD

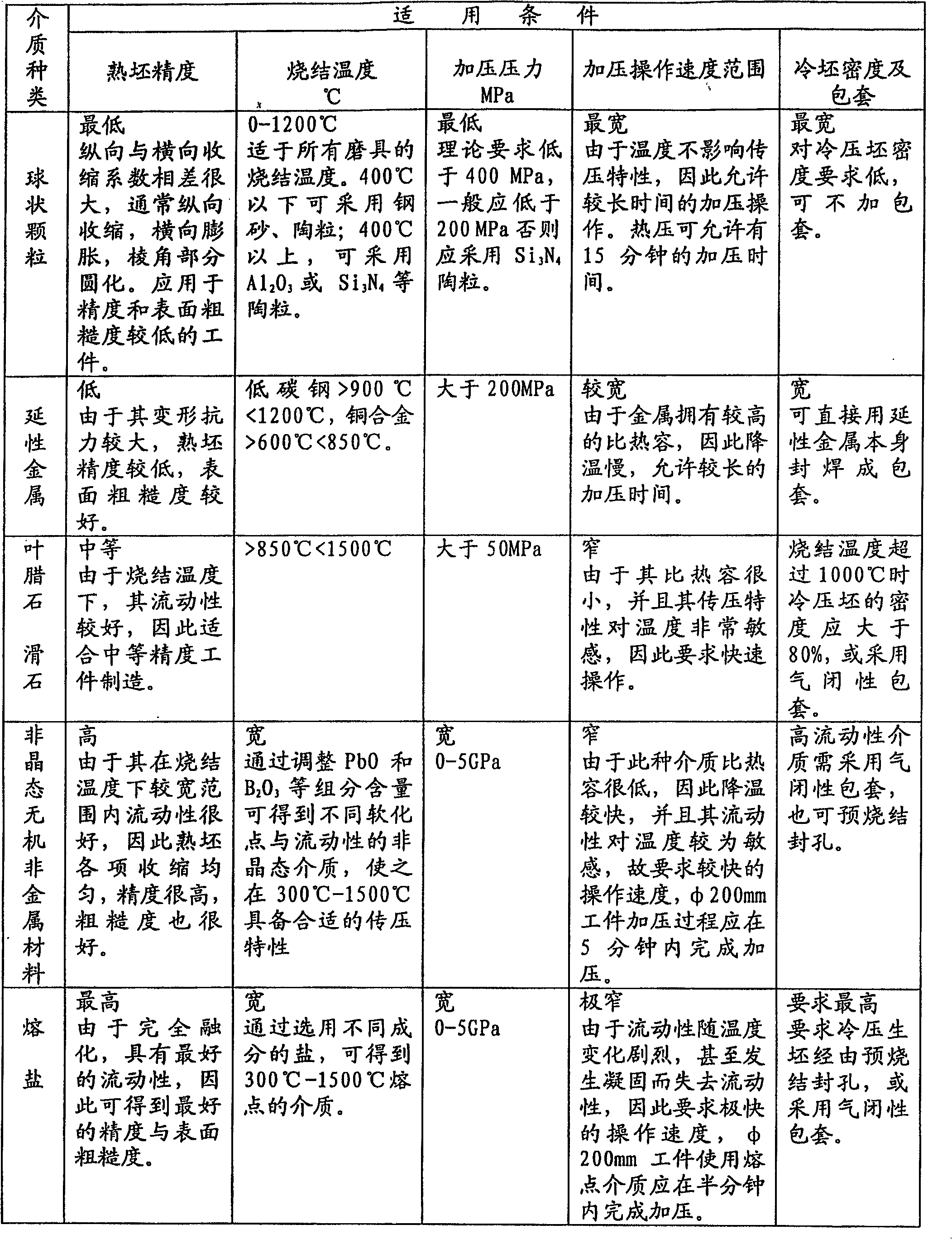

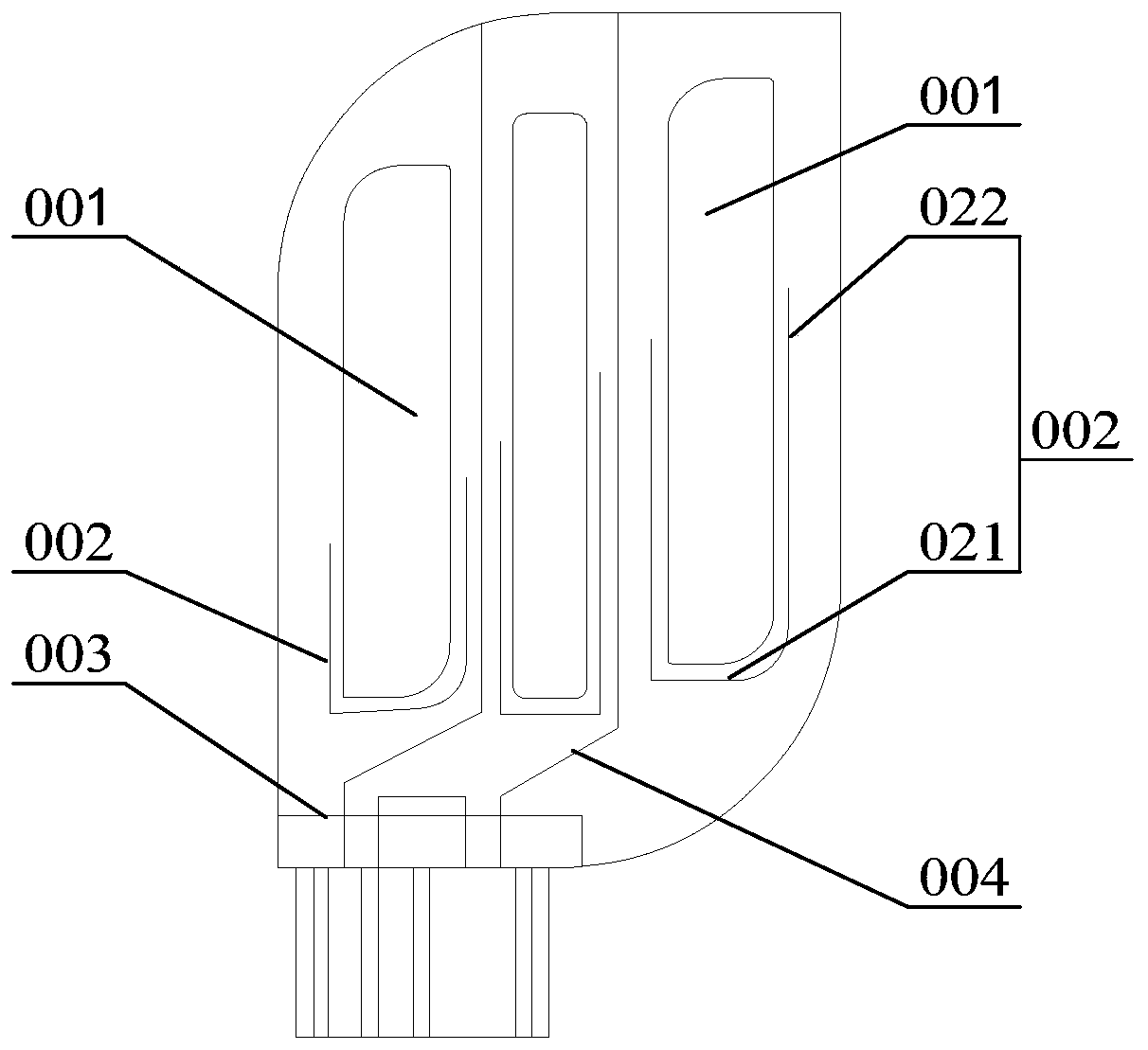

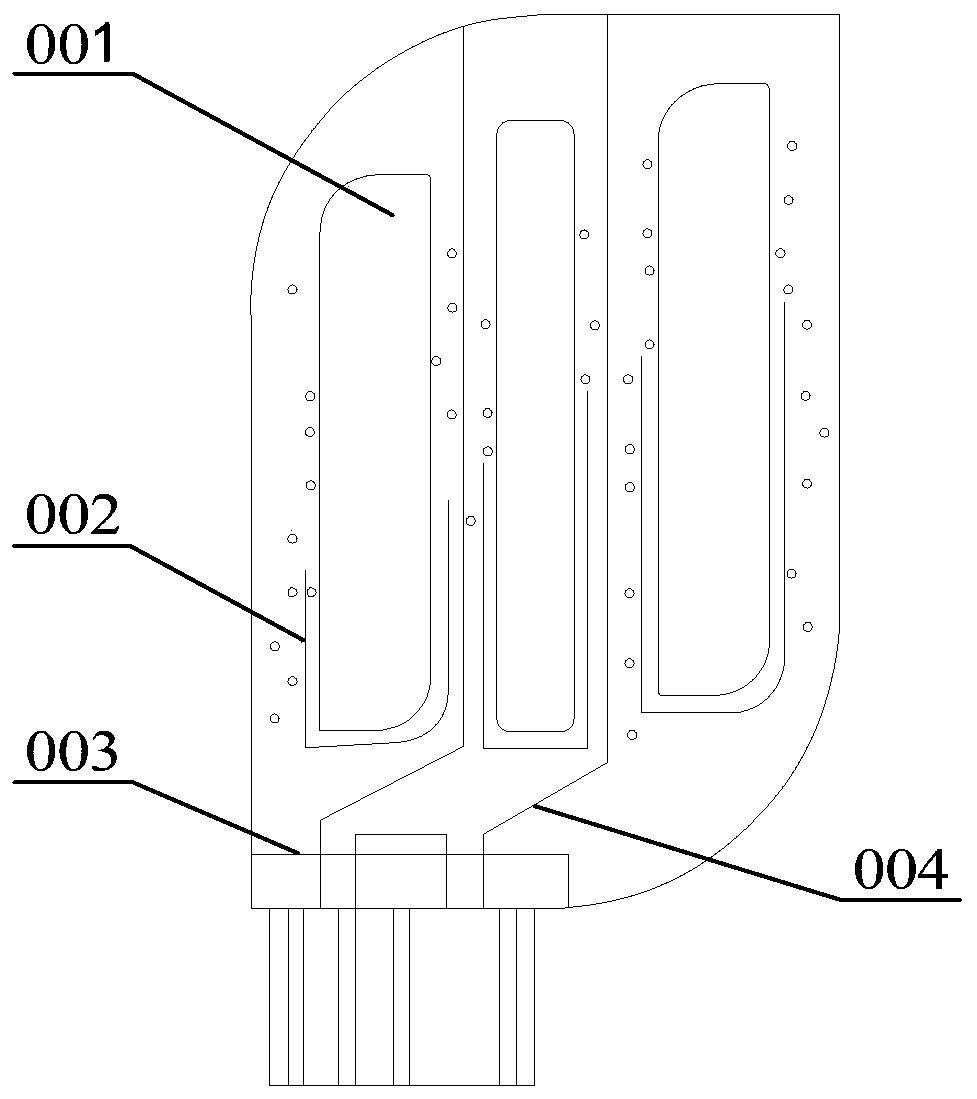

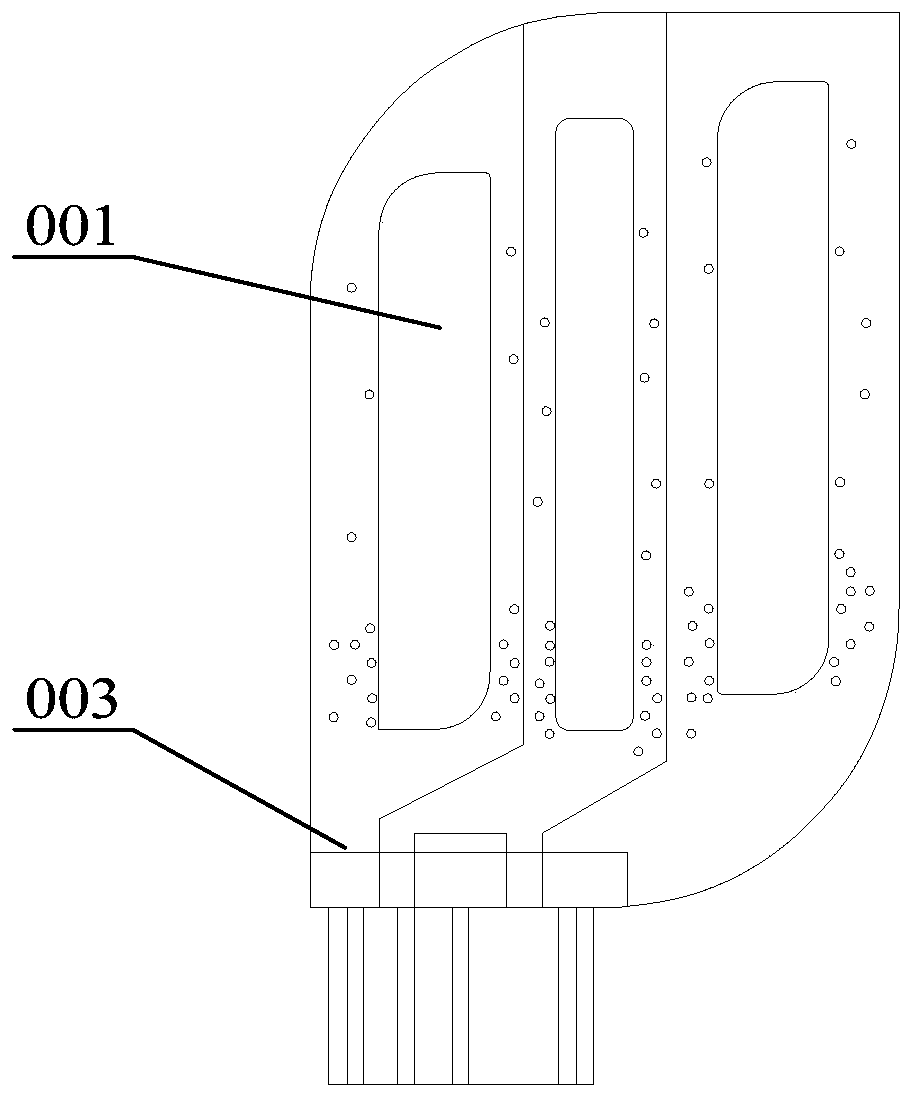

Manufacture method of super-hard grinding tool containing metallic or ceramic binder

ActiveCN100534723CManufacturing Method AdvantagesReduce occupancyGrinding devicesEnergy sourceMaterials preparation

The invention relates to a manufacture method of super-hard grinding tool containing metallic or ceramic binder, comprising following steps: material preparation, preparation of grinding tool green bodies, formation of the combination of the grinding tool green bodies and medium and its heating and pressing, machining of grinding tool green bodies, namely: firstly preparing for the working layer powder material, then chill-pressing to produce the green bodies or loosing to producing the green bodies, combining into a combination of green body-medium, rapidly heating and pressing the combination, at last further processing the grinding tool green bodies. The manufacture method can ensure an uniform pressure to the blank from the all directions and saves the dies and saves the money and energy source.

Owner:QINHUANGDAO DAOTIAN HIGH TECH

OLED screen device, vehicle lamp, and manufacturing method of shunt unit in OLED screen device

ActiveCN109037466BImprove uniformity of light emissionBackflow barrierSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringHole transport layer

The invention discloses an OLED screen device, a car lamp, and a method for manufacturing a shunt unit in the OLED screen device, relates to the technical field of car lamps, and aims to solve the technical problem that the existing OLED screen device is prone to uneven light emission. The OLED screen device of the present invention includes: a light-emitting area, the light-emitting area is provided with a shunt unit, and the shunt unit is used to prevent holes from meeting electrons in the area close to the electrode and excite organic materials to emit light. The OLED screen device of the present invention can make the OLED screen body have the same amount of holes as possible passing through the hole transport layer and the electrons passing through the electron transport layer in the area nearer to the electrode and the area farther away from the electrode. The organic light-emitting layer meets and excites the organic material to emit light, so as to effectively improve the uniformity of light emission of the OLED panel device.

Owner:HASCO VISION TECHNOLOGY CO LTD

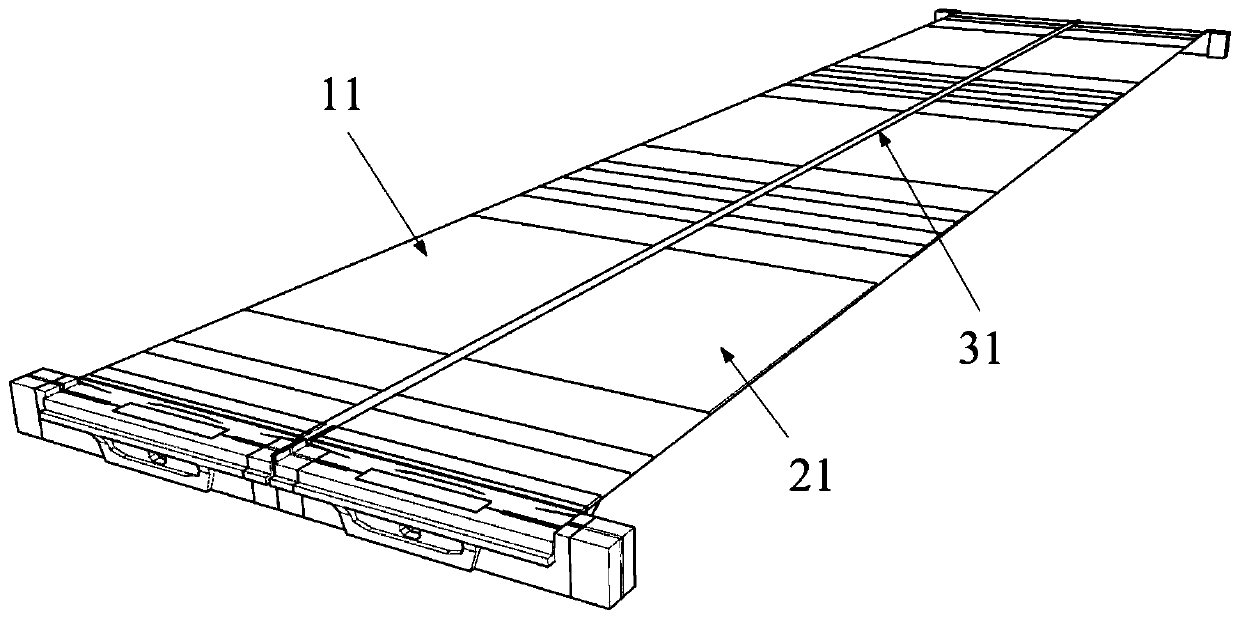

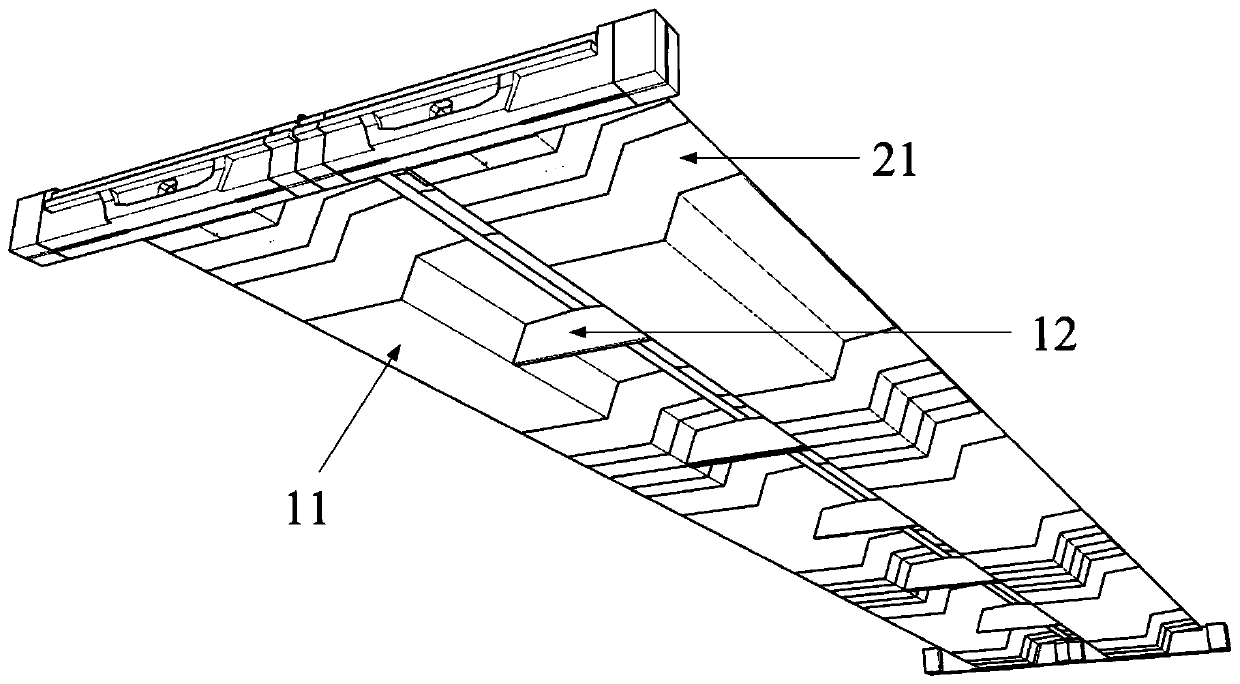

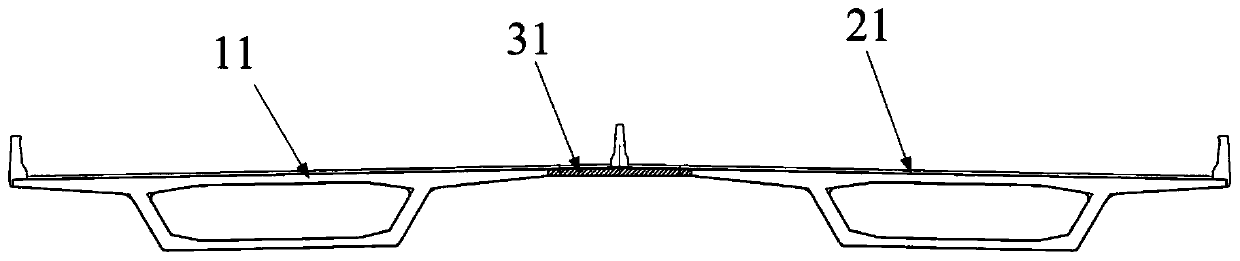

Combined box girder and manufacturing method thereof

PendingCN111236037ARoad widthMeet widening needsBridge structural detailsBridge erection/assemblyBox girderIndustrial engineering

The invention provides a combined box girder and a manufacturing method thereof, and relates to the technical field of bridge design and construction. The combined box girder comprises a first beam section and a second beam section, a first gap is formed between the first beam section and the second beam section; a first connecting piece and a second connecting piece are arranged in the first gap;the first connecting piece is connected with a flange plate of the first beam section, the second connecting piece is connected with a flange plate of the second beam section, the first connecting piece and the second connecting piece are fixed through a first binding piece, and concrete is poured into the first gap so that a first joint can be formed between the first beam section and the secondbeam section. The first beam section and the second beam section in the combined box beam do not need to be manufactured on site and can be transported to the site after being manufactured, so that the field operation amount is relatively small, the influence on the environment is reduced, and the quality control difficulty is reduced.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com