Composite steel plate for plastic mold and manufacturing method of composite steel plate

A technology of plastic mold and composite steel plate, applied in the field of composite steel plate and its manufacturing, can solve the problems affecting the uniformity of product structure and mechanical properties, increase of production cost, low production efficiency, etc., achieve excellent processability, improve quality, and blank thickness increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

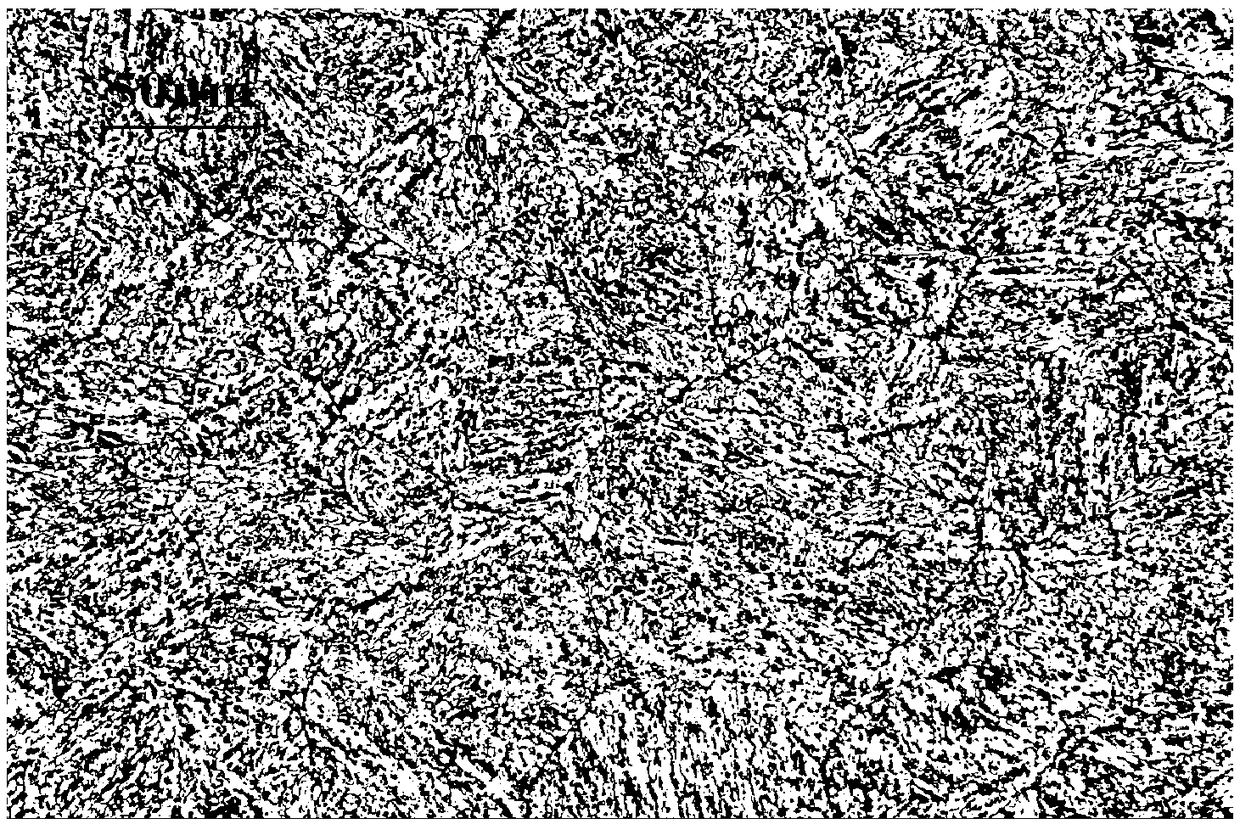

Image

Examples

Embodiment 1-10

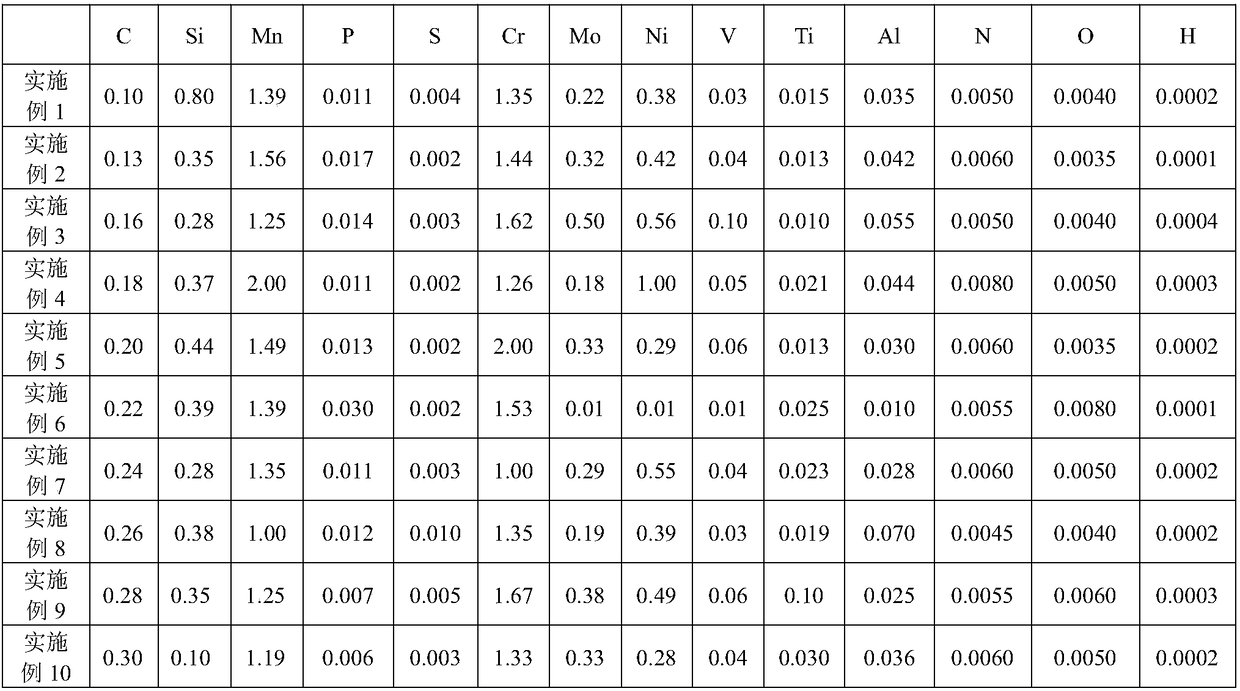

[0056] Table 1 lists the mass percentages of chemical elements in the composite steel plates for plastic molds of Examples 1-10.

[0057] Table 1. (wt%, the balance is Fe and other unavoidable impurities except P, S, N, O and H)

[0058]

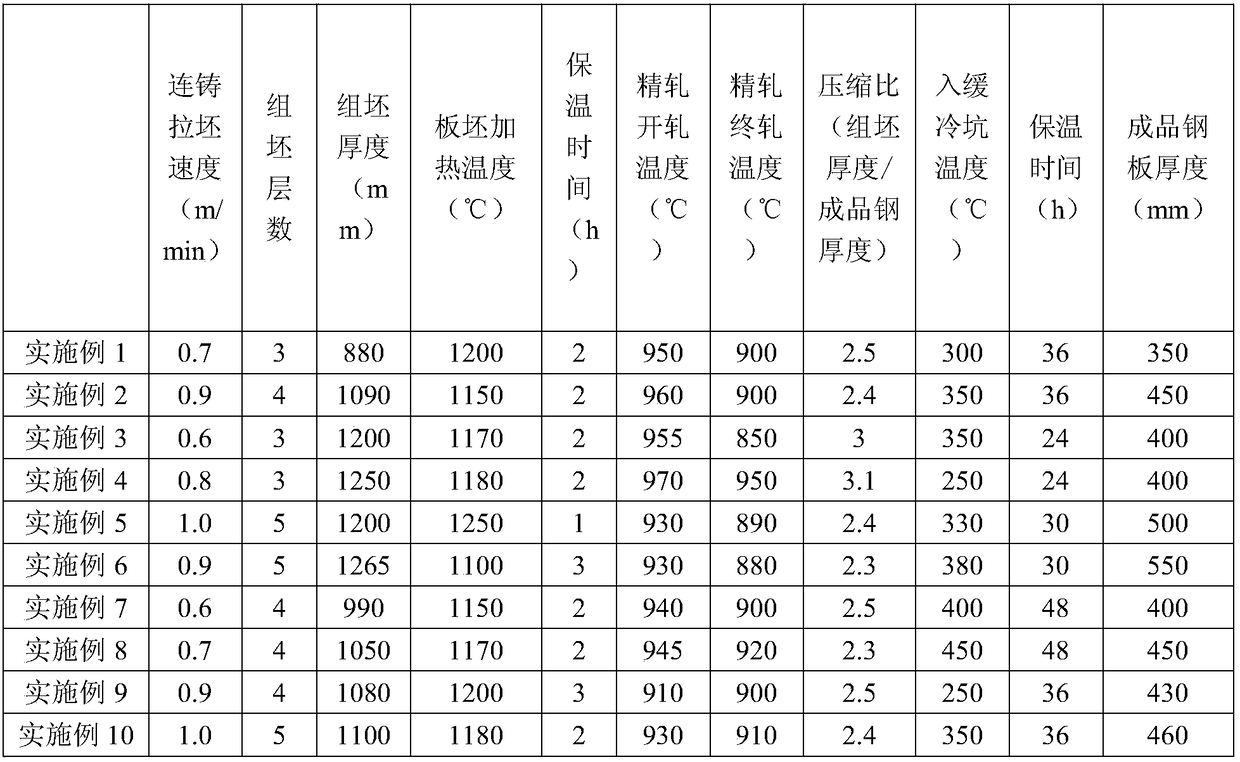

[0059] The manufacturing method of the composite steel plate for plastic mold described in the embodiment 1-10 adopts the following steps to make (concrete process parameters in each embodiment are referring to Table 2):

[0060] (1) Smelting and casting to obtain cast slabs, and controlling the casting speed of continuous casting to ≤1.0m / min.

[0061] (2) Pretreatment is carried out on the surface of the slab by mechanical method to remove the oxide layer on its surface;

[0062] (3) Assembling the above-mentioned cast slabs of two or more layers, welding and sealing around the bonding surfaces of each layer, and then vacuuming;

[0063] (4) Heating, wherein the heating temperature is 1000-1250° C., and the temperature is kept for 1-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com