Manufacturing method of colour vein artificial marble

A technology of artificial marble and manufacturing methods, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of heavy equipment, unsatisfactory effect, failure to achieve natural marble texture and texture, etc., and achieve simple equipment, colorful patterns, and methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

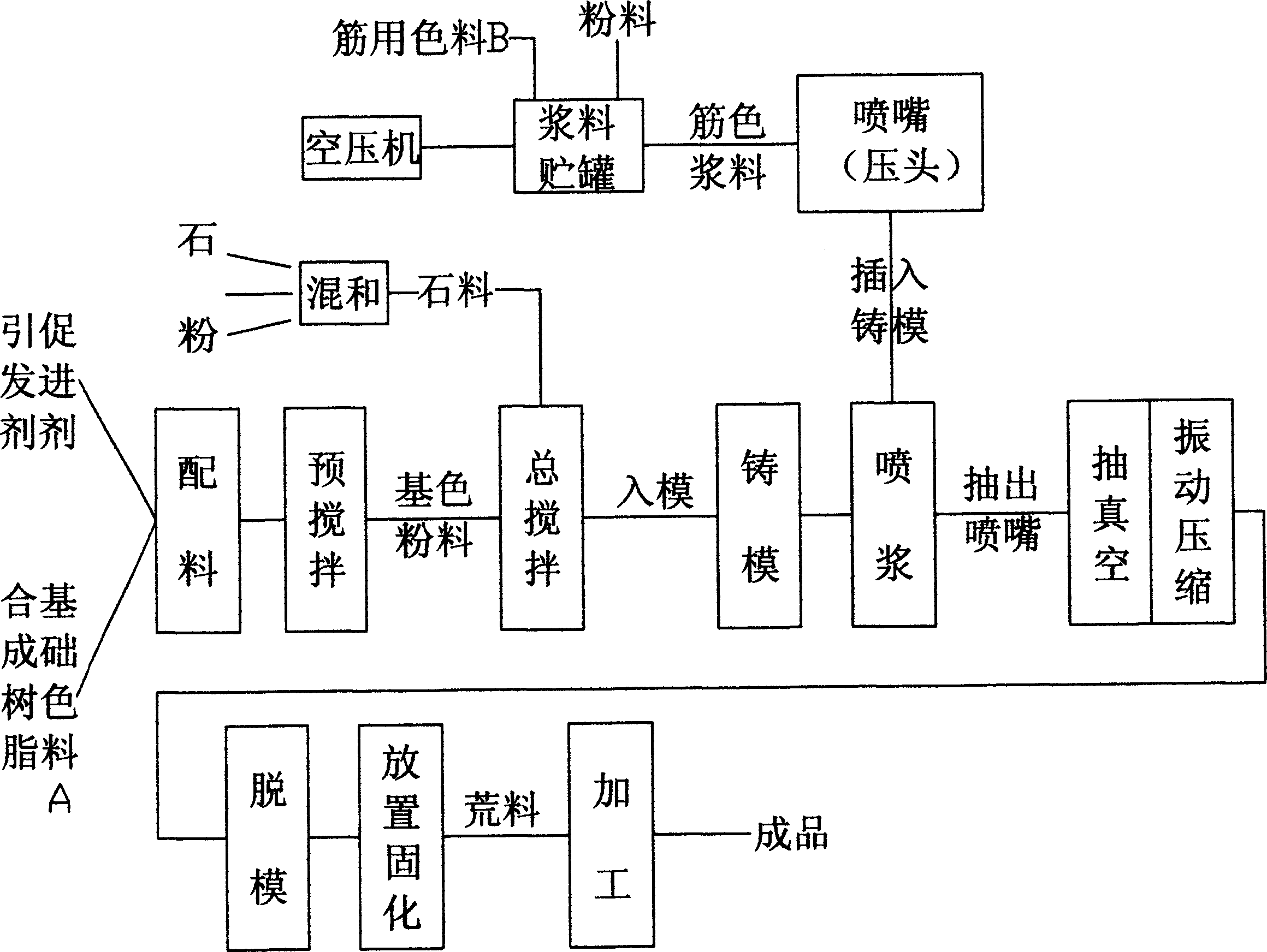

[0018] Mix 10 tons of 80-mesh stone powder, 1 ton of 100-mesh stone powder and 1 ton of 400-mesh stone powder or make 10 tons of stone materials, and send them to the main mixer;

[0019] In addition, 1 ton of unsaturated polyester resin, and initiator 1.2Kg, 600 grams of accelerator, and 10Kgs basic color material A (this color material is made up of iron red 1Kg, iron black 2Kgs and iron yellow 8Kgs), put into pre-stirring Stir in the mixer to get the base color powder, put it into the total mixer and fully stir and mix with the above-mentioned stone materials;

[0020] After stirring the above materials for about 10 minutes, put them into a 1.25×1.65×2.45m 3 The mold of 3 Li;

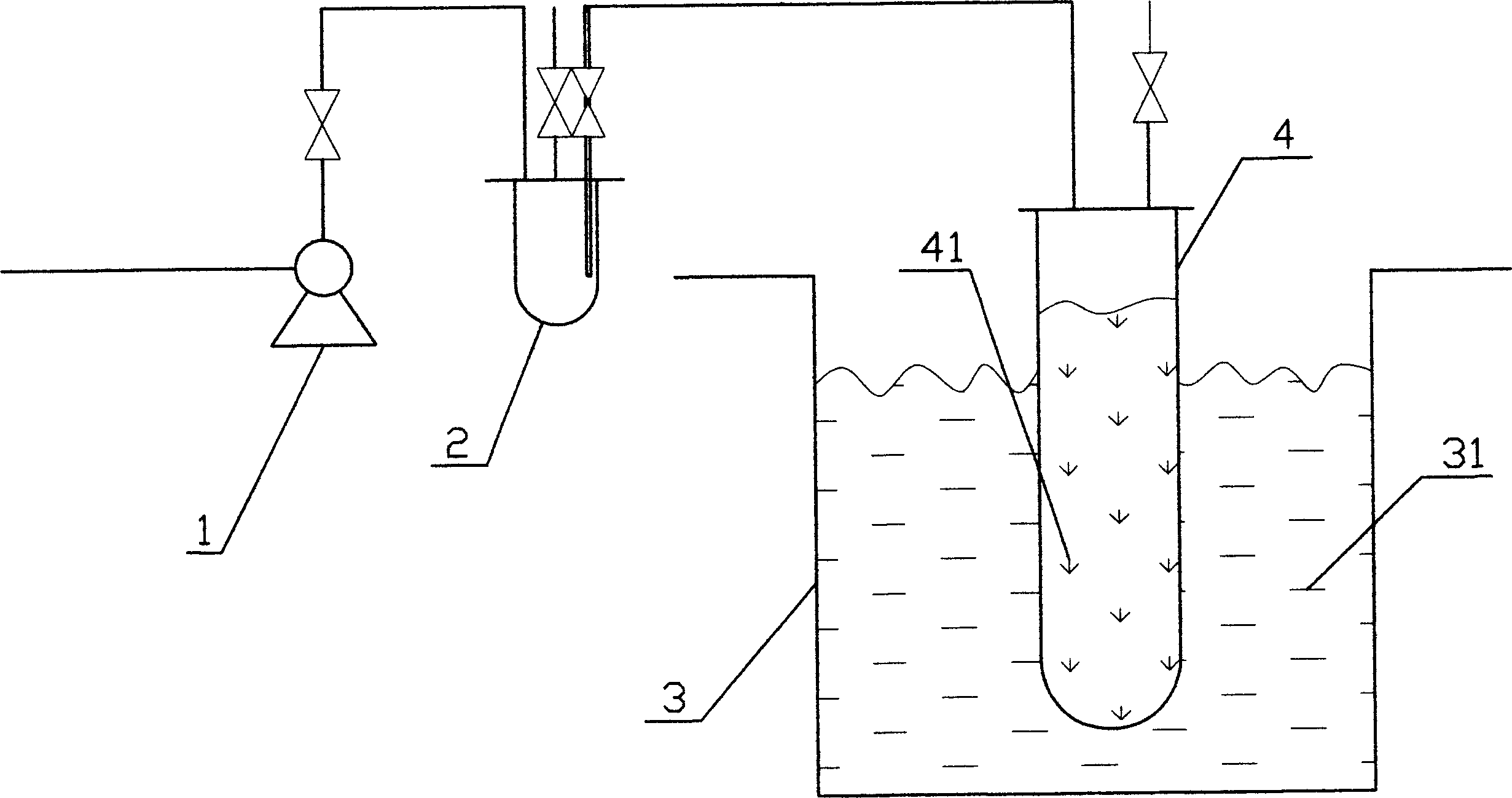

[0021] In addition, add 10Kgs base color powder to make a slurry, add 0.5Kgs titanium dioxide, and put it into the rib color paste storage tank 2 as the color material B for the ribs. The storage tank 2 is connected to the air compressor 1 on one side. The material outlet on the other side is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com