Patents

Literature

37results about How to "Colorful patterns" patented technology

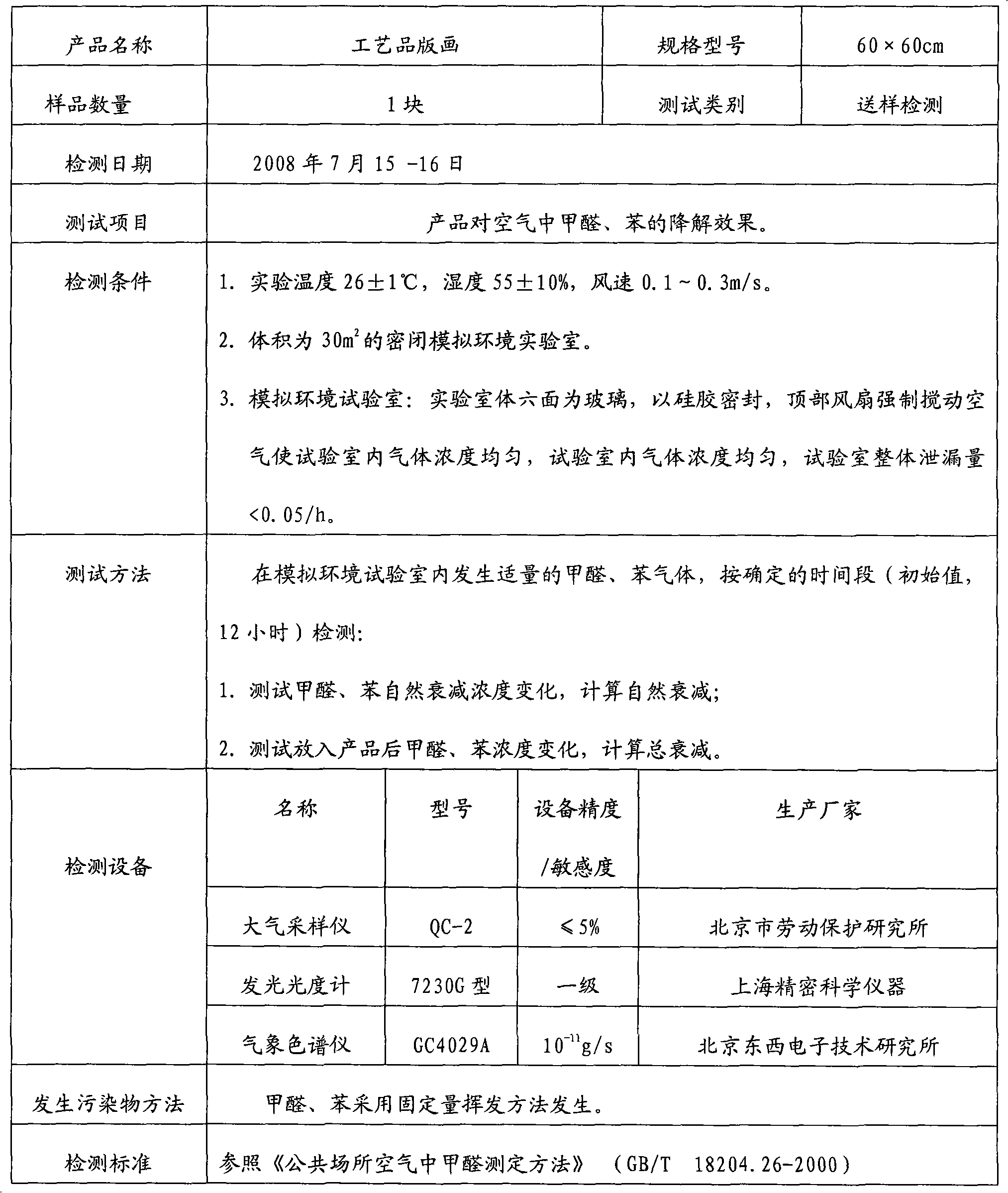

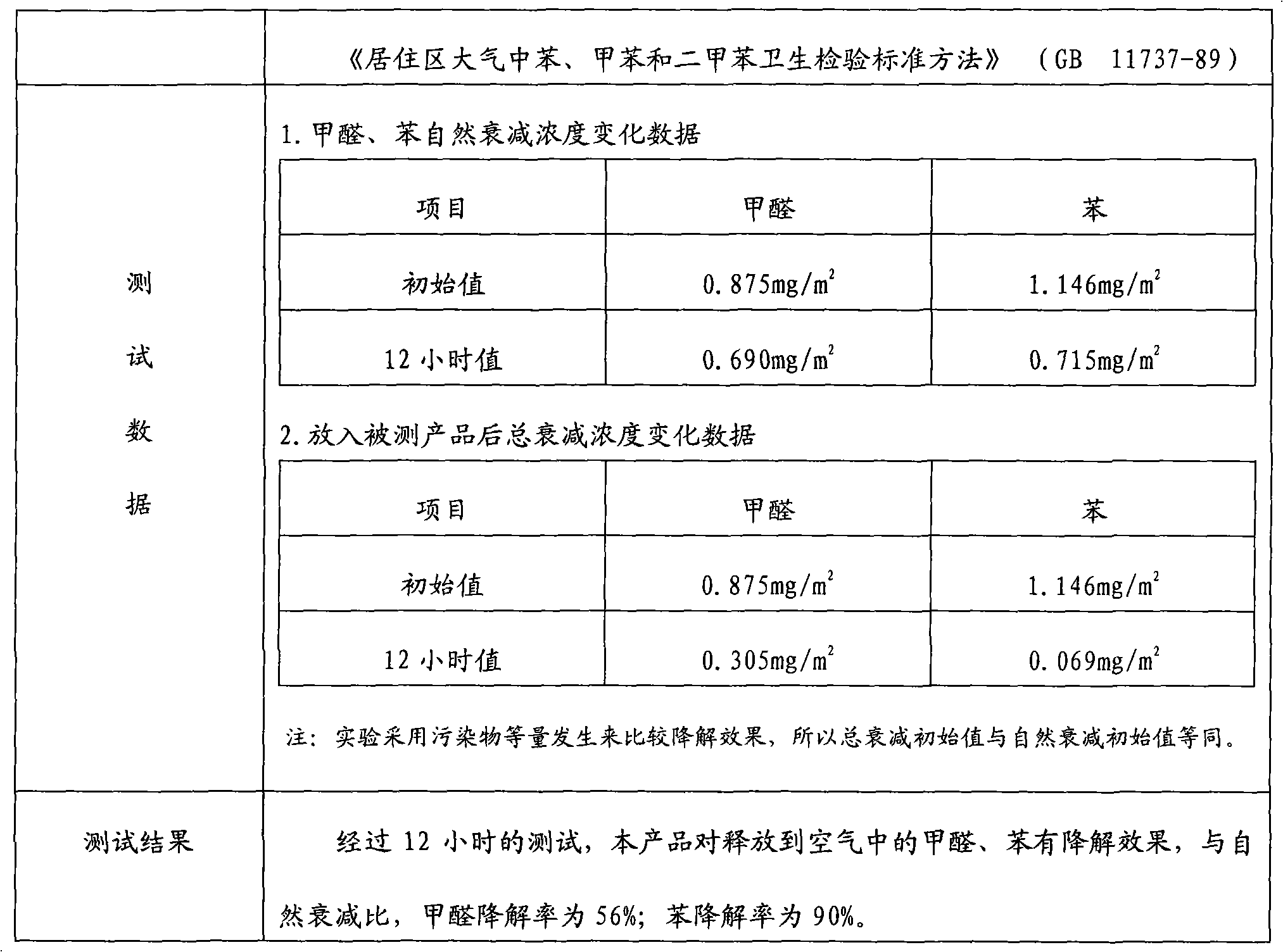

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment protection plastic printing ink and its prepn

The no-benzene green plastic printing ink consists of inorganic pigment or organic pigment, antistatic agent, dispersant, adhesion promoter, alcohol soluble synthetic PVB resin and alcohol solvent. The preparation process includes the following steps: dissolving the alcohol soluble synthetic PVB resin in alcohol solvent to form translucent resin solution; mixing the inorganic pigment or organic pigment with the resin solution to form color slurry semi-product; grinding the color slurry semi-product in a sand mill and adding the other components via stirring; filtering and packing to obtain no-benzene green plastic printing ink product. The no-benzene green plastic printing ink is boiling resistant and freezing resistant and may be used in packing milk, wine, seasoning, aquatic product, medicine, etc.

Owner:TENGXIA PRINT INK ZHUCHENG

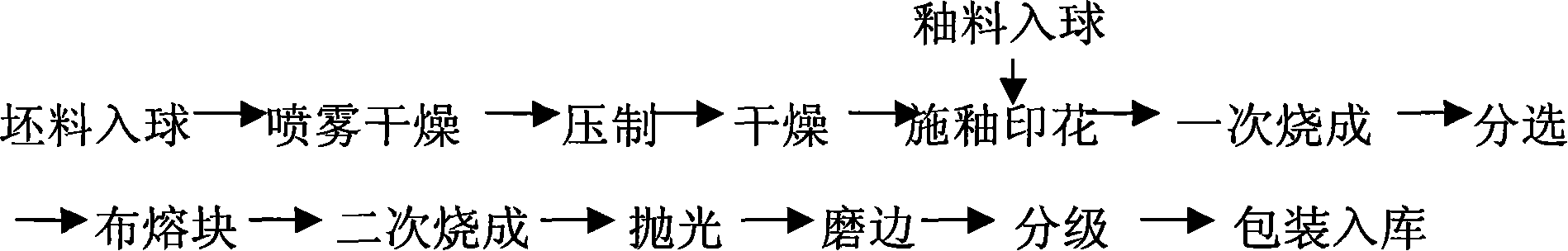

Preparation technology of enamel composite board

The invention relates to a preparation technique for the composite board of coloured glaze, belonging to the technical field of building ceramic tile preparation, which comprises the steps in sequence of sphere forming of blanks, spray drying, pressing, drying, glazing printing, first firing, separating, transparent frit distributing, second firing, polishing, edging, grading, packing and warehousing. The preparation technique is characterized in that: a) a screen or a drum is adopted for the glazing printing of a green body to form a plurality of patterns, then the first firing is conducted under the firing temperature of 1200 to 1255 DEG C to form a printing layer; b) the transparent frits are evenly distributed with the dry distributing method of funnel blanking and drum pressing, and the heights are 3 to 5 mm; c) the fixative is applied to fix the frits after distributing the transparent frits on the printing layer, and the amount of the fixative is 180 to 240 g / m<2> with the ratio of water to viscosity modifier being 99 : 1. Adopting the technical proposal, the preparation technique for the composite board of coloured glaze has the advantages of high surface finish of the ceramic tile, low water absorption, rich pattern colours and large product specification.

Owner:叶荣崧 +1

Method for manufacturing marbleizing decorating plates

ActiveCN101638028AOptionalReduce construction difficultyNatural patternsSpecial ornamental structuresMetallurgyFree cooling

The invention relates to a method for manufacturing marbleizing decorating plates, which comprises a step of plate processing, a step of pretreatment and a step of spray finishing, wherein the step ofspray finishing comprises the following steps: firstly, racking an aluminum veneer or an aluminum profile; secondly, performing dust blowing, and spraying a priming paint and a finishing paint on thesurface of the aluminum veneer or the aluminum profile; thirdly, naturally levelling the priming paint and the finishing paint on the surface of the aluminum veneer or the aluminum profile, and thenperforming scattering spray finishing and leveling at least two times; and finally, drying and solidifying the aluminum veneer or the aluminum profile, and naturally cooling the aluminum veneer or thealuminum profile. The marbleizing decorating plate manufactured by the method not only has the decoration advantages of marbles, but also avoids the defects and the limitations of the marbles. The marbleizing decorating plate has the advantages of abundant and subtle pattern colors, vivid marble imitating effect, greatly reduced unit area weight, and greatly improved security level. The marbleizing decorating plate has greatly reduced construction difficulties and correspondingly shortened construction period.

Owner:SHANGHAI HUAHUI CURTAIN WALL MFG

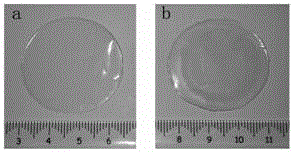

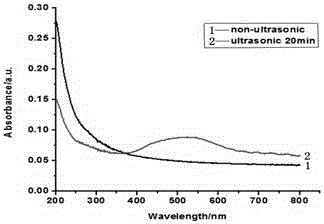

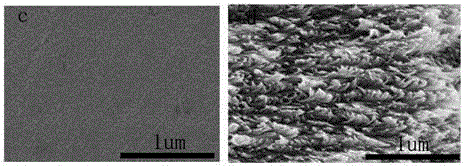

Preparation method of cellulose nanocrystal iridescent anti-counterfeiting mark

The invention relates to a preparation method of a cellulose nanocrystal iridescent anti-counterfeiting mark. The preparation method comprises the following processing steps: 1. preparing nanocrystal suspension with microcrystalline cellulose; 2. preparing an iridescent solid thin film; 3. preparing an iridescent anti-counterfeiting mark. The prepared iridescent solid thin film has a cholesteric liquid crystal phase structure and has selective reflectivity toward light waves. The prepared iridescent solid thin film can obtain colorful patterns under a polarizing microscope. The iridescent anti-counterfeiting mark prepared by utilizing the patterns has unduplicatedness and has application value in the package anti-counterfeiting field.

Owner:NANJING FORESTRY UNIV

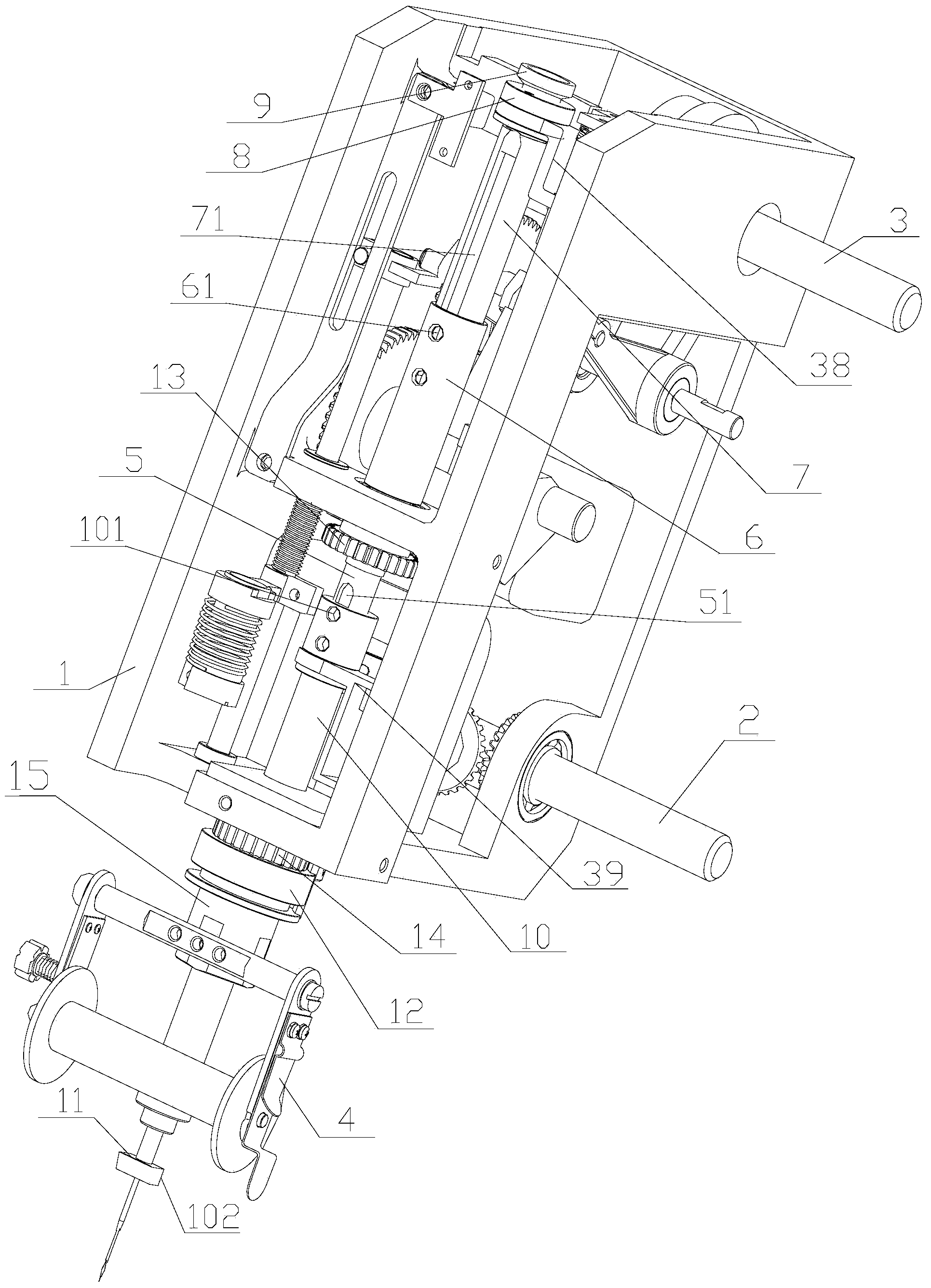

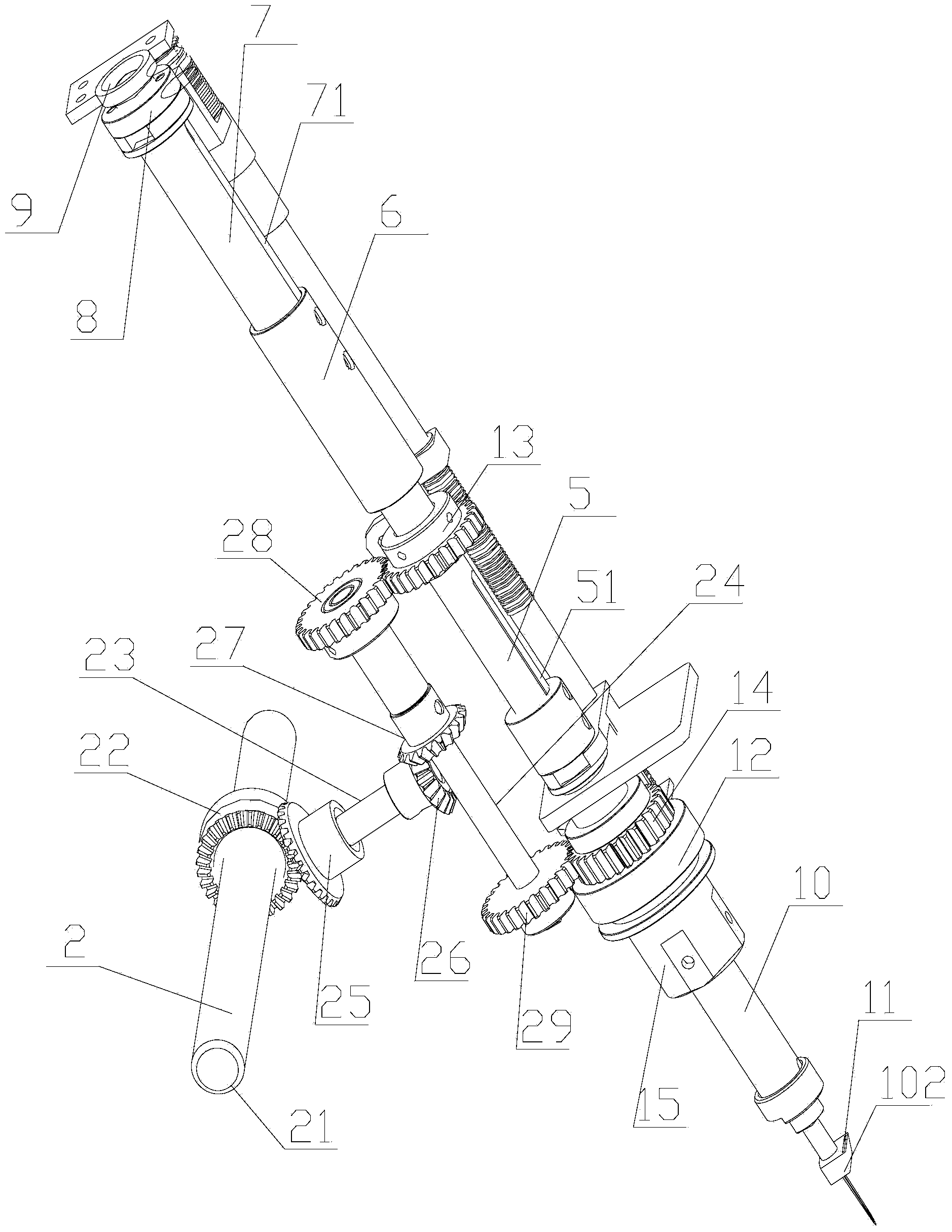

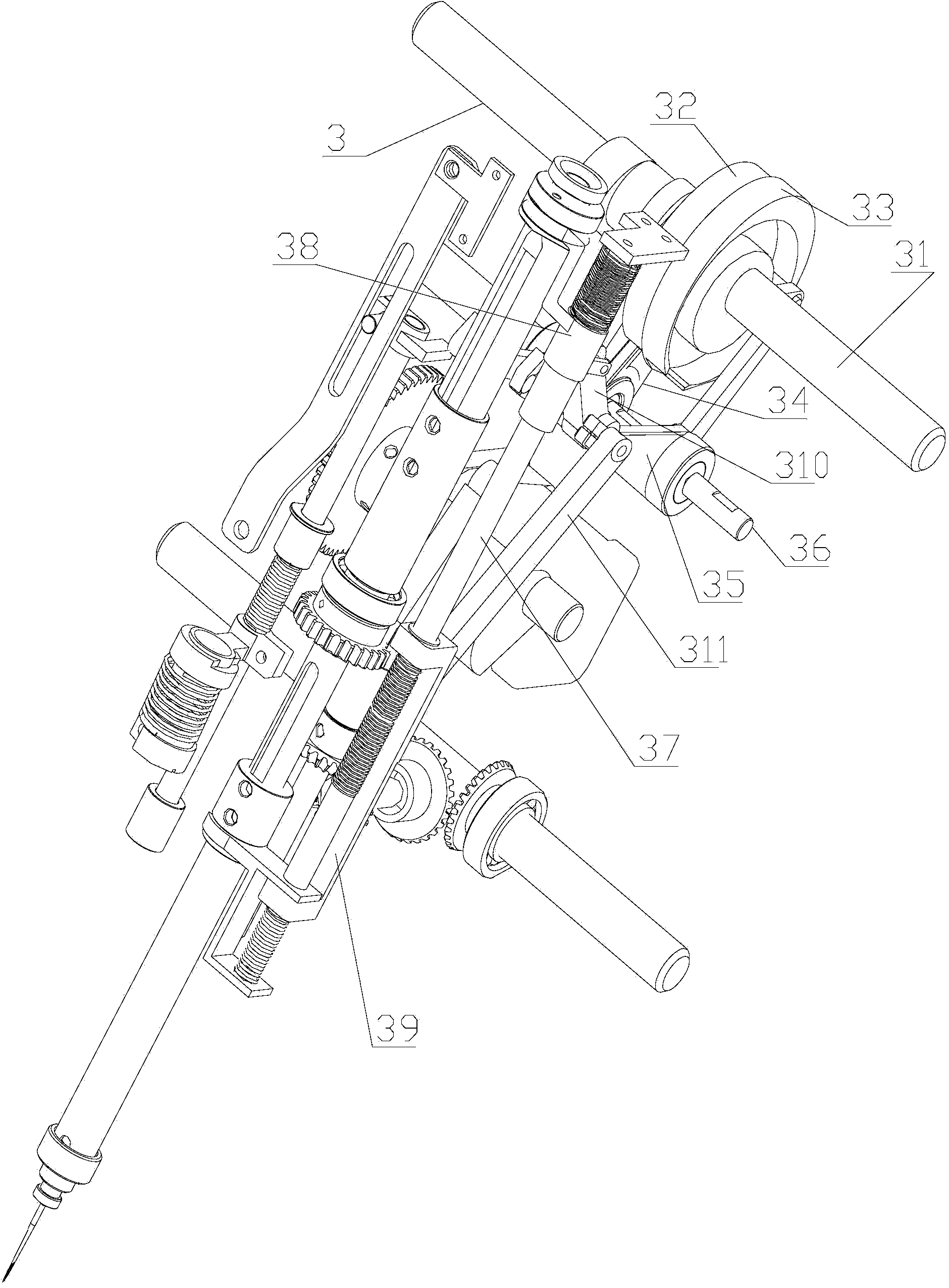

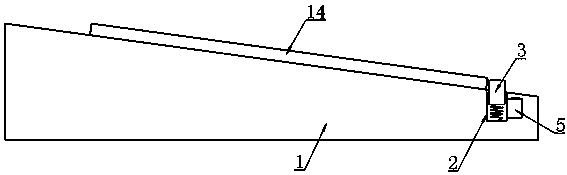

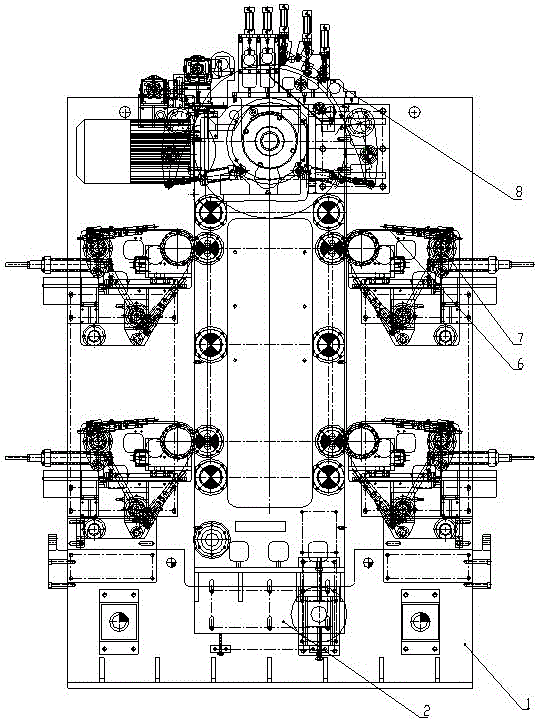

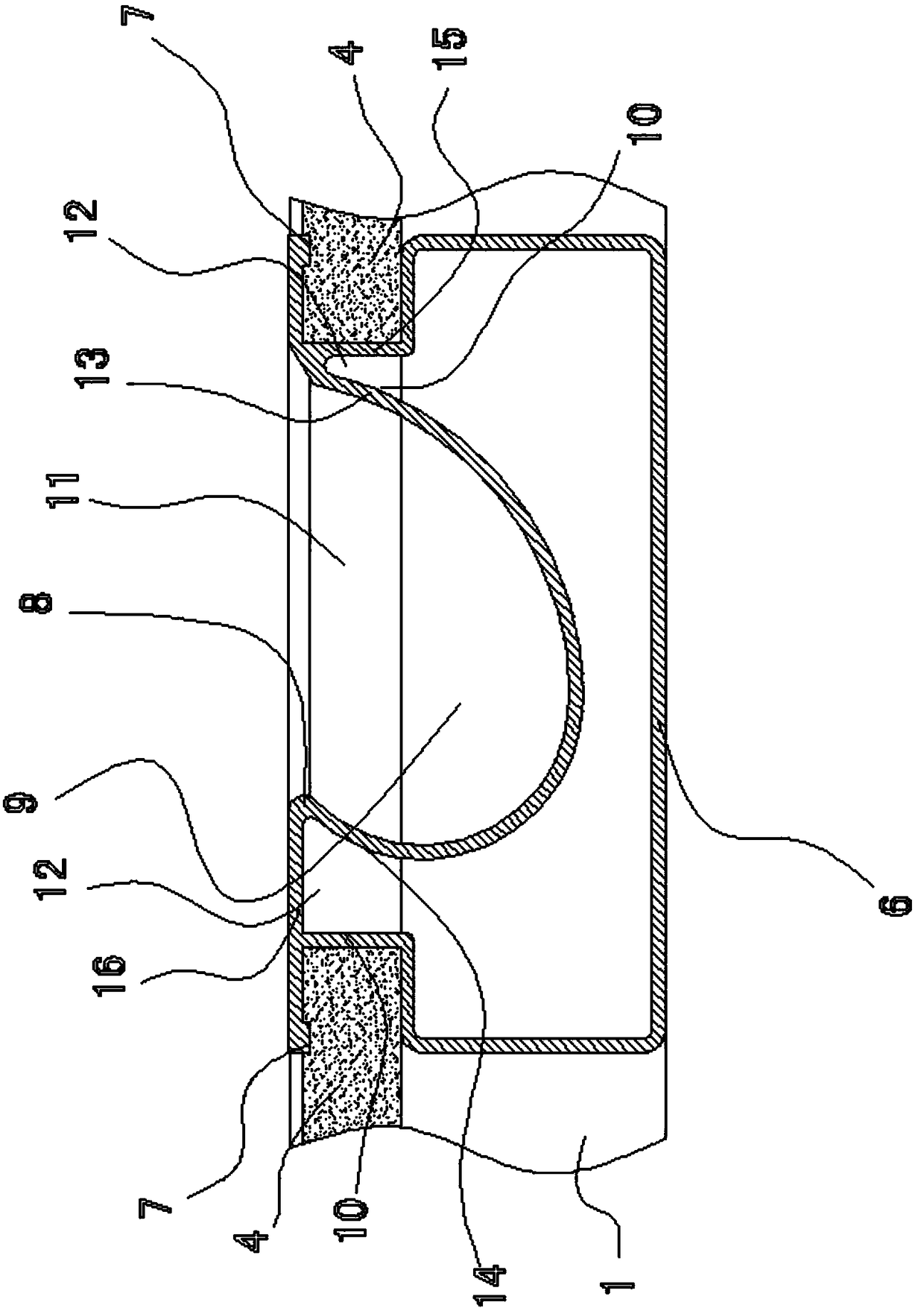

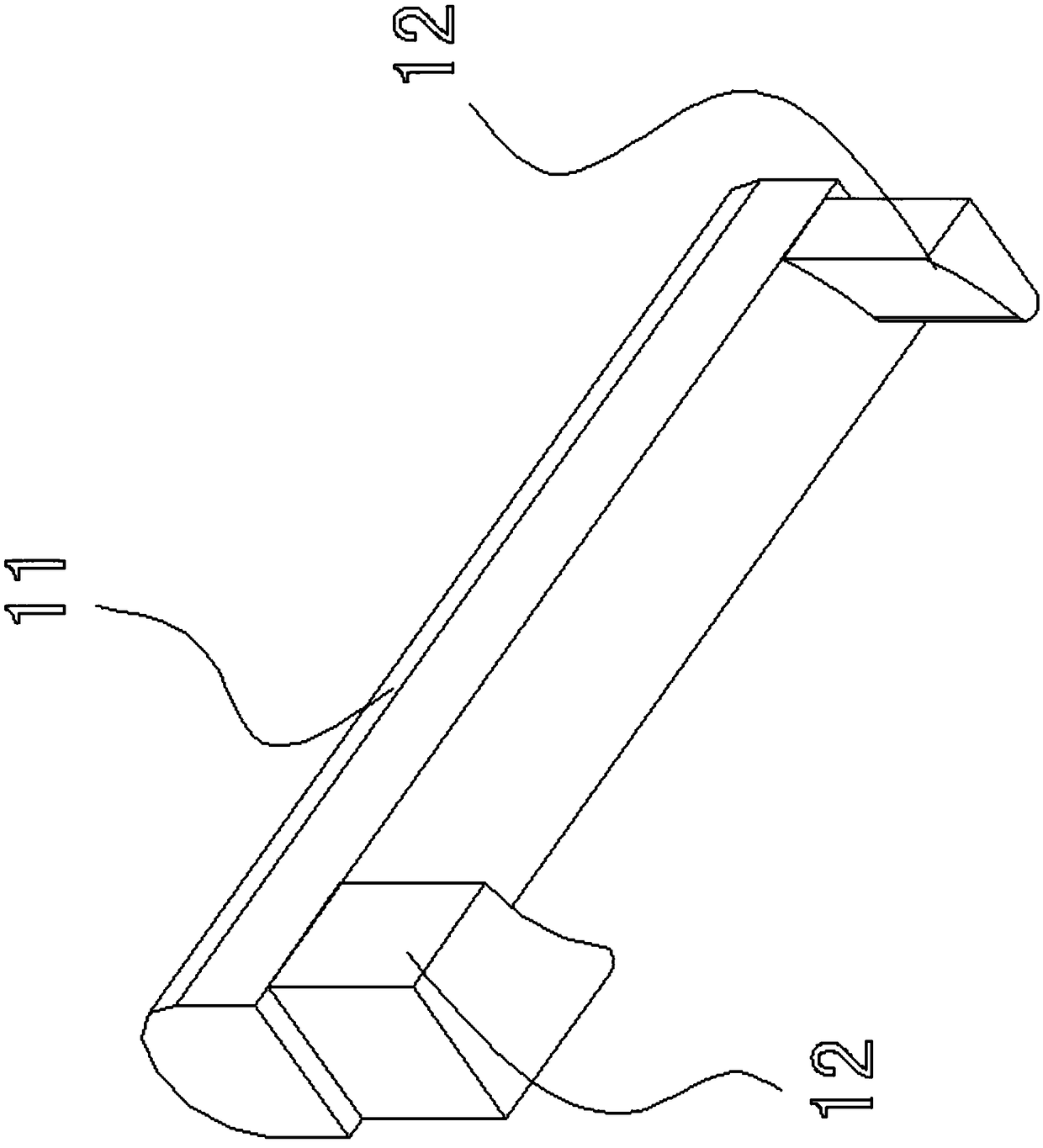

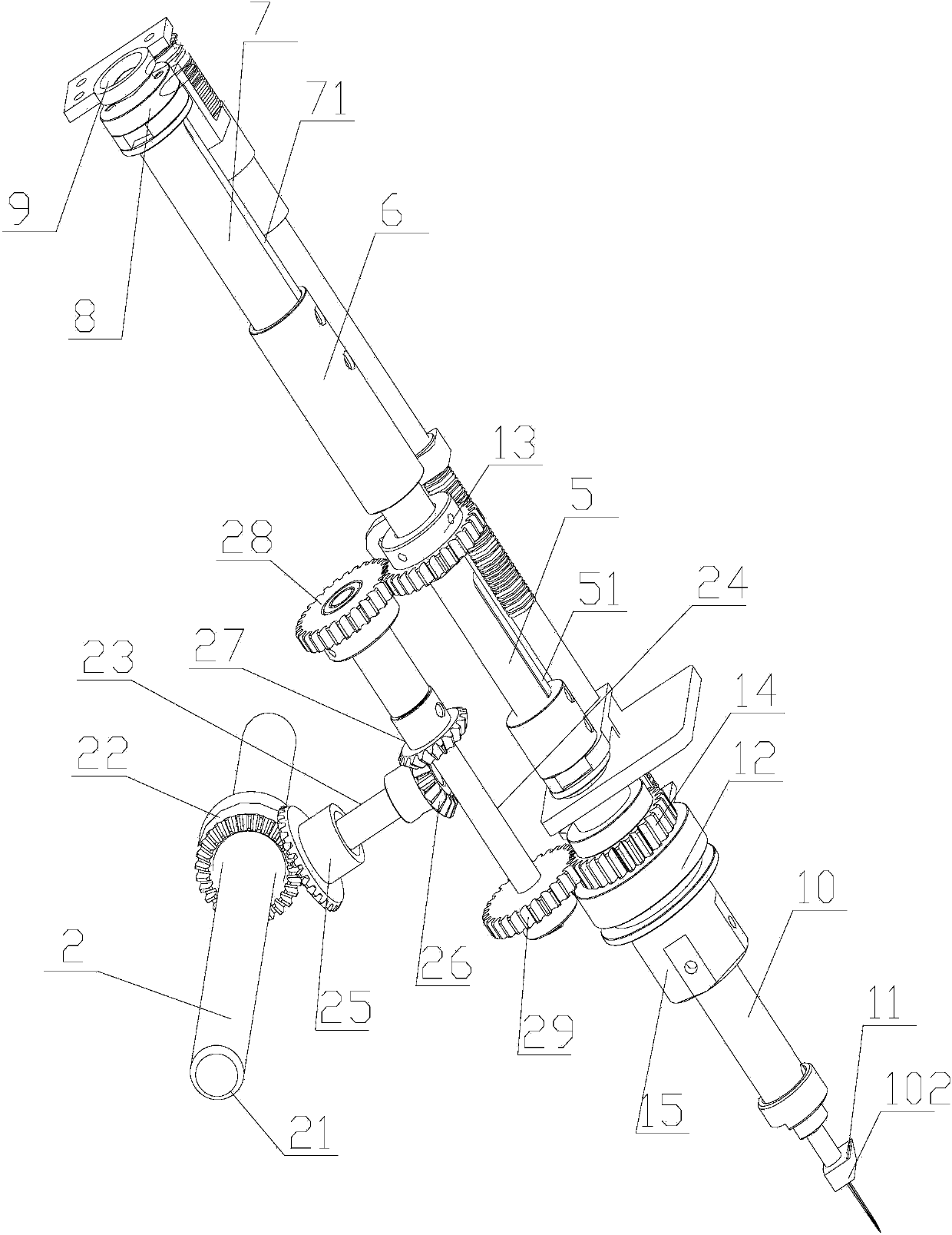

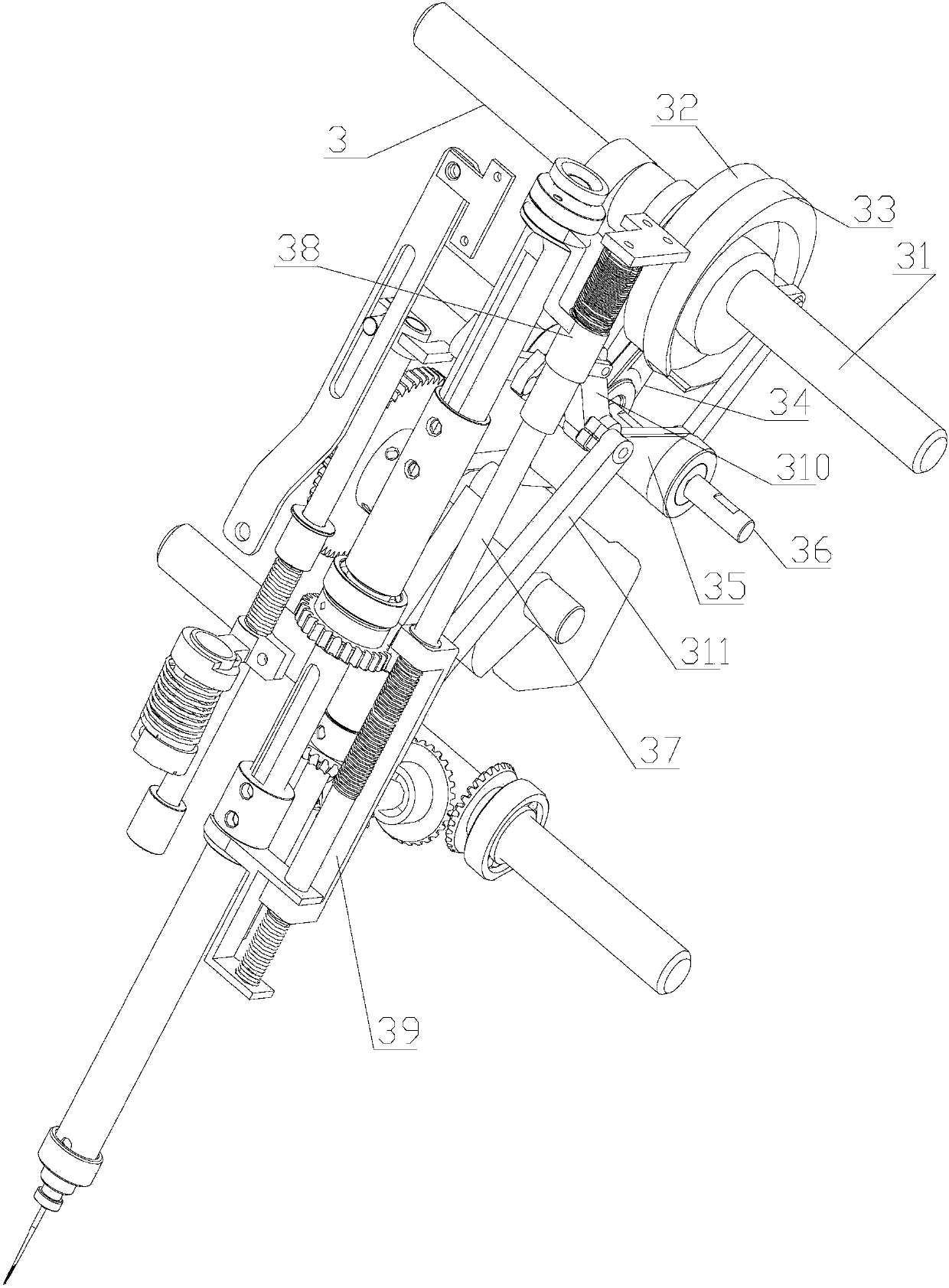

Computer embroider machine towel embroidering machine head of bobbin tape embroidery

The invention discloses a computer embroider machine towel embroidering machine head of bobbin tape embroidery. The computer embroider machine towel embroidering machine head comprises an enclosure, a first drive mechanism, a second drive mechanism, a bobbin tape frame support assembly, a first needle bar sleeve, a transmission sleeve, a second needle bar sleeve, a locking ring, a needle bar, a needle tip sleeve assembly, a bobbin tape through hole, a positioning ring, a first gear, a second gear and an installation sleeve, wherein the first needle bar sleeve is provided with the first gear, the upper part of the first needle bar sleeve is provided with the transmission sleeve, the second needle bar sleeve is arranged in the transmission sleeve, the locking ring is arranged on the second needle bar sleeve, the locking ring is fixedly connected with the needle bar, the lower part of the first needle bar sleeve is provided with the needle tip sleeve assembly, the upper end of the installation sleeve is provided with the second gear, the installation sleeve is provided with the bobbin tape frame support assembly, the first drive mechanism is connected with the first gear and the second gear in a transmission manner, and the second drive mechanism is connected with the needle tip sleeve assembly and the locking ring in a transmission manner. According to the computer embroider machine towel embroidering machine head, the layering property and stereoscopic impression of patterns of a product can be improved, the color is rich, and the patterns are diversified.

Owner:诸暨市乐业机电有限公司

Novel yarn dyeing, printing and dyeing fabric and production method thereof

The invention discloses novel yarn dyeing, printing and dyeing fabric and a production method thereof. The novel yarn dyeing, printing and dyeing fabric is produced by adopting high quality yarns through the process that yarn dyeing, dyeing and printing are combined. Compared with the prior art, the novel yarn dyeing, printing and dyeing fabric has the advantages of simpleness in production process, high production efficiency, rich and colorful patterns, exquisite hand feel and texture feeling, and a sense of dignity and generosity is created; in addition, full-cotton yarns of different colors are taken as weft yarns, color of the reverse of the yarn dyeing fabric can be enriched, and meanwhile, waste of dyed yarns can be greatly reduced.

Owner:张伟夫

Outer wall decoration technique

An outer wall decoration technique relates to the technical field of construction and is characterized in that single-color or multicolor building coatings are coated on an outer wall of a building and painted with white cement to form a colorful decoration surface of the outer wall. The coatings are composed of dyestuff, adhesives and penetrants, and when the coatings painted on the decoration surface are dried, a layer of finishing varnish cured decoration surface is re-painted. The outer wall decoration technique has the advantages that materials such as tiles and marble decoration plates are not used, decoration color and patterns are rich and colorful, and color is added to urban construction. The outer wall decoration technique enables the outer wall to be attractive and firm, is low in price, practical and simultaneously capable of being fireproof and waterproof, removes hidden dangers that tiles or decoration plates fall off from high-rise buildings and greatly saves outer wall decoration cost.

Owner:田卓

Reactive-dye wet-transfer printing technology of pure-cotton fabric

InactiveCN104562811ARealistic patternImprove the artistic effectTransfer printing processDyeing processSodium silicateChemistry

The invention discloses a reactive-dye wet-transfer printing technology of pure-cotton fabric. The reactive-dye wet-transfer printing technology adopts the technical process as follows: conducting alkali rolling on the fabric, rolling and transferring, piling and performing color fixing, and washing and drying; a formula of an alkali solution is as follows: 15g / L of a caustic soda solution and 31g / L of sodium silicate solution; transfer printing conditions are as follows: the alkali rolling liquid rate is 70-80% and the transfer printing pressure is 0.2-0.4MPa; printing of transfer printing paper adopts the technical process as follows: concocting a color paste, printing transfer paper and airing; a formula of the color paste is as follows: 0.5-3.0% of reactive dye, 3-15% of urea, 25-40% of modified starchRX60+ emulsified paste and the balance of water. Transfer printing adopts a method of printing the transfer printing paper, is rich and colorful and multi-layered in pattern, convenient and free in pattern design and strong in expressive ability, can print the pattern with vivid pattern shape and strong artistry, is simple in equipment and convenient in management, and can reduce pollution to the environment.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Spraying technology for colored sculpture of ceramic tile and product thereof

InactiveCN103407317AStrong three-dimensional senseStrong aestheticsDecorative surface effectsMetallurgyCeramic tiles

The invention discloses a spraying technology for colored sculpture of a ceramic tile. The technology comprises the following steps: 1) pasting a protection membrane; 2) cutting edge; 3) peeling off the protection membrane; 4) sculpturing; 5) cleaning; 6) spraying paint. The invention further discloses a ceramic tile product which implements the technology. The technology provided by the invention has simple steps, can be implemented easily, is high in spraying efficiency, strong in character, high in flexibility, and free from limitation of bottom color of the ceramic tile, and can have customized color, pattern and size, enable the surface of the ceramic tile to display stereoscopic embossing quickly, and spray corresponding colors on the embossing according to personal preference, so that the ceramic tile has richer and more various patterns and colors, stronger attraction and artistry, and better decoration, and can enable people to perceive the art during busy and boring working and living and to enjoy life; the pattern of the ceramic tile product provided by the invention is colorful, various, beautiful, elegant, fashionable, and suitable for popularization and application.

Owner:陈权胜

Water transfer printing method for decorative plate of plant fiber molding wall

InactiveCN102700343AColorful patternsClear hierarchyDecorative surface effectsWater transferAgricultural engineering

The invention discloses a water transfer printing method for a decorative plate of a plant fiber molding wall. The method comprises the following steps: (1), uniformly coating a layer of poly urethane (PU) transparent primer on the front side, back side and periphery of the decorative plate of the plant fiber molding wall, then drying the PE transparent primer; (2), regulating the PE transparent primer into the required color, uniformly coating the PE transparent primer on the front side and periphery of the decorative plate, and then drying; (3), polishing the primer layer surface on the front side of the decorative plate smooth; (4), upturning the face of a water transferring printing film with a pattern and laying the water transferring printing film on a water surface, uniformly spraying an activator on the water transferring printing film, pressing the front side of the decorative plate on the water transferring printing film after 1 to 5 minutes and pasting the front side of the decorative plate with the water transferring printing film, and the taking the materials out and drying the materials; and (5), washing impurities remained on the front side of the decorative plate by clean water firstly, then drying the decorative plate, and uniformly spraying the PU furniture paint on the front side of the decorative plate and then drying to obtain the decorative plate. The water transfer printing method for the decorative plate of the plant fiber molding wall, provided by the invention, is simple in process; the water-resisting property and stain-resisting property of the surface of a prepared product are greatly improved; and the prepared product cannot be damaged and polluted easily.

Owner:SOUTH CHINA UNIV OF TECH

Preparation technology of water-based PU (Polyurethane) glue substituting solvent type printing ink TPU (Thermoplastic Polyurethane)

The invention relates to a preparation technology of water-based PU (Polyurethane) glue substituting solvent type printing ink TPU (Thermoplastic Polyurethane). The technology is characterized by comprising the following steps: slowly stirring 24-30% of acrylic resin in a dispersion tank at normal temperature and pressure state, adding ammonium hydroxide for regulating the pH value to 7-8; sequentially feeding a polyurethane aqueous dispersion, propylene glycol monomethyl acetate, ethylene glycol butyl ether and the like into the dispersion tank, and continuously dispersing for one hour; after the dispersion is over, heating, continuously vacuumizing the tank through a vacuum pump, injecting cooling circulation water to the outer wall of the dispersion tank under the condition that the pressure in the tank is maintained at the negative pressure state of 0.8-1Pa, cooling the temperature to 50DEG C below, releasing the negative pressure in the tank to be normal pressure, filtering through a vacuum filtering machine, to obtain the printing ink TPU water-based PU glue. The product can be used as a printing ink in the ink printing technology of a TPU shoe material. Furthermore, no pollutant solvent is volatized in the process of drying shoe shell fabric using the water-based PU glue, and patterns are colorful.

Owner:SHISHI DECAI CHEM TECH

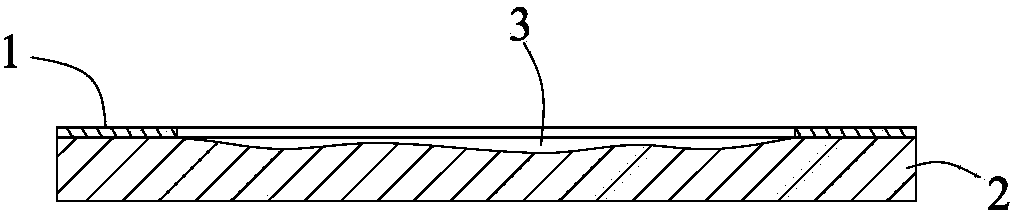

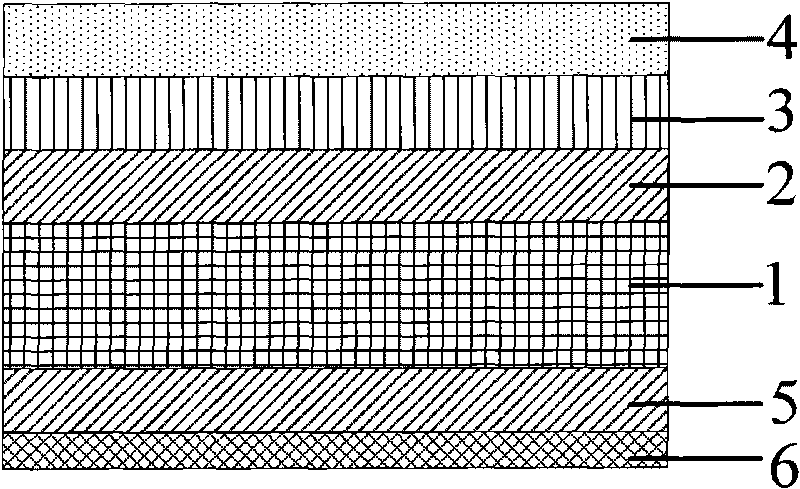

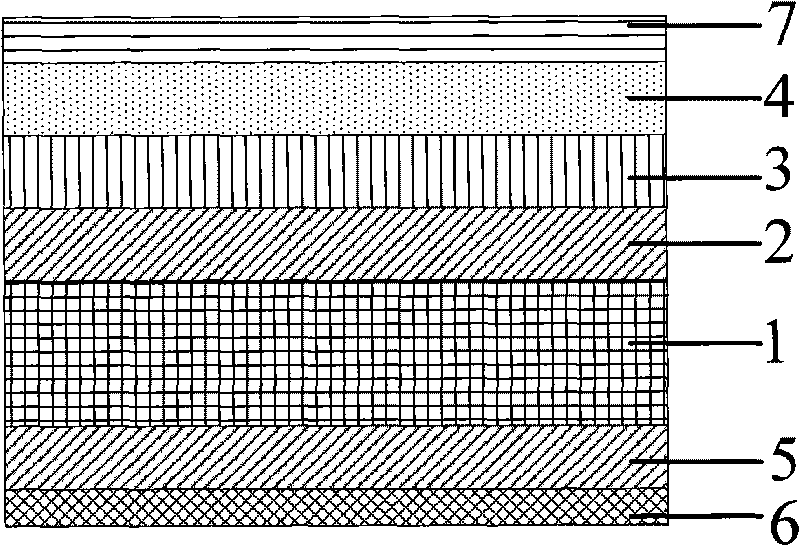

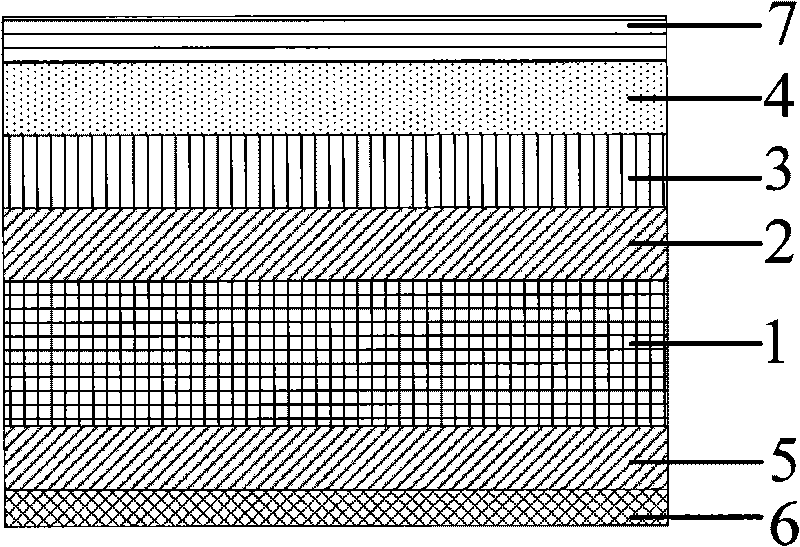

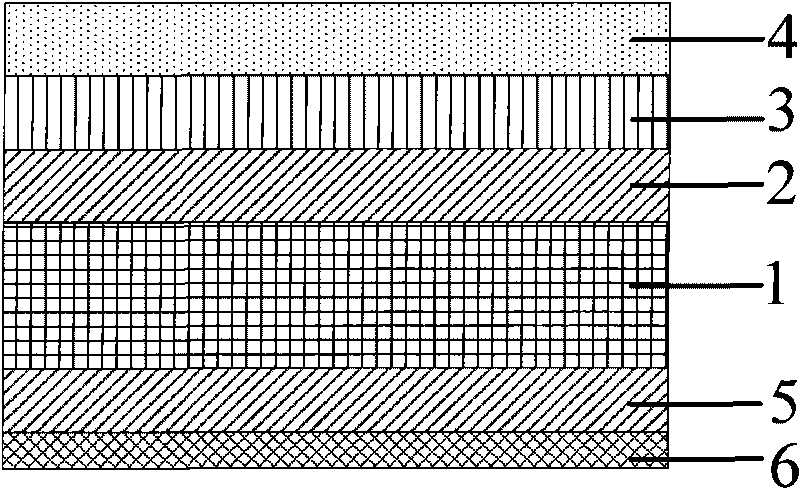

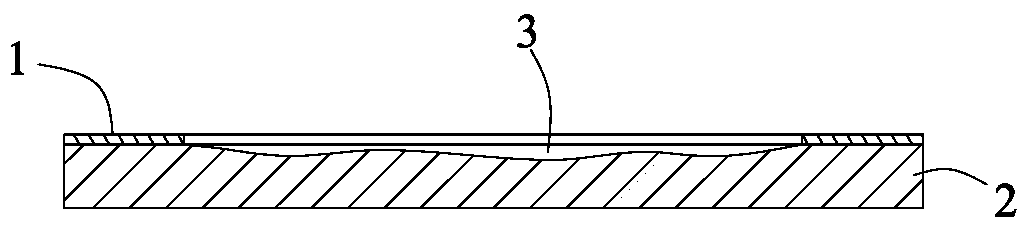

Polyvinyl chloride (PVC) plastic steel plate

InactiveCN101746087AGuaranteed fastnessRich in colorMetal layered productsTectorial membraneSheet steel

The invention provides a polyvinyl chloride (PVC) composite plastic steel plate. The front face of the steel plate is coated with a passivation layer, an adhesive layer is coated on the surface of the passivation layer, a PVC membrane layer is adhered on the adhesive layer, a protective membrane layer covers on the PVC membrane layer; and the back face of the steel plate is coated with a passivation layer, and a back paint layer is coated on the passivation layer. The invention can play roles of decoration, protection and attraction after the PVC membrane is adhered, has variable colors because the PVC membrane layer can achieve the effect of simulating wood grains, and can be used in industries of home appliances, decoration and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

Method for fabricating cover for sucking plastic in color printing

InactiveCN1562614AEasy to implementIncrease production capacityOther printing apparatusColor effectColor printing

Owner:蔡三键

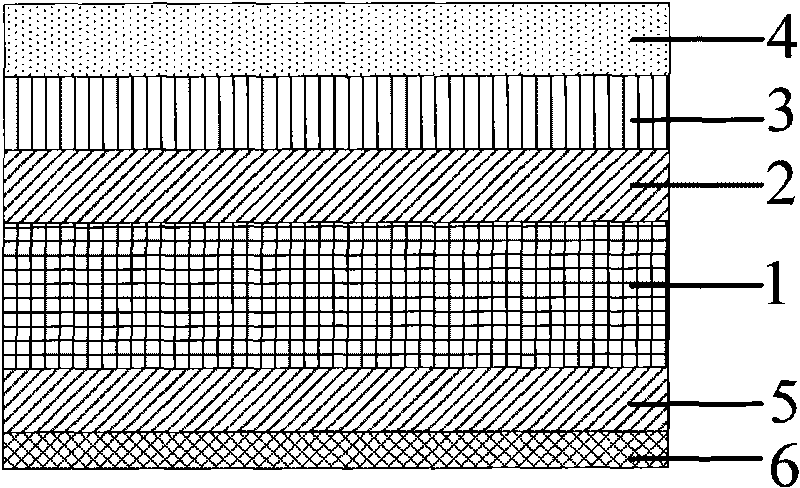

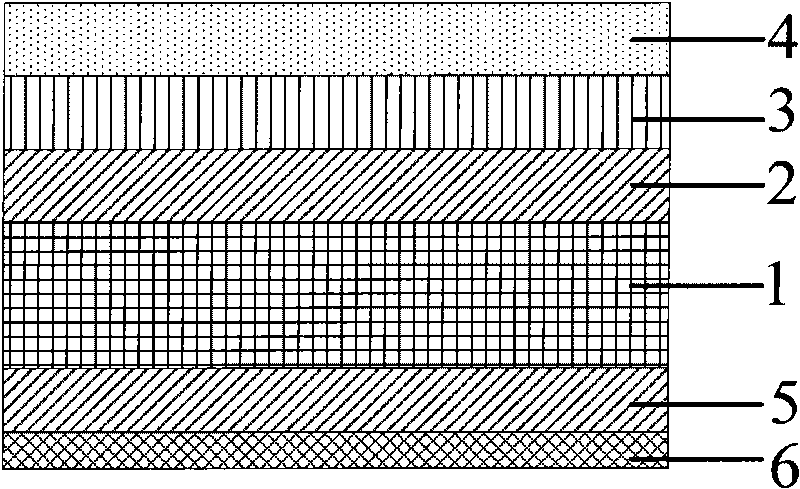

Polypropylene composite plastic coated steel plate

InactiveCN101746086AGuaranteed fastnessHigh glossMetal layered productsTectorial membranePolypropylene composites

The invention provides a polypropylene composite plastic coated steel plate, a passivation layer is coated on the front surface of a steel plate, an adhesive layer is coated on the surface of the passivation layer, a polypropylene film layer is adhered on the adhesive layer, and a protective film layer is covered on the polypropylene film layer; the passivation layer is coated on the back surface of the steel plate, and a back paint layer is coated on the passivation layer; the polypropylene film layer adhesion has decorating, protecting and beautifying effect, by adopting vacuum aluminizing, the polypropylene film layer achieves the stainless steel simulation appearance effect, the color is verified and the polypropylene composite plastic coated steel plate can be used for household and decorating industries.

Owner:SUZHOU HESHENG NEW MATERIALS

Environment protection plastic printing ink and its preparation

The no-benzene green plastic printing ink consists of inorganic pigment or organic pigment, antistatic agent, dispersant, adhesion promoter, alcohol soluble synthetic PVB resin and alcohol solvent. The preparation process includes the following steps: dissolving the alcohol soluble synthetic PVB resin in alcohol solvent to form translucent resin solution; mixing the inorganic pigment or organic pigment with the resin solution to form color slurry semi-product; grinding the color slurry semi-product in a sand mill and adding the other components via stirring; filtering and packing to obtain no-benzene green plastic printing ink product. The no-benzene green plastic printing ink is boiling resistant and freezing resistant and may be used in packing milk, wine, seasoning, aquatic product, medicine, etc.

Owner:TENGXIA PRINT INK ZHUCHENG

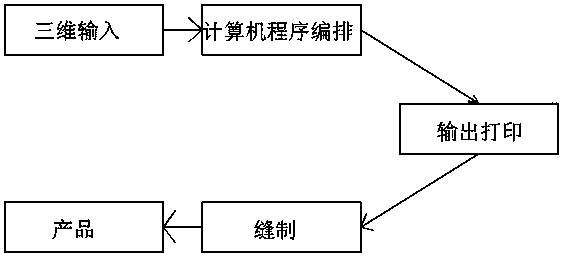

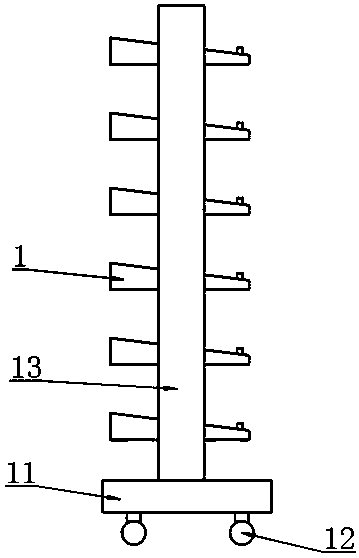

An advanced sewing manufacturing process based on three-dimensional design

ActiveCN109300171AEasy to use and stableReasonable and effective manufacturing process steps2D-image generationSpecial data processing applicationsThree-dimensional spaceCombined use

The invention belongs to the technical field of sewing manufacturing process, in particular to an advanced sewing manufacturing process based on three-dimensional design. The invention achieves the effect of effectively sewing and manufacturing furniture products through three-dimensional input, adding advanced printing technology and combining with convenient sewing sheet placement rack. The invention has the advantages of reasonable and effective manufacturing process steps, good three-dimensional space expression of the manufactured product, rich pattern color, few sewing procedures, high overall efficiency, stable and convenient use of the sewing sheet placement frame, and ensuring that the sewing sheets do not affect each other.

Owner:DAKANG HLDG GROUP

Production method for microcrystal glass ceramic compound brick

The invention discloses a production method for a microcrystal glass ceramic compound brick. The production method comprises the following steps: firstly, carrying out blanking and biscuitfiring on powder according to a known production technology for a ceramic brick, thereby forming an unburned brick; utilizing an engraving roller to print patterns and distribute materials, distributing colorfulmicrocrystal fused cakes onto the unburned brick, and using a fixing agent for fixing, thereby forming patterns; arranging transparent fused blocks on the unburned brick with the colorful microcrystal fused cakes, using the fixing agent for fixing, covering the colorful microcrystal fused cakes, pre-pressing and leveling; and firing at high temperature, thereby compounding the colorful microcrystal fused cakes and the transparent fused blocks on the unburned brick in a manner of firing. According to the production method, the engraving roller is used for printing patterns and distributing materials so as to form the patterns, so that the texture patterns of products are rich, the texture is soft and vivid and the brick feels like a natural stone; the surface glossiness is high, the water absorption is low, the patterns are rich in color, the performance is stable, the abrasion resistance is high, the performance of the products is stable, and the products are free from being corroded and cracked; and the large-size production can be realized, thereby greatly breaking through the limitation on the size of the products.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Method for producing glass and ceramics waterstone building decorative sheet material

The invention relates to a method for producing a constructional decorative panel, in particular to a method for producing a glass and ceramics terrazzo constructional decorative panel. The constructional decorative panel is prepared by the following steps of: a pre-formed inlay material is produced and the raw materials can be one or two or a combination of ceramics, glass, microcrystalline glass and vitrified ceramics, the raw materials are processed into powder and are made into a billet needed by the inlay material through a forming method, the thickness of the pre-formed material is less than that of the billet of a finished product, and the dimension of a long plane and a wide plane are less than that of the billet of the finished product; the vitrified ceramics are made into substrate powder so as to prepare a billet by mixing with the inlay material; the billet is dried by adopting a method for drying ceramics; the dried billet is fired through the glass and ceramics firing technique; the dried billet is grinded, polished and processed into a fixed-length finished product. Compared with the prior art, with the method, the method can obtain combined products with three-dimensional effect, and rich design and color, and has good capabilities in resisting stains, weather, wearing and fire.

Owner:褚凤民

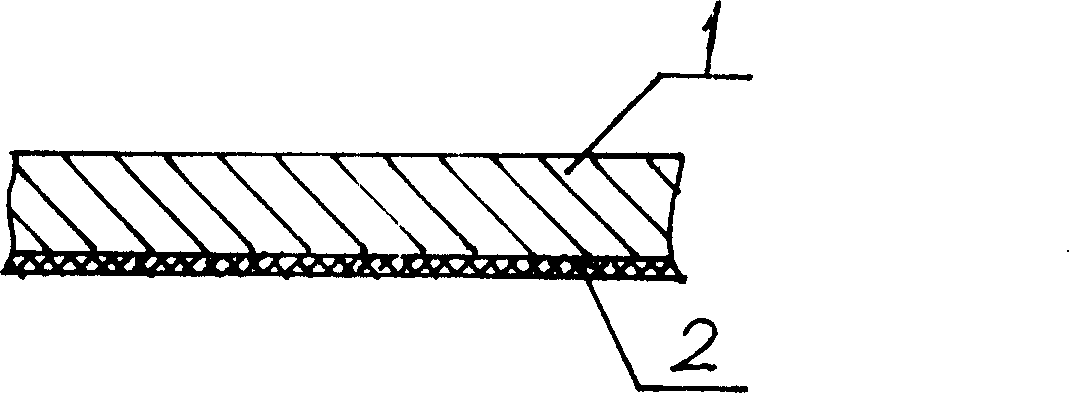

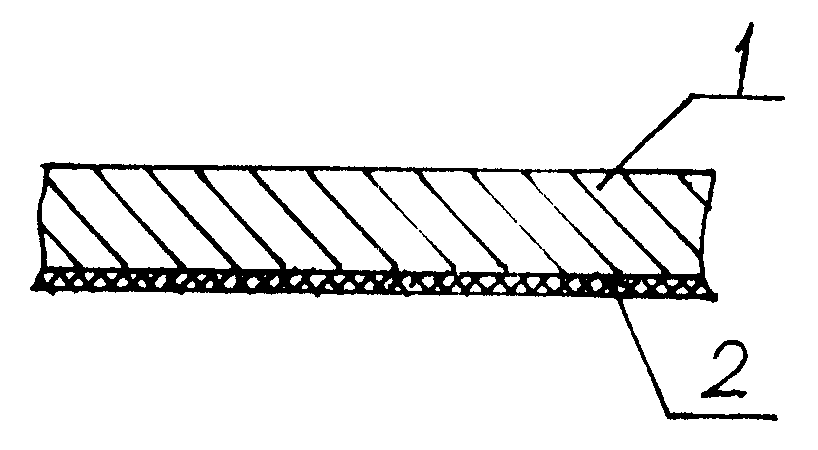

Method for manufacturing active carbon slab and carbon slab painting

InactiveCN101590781AWith health functionHealth care functionOrnamental structuresSpecial artistic techniquesActivated carbonMetallurgy

The invention relates to a method for manufacturing a decoration material and a decoration, in particular to a method for manufacturing an active carbon slab. The method comprises the following steps: firstly, adding a bonding agent in active carbon; then, injecting the active carbon material in a carbon slab die to carry out shaping and pattern drawing; and finally, putting the material in a drying cabinet. The invention also provides a method for manufacturing active carbon slab paintings, and the method comprises the steps of pruning, polishing, decorating, embroidering, and the like. The carbon slab and the decoration thereof made by the method have simple process, aesthetic appearance and excellent air purification function.

Owner:王立新

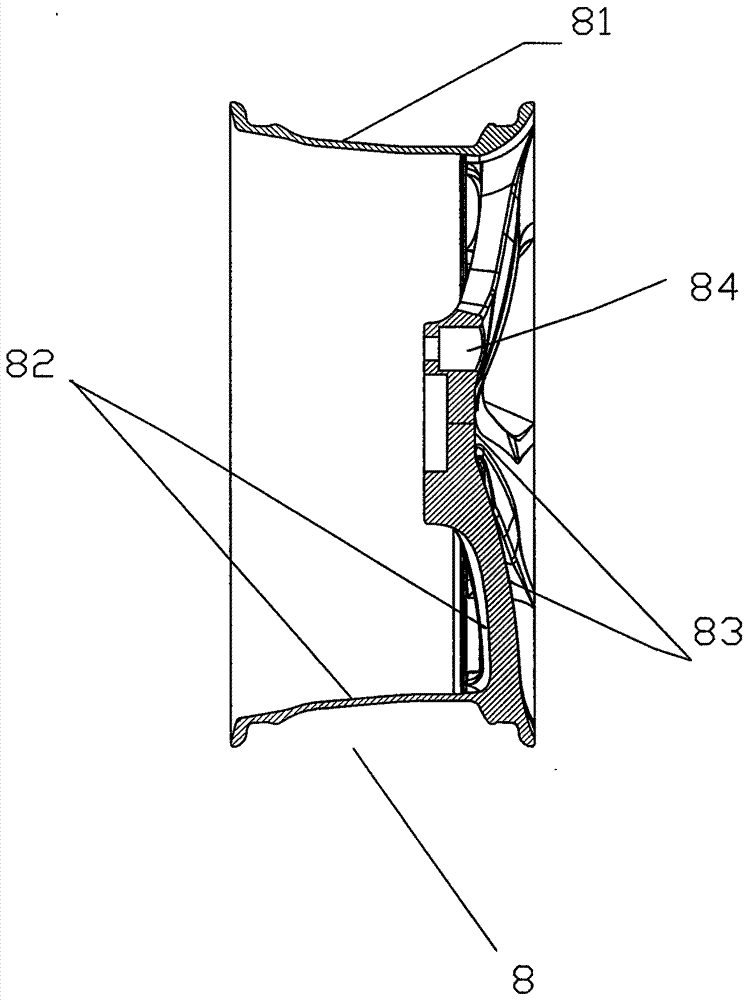

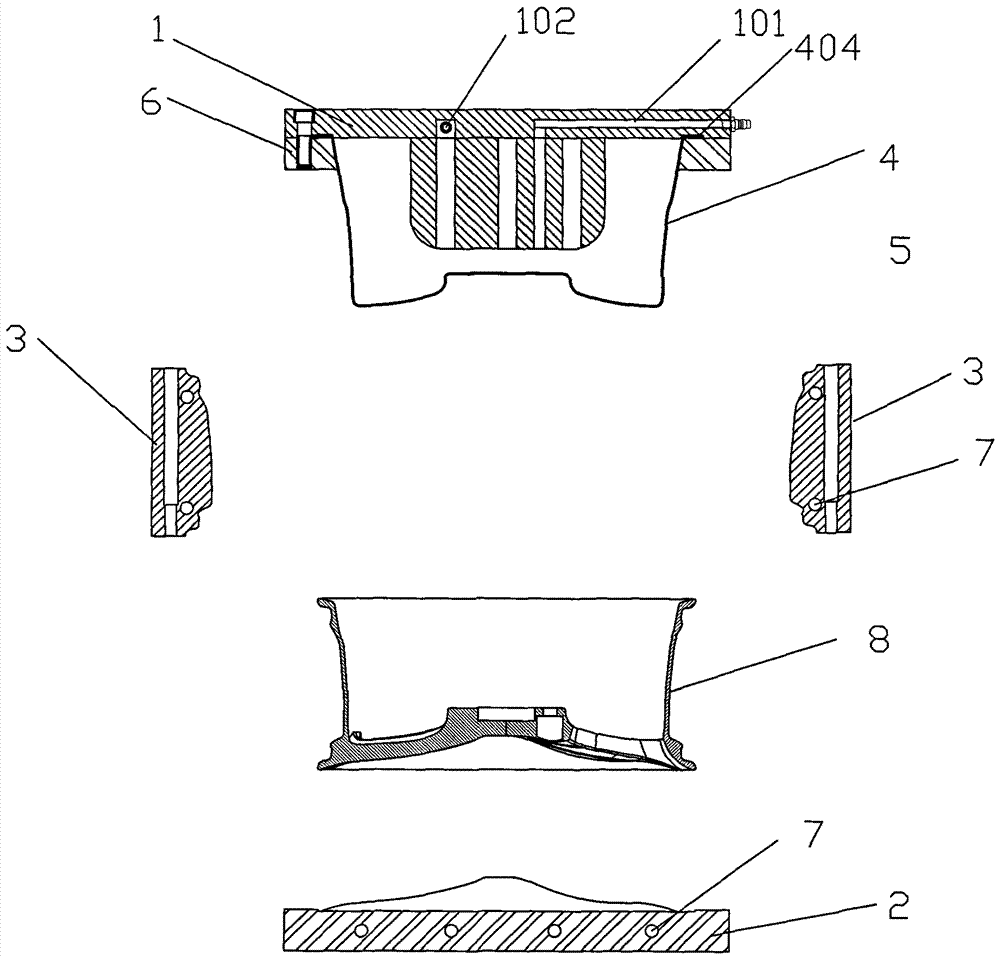

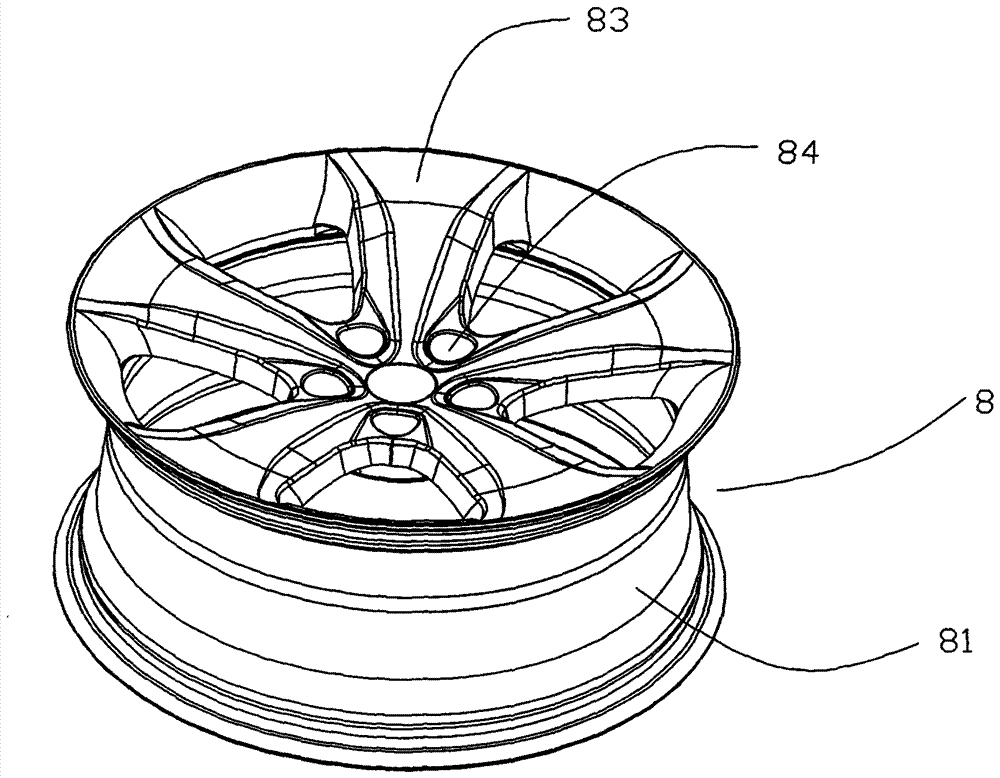

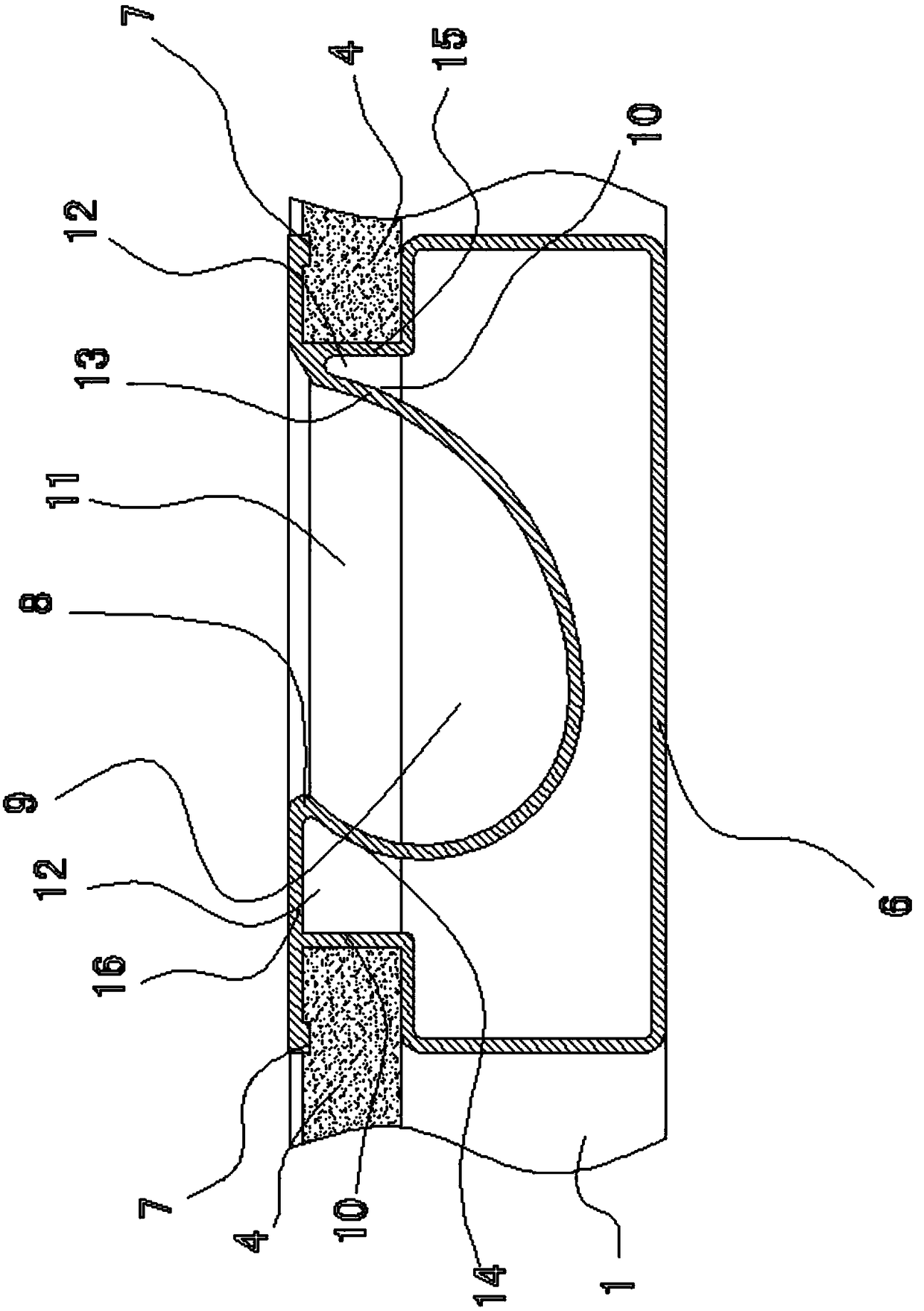

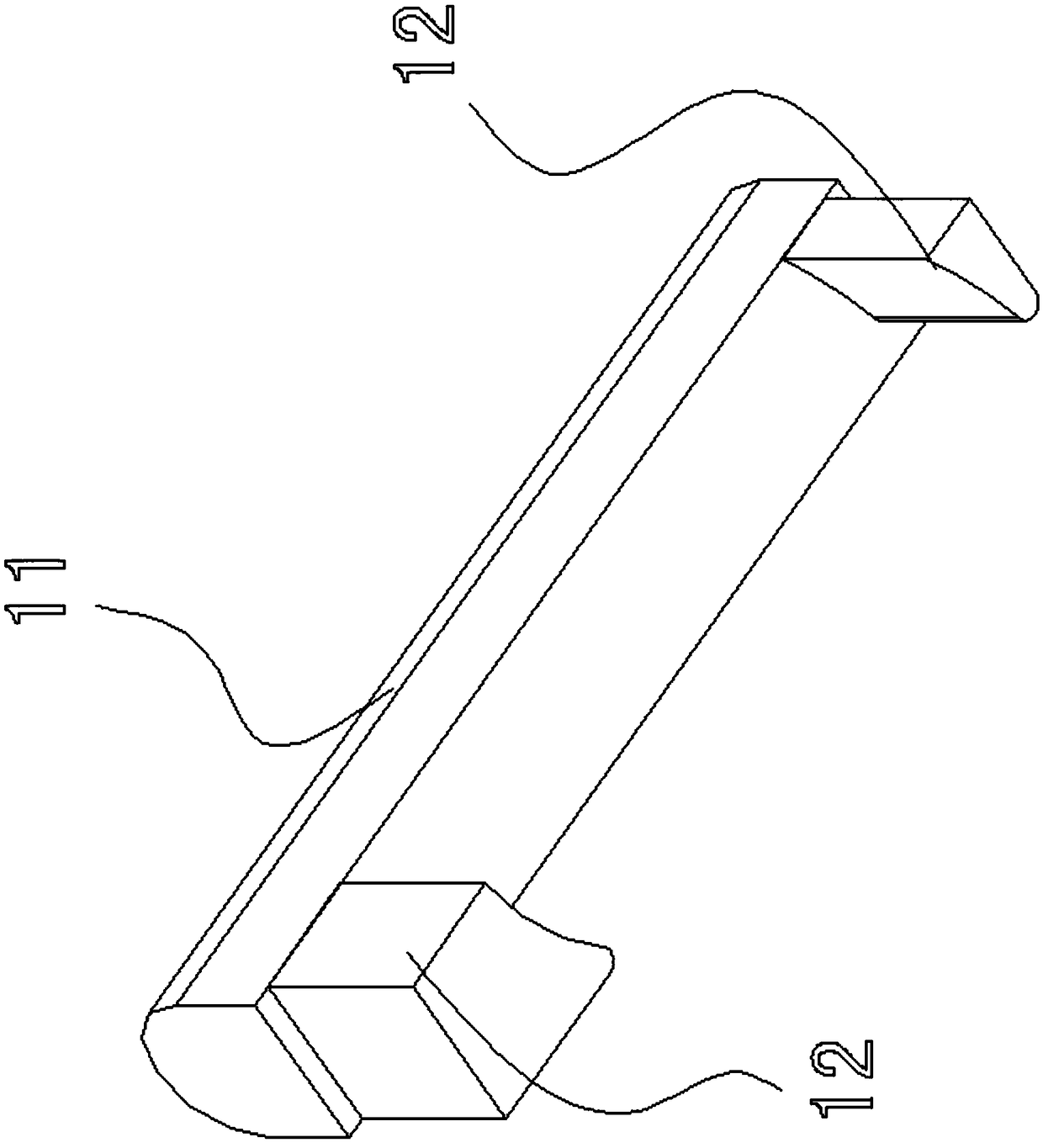

A mold structure for solidification and molding of carbon fiber automobile wheel hub blanks and a method for making products with the mold

The invention discloses a mold structure for curing and forming carbon fiber automobile rim blank products and a method for manufacturing products by the mold. The product intensity and integrality of the carbon fiber automobile rims manufactured by the mold and the method are good, and because full-carbon-fiber automobile rims are adopted, the product quality and level are improved. Compared with aluminum rims, the full-carbon-fiber automobile rims can be reduced by 60-80% in weight, save energy and reduce consumption, and reduce the driving cost. The full-carbon-fiber automobile rims do not need product processing, are formed integrally, reduce the production process, and improve the product intensity.

Owner:XIAMEN HONGJI WEIYE INDAL

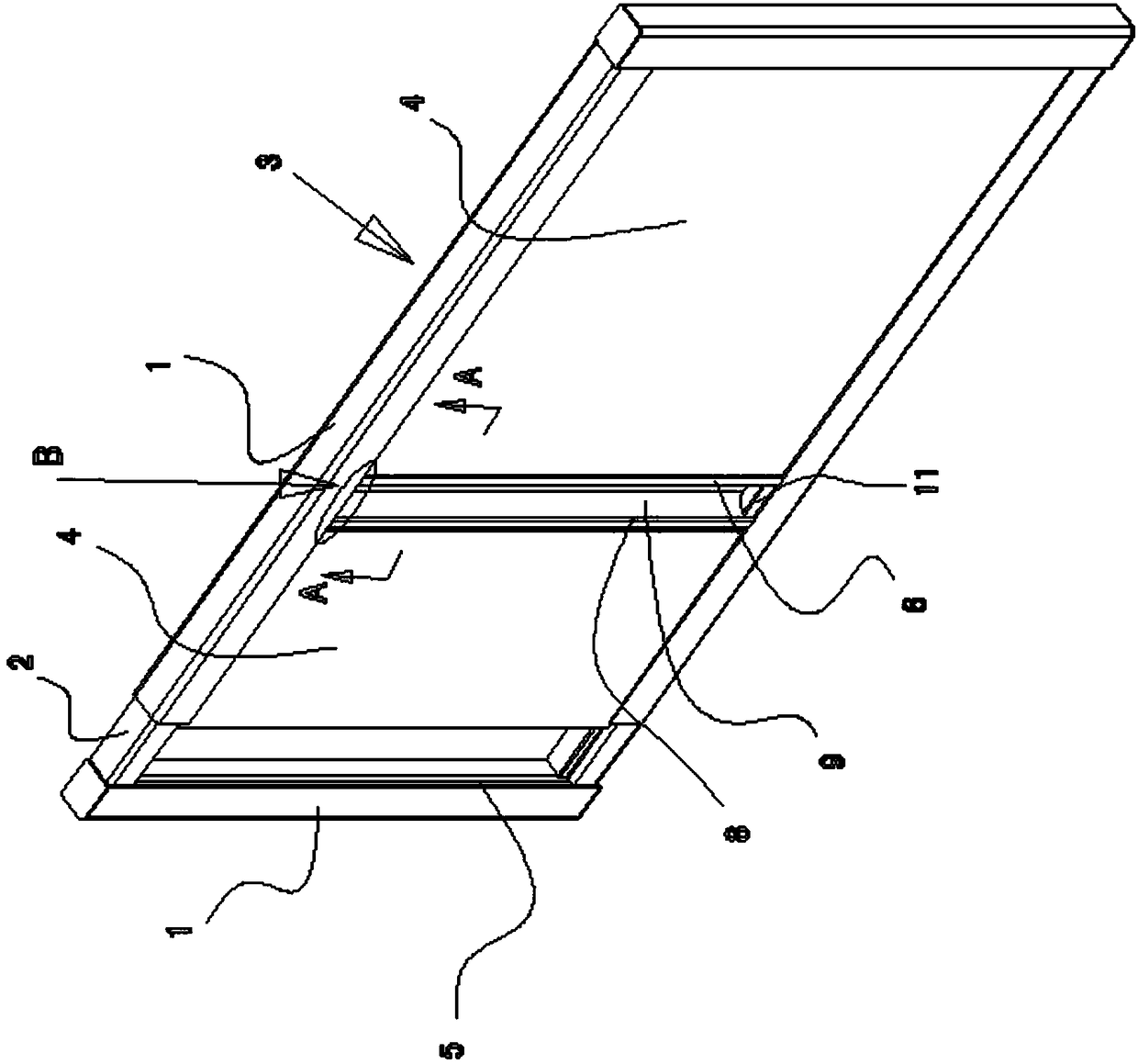

Resin building faced decoration plate with stone imitated face

InactiveCN108240159AImprove standardization and aestheticsQuick connect and plug systemWing handlesWing framesFire retardantSurface plate

The invention provides a resin building faced decoration plate with a stone imitated face and further provides a fire retardant material. The resin building faced decoration plate with the stone imitated face comprises a frame and glass face plates, the frame is provided with a tubular sucker aluminum alloy profile, and embedding grooves are formed in the tubular sucker aluminum alloy profile. Thesucker aluminum alloy profile is provided with a notch with a lintel, the two glass face plates are embedded to the two frame-shaped embedding grooves of the frame, and a groove is formed in the tubular sucker aluminum alloy profile. Embedding blocks are arranged on the tubular sucker aluminum alloy profile, embedding feet are arranged on the embedding blocks, and the embedding blocks are embedded into the embedding grooves at the two edges in the frame. Compared with the prior art, the resin building faced decoration plate has the advantages that the face plates can form a plurality of decoration areas, and the position of a sucker combined with the aluminum alloy frame can adapt to the actual using requirement. The adhesion property of the fire retardant direction plate prepared throughthe method meets the national standard requirement, and a base material has the fire retardant property; and the mechanical property of the base material is not affected, the releasing quantity of formaldehyde reaches the grade E1 or above, and safety and environment protection are achieved; and meanwhile the natural texture of woods is kept, and the decoration effect is good.

Owner:秦春玉

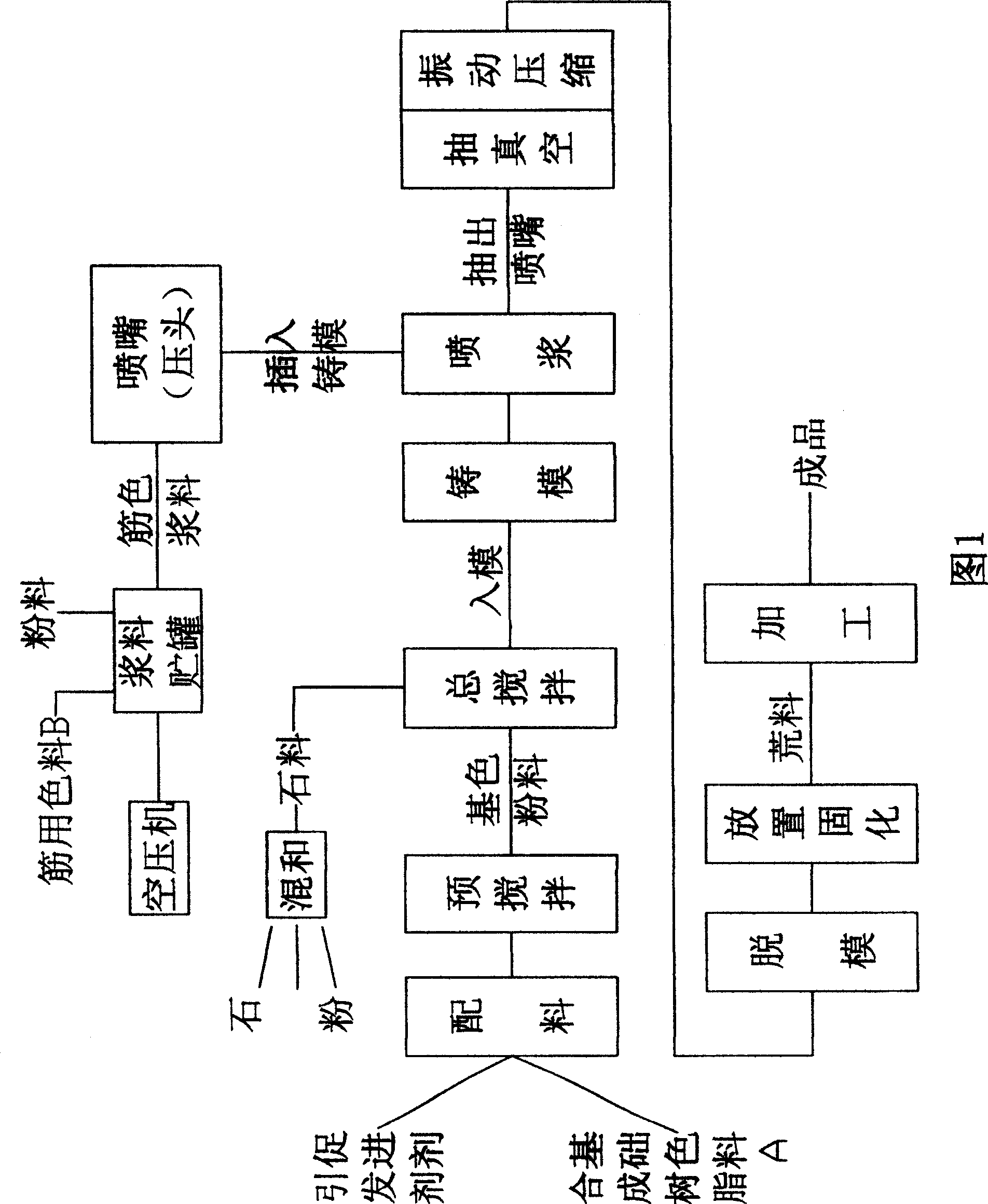

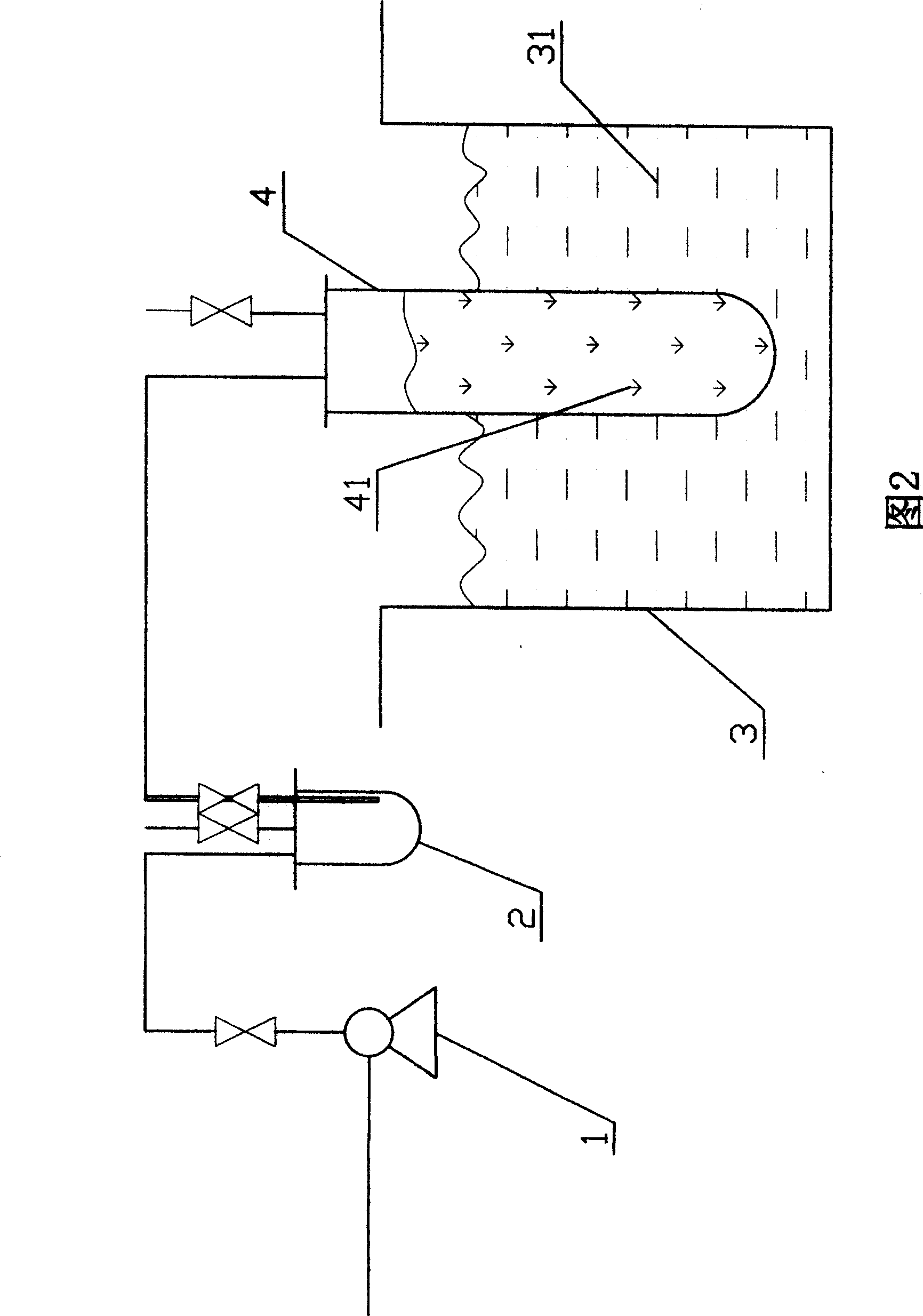

Manufacturing method of colour vein artificial marble

InactiveCN100500404CMeet different requirementsSimple methodCeramic shaping apparatusPolymer scienceSpray nozzle

Owner:林志敏

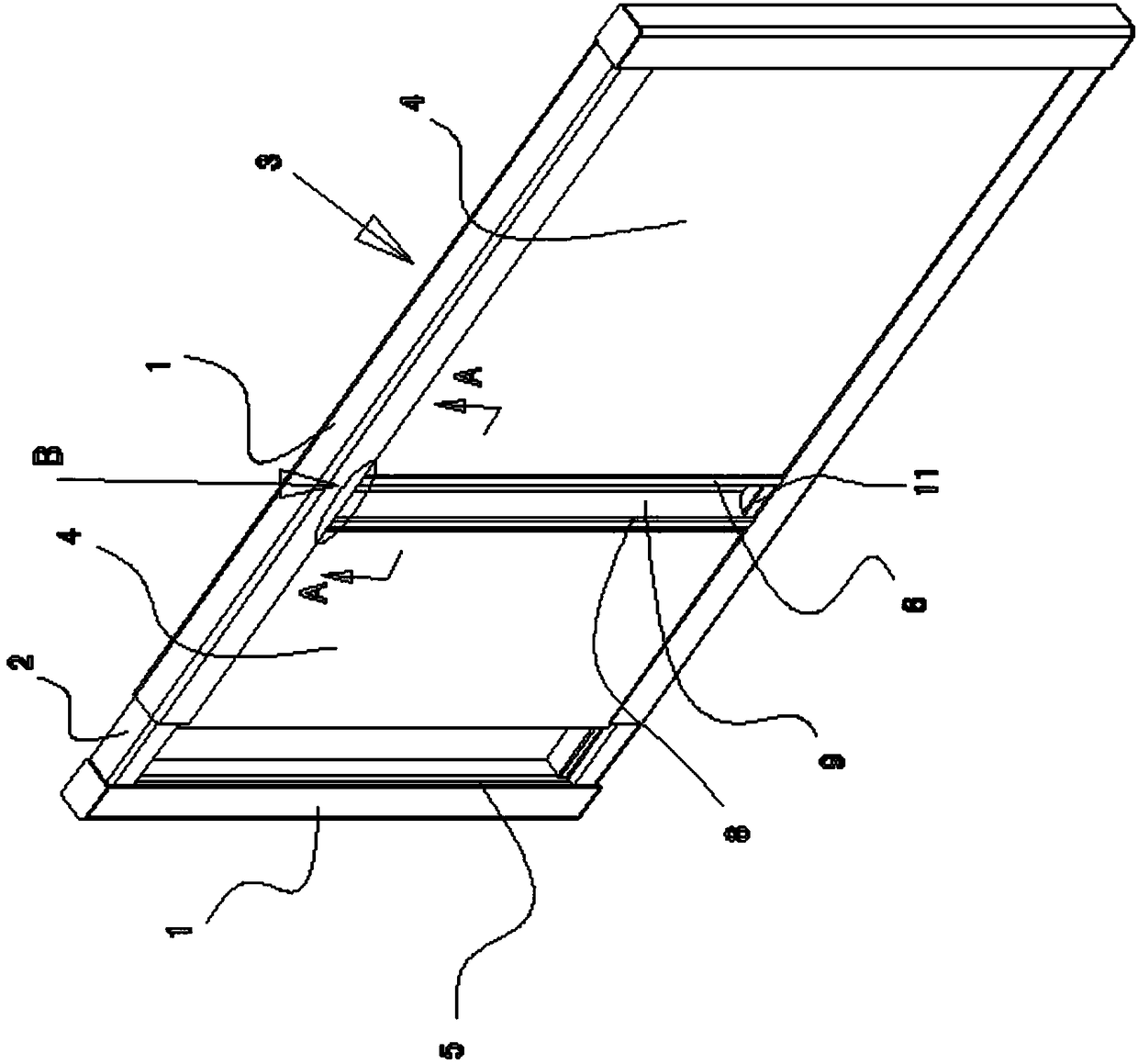

Preparation method of textile fabric Textilene mat

PendingCN114292477AImprove production efficiencyColorful patternsLamination ancillary operationsLaminationDigital printingDigital ink

The invention discloses a preparation method of a textile weaving textilene mat, which is characterized by comprising the following preparation steps: S1, selecting a textilene grid pattern, typesetting, programming a mold, and manufacturing the mold through laser engraving; s2, preparing a preparation formula for blending; s3, hot melting forming; s4, demolding treatment; s5, pasting a transparent layer at high temperature; s6, deformation thickness springback control is carried out; s7, temperature control; s8, rolling the roll material; s9, ink-jet printing is carried out; s10, cutting and slicing; and S11, packaging and packaging. According to the invention, the structural shape of a matured woven fabric type textilene woven product in the market is applied to a plastic type lace product, the textilene woven shape is reproduced in a screw extrusion discharging and die blade coating fitting mode, and the digital printing pattern is supplemented; the lace pad structurally comprises a transparent PVC (polyvinyl chloride) layer, a foaming grid layer and a digital ink-jet phase-forming printing layer from bottom to top, is different from Textilene products of a textile process series in the market, and is a lace pad product which is made of a brand new material and has a Textilene style.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Method for producing glass and ceramics waterstone building decorative sheet material

The invention relates to a method for producing a constructional decorative panel, in particular to a method for producing a glass and ceramics terrazzo constructional decorative panel. The constructional decorative panel is prepared by the following steps of: a pre-formed inlay material is produced and the raw materials can be one or two or a combination of ceramics, glass, microcrystalline glass and vitrified ceramics, the raw materials are processed into powder and are made into a billet needed by the inlay material through a forming method, the thickness of the pre-formed material is lessthan that of the billet of a finished product, and the dimension of a long plane and a wide plane are less than that of the billet of the finished product; the vitrified ceramics are made into substrate powder so as to prepare a billet by mixing with the inlay material; the billet is dried by adopting a method for drying ceramics; the dried billet is fired through the glass and ceramics firing technique; the dried billet is grinded, polished and processed into a fixed-length finished product. Compared with the prior art, with the method, the method can obtain combined products with three-dimensional effect, and rich design and color, and has good capabilities in resisting stains, weather, wearing and fire.

Owner:褚凤民

A kind of exterior wall decoration technology

InactiveCN102926512BReduce decoration costsEliminate hidden dangersCovering/liningsAdhesiveHigh rise

An outer wall decoration technique relates to the technical field of construction and is characterized in that single-color or multicolor building coatings are coated on an outer wall of a building and painted with white cement to form a colorful decoration surface of the outer wall. The coatings are composed of dyestuff, adhesives and penetrants, and when the coatings painted on the decoration surface are dried, a layer of finishing varnish cured decoration surface is re-painted. The outer wall decoration technique has the advantages that materials such as tiles and marble decoration plates are not used, decoration color and patterns are rich and colorful, and color is added to urban construction. The outer wall decoration technique enables the outer wall to be attractive and firm, is low in price, practical and simultaneously capable of being fireproof and waterproof, removes hidden dangers that tiles or decoration plates fall off from high-rise buildings and greatly saves outer wall decoration cost.

Owner:田卓

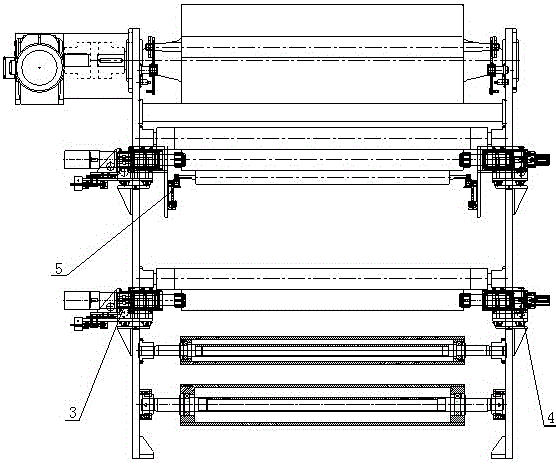

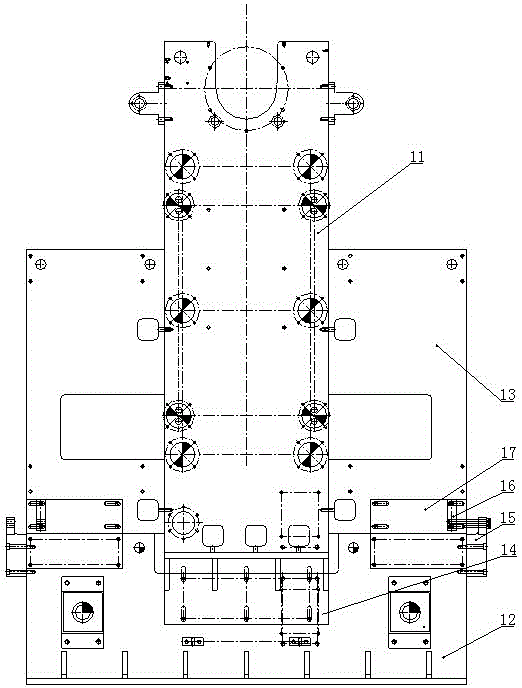

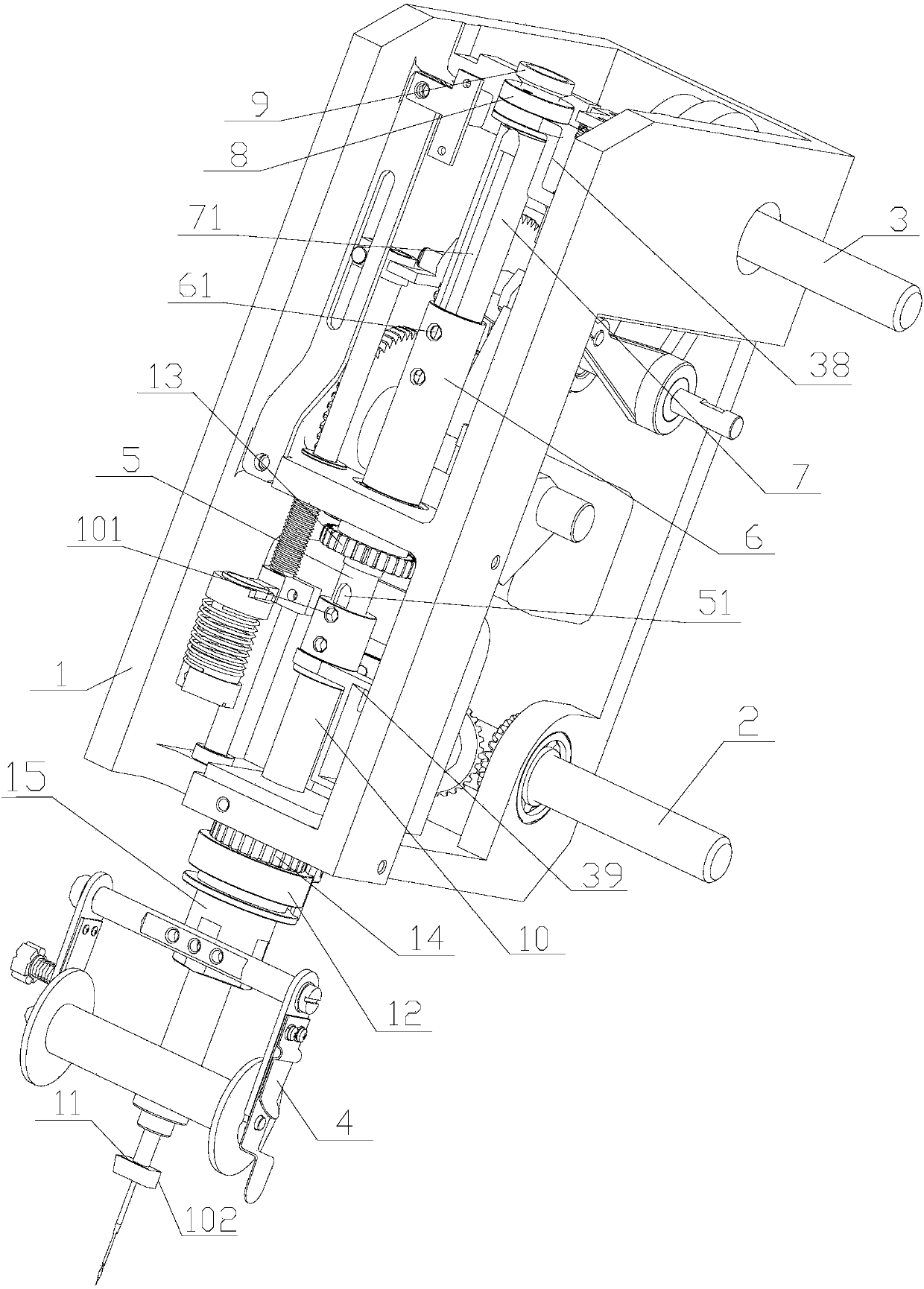

Mechanical digital printing machine

ActiveCN104354465BHigh coloring rateEasy dischargeRotary pressesPrinting press partsSurface patternPollutant emissions

The invention discloses a mechanical digital printing machine, which is sequentially provided with a scotching cloth feeding device, a centering deviation correcting device, a brush hair box, a three-roller padder, a roller tube drying device, a plasma processing device, a four-color embossing machine, an infrared ray drying device, a lower layer guide belt, a two-color embossing machine, an upper layer guide belt drying box and a cropping device according to work procedures, wherein a fabric is flattened and is then fed into the deviation correcting device for carrying out centering cloth feeding, surface dust on the surface of the fabric is brushed, then, the fabric is fed into the three-roller padder for two-soaking two-rolling operation, and then enters the roller tube drying device, the fabric surface reaches a high dyeing degree through the plasma processing device, next, the requirement of front side embossing is reached through the four-color embossing machine, then, the reverse surface pattern is printed through drying the embossing surface, the humidity of the fabric surface is dried, and finally, the printed fabric uniformly falls onto the cropping device. After the whole work procedure, the fabric dyeing degree is high, the feeding and the discharging of a great amount of dye are avoided during embossing, the dye is saved, the pollutant emission is little, the printing speed is high, the printing quality is high, and the printed patterns are richer and more colorful.

Owner:NANTONG SANXIN PLASTICS EQUIP TECH

Magnesian inorganic decorative integral plate

InactiveCN108252465AEasy to fixEasy to set upCovering/liningsFlooringNational standardMechanical property

The invention provides a magnesian inorganic decorative integral plate. The magnesian inorganic decorative integral plate comprises a frame body and a glass panel. A pipe-shaped handle aluminum alloyprofile is arranged on the magnesian inorganic decorative integral plate, and inlaid grooves are formed in the pipe-shaped handle aluminum alloy profile; a notch with a lintel is formed in the handlealuminum alloy profile, and two glass panels are inlaid on the two frame-shaped inlaid grooves of the frame body; a groove is formed in the pipe-shaped handle aluminum alloy profile, and an inlaid block is arranged on the pipe-shaped handle aluminum alloy profile; and inlaid feet are arranged on the inlaid block, and the inlaid block is inlaid in the inlaid grooves on the two sides of the frame body. Compared with the prior art, the magnesia inorganic decorative integral plate has the advantages that planes can form a plurality of decorative areas, and the position of a handle combined with analuminum alloy frame can adapt to the practical use. The invention further provides a flame retardant material. The adhesive property of a flame-retardant decorative plate prepared by the method canmeet the national standard, and the base material flame-retardant property can be achieved; the mechanical property of the base material is not affected, the release amount of formaldehyde is above E1level, and safety and environmental protection are achieved; and at the same time, the natural texture of wood is kept, and the decorative effect is good.

Owner:肖群伟

Ceramic tile color carving inkjet painting process and its products

InactiveCN103407317BStrong three-dimensional senseStrong aestheticsDecorative surface effectsPersonalizationMaterials science

The invention discloses a ceramic tile color carving inkjet process, which comprises the following steps: 1) pasting a protective film; 2) edge cutting; 3) tearing off the protective film; 4) engraving; 5) cleaning; A ceramic tile product obtained by implementing the process; the process steps provided by the invention are simple, not only easy to implement, but also high in printing efficiency, strong in personalization, high in flexibility, not limited by the background color of the ceramic tile, and the color, pattern and size can be adjusted Personalized customization can quickly make the surface of the tiles present a three-dimensional pattern concave pattern, and then spray the corresponding color spray paint on the pattern concave pattern according to personal preferences, making the pattern color of the tile more colorful, beautiful and artistic. Stronger, better decorative effect, allowing people to experience art and enjoy life in busy and boring life at the same time. The ceramic tile product provided by the invention has bright and diverse patterns, strong three-dimensional effect, elegant appearance and fashion, and is favorable for wide popularization and application.

Owner:陈权胜

A computerized embroidery machine towel embroidery head for tape embroidery

The invention discloses a computer embroider machine towel embroidering machine head of bobbin tape embroidery. The computer embroider machine towel embroidering machine head comprises an enclosure, a first drive mechanism, a second drive mechanism, a bobbin tape frame support assembly, a first needle bar sleeve, a transmission sleeve, a second needle bar sleeve, a locking ring, a needle bar, a needle tip sleeve assembly, a bobbin tape through hole, a positioning ring, a first gear, a second gear and an installation sleeve, wherein the first needle bar sleeve is provided with the first gear, the upper part of the first needle bar sleeve is provided with the transmission sleeve, the second needle bar sleeve is arranged in the transmission sleeve, the locking ring is arranged on the second needle bar sleeve, the locking ring is fixedly connected with the needle bar, the lower part of the first needle bar sleeve is provided with the needle tip sleeve assembly, the upper end of the installation sleeve is provided with the second gear, the installation sleeve is provided with the bobbin tape frame support assembly, the first drive mechanism is connected with the first gear and the second gear in a transmission manner, and the second drive mechanism is connected with the needle tip sleeve assembly and the locking ring in a transmission manner. According to the computer embroider machine towel embroidering machine head, the layering property and stereoscopic impression of patterns of a product can be improved, the color is rich, and the patterns are diversified.

Owner:诸暨市乐业机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com