Method for manufacturing sanitary ware shell combined with decorative pattern layer

A manufacturing method and pattern layer technology, which is applied in the field of sanitary ware, can solve problems such as easy product sags, easy peeling of the adhesive layer, and complicated production processes, and achieve remarkable decorative effects, colorful patterns, and simple production procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A method for manufacturing a sanitary ware shell compounded with a decorative pattern layer. First, a mixed ink is prepared, and the mixed ink is mixed according to the following chemical components (weight percentage):

[0012] PVC resin powder: 5%; dispersant (polyether modified silicone): 10%;

[0013] Colorant: 5%; Solvent (xylene): 80%.

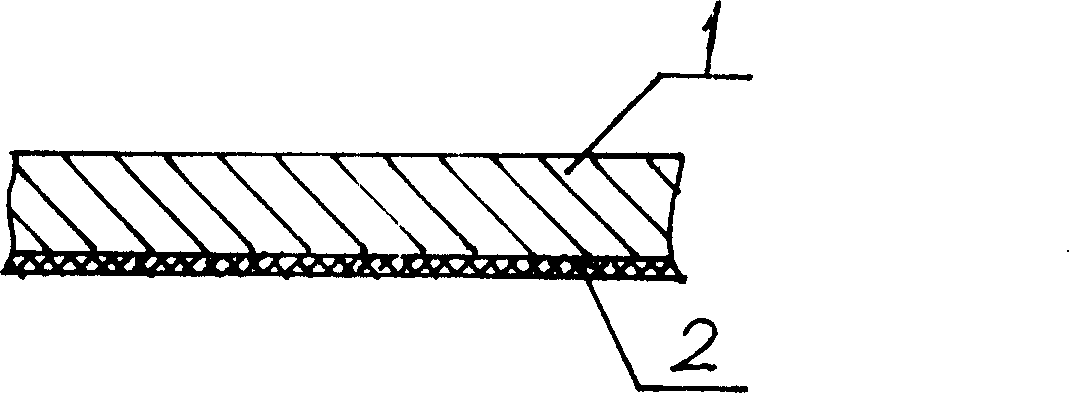

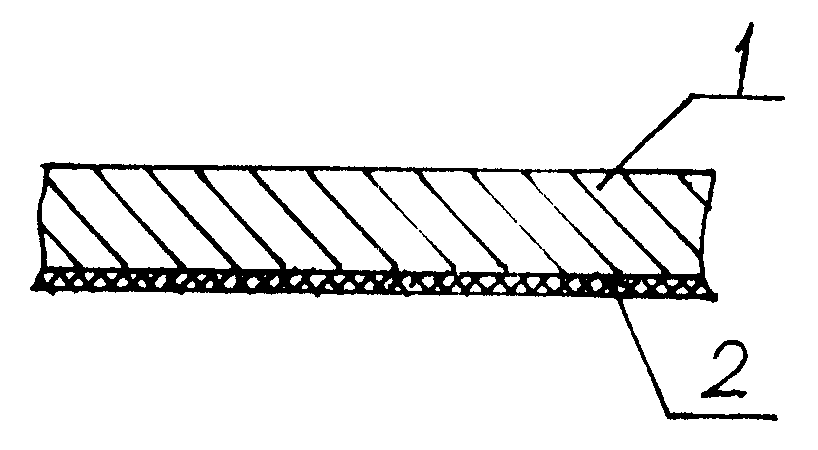

[0014] The mixed ink adjusted above is directly printed on one side of the transparent polymethyl methacrylate plate 1 with a conventional screen printing process or an inkjet process, see figure 1 shown, and then heated to 110°C and kept warm for 15 minutes to become a sanitary ware shell plate compounded with patterned pattern layer 2, and then put it on the required sanitary ware mold prepared in advance, printed with patterned patterns One side faces the front of the mould, and it is formed by sealing and evacuating the molding method. After natural cooling or blowing cooling, it becomes a sanitary ware shell with patterned l...

Embodiment 2

[0017] The chemical composition (percentage by weight) of mixed ink is:

[0018] PVC resin powder 17%; Dispersant (polyether modified silicone) 15%;

[0019] Colorant 18%; solvent (cyclohexanone) 50%.

[0020] The heating temperature in the thermoforming process is 150° C., the holding time is 8 minutes, and the rest of the process methods are the same as in Example 1.

Embodiment 3

[0022] The chemical composition (percentage by weight) of mixed ink is:

[0023] PVC resin powder 30%; dispersant (polyether modified silicone) 2%;

[0024] Colorant 40%; solvent (butyl acetate) 28%.

[0025] The heating temperature in the thermoforming process is 210° C., the holding time is 2 minutes, and the rest of the process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com