Anti-static ceramic tile and preparation method thereof

A ceramic brick, anti-static technology, applied in the field of ceramic materials, can solve the problem of unstable anti-static performance, and achieve the effect of strengthening the conductive performance, adding less amount, and hard material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

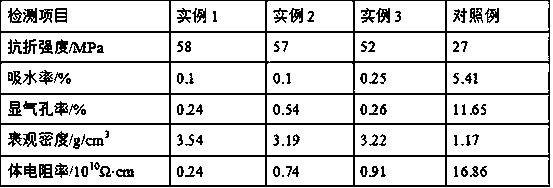

Examples

example 1

[0024] Take 1.0g graphene and add it to 120g mass fraction of 50% ethanol solution, disperse it with 300W ultrasonic wave for 30min, then add 12g mass fraction of 10% lanthanum nitrate solution dropwise at 1mL / min. Sodium hydroxide solution adjusts the pH to 10, and keeps warm at 60°C for 2 hours to obtain a mixed solution. Take 30g of kaolin, 30g of bentonite, 15g of hydrotalcite, 200g of fly ash, and 50g of the mixed solution into a ball mill, and ball mill at 200r / min 30min, then add 2g of hydroxymethyl cellulose, 1g of magnesium sulfate and 2g of calcium stearate, continue ball milling for 1h, discharge the material, and put it into a mold and press it into shape to obtain ceramic tiles. Take 20g of calcium carbonate, 30g of alumina, 40g Cordierite, 4g potassium feldspar, 30g silicon dioxide, 2g boron oxide, 2.5g potassium oxide, 1.2g sodium oxide, 10g tin oxide, 8g antimony trioxide, 3g vanadium pentoxide, 4g zinc oxide, put into ball mill Ball mill in a pot for 10 hours....

example 2

[0026] Take 1.1g of graphene and add it to 135g of 50% ethanol solution by mass fraction, disperse it with 300W ultrasonic wave for 35min, then add dropwise 16g of 10% lanthanum nitrate solution by mass fraction at 1mL / min. Sodium hydroxide solution adjusts the pH to 10, and keeps warm at 65°C for 2 hours to obtain a mixed solution. Take 40g of kaolin, 40g of bentonite, 18g of hydrotalcite, 250g of fly ash, and 55g of the mixed solution into a ball mill, and ball mill at 250r / min. 40min, then add 2g of hydroxymethyl cellulose, 1g of magnesium sulfate and 2g of calcium stearate, continue ball milling for 1h, discharge the material, put it into a mold and press it into shape, and get a ceramic brick. Take 22g of calcium carbonate, 32g of alumina, 42g Cordierite, 4g potassium feldspar, 35g silicon dioxide, 2g boron oxide, 2.8g potassium oxide, 1.3g sodium oxide, 13g tin oxide, 9g antimony trioxide, 3g vanadium pentoxide, 4g zinc oxide, put into ball mill Ball mill in a tank for 1...

example 3

[0028] Take 1.2g graphene and add it to 150g mass fraction of 50% ethanol solution, disperse it with 300W ultrasonic wave for 40min, then add dropwise 20g mass fraction of 10% lanthanum nitrate solution at 2mL / min. Sodium hydroxide solution adjusts the pH to 11, and keeps warm at 70°C for 3 hours to obtain a mixed solution. Take 50g of kaolin, 50g of bentonite, 20g of hydrotalcite, 300g of fly ash, and 60g of the mixed solution into a ball mill, and ball mill at 300r / min 50min, then add 3g of hydroxymethyl cellulose, 2g of magnesium sulfate and 3g of calcium stearate, continue ball milling for 2h, discharge, and put into a mold for pressing to form ceramic tiles. Take 25g of calcium carbonate, 35g of alumina, 45g Cordierite, 5g potassium feldspar, 40g silicon dioxide, 3g boron oxide, 3.0g potassium oxide, 1.5g sodium oxide, 16g tin oxide, 10g antimony trioxide, 4g vanadium pentoxide, 5g zinc oxide, put into ball mill Ball mill in a tank for 12 hours. After ball milling, add 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com