Multi-edge shear

A technology of shearing machines and slide rails, which is applied in the direction of shearing devices, shearing machine equipment, and knives used in shearing machine devices, etc., which can solve the problem of difficult matching of the arrangement accuracy of the gripper jaws on both sides of the arrangement accuracy and waste Material sawing process and other issues, to achieve the effect of simple structure, simplified shape, low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

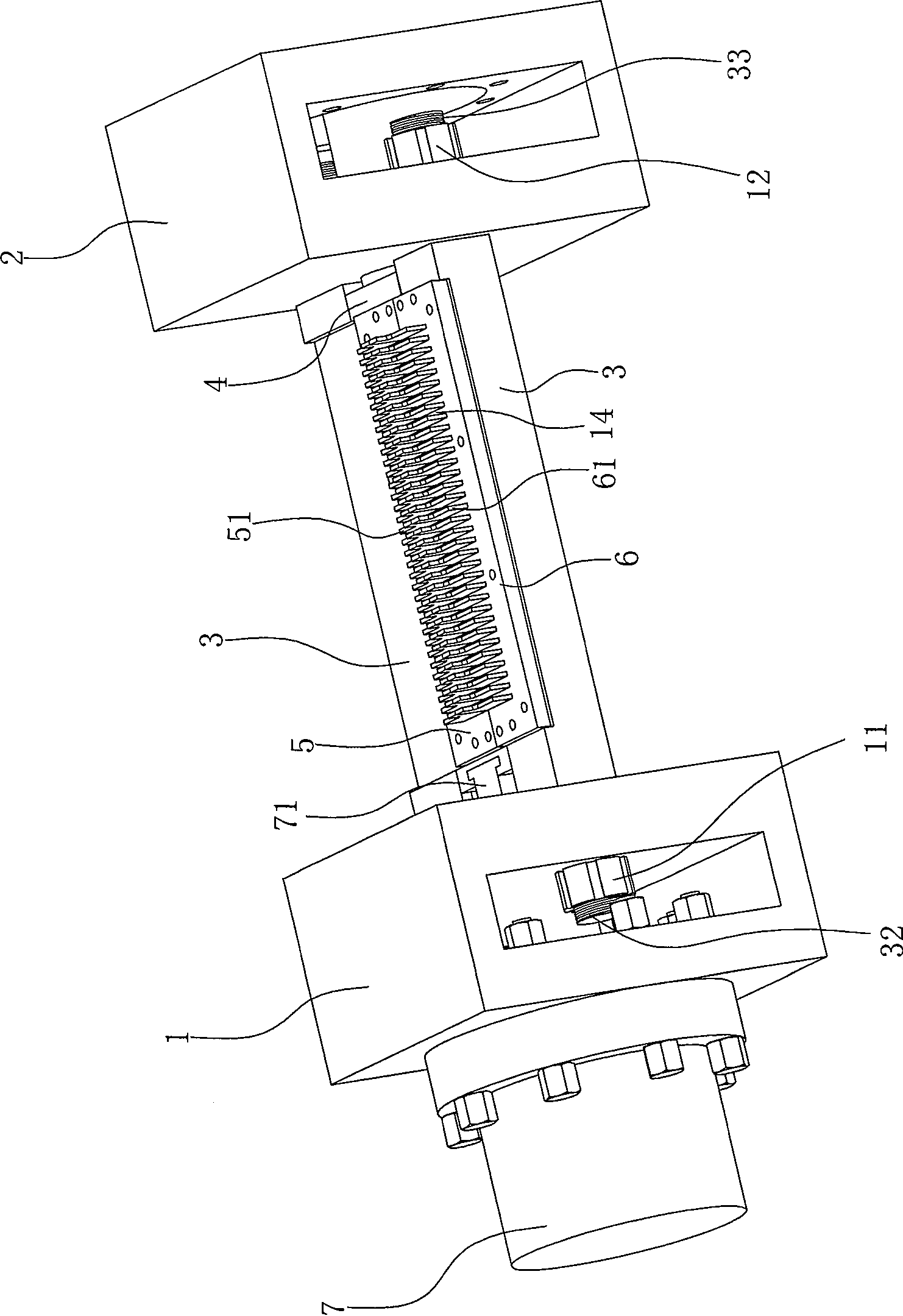

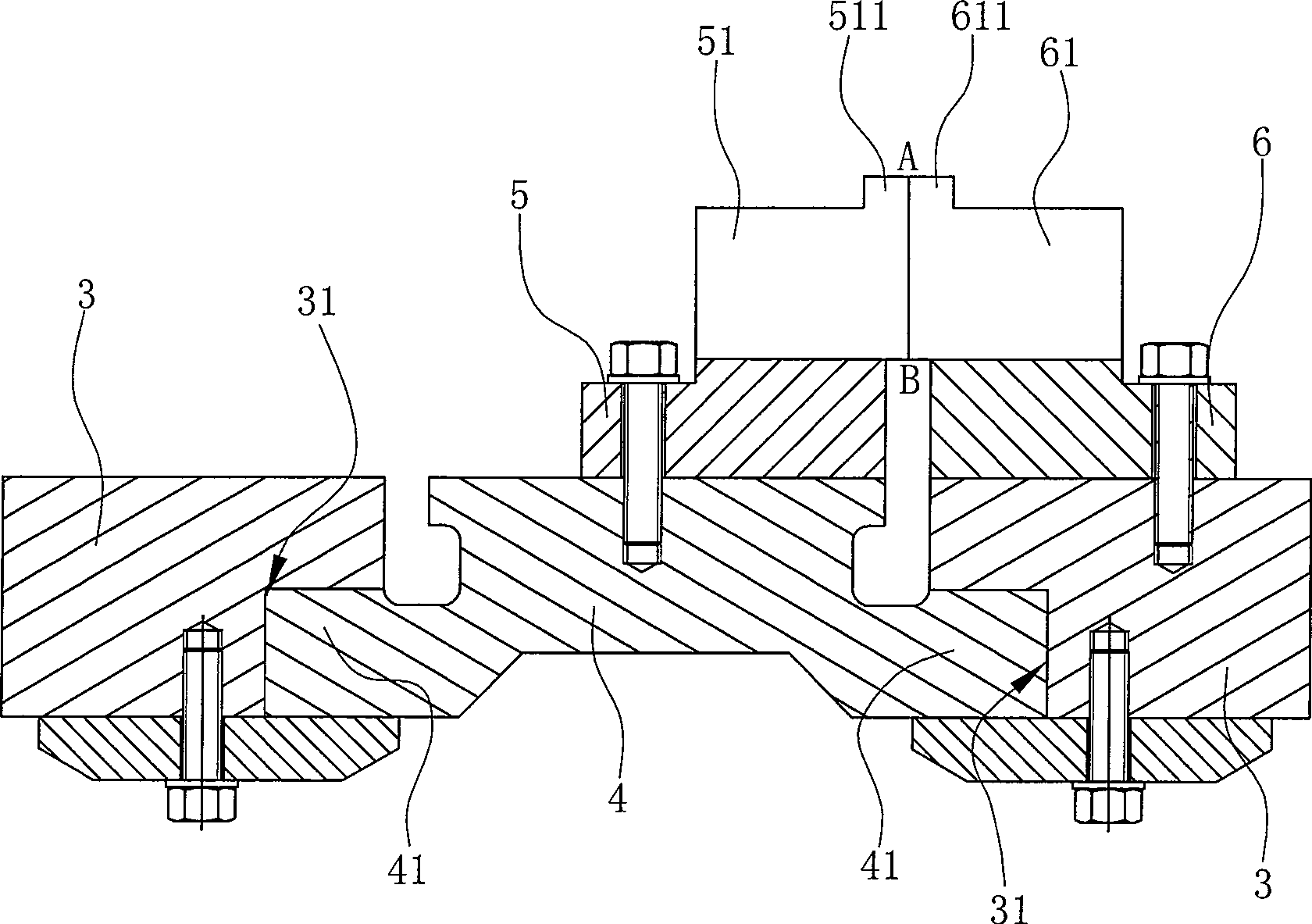

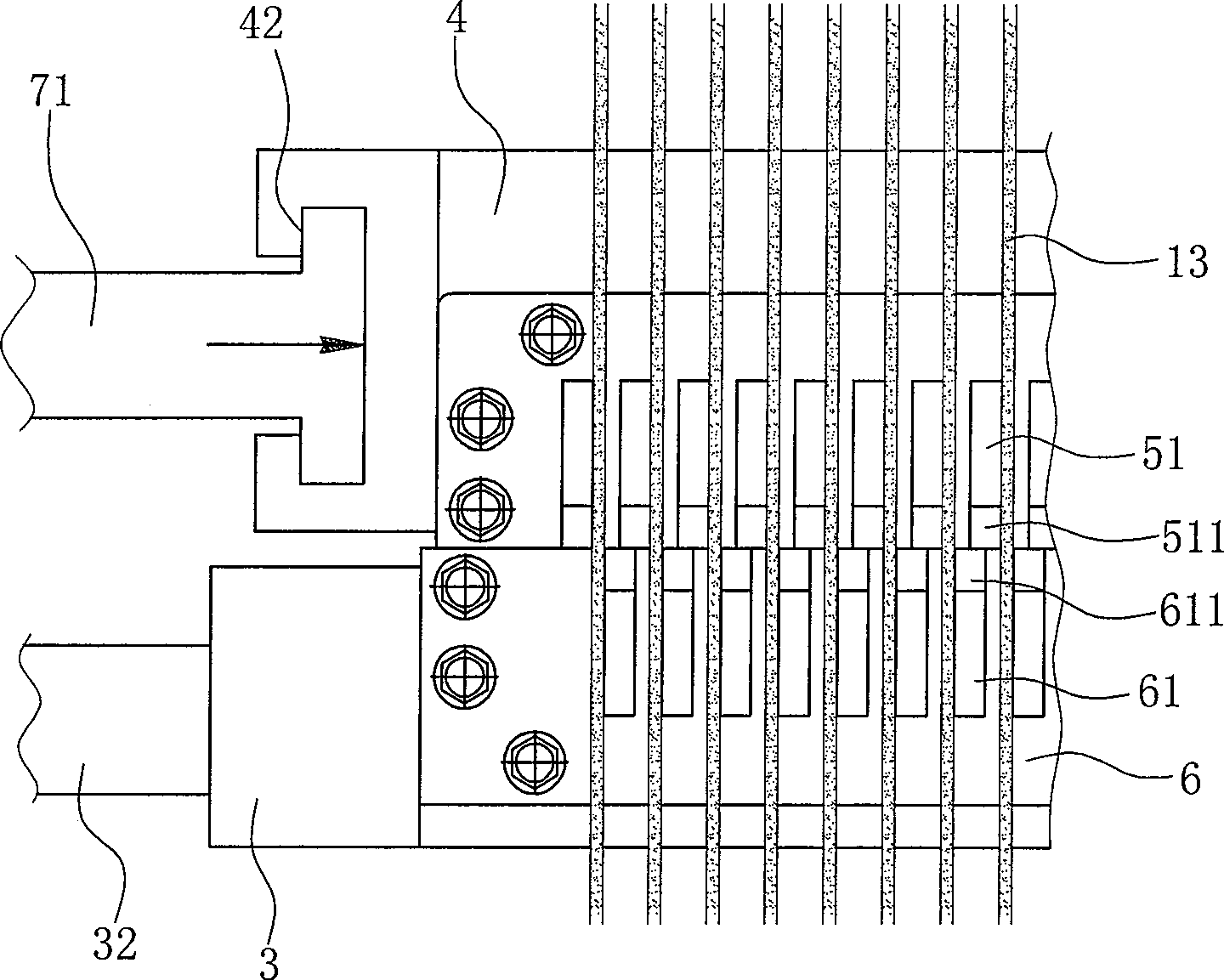

[0020] Such as Figure 1~4 Shown is a preferred embodiment of the present invention.

[0021] A multi-bladed shearing machine, comprising a front wall panel 1 and a rear wall panel 2 spaced apart from each other, the front wall panel 1 and the rear wall panel 2 are directly fixed on the ground, and between the front wall panel 1 and the rear wall panel 2 There are two slide rails 3, the head and tail ends of the two slide rails 3 are respectively fixed to the front wall panel 1 and the rear wall panel 2, the two slide rails 3 are arranged in parallel and spaced apart, and the two ends of each slide rail 3 are threaded. Parts 32, 33, the threaded connection part 32 at one end of the slide rail 3 passes through the inner wall of the front wall panel 1 and is locked with a nut 11, and the threaded connection part 33 at the other end of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com