Polypropylene composite plastic coated steel plate

A technology of plastic steel plate and polypropylene, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of losing the texture of metal materials, short service life, covering metallic luster, etc., and achieve rich and colorful patterns , easy to operate, increase the effect of metallic luster and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

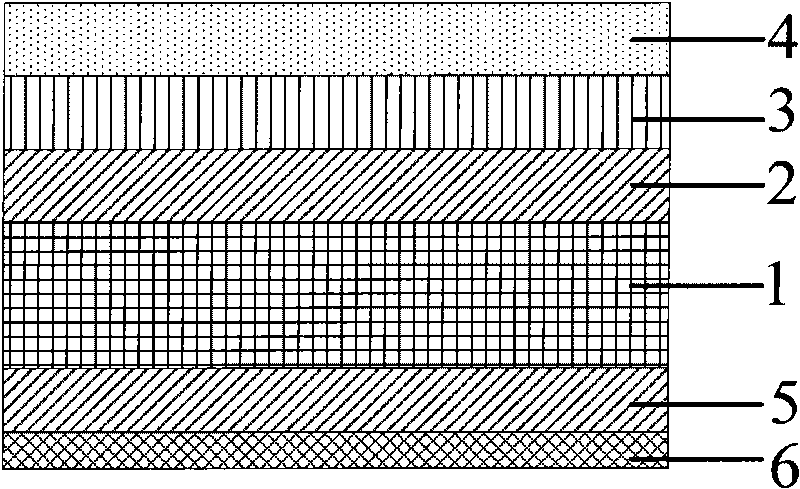

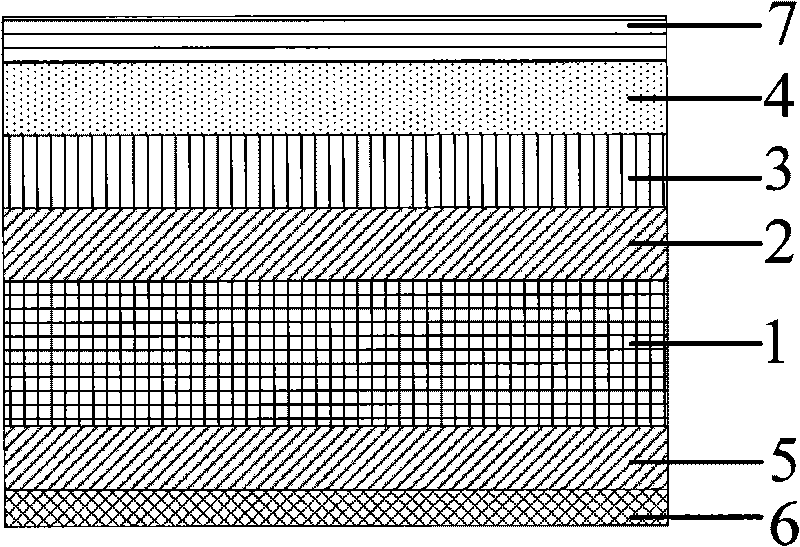

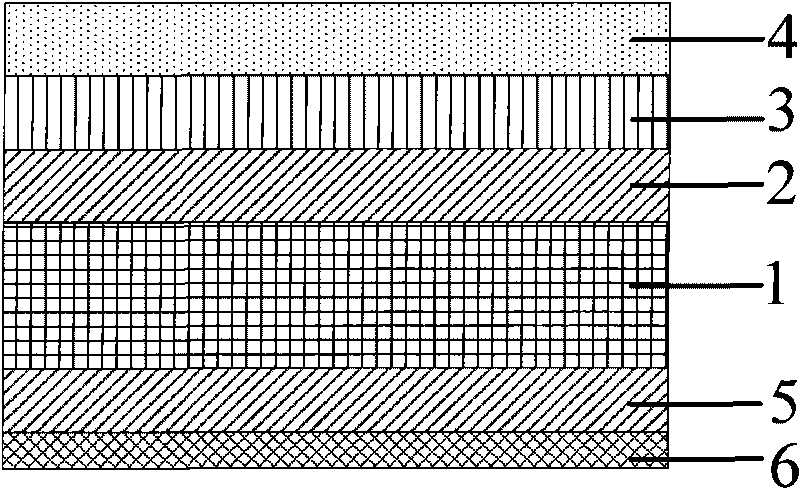

[0016] Such as figure 1 As shown in the polypropylene composite steel plate, the base material is a steel plate, a passivation layer 2 is coated on the front of the steel plate 1, and an adhesive layer 3 is coated on the surface of the passivation layer 2, and the adhesive layer 3 is bonded to a polypropylene (PP) film Layer 4, the polypropylene film layer 4 is bonded to the steel plate; in addition, a passivation layer 5 is coated on the back of the steel plate 1, and a back paint layer 6 is coated on the passivation layer 5.

[0017] Such as figure 2 , on the basis of the above structure, the polypropylene film layer 4 is also covered with a protective film layer 7 .

[0018] The steel plate of the present invention can be a cold-rolled thin plate, an aluminum plate, or a galvanized plate, and the passivation layer is used for processing the steel plate to ensure the fastness of the adhesive layer; After the propylene film layer can play the role of decoration, protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com