Preparation technology of enamel composite board

A composite plate and preparation technology, which is applied to clay products, other household utensils, household utensils, etc., can solve the problems of fine patterns, lack of magnificence, specifications, use place restrictions, and monotonous colors of porcelain tiles, and achieve rich patterns and colors. Eliminate the effects of surface dirt absorption and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

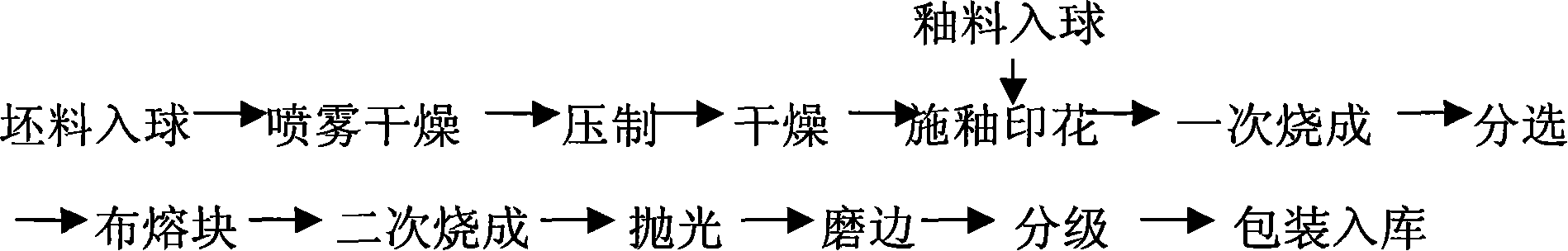

[0010] 1, the general technological process of the present invention is as follows:

[0011]

[0012] 2, the main process characteristics of the present invention are as follows:

[0013] a. Glaze printing is to use screen or roller printing to form a pattern on the green body, and then fire at a firing temperature of 1180-1230°C to form a printing layer;

[0014] b. The transparent frit is uniformly distributed by means of funnel blanking and roller compaction, with a thickness of 3mm-5mm;

[0015] c. After the printing layer of the transparent frit cloth, a fixative should be applied to fix the frit. Water in the fixative: viscosity adjusting agent = 99:1, and the amount of the fixative is 180-240g / m 2 .

[0016] 3. Process analysis

[0017] (1) Chemical composition of green body

[0018] SiO 2

Al 2 o 3

K 2 O+Na 2 o

CaO+MgO

Fe 2 o 3

IL

60~70%

18~22%

5~8%

<2%

<0.5%

<4%

[0019] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com