A mold structure for solidification and molding of carbon fiber automobile wheel hub blanks and a method for making products with the mold

A technology for solidification and molding of automobile wheels, which is applied to the mold structure for solidification and molding of carbon fiber automobile wheel blanks and the field of products made with the molds, which can solve the problem of insufficient product strength and sealing effect, increase the production process of rims and Production time, increase product cost and other issues, to achieve the effect of rich colors and patterns, improve product quality level, and reduce driving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

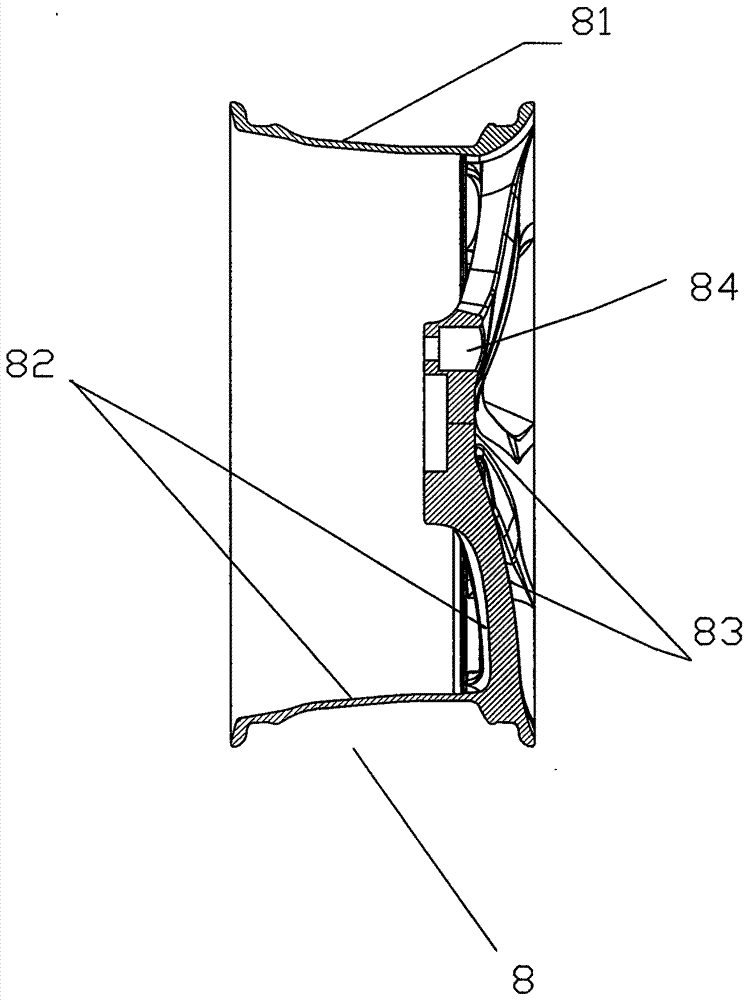

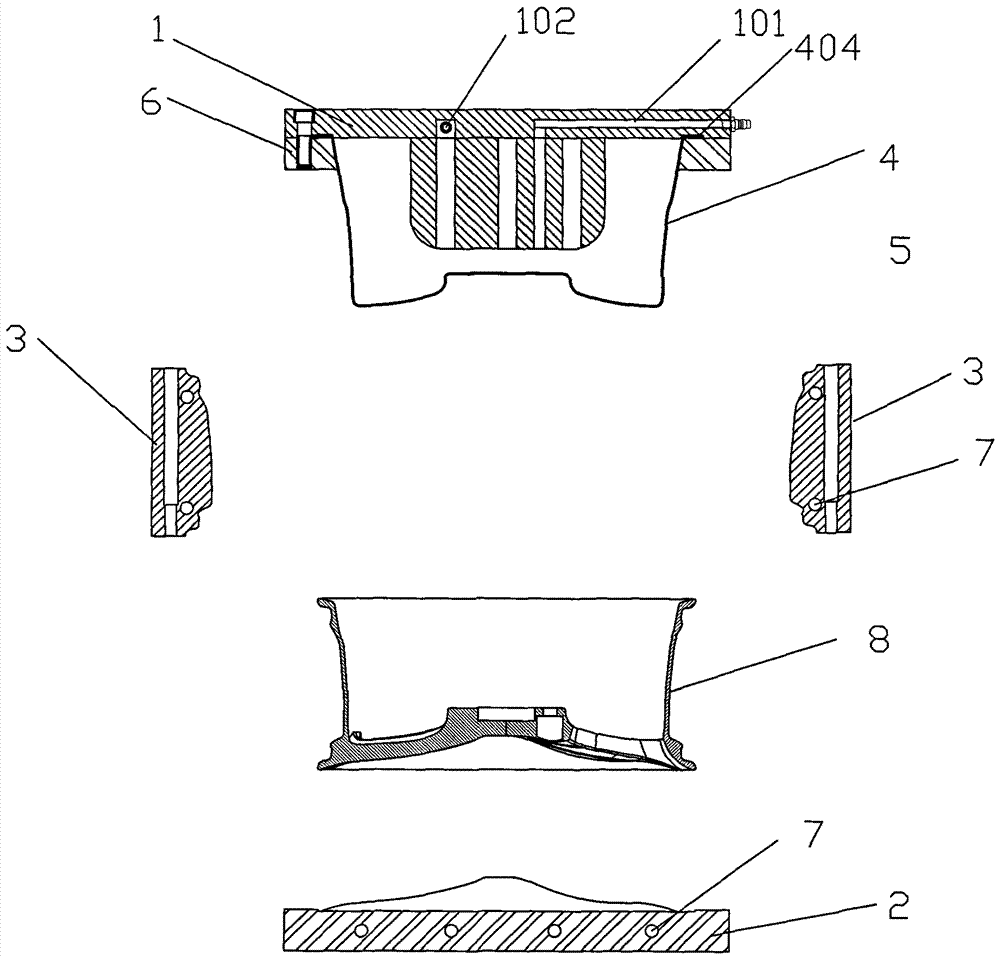

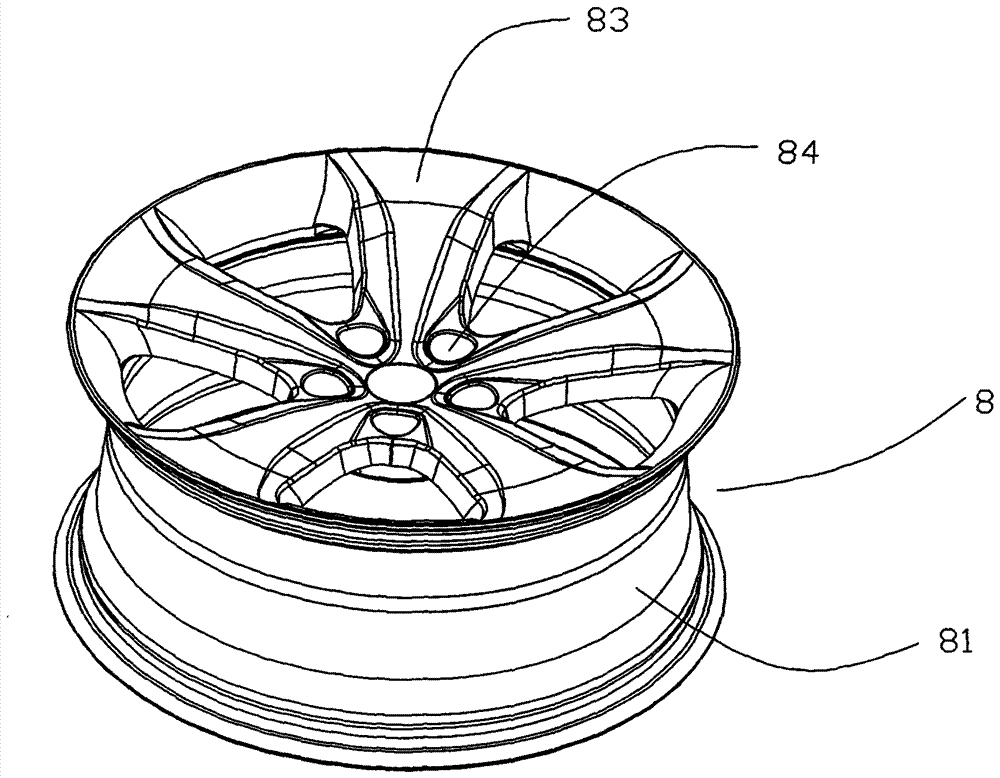

[0035] The present invention is a kind of mold structure that is used for solidification molding of carbon fiber automobile wheel hub blank product, and it comprises upper mandrel 1, lower mandrel 2 and two side molds 3 of the outer ring 81 shape of solidification molding carbon fiber automobile wheel hub blank product, such as figure 2 shown;

[0036] The upper mandrel 1 is fixed with an inner air bag 4 in the shape of the inner cavity 82 of the solidified and formed wheel hub. The inner air bag 4 is made of silica gel. The inner cavity 82 of the blank, the inner air bag 4 and the upper core mold 1 are provided with a flange 404, and the inner air bag 4 locks the flange 404 on the upper mandrel 1 through the pressure plate 6. When opening and closing the mold The inner air bag 4 can move together with the upper mandrel 1; the upper mandrel 1 is also provided with two steam passages, one is a steam passage 101 for heating and pressurizing the inner air bag 4, and the other is...

Embodiment 2

[0047] Embodiment two: if Image 6 , Figure 7 Shown, differs from embodiment one mold structure in that:

[0048] An outer air bag 5 is also sandwiched between the hub blank 8, the upper core mold pressing plate 6, and the inner air bag 4; the outer air bag 5 is made of silica gel, and a flange 501 is provided on the mating surface of it and the pressing plate 6, and at the same time The splint 6 is provided with a concave annular surface 601 that matches the shape of the flange 501 and can accommodate the flange 501 at the corresponding position. When the mold is closed, the outer air bag 5 is sandwiched by the inner air bag 4, the pressure plate 6 and the wheel hub through the flange 501. Between the blanks 8, the shape of the inner 4 and outer 5 airbags is consistent with the shape of the inner cavity of the hub, and the size of the inner airbag 4 is slightly smaller than the size of the outer airbag 5, so that when the mold is closed, the inner airbag 4 will not be in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com