Mechanical digital printing machine

A printing machine and digital technology, applied in the field of mechanical digital printing machine, can solve the problems of high sewage treatment cost, high pollutant discharge, large amount of dye waste, etc., and achieve colorful patterns, high printing quality and high coloring rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

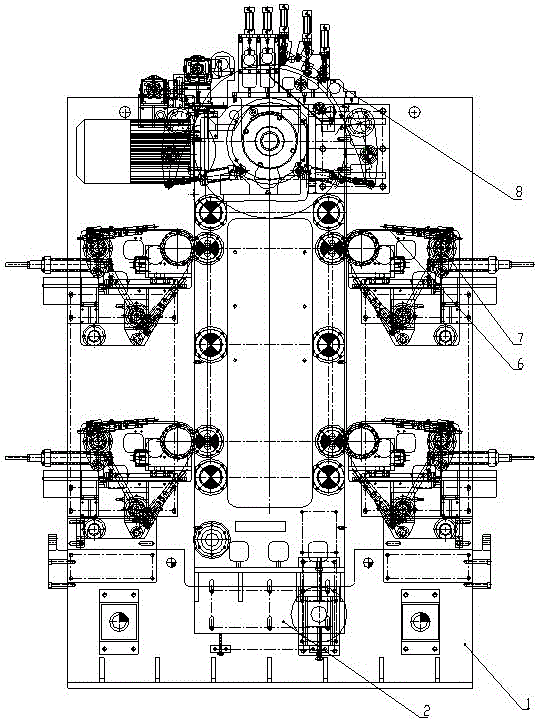

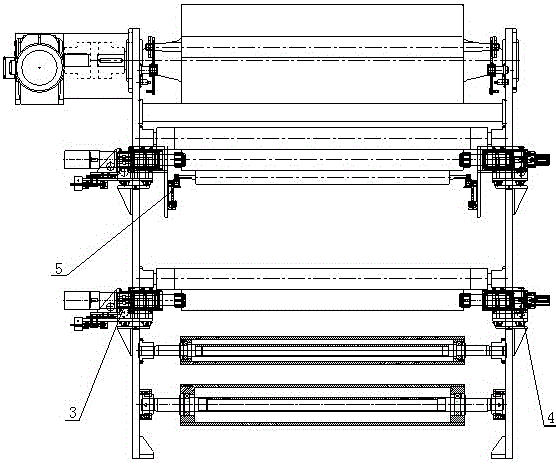

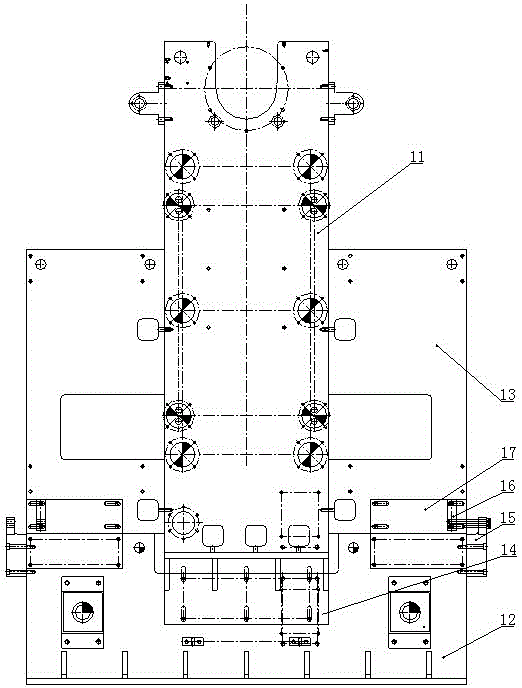

Image

Examples

Embodiment Construction

[0048] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0049] like Figure 14 As shown, the mechanical digital printing machine of the present invention is sequentially provided with an opening cloth feeding device 111, a centering and deviation correcting device 112, a bristle box 113, a three-roll padding machine 114, a roller drying device 115, a plasma processing device 116, Four-color printing machine 117, infrared drying device 118, lower layer guide belt 119, two-color printing machine 120, upper layer guide belt oven 121, cloth drop device 122, open-width cloth feeding device 111 to flatten the fabric and send it to centering and deviation correction The device 112 carries out the centering f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com