Multifunctional environment-friendly color paste

A multi-functional and environmentally friendly technology, applied in the field of coatings, it can solve the problems of decreased water resistance of the paint film, coloration rate, and a large amount of foam, and achieve the effect of wide application range, high water resistance of the paint film, and high coloring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

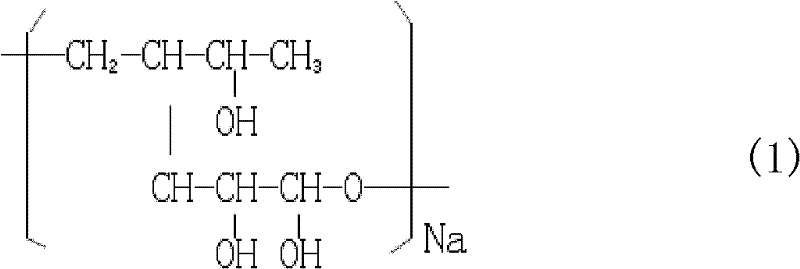

Method used

Image

Examples

Embodiment 3

[0019] Color paste (embodiment 3) 5 grams

[0020] Screen printing adhesive 15g

[0021] Helping pulp A 80g

[0022] After mixing according to the above ratio, apply and scrape on the cloth sample by screen printing method, and dry it at 130°C for 5 minutes. The measured results are as follows:

[0023] Shade

color power

Washing fastness

Dry rubbing fastness

Wet rub fastness

Level dyeing

approximately

100%

level 4

Level 3-4

level 4

160℃

excellent

[0024] The above test results are higher than the indicators of the original printing paste.

[0025] 2. Architectural paint coloring:

[0026] Color paste (embodiment 1) 0.5 gram

[0027] Paint white paste 99.5 grams

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com