Manufacturing method of cell

A manufacturing method and cell technology, which is applied in secondary battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as pole piece misalignment in the battery core, so as to improve flatness and prevent pole piece misalignment Layers, the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

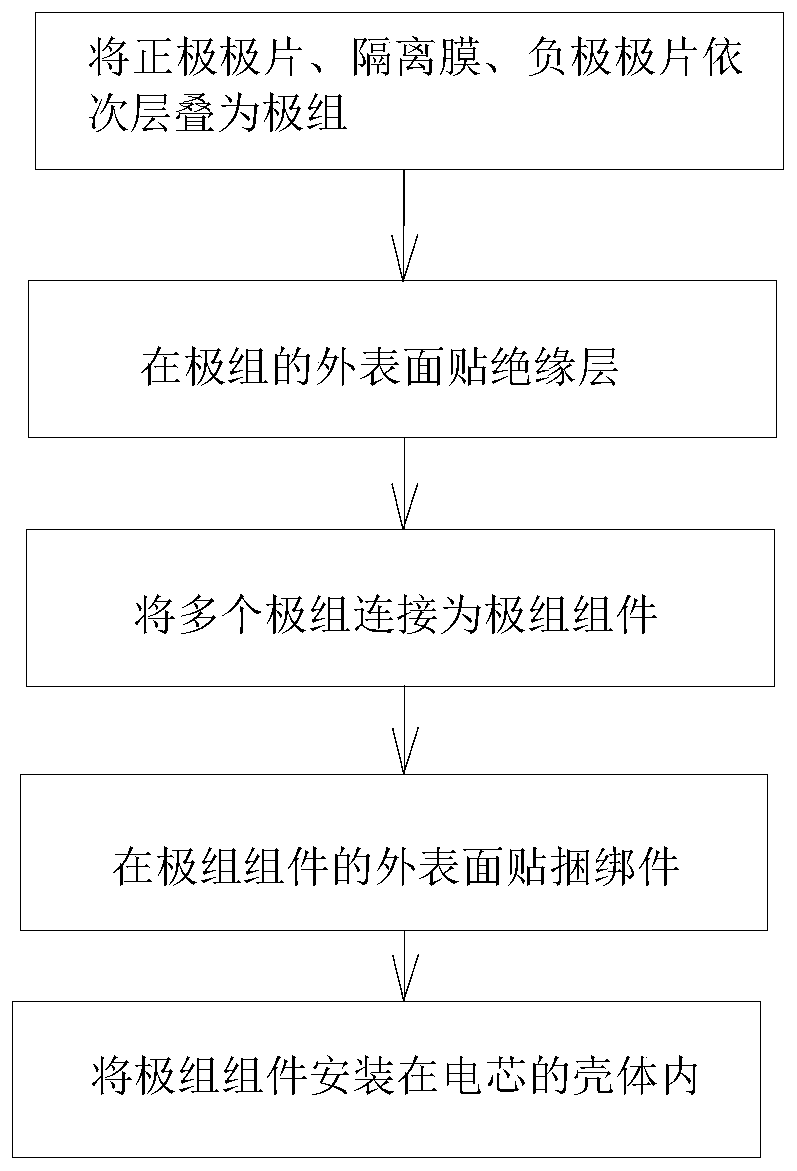

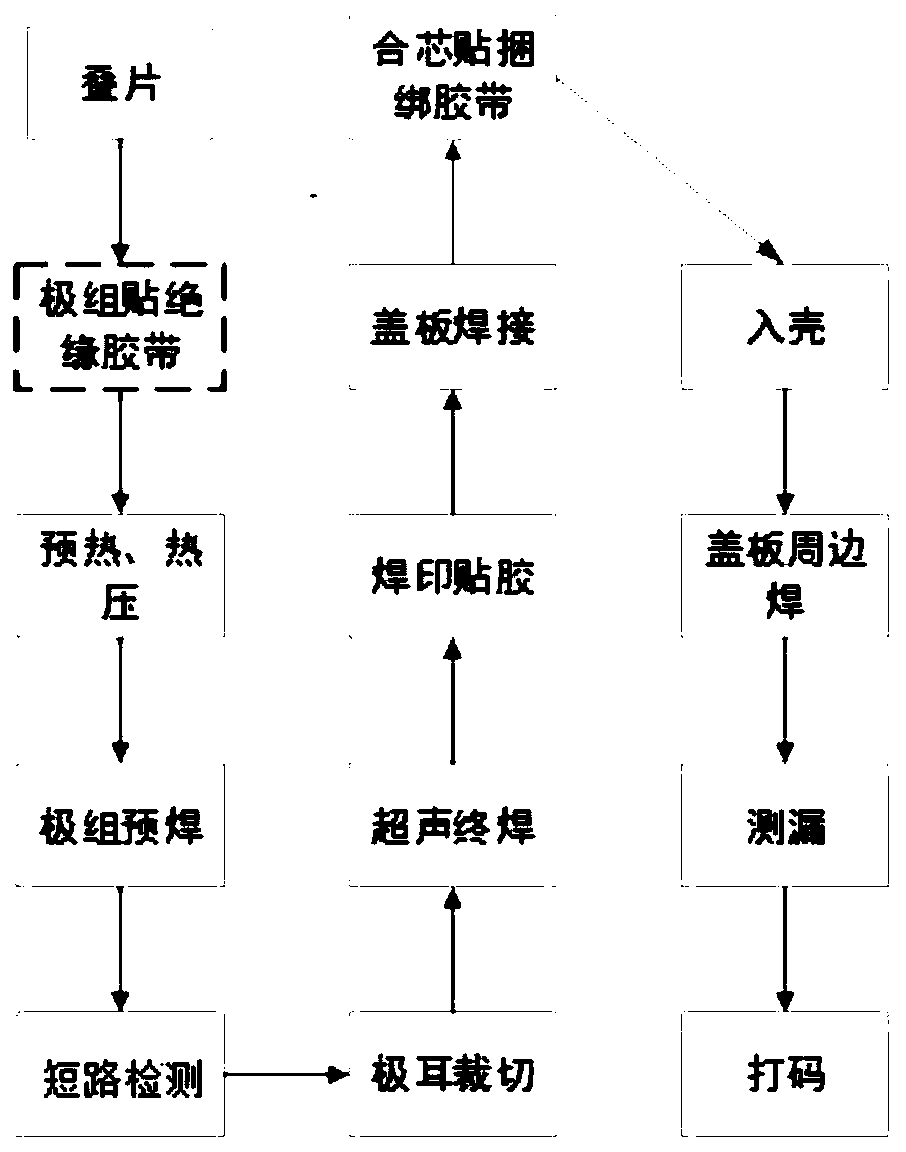

Method used

Image

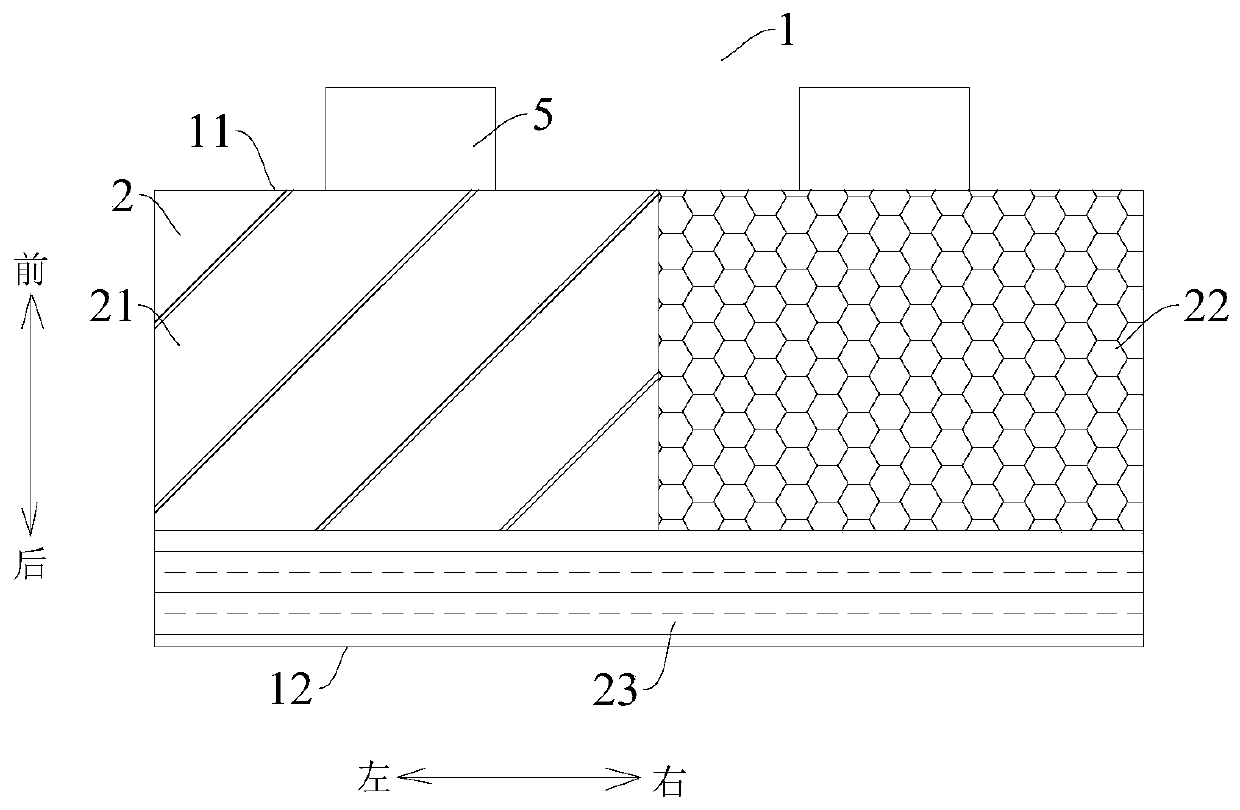

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] When using the existing manufacturing method to produce batteries, the electrode group will be hot-pressed and shaped, and the electrode group will be preheated for 15-30 minutes before hot pressing to increase the internal and external temperature of the electrode group to soften the organic adhesive polymer coating Particles are then hot-pressed under a high pressure of 2-3T, so that the separator and the pole piece are fully bonded, but because the organic binder polymer coating particles have been cured, even under hot-pressing conditions, they cannot achieve a high degree of bonding. Good bonding effect, there is still the occurrence of dislocation between the separator and the pole piece. In this case, the adhesion between the coating and the pole piece is weakened, and the coating force that inh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com