Patents

Literature

41results about How to "Give full play to wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

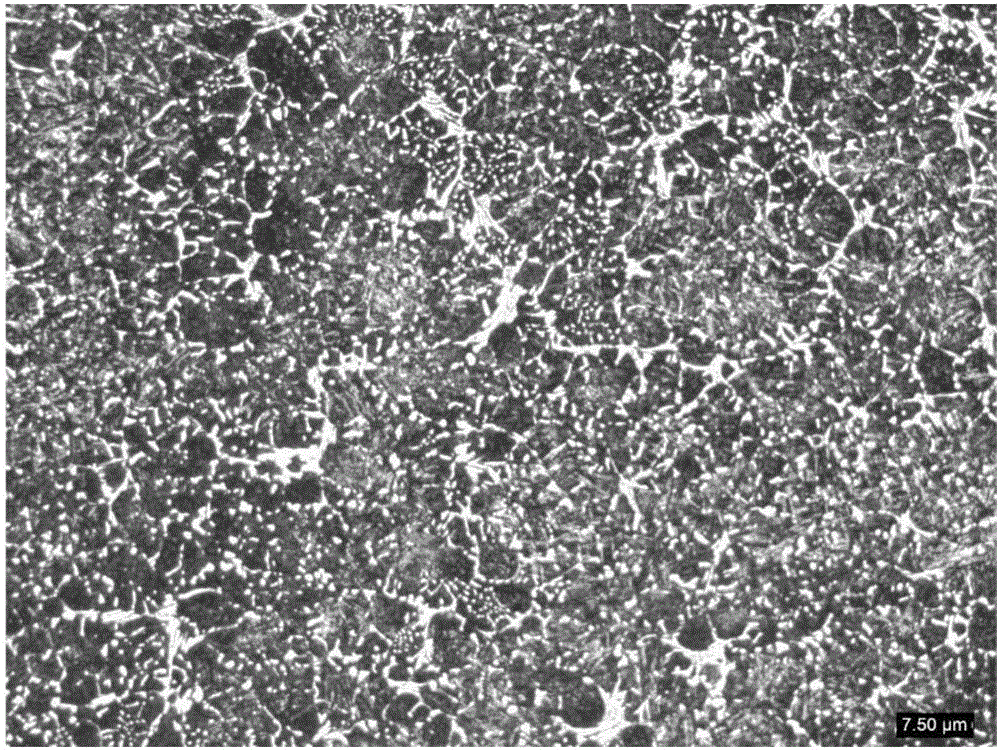

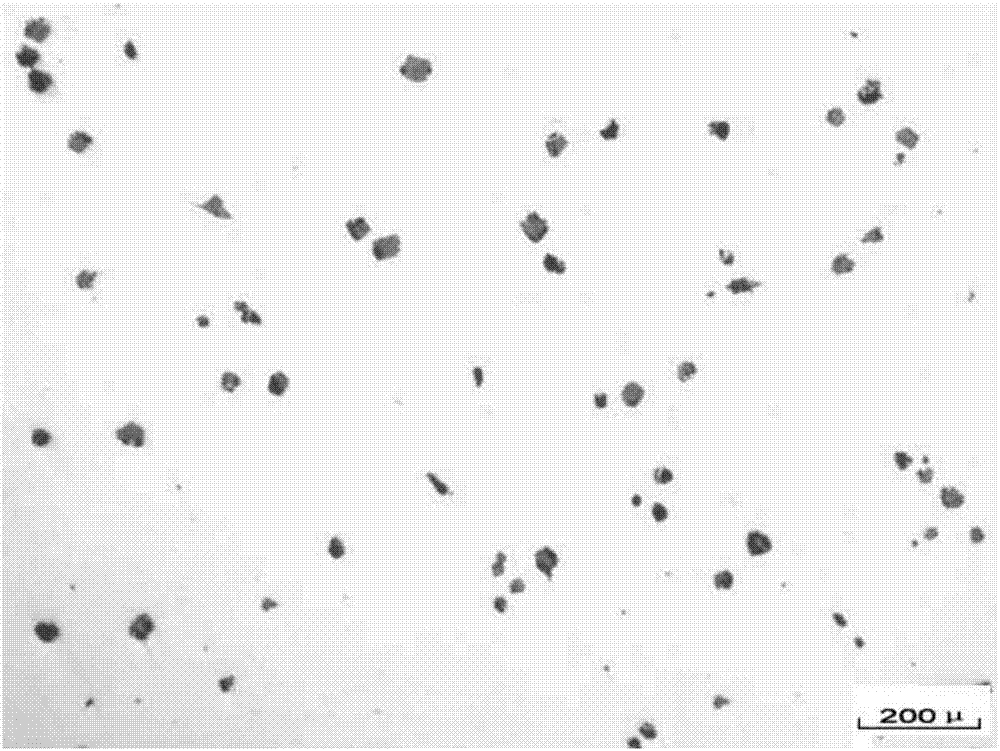

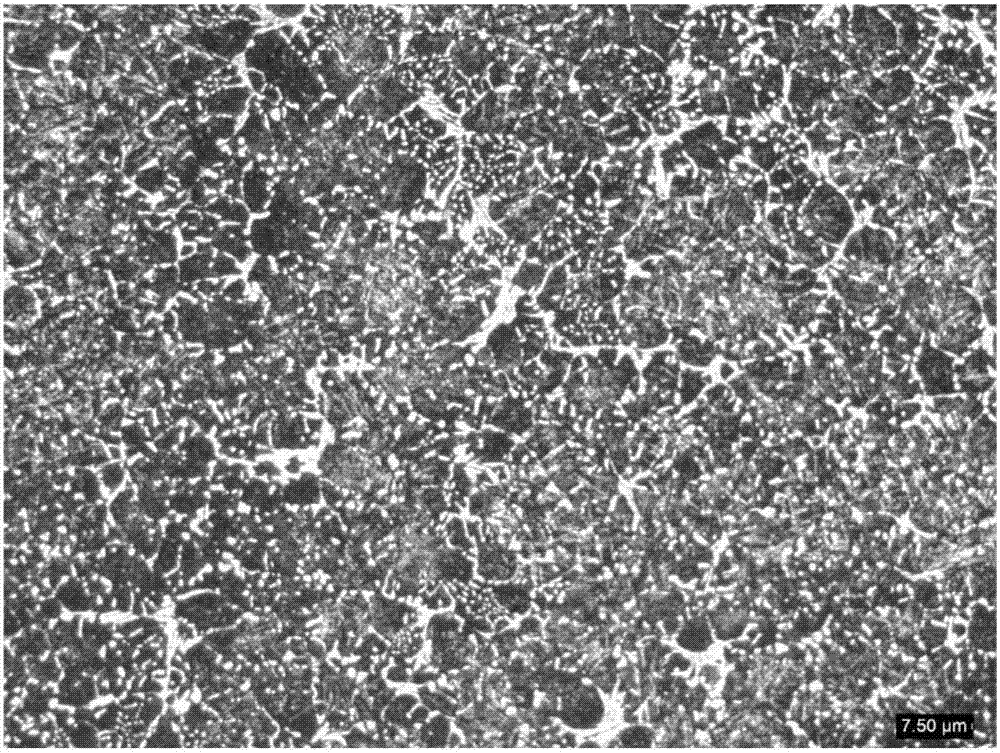

Graphite-containing high-speed steel roller

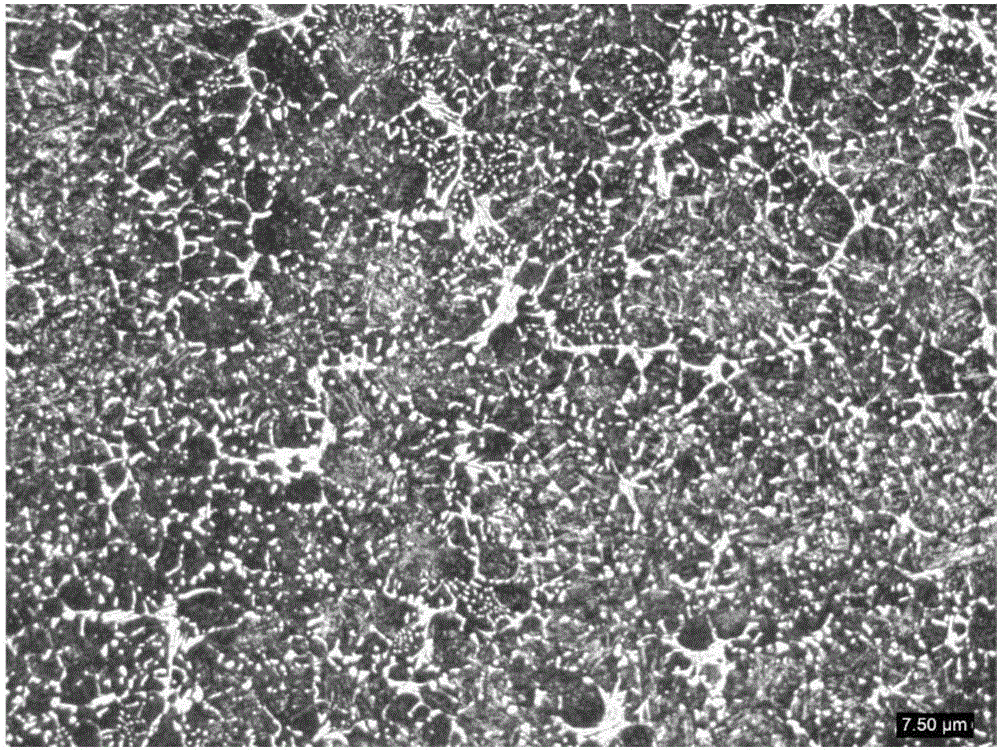

ActiveCN106086705AAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideSurface brightness

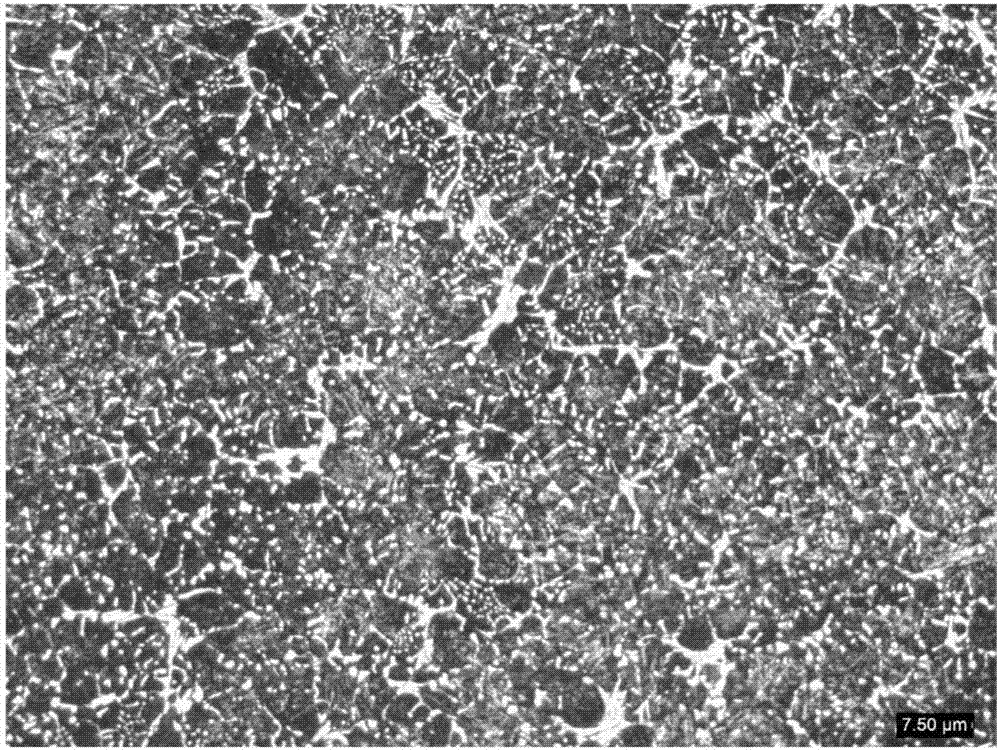

The invention discloses a graphite-containing high-speed steel roller and belongs to the field of mechanical casting. B and N chemical elements are introduced into traditional high-speed steel components; MC-type and / or M<2>C-type, and dot-shaped and / or blocky highly-hard alloy carbides, nitrides and borides with the total area percentage being 20-35% are dispersed and distributed in a matrix structure of a working layer; the two steps that firstly, carbide, nitride and boride modification treatment is performed, and then graphite modification inoculation treatment is performed are adopted, graphite is separated out of an original structure, therefore, the high-speed steel roller maintains the unique advantage of high temperature abrasion resistance of traditional high-speed steel, meanwhile, the problem of a large friction coefficient of original traditional high-speed steel rollers is solved, the abrasion resistance of high-speed steel is fully achieved, the lubrication effect between the roller and a workpiece during rolling is achieved, and therefore, occurrence of the steel-adhesion phenomenon is prevented; and besides, by means of heat-conducting property and lubricating property of graphite, the defects of thermal impact, hot cracking sensitivity, steel adhesion tendency and surface texturing tendency of the high-speed steel rollers can be overcome, and especially during usage for a finished product rack, the surface brightness of rolled products is improved remarkably.

Owner:SANXIN HEAVY IND MACHINERY

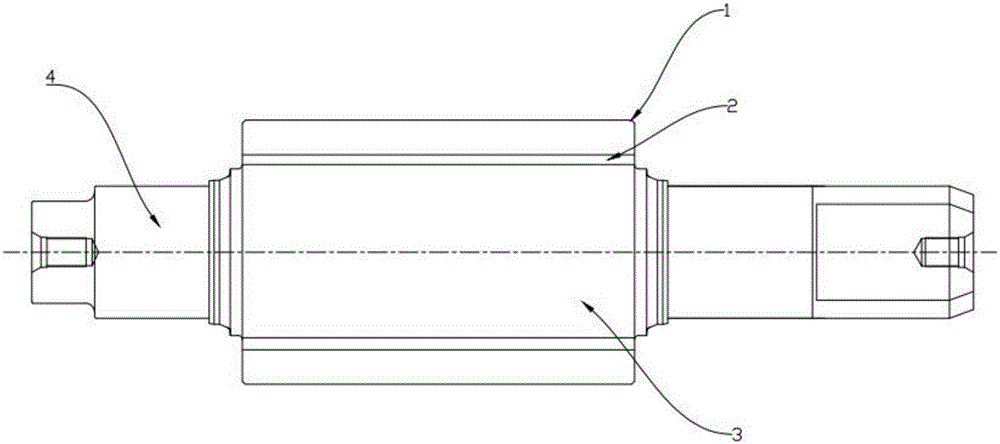

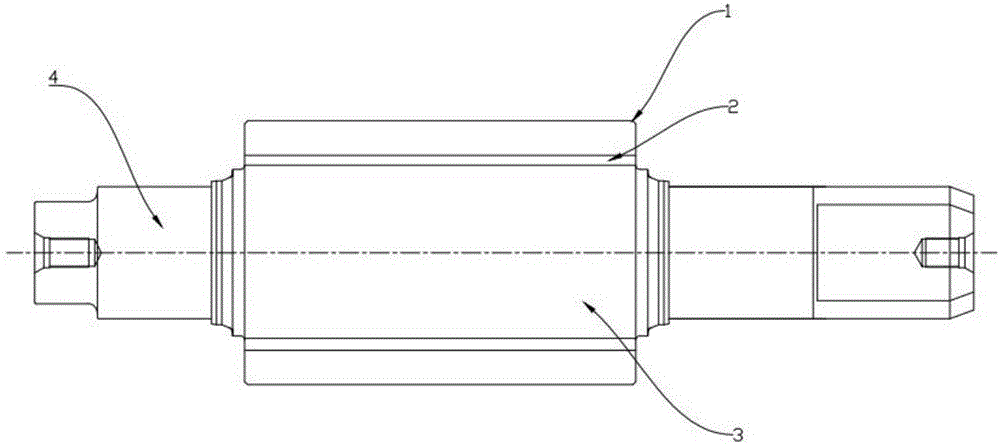

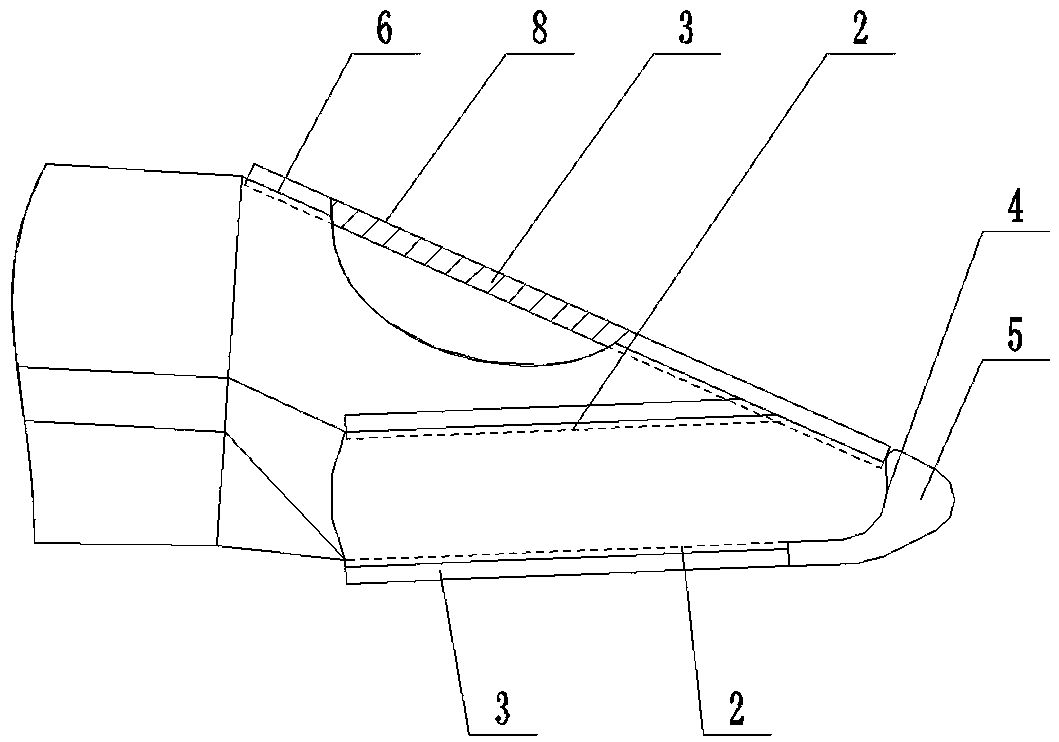

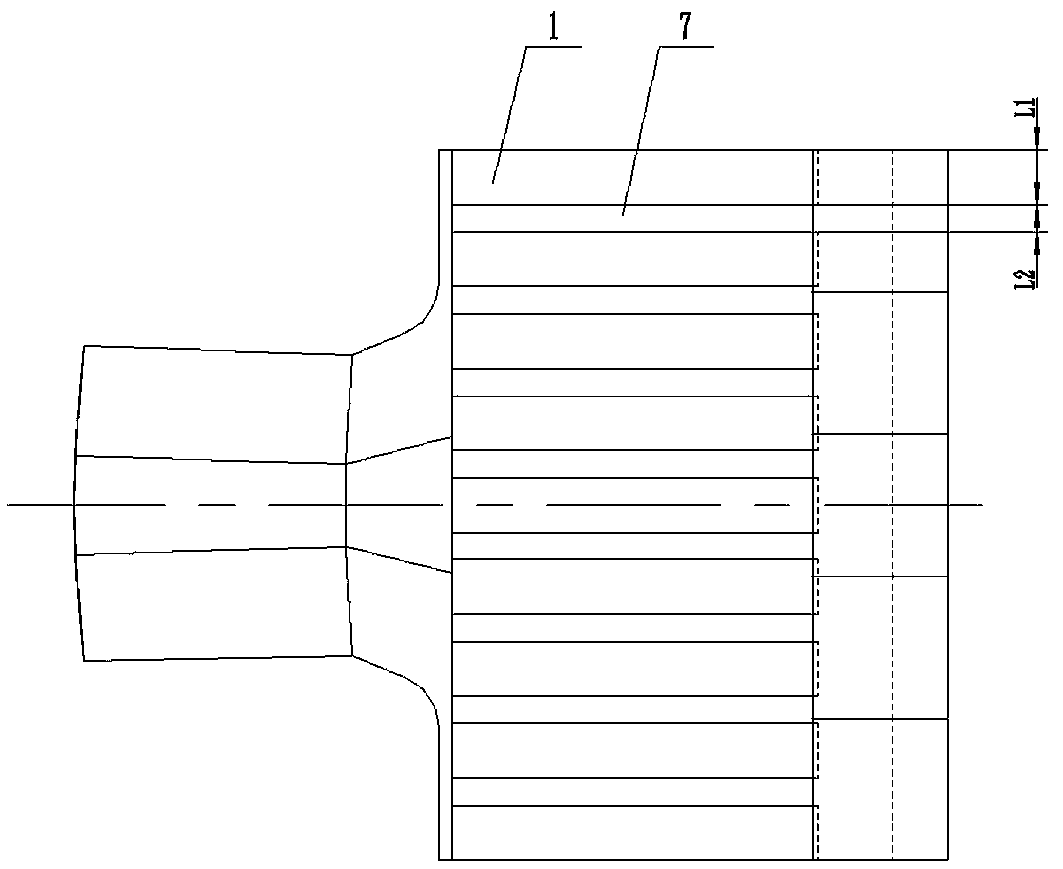

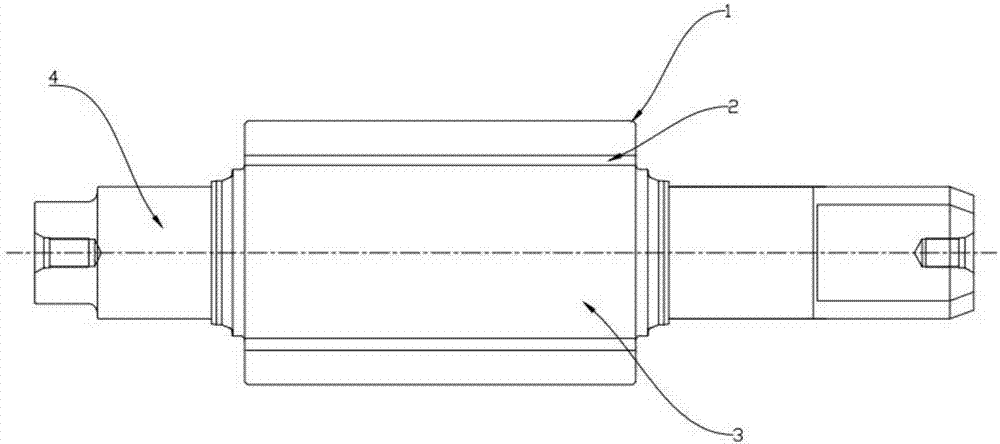

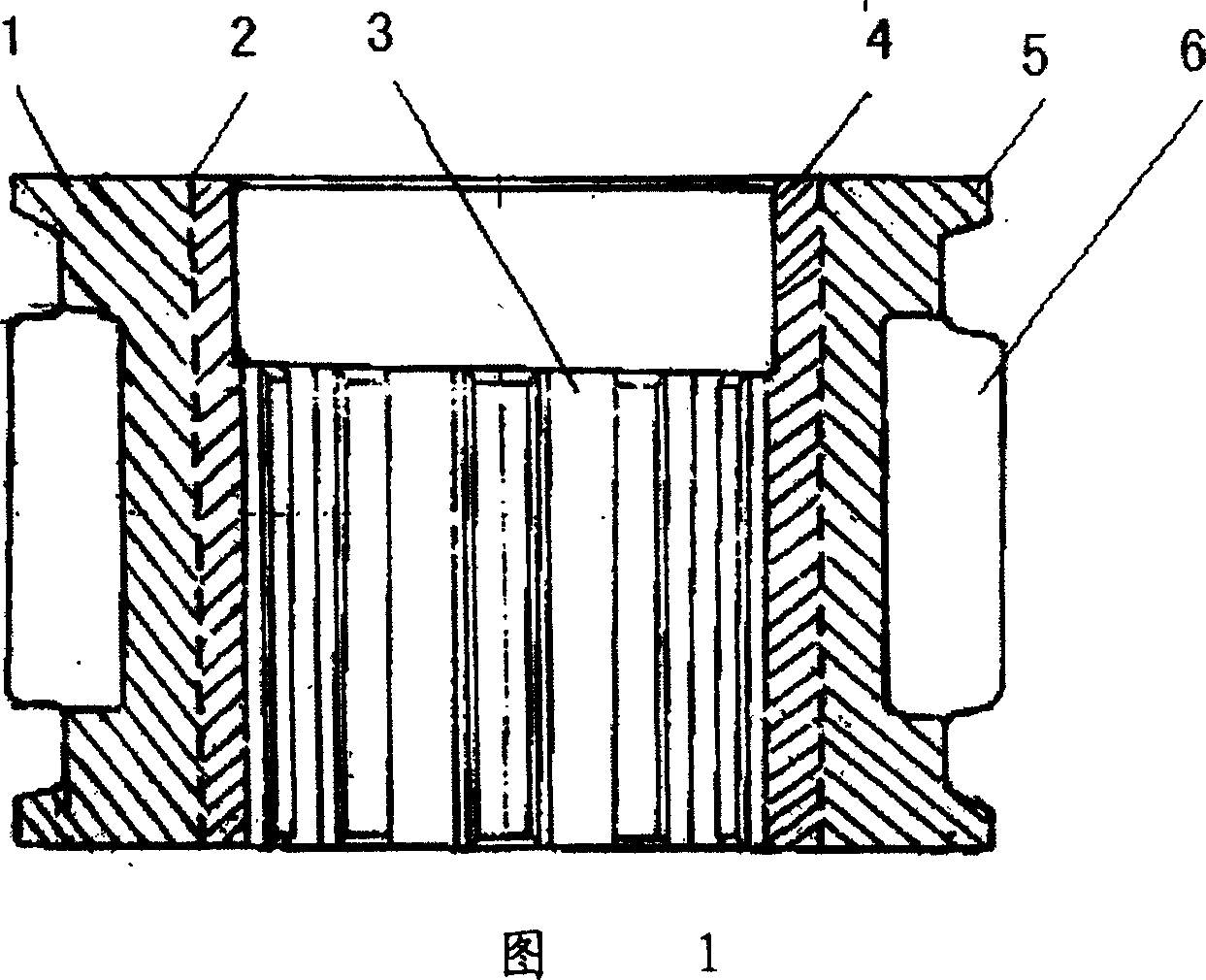

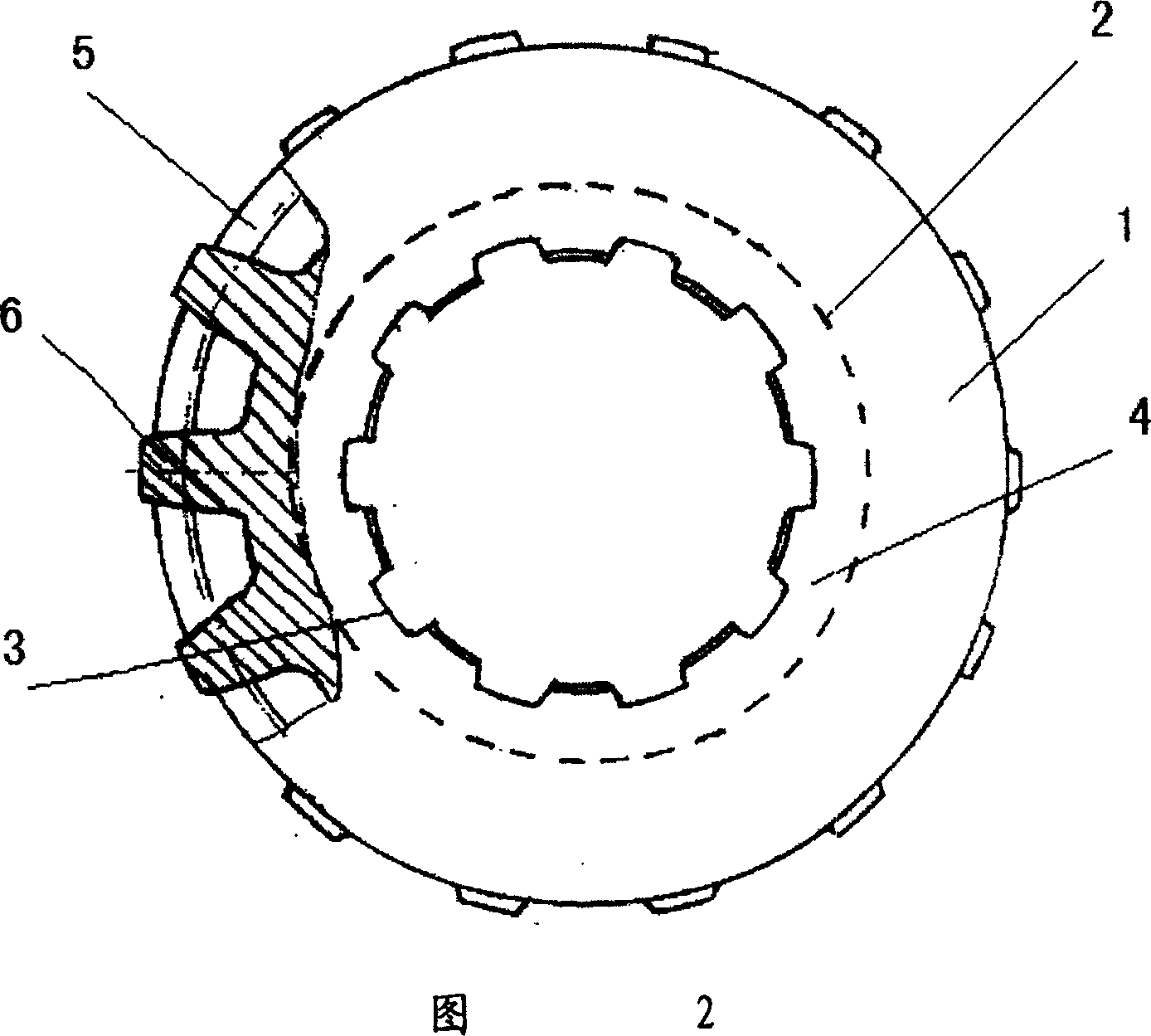

Manufacturing method of graphite-contained high-speed steel centrifugal composite steel core roller

ActiveCN106282821AAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideFully developed

The invention discloses a manufacturing method of a graphite-contained high-speed steel centrifugal composite steel core roller, and belongs to the field of mechanical casting. Chemical elements of B and N are introduced in a traditional high-speed steel component, MC type and / or M2C type dotted and / or blocky high-hard alloy carbides, nitrides and borides with the total area percentage of 20% to 35% are dispersed and distributed in a work layer base body structure; through carbide, nitride and boride modification, graphite is subject to two-step treatment of modification and inoculation, graphite is precipitated in an original structure, and therefore the high-speed steel roller has the advantages of the specific high-temperature wear resisting of traditional high-speed steel and meanwhile the problem that an original traditional high-speed steel roller is large in friction coefficient is solved; wear-resisting performance of the high-speed steel is fully developed, the lubricating effect between the roller and a workpiece in the rolling process is achieved, and happening of the steel bonding phenomenon is avoided; due to the heat conduction performance and the lubricating characteristic of graphite, the defects that the high-speed steel roller is sensitive to hot impact and hot-cracking susceptibility, steel bonding is prone to happening, and surface roughing is prone to happening can be overcome, and particularly when a finished product rack is used, the surface bright degree of a rolled material is obviously improved.

Owner:SANXIN HEAVY IND MACHINERY

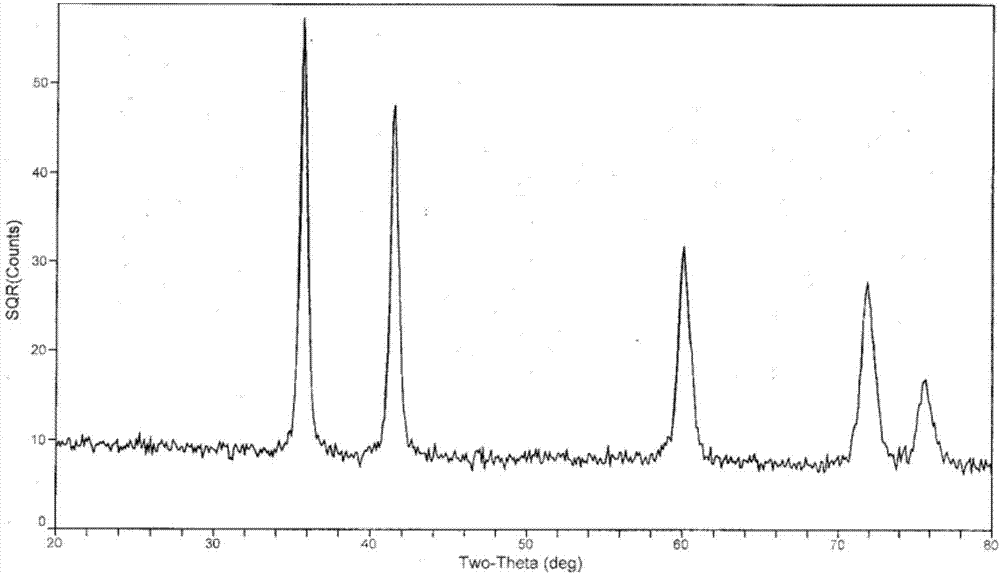

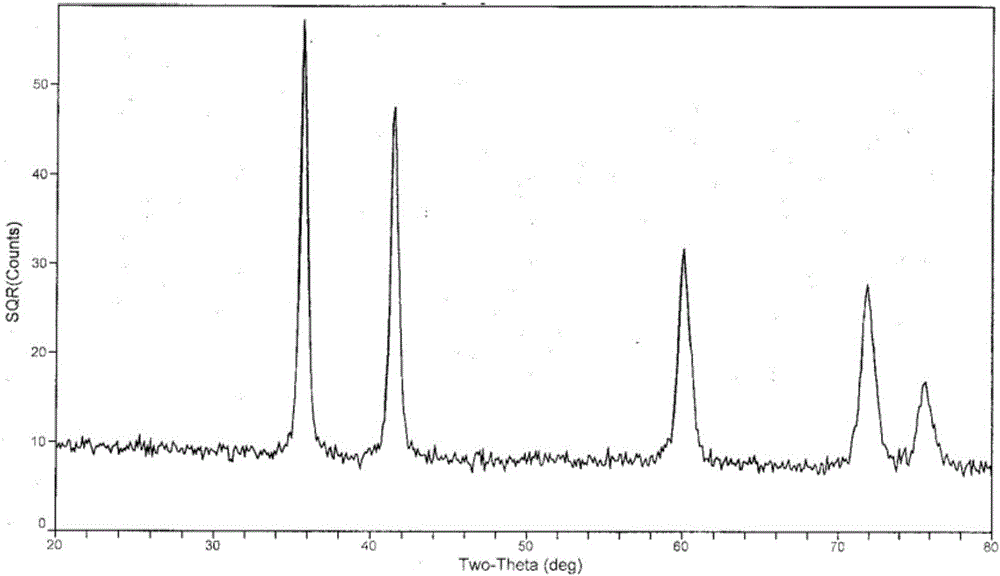

Five-membered hard alloy solid solution and preparation method thereof

InactiveCN107244661AQuality improvementImprove performanceNitrogen and non-metal compoundsAlloyMixed materials

The invention relates to a five-membered hard alloy solid solution, a metal ceramic cutter and a preparation method thereof. The five-membered hard alloy solid solution adopts the chemical formula of (W0.26-0.33Ta0.19-0.25Ti0.44-0.54)(C0.70-0.79N0.20-0.29). The preparation method comprises the following steps: respectively weighing 32-37 parts of WC, 27-32 parts of Ta2O5, 19-24 parts of TiO2 and 10-15 parts of carbon black powder by weight, performing ball milling, then drying to obtain mixed material powder, pressing into a blank, transferring to a vacuum reactor, performing a carbonation reduction reaction for 1.5-2.5h in a N2 atmosphere and at the temperature of 1600-1800 DEG C, and then performing a solid solution reaction for 3-5h in an N2 atmosphere and at the temperature of 1800-1900 DEG C to obtain (W, Ta, Ti)(C, N) five-membered hard alloy solid solution powder. The five-membered hard alloy solid solution prepared by the preparation method provided by the invention is high in solid solubility, low in oxygen content and excellent in performance and can greatly improve the performance of the cutter; a metal ceramic cutter material prepared from the five-membered hard alloy solid solution can obtain excellent mechanical properties.

Owner:长沙伟徽高科技新材料有限公司

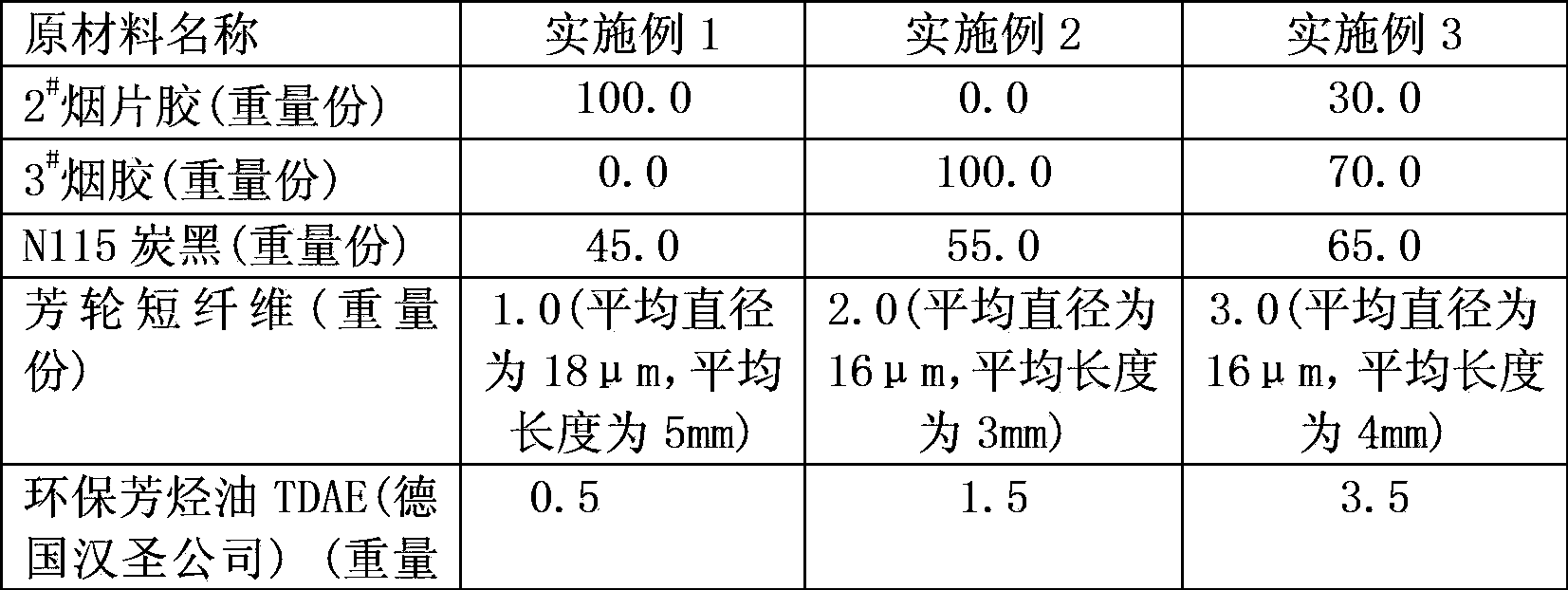

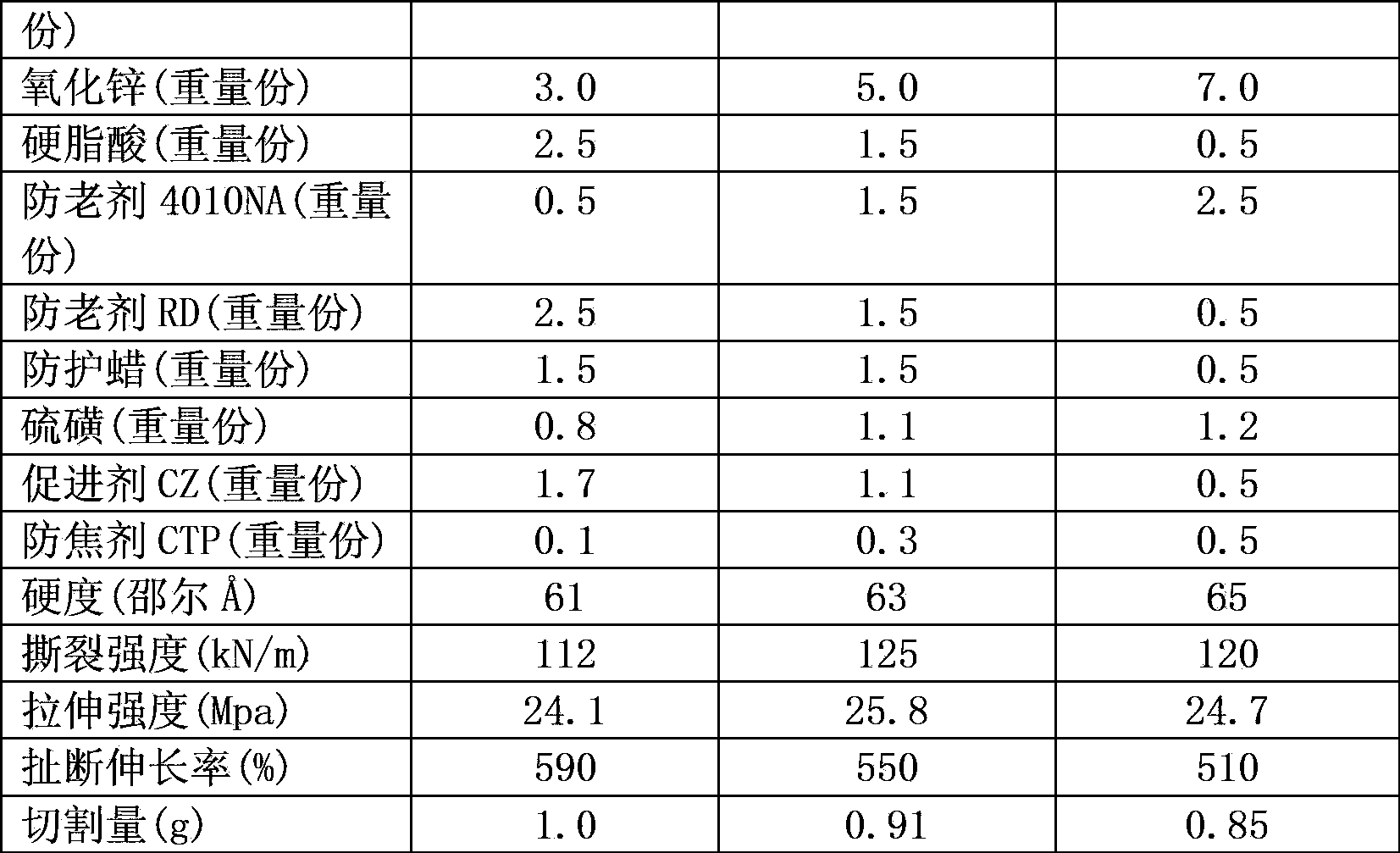

Environmentally-friendly cutting-resistant off-the-road tyre tread rubber

InactiveCN103849012AGive full play to wear resistanceGive full play to the good wear resistance of N115 carbon blackSpecial tyresStearic acidAramid

The invention discloses environmentally-friendly cutting-resistant off-the-road tyre tread rubber. The environmentally-friendly cutting-resistant off-the-road tyre tread rubber comprises, by weight, 100 parts of natural rubber, 45-65 parts of N115 carbon black, 1-3 parts of aramid short fibers, 0.5-3.5 parts of environmentally-friendly aromatic oil, 3-7 parts of zinc oxide, 0.5-2.5 parts of stearic acid, 0.5-2.5 parts of N-isopropyl-N-phenyl-para-phenylene diamine, 0.5-2.5 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.5-2.5 parts of protection wax, 0.8-1.2 parts of sulphur, 0.5-1.7 parts of N-cyclohexyl-2-benzothiazolylsulfenamide and 0.1-0.5 parts of an anti-scorching agent CTP. The environmentally-friendly cutting-resistant off-the-road tyre tread rubber satisfies REACH regulations, has the characteristics of excellent cutting resistance, wear resistance and collapse resistance and realizes good balance between toughness, a thermogenesis value, heat aging resistance and wear resistance.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

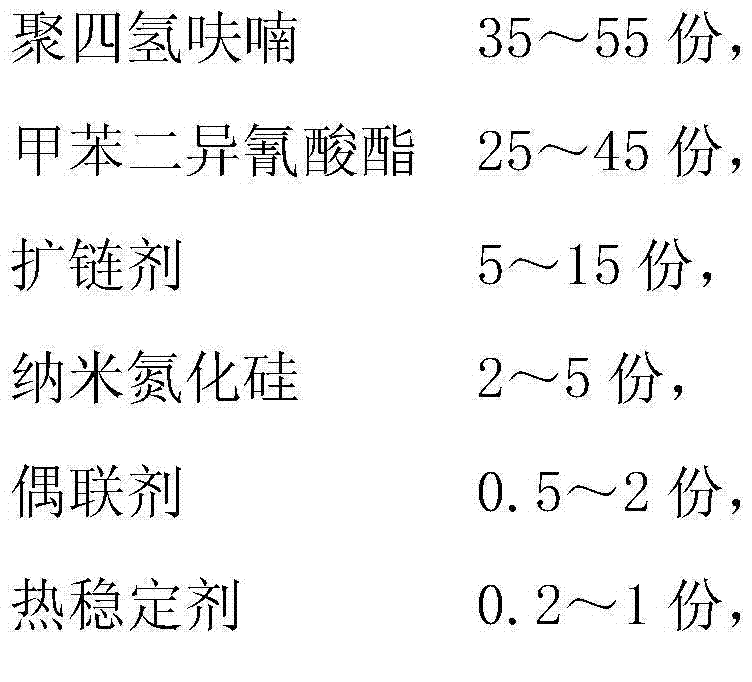

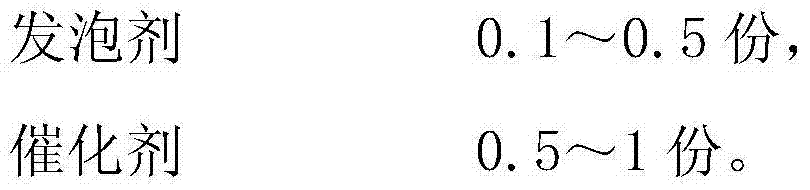

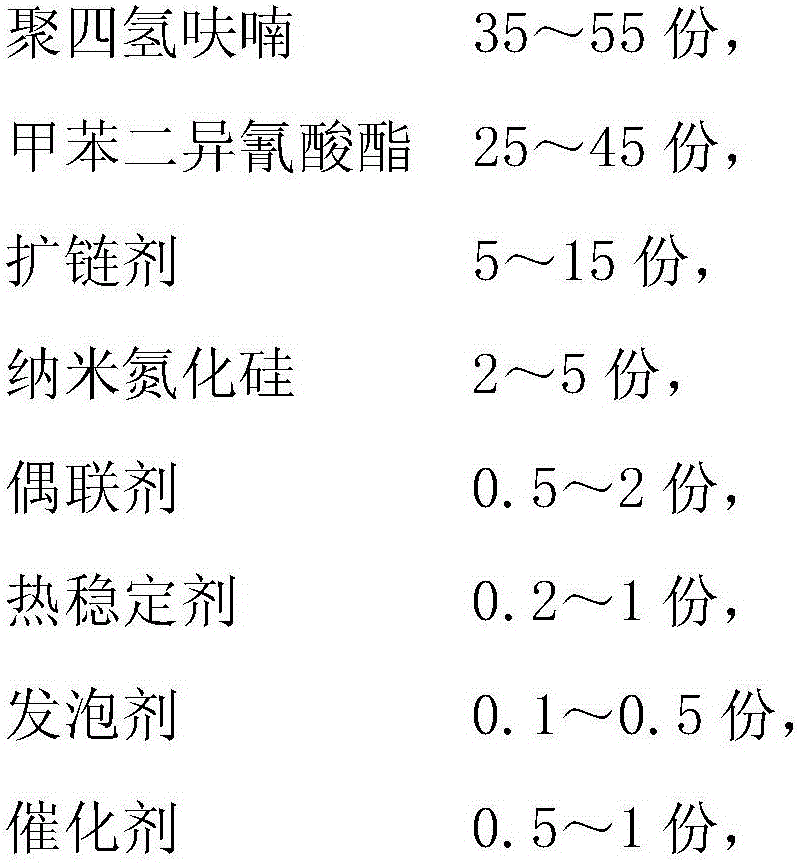

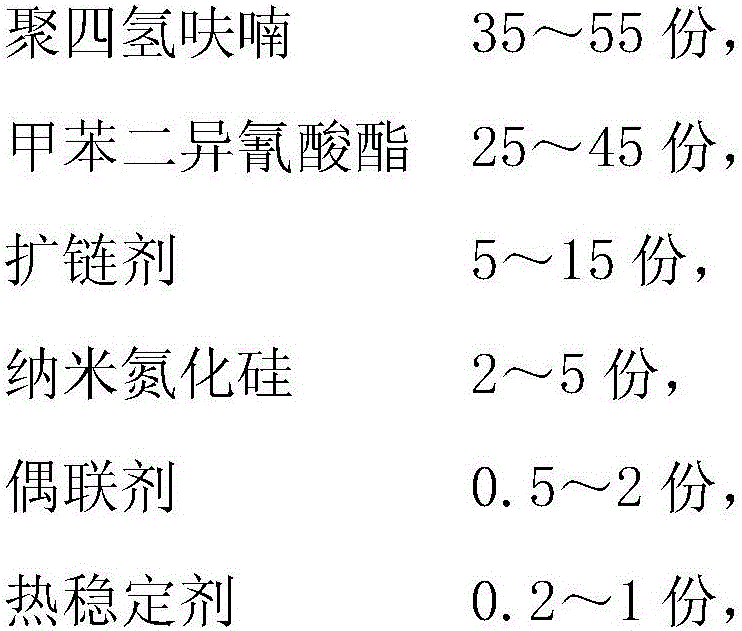

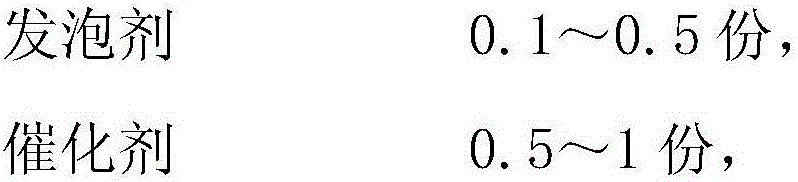

High-wear-resistance polyurethane shoe material and manufacturing method thereof

ActiveCN104262569AGood self-lubricationGood wear resistanceFootwearToluene diisocyanatePolytetrahydrofuran

The invention provides a high-wear-resistance polyurethane shoe material which is prepared from the following components in parts by weight: 35-55 parts of polytetrahydrofuran, 25-45 parts of toluene diisocyanate, 5-15 parts of chain extender, 2-5 parts of nano silicon nitride, 0.5-2 parts of coupling agent, 0.2-1 part of heat stabilizer, 0.1-0.5 part of foaming agent and 0.5-1 part of catalyst. The invention also provides a manufacturing method of the high-wear-resistance polyurethane shoe material. The polyurethane shoe material provided by the invention has favorable wear resistance.

Owner:SUZHOU JINGRO TECH

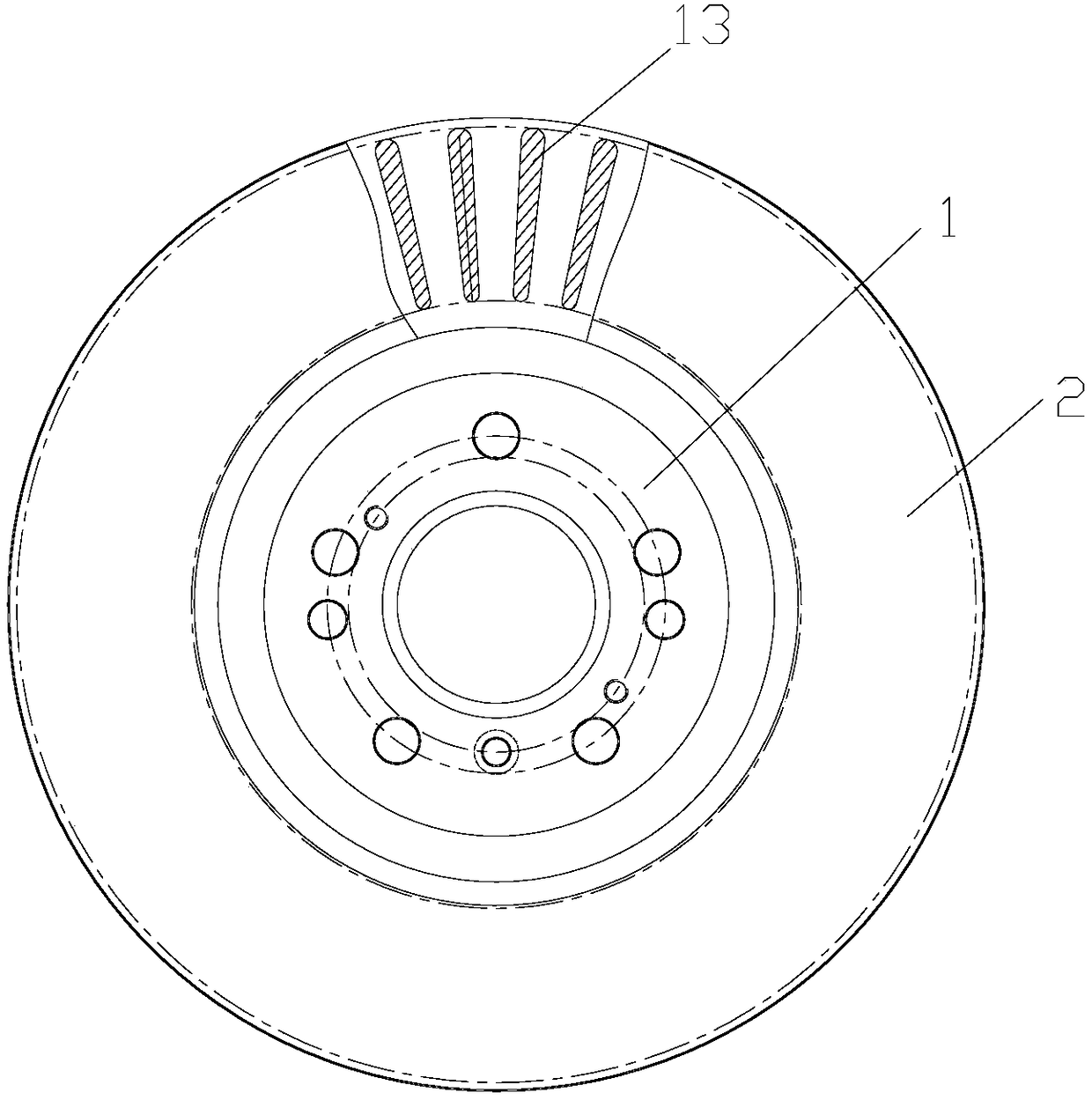

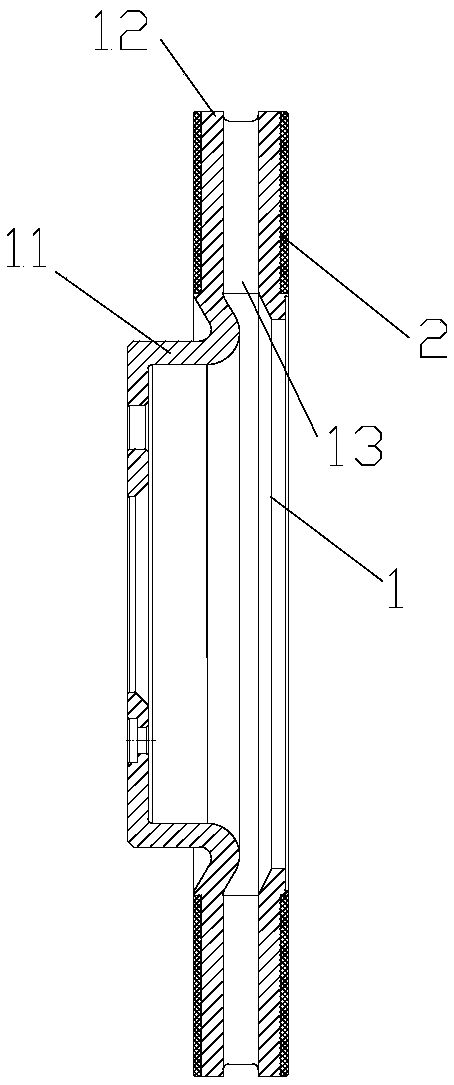

Manufacturing method of vehicle brake disc

InactiveCN109249005AManufacturing Method AdvantagesGive full play to wear resistanceBraking discsFurnace typesCast ironRough surface

The invention relates to the field of vehicle component processing, and provides a manufacturing method of a vehicle brake disc, wherein the brake disc comprises a body disc and two friction rings, the manufacturing method comprises the following steps of: casting two friction rings by adopting a cast iron material; preparing a casting mold and a core mold, wherein the core mold and the two friction rings are respectively fixed in corresponding positions in a mold cavity; pouring molten aluminum alloy into the cavity to form the brake disc; carrying out heat treatment on the brake disc, wherein the inner surface of the friction rings jointed with the body disc is a rough surface, so that the body disc and the friction rings can be embedded into each other. The production method of the invention can be used for manufacturing an aluminum alloy body disk and a cast iron friction ring, and can fully give play to the wear resistance, high friction and high temperature resistance of the castiron by the combination of two materials of cast iron and aluminum alloy, meanwhile, the aluminum alloy material can fully reduce the overall mass of the brake disc, so that the mass of the spring isreduced, and the operation stability of the vehicle is improved.

Owner:GREAT WALL MOTOR CO LTD

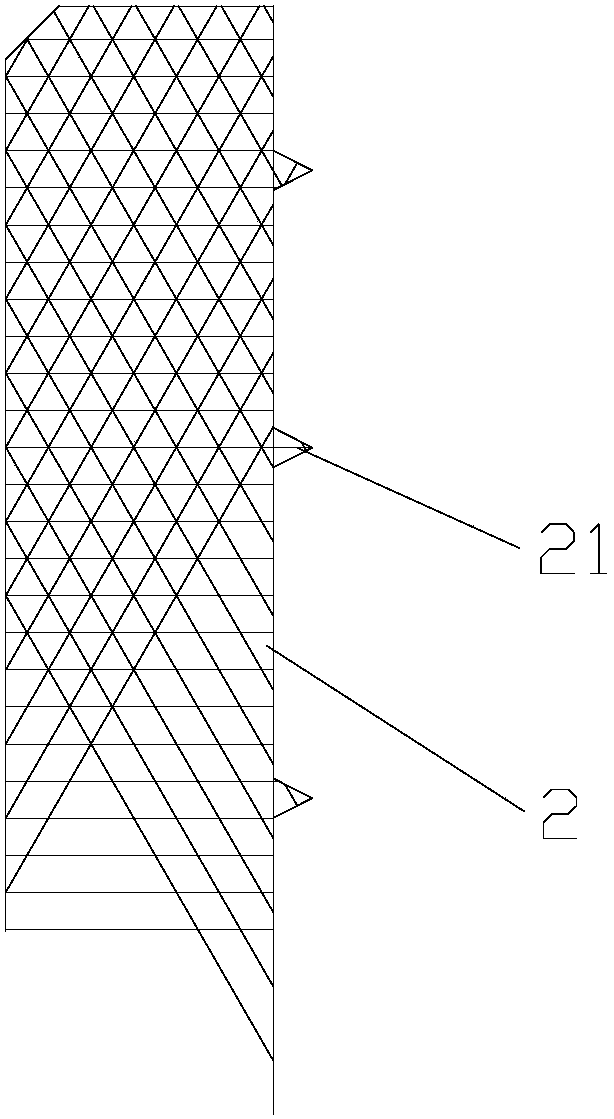

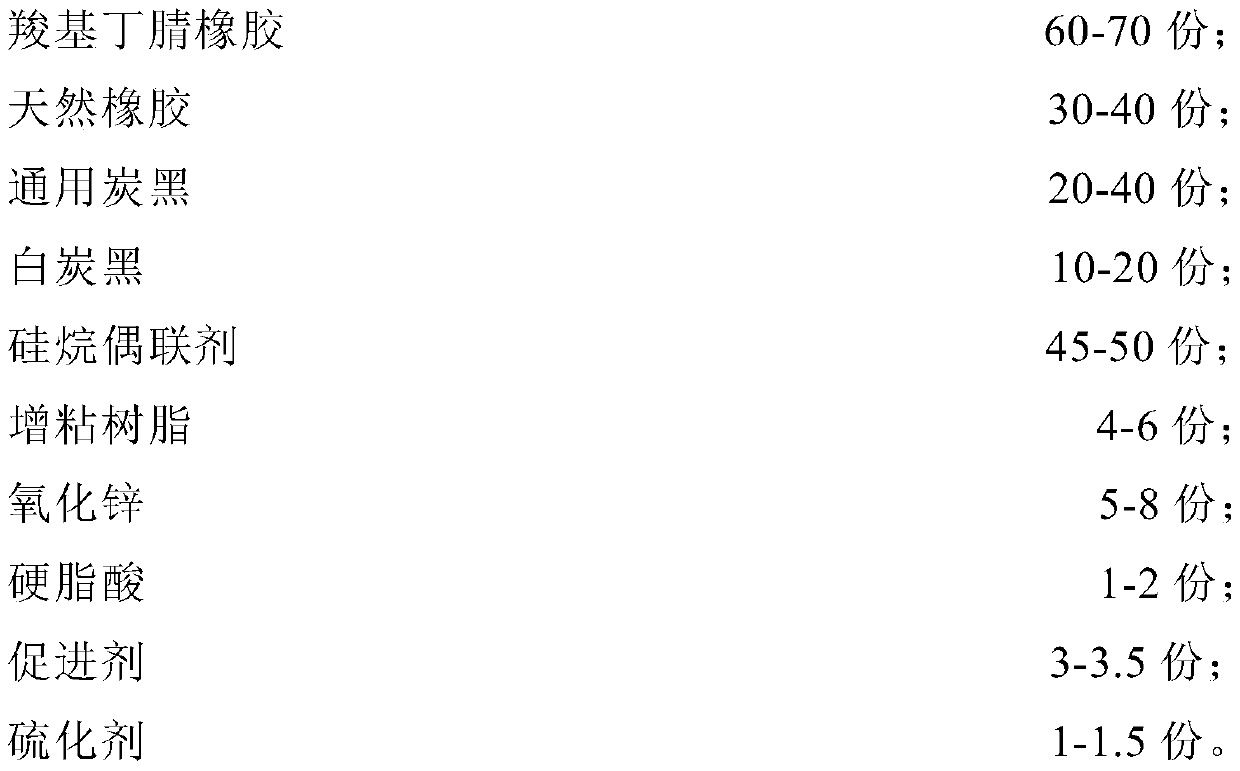

Adhesive material for laminated composite bonding transition layer of hydrogenated nitrile rubber and unsaturated non-polar rubber

The invention discloses an adhesive material for a laminated composite bonding transition layer of hydrogenated nitrile rubber and unsaturated non-polar rubber and a preparation method of the adhesivematerial. The adhesive material for the transition layer comprises the following components in parts by weight: 60-70 parts of carboxyl nitrile rubber, 30-40 parts of natural rubber, 20-40 parts of general carbon black, 10-20 parts of white carbon black, 45-50 parts of silane coupling agent, 4-6 parts of tackifying resin, 5-8 parts of zinc oxide, 1-2 parts of stearic acid, 3-3.5 parts of accelerator and 1-1.5 parts of valcanizer.

Owner:ZHEJIANG ZANSHENG NEW MATERIALS CO LTD

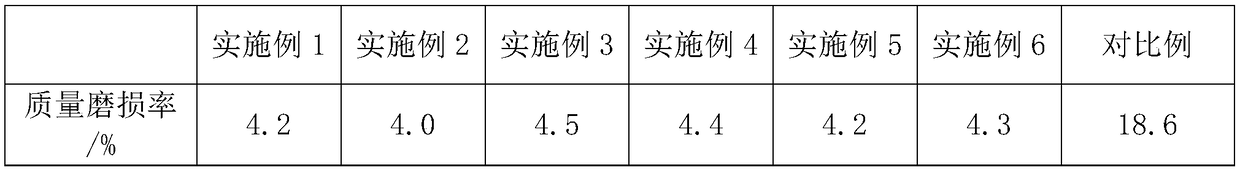

High-wear-resistance nitrile rubber composite cable material and preparation method thereof

The invention provides a high-wear-resistance nitrile rubber composite cable material. The high-wear-resistance nitrile rubber composite cable material is prepared from components in parts by weight as follows: 100 parts of nitrile rubber, 4-5 parts of an accelerant, 2-2.5 parts of an antioxidant, 8-13 parts of a fire retardant, 10-15 parts of filler, 1.5-2 parts of a coupling agent, 5-10 parts of a plasticizer, 1-1.5 parts of a vulcanizing agent, 2.5-3 parts of an anti-aging agent, 6-8 parts of modified compound zirconia, 4 parts of zinc oxide and 2 parts of stearic acid. The invention further provides a preparation method of the nitrile rubber composite cable material. The wear resistance of the nitrile rubber composite cable material is very high.

Owner:贵州安众成电线电缆有限公司

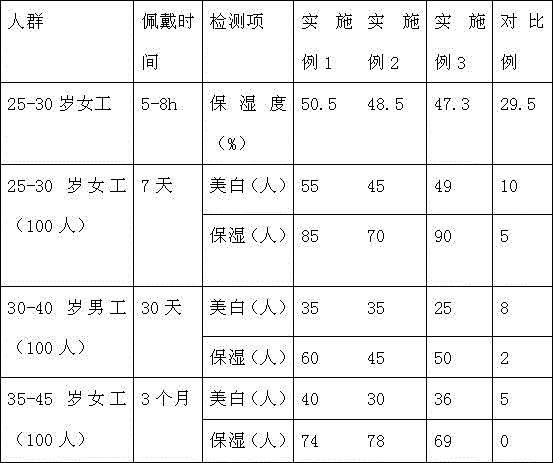

Lanolin-rubber gloves with skin care effect

ActiveCN105622994AActivate self-healing potentialHealthy and radiantGlovesProtective garmentCross-linkAcrylonitrile

The invention relates to lanolin-rubber gloves with a skin care effect. Each rubber glove is prepared from the components, i.e., a rubber matrix A and a rubber matrix B which are in the mass ratio of 1.7: 1, wherein the rubber matrix A consists of natural rubber, lanolin, vinyl silicone oil, a cross-linking agent, a vulcanizing agent and an accelerant, and the rubber matrix B consists of butadiene-acrylonitrile rubber, lanolin, an anti-aging agent, a plasticizer, a diluent, glycerine, aloe raw juice, snail raw juice, rose essential oil and geranium essential oil. According to the lanolin-rubber gloves with the skin care effect, hands can be better cared while users use the gloves.

Owner:ZHENJIANG SUHUI LATEX PROD

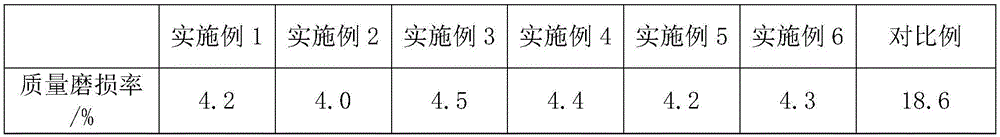

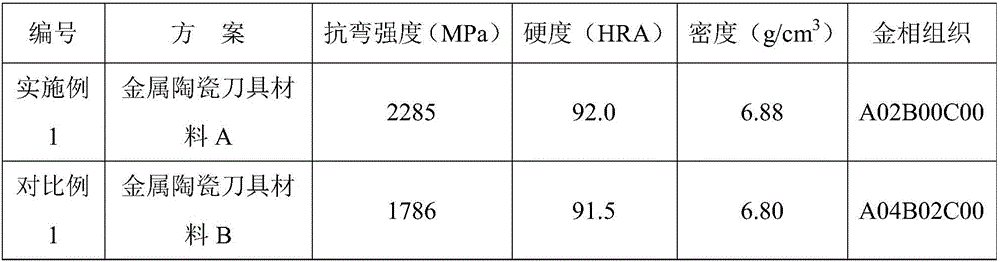

Metal ceramic tool material and preparation method thereof

InactiveCN107177766AMake the most of synergiesGive full play to wear resistanceStrength of materialsSolid solution

The invention relates to a cermet tool material. The cermet cutting tool material contains 6-10 parts of Co, 6-10 parts of Ni, 6-10 parts of Mo2C, 20-40 parts of quinary solid solution and 30-62 parts of TiC0.7N0.3 in parts by mass. The chemical formula of the pentad solid solution is (W0.26‑0.33Ta0.19‑0.25Ti0.44‑0.54) (C0.70‑0.8N0.20‑0.30). The cermet cutting tool material of the invention has excellent mechanical properties, high bending strength, good toughness, greatly improved service life, and the service life is about 50% higher than that of traditional cutting tools, and has higher cost performance.

Owner:成都众鑫达超硬工具材料科技有限公司

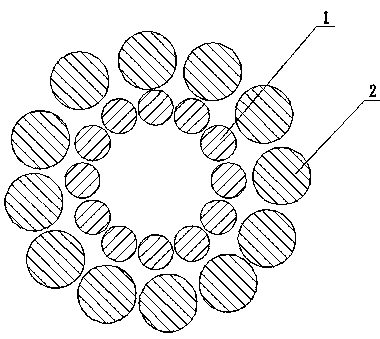

Novel high-strength wear-resisting mooring rope

The invention discloses a novel high-strength wear-resisting mooring rope. The novel high-strength wear-resisting mooring rope comprises an inner 12-strand mooring rope body and 12 outer polyester strands, wherein the 12-strand mooring rope body is composed of a central column, an inner layer and an outer layer, the inner column is a rubber column, the inner layer is interwoven from a plurality ofbearing ropes which are composed of a plurality of S-directionally twisted tensile ropes and a plurality of Z-directionally twisted tensile ropes, and the tensile ropes are mixed and twisted by polyester, nylon and fibrous ultrahigh-molecular-weight polyethylene. The novel high-strength wear-resisting mooring rope has the advantages of being lower in elongation, safer to use and higher in stability and gives full play to the tenacity and strength of high-performance polyethylene fiber and the wear-resisting, corrosion-resisting and uvioresistant properties of polyester fiber.

Owner:江苏神韵绳缆有限公司

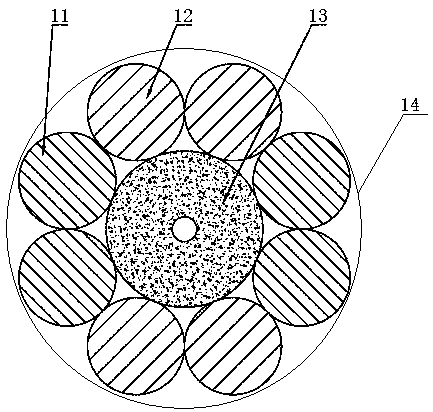

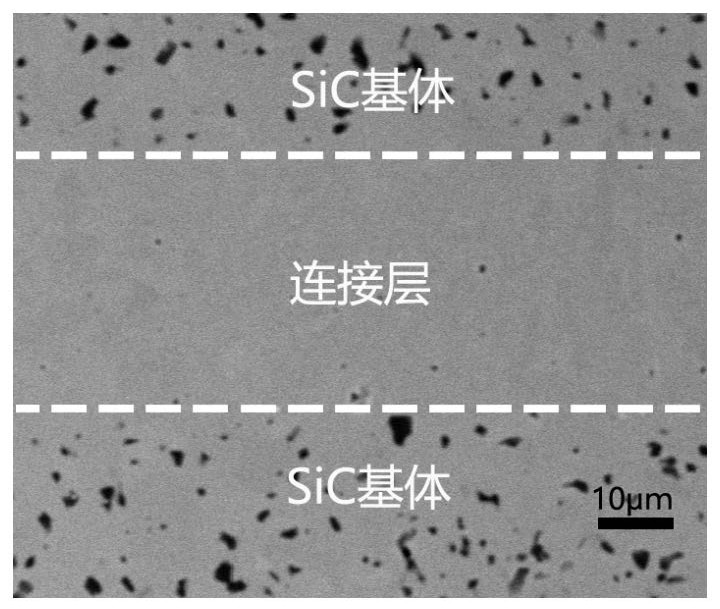

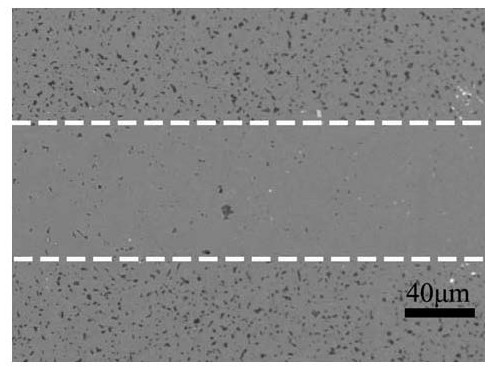

Connection method of silicon carbide ceramics based on liquid phase sintering

The invention relates to a connection method of silicon carbide ceramics based on liquid phase sintering, which comprises the following steps: (1) mixing silicon carbide powder, a sintering aid, a dispersant, a binder and a solvent to obtain suspension slurry; the sintering aid is AlN powder and Y2O3 powder; and (2) uniformly spreading the obtained suspension slurry on the to-be-connected surface of the first silicon carbide ceramic to obtain a slurry layer, attaching the to-be-connected surface of the second silicon carbide ceramic to the slurry layer, fixing the to-be-connected surface of the second silicon carbide ceramic by using a clamp, and finally realizing connection of the silicon carbide ceramics in a normal-pressure sintering furnace, preferably, the temperature of the liquid phase sintering is 1600-2000 DEG C, the heat preservation time is 0.5-5 hours, and the atmosphere is inert atmosphere, more preferably argon; wherein the pressure applied by the clamp is 1 to 10 MPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Head soldered structure for tamping pick

PendingCN109440552AGive full play to wear resistanceBallastwayTrack superstructureWear resistantHeight difference

The invention relates to a wear-resistant tamping pick in railway ballast tamping machinery, in particular to a head soldered structure for a tamping pick. The head soldered structure comprises a tamping pick head body; the surface of the tamping pick head body is provided with grooves, having a depth greater than the solder thickness, at intervals; protrusions are arranged among the grooves; a first wear-resistant alloy sheet is soldered in each groove through solder; a plurality of second wear-resistant alloy sheets are attached to the front end of the tamping pick head body in covering manner. According to the principle that protruding parts of mutually abrasive surfaces are more abraded than concave parts, the upper and lower abrasive surfaces of the tamping pick head are provided witha height difference in a manner that the outer surface of the alloy sheets of high hardness is higher than the outer surface of the tamping pick head body of low hardness; therefore, the usage of wear-resistant alloy material is decreased, longer life is gained, manufacture and application costs of the tamping pick head are reduced, the service life of the tamping pick is extended with manufacture cost reduced, and wear resistance is greatly improved.

Owner:TANGSHAN KUNTIE TECH

A manufacturing method of graphite-containing high-speed steel centrifugal composite steel core roll

ActiveCN106282821BAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideFully developed

The invention discloses a manufacturing method of a graphite-contained high-speed steel centrifugal composite steel core roller, and belongs to the field of mechanical casting. Chemical elements of B and N are introduced in a traditional high-speed steel component, MC type and / or M2C type dotted and / or blocky high-hard alloy carbides, nitrides and borides with the total area percentage of 20% to 35% are dispersed and distributed in a work layer base body structure; through carbide, nitride and boride modification, graphite is subject to two-step treatment of modification and inoculation, graphite is precipitated in an original structure, and therefore the high-speed steel roller has the advantages of the specific high-temperature wear resisting of traditional high-speed steel and meanwhile the problem that an original traditional high-speed steel roller is large in friction coefficient is solved; wear-resisting performance of the high-speed steel is fully developed, the lubricating effect between the roller and a workpiece in the rolling process is achieved, and happening of the steel bonding phenomenon is avoided; due to the heat conduction performance and the lubricating characteristic of graphite, the defects that the high-speed steel roller is sensitive to hot impact and hot-cracking susceptibility, steel bonding is prone to happening, and surface roughing is prone to happening can be overcome, and particularly when a finished product rack is used, the surface bright degree of a rolled material is obviously improved.

Owner:SANXIN HEAVY IND MACHINERY

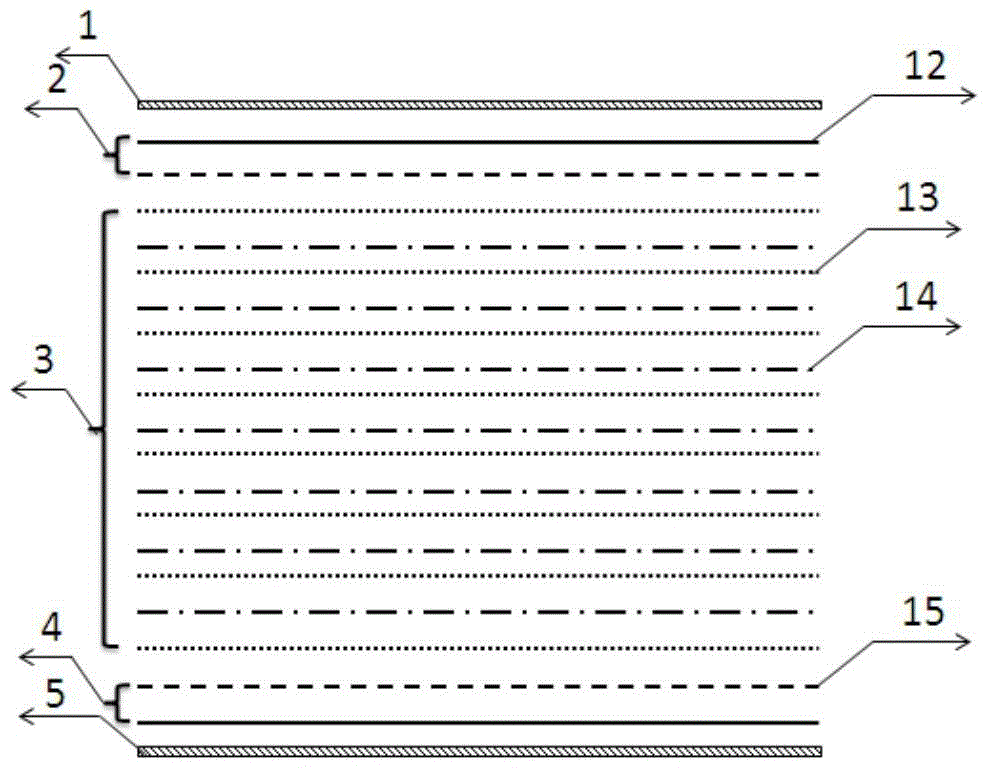

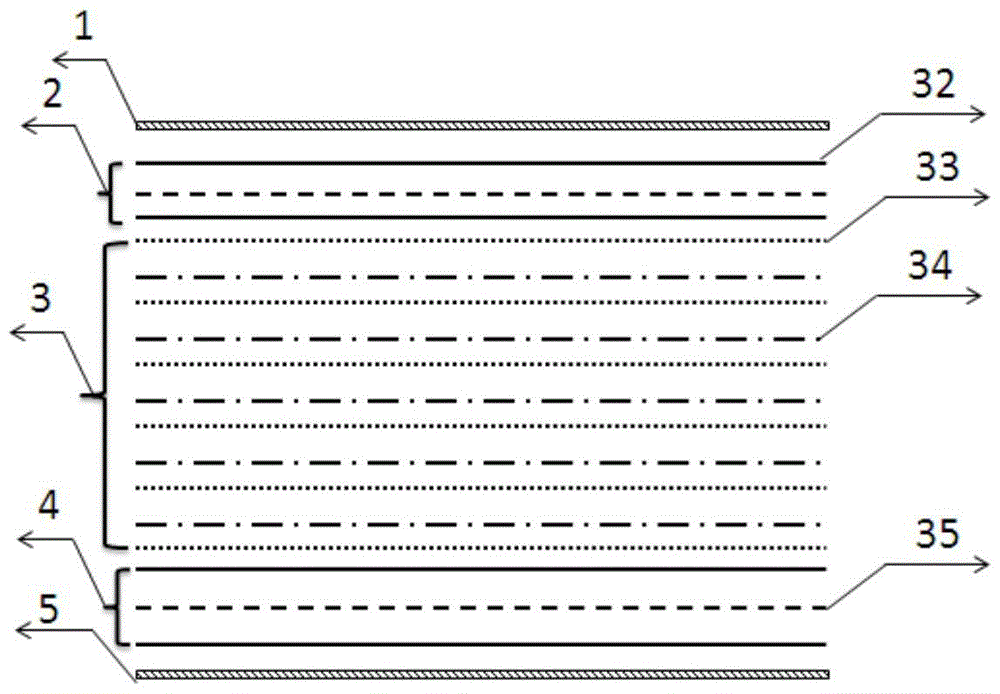

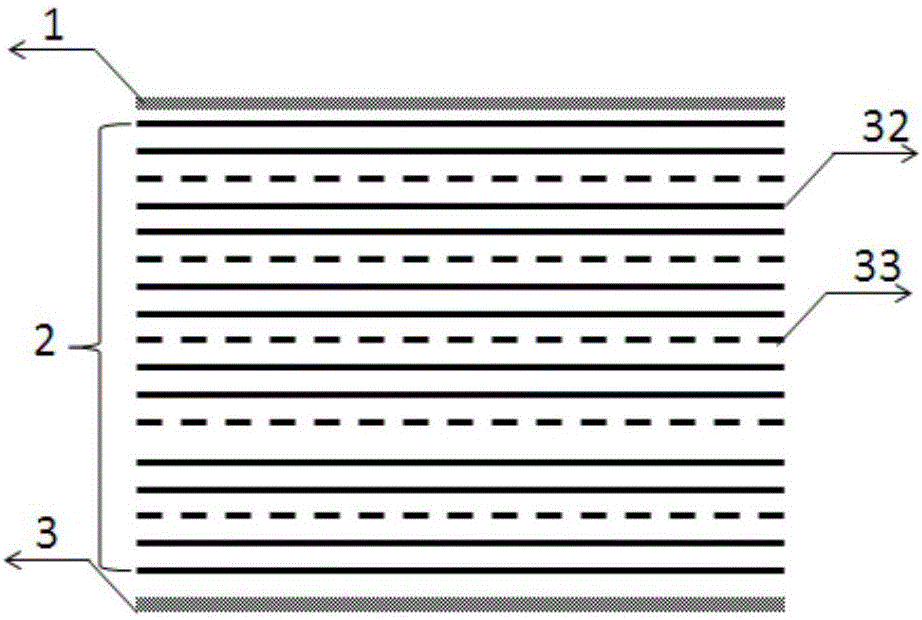

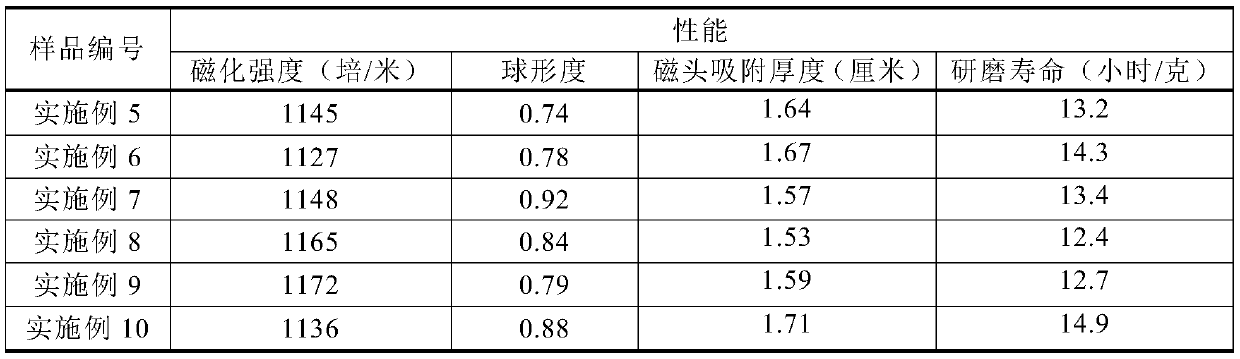

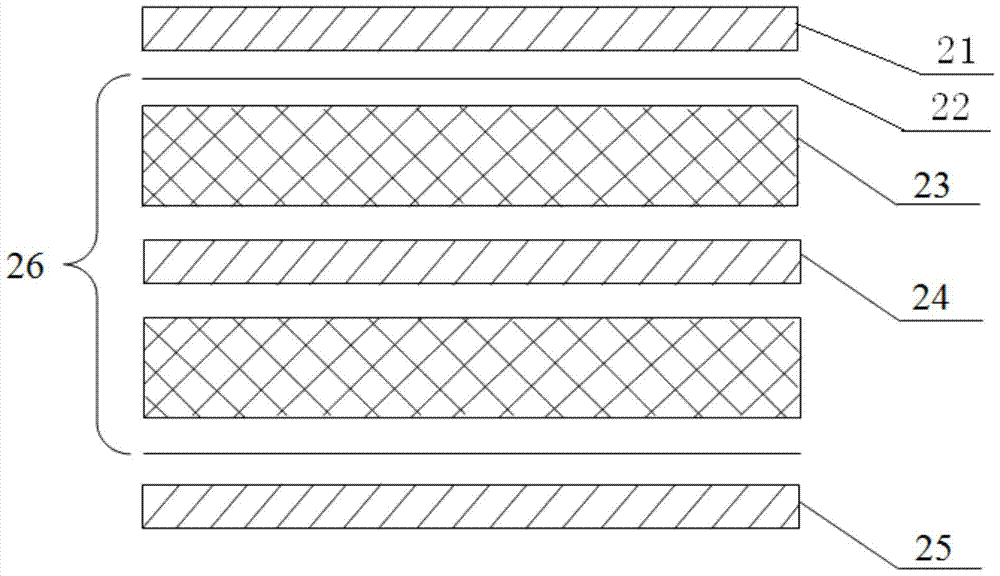

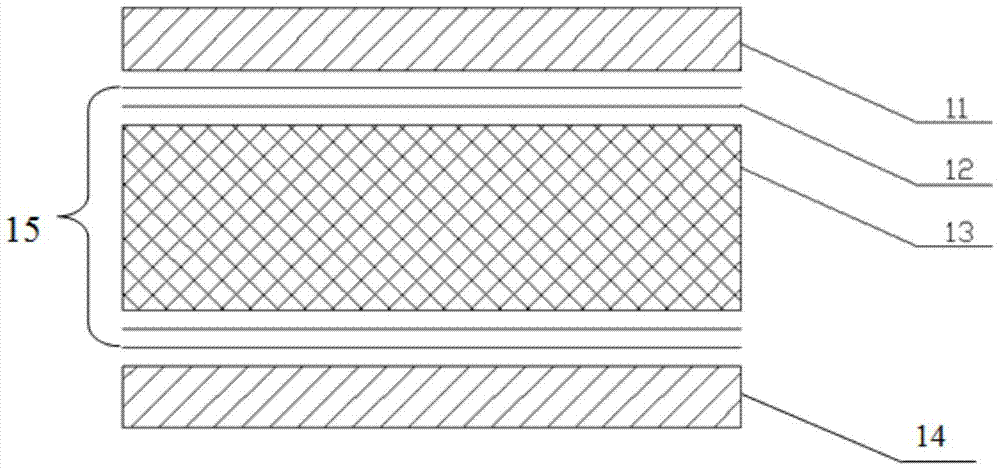

A kind of composite plate, preparation method and application thereof

ActiveCN104802236BStrong designabilityImprove economyLaminationLarge containersSurface layerBaseboard

The invention discloses a composite board. The composite board sequentially includes a surface layer, a sandwich layer, a middle sandwich layer, a bottom sandwich layer and a bottom layer from top to bottom, and all layers are connected in a hot pressing manner. A method for preparing the composite board comprises the following steps: paving the bottom layer on a die; paving the bottom sandwich layer on the upper surface of the bottom layer; paving the middle sandwich layer on the upper surface of the bottom sandwich layer; paving the sandwich layer on the upper surface of the middle sandwich layer; paving the surface layer on the upper surface of the sandwich layer, covering the die, and performing hot pressing and pressure maintaining; depressurizing and exhausting or firstly cooling to ambient temperature and releasing pressure in a segmentation manner to prepare the composite board. The density, strength, elasticity modulus, surface quality and various property indexes of the composite board can meet a composite container baseboard with industry standards of the international container, and the composite board can be used as the container baseboard, has strong design, and can reasonably select thickness and density of the surface layer and the core material according to actual demands, thereby realizing the best economic effect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

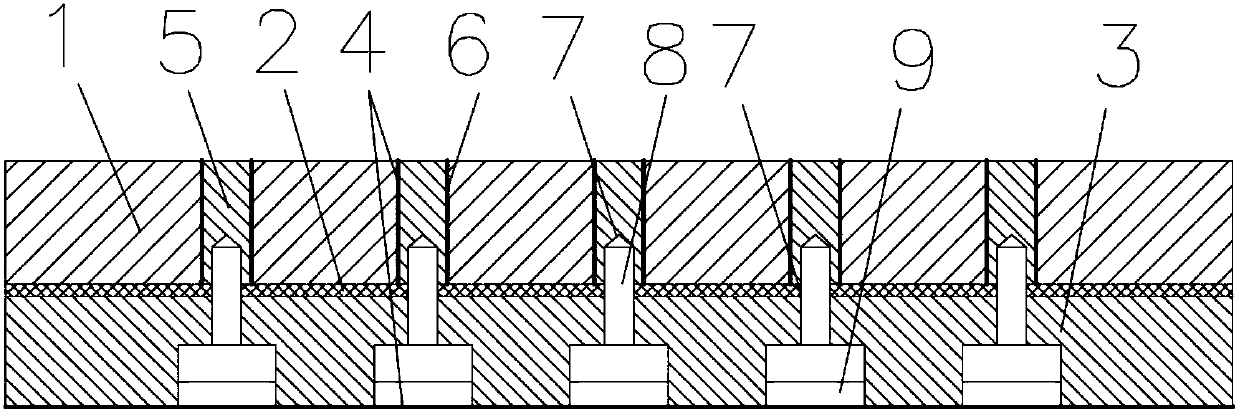

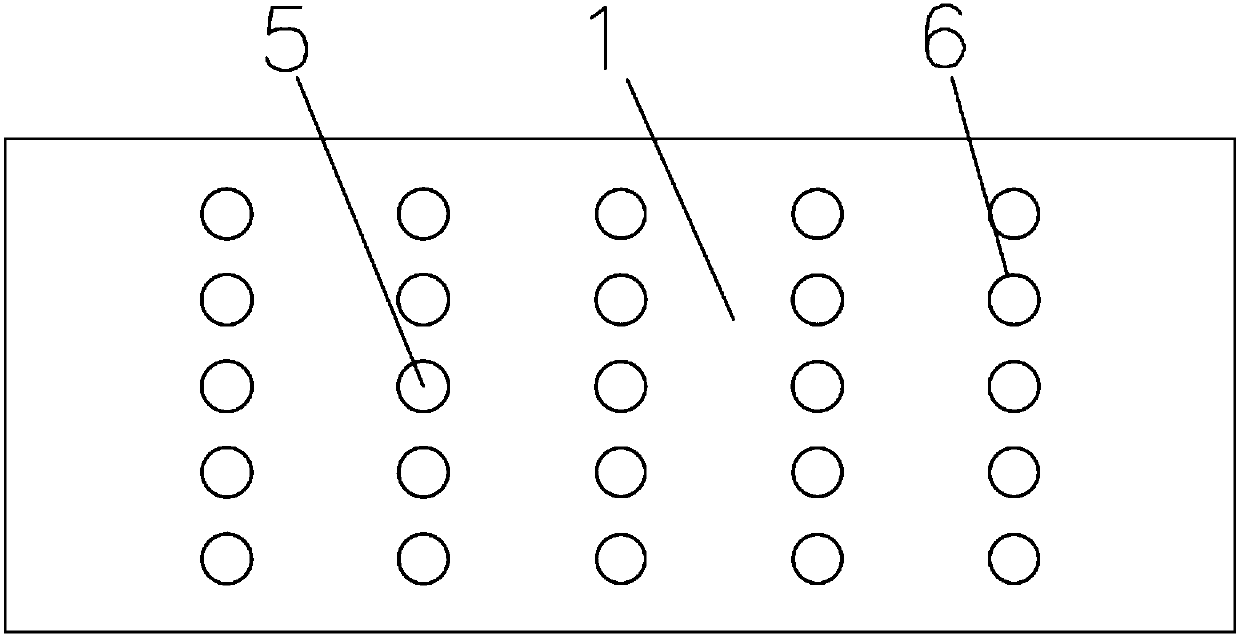

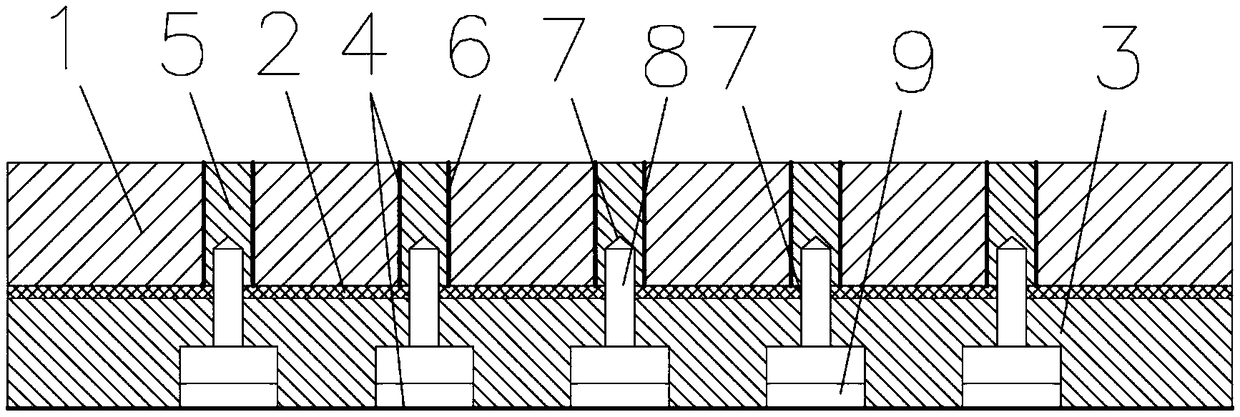

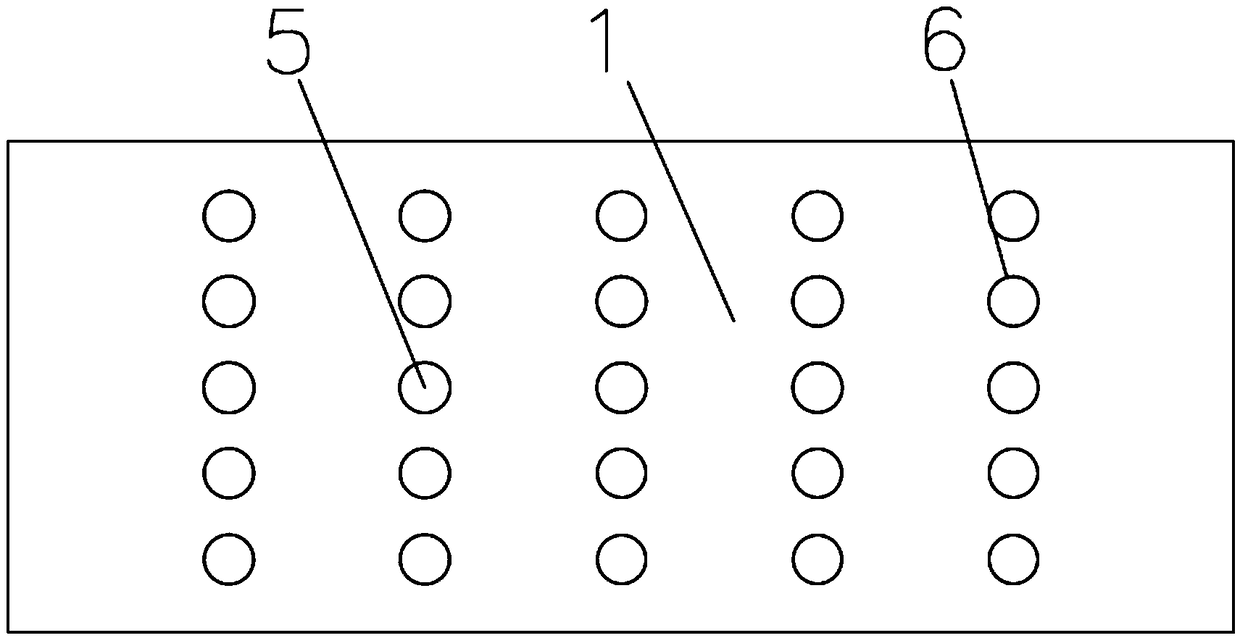

Preparation technology of improved flame retardant abrasion-resistant plate

The invention relates to the technical field of abrasion-resistant plates, in particular to a preparation technology of an improved flame retardant abrasion-resistant plate. The abrasion-resistant plate prepared through the technology comprises a flame retardant layer, abrasion-resistant posts and a reinforced plate body. A layer of adhesive is arranged between the flame retardant layer and the reinforced plate body. The material of the flame retardant layer is a glass-magnesium-plant-fiber composite flame retardant plate material; the material of the abrasion-resistant posts is an aluminum oxide ceramic material; the material of the reinforced plate body is an abrasion-resistant steel plate material; a plurality of mounting holes are formed in the flame retardant layer in an arrayed mode,and the abrasion-resistant posts are mounted in the mounting holes in a matched mode; a layer of fire retardant is arranged on the outer surfaces of the abrasion-resistant posts, threaded holes are formed in the bottom ends of the abrasion-resistant posts and the reinforced plate body correspondingly, counterbores are formed in the lower ends of the threaded holes located in the reinforced platebody, and screws used for reinforcing and fixing the abrasion-resistant posts and the reinforced plate body are mounted in the threaded holes and the counterbores; and a layer of fire retardant is arranged at the bottom of the reinforced plate body. The preparation technology provided by the invention is good in fire retardant performance, and good in practical value and popularization value.

Owner:车智路数据管理有限公司

A kind of highly wear-resistant nitrile rubber composite cable material and preparation method thereof

ActiveCN106750640BImprove wear resistanceImprove toughnessRubber insulatorsNitrile rubberWear resistant

The invention provides a high-wear-resistance nitrile rubber composite cable material. The high-wear-resistance nitrile rubber composite cable material is prepared from components in parts by weight as follows: 100 parts of nitrile rubber, 4-5 parts of an accelerant, 2-2.5 parts of an antioxidant, 8-13 parts of a fire retardant, 10-15 parts of filler, 1.5-2 parts of a coupling agent, 5-10 parts of a plasticizer, 1-1.5 parts of a vulcanizing agent, 2.5-3 parts of an anti-aging agent, 6-8 parts of modified compound zirconia, 4 parts of zinc oxide and 2 parts of stearic acid. The invention further provides a preparation method of the nitrile rubber composite cable material. The wear resistance of the nitrile rubber composite cable material is very high.

Owner:贵州安众成电线电缆有限公司

Method for casting high manganese steel composite gear, and high manganese steel composite casted gear

InactiveCN100340360CGive full play to the impact resistanceGive full play to wear resistanceGear wheelMechanical drive

A high-Mn steel contained gear is prepared through providing a mould, pouring the molten high-Mn steel in the external toothed ring part of mould, solidifying it while pouring the molten carbon steel or alloy steel in the internal ring part of mould, and solidifying the internal and external rings at same time. Its gear product is also disclosed, which has high anti-impact and anti-wear performance and high machinability.

Owner:张立富

A kind of manufacturing method of graphite-containing high-speed steel roll

ActiveCN106282820BAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideChemical element

The invention discloses a manufacturing method of a graphite-containing high-speed steel roll and belongs to the technical field of mechanical casting. B and N chemical elements are introduced into a conventional high-speed steel component, and MC type and / or M2C type dotted and / or blocky high-hardness alloy carbide, nitride and boride with the total percentage of the area being 20%-35% are / is distributed in a matrix structure of a work layer; graphite is separated out of original tissue through two steps including modification of carbide, nitride and boride and metamorphic inoculation of graphite, so that the high-speed steel roll not only reserves the advantage of peculiar high-temperature wear resistance of conventional high-speed steel, but also solves the problem that an original conventional high-speed steel roll has a large friction coefficient, the wear-resisting property of the high-speed steel is sufficiently played, the lubricating function between the roll in rolling and a workpiece is realized, and the steel bonding phenomenon is prevented; by means of the heat conductivity and lubrication characteristics of graphite, the defects that high-speed steel rolls are sensitive to heat shock and heat cracking and are prone to steel bonding and surface texturing can be overcome, and particularly, when the graphite-containing high-speed steel roll is used in a finished rack, the brightness degree of the surface of the roll material is remarkably improved.

Owner:SANXIN HEAVY IND MACHINERY

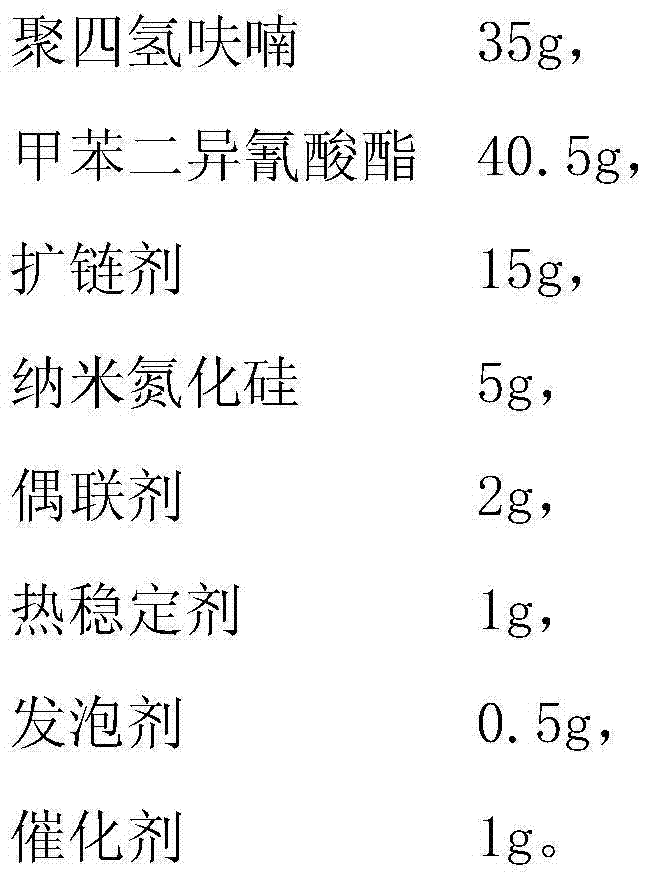

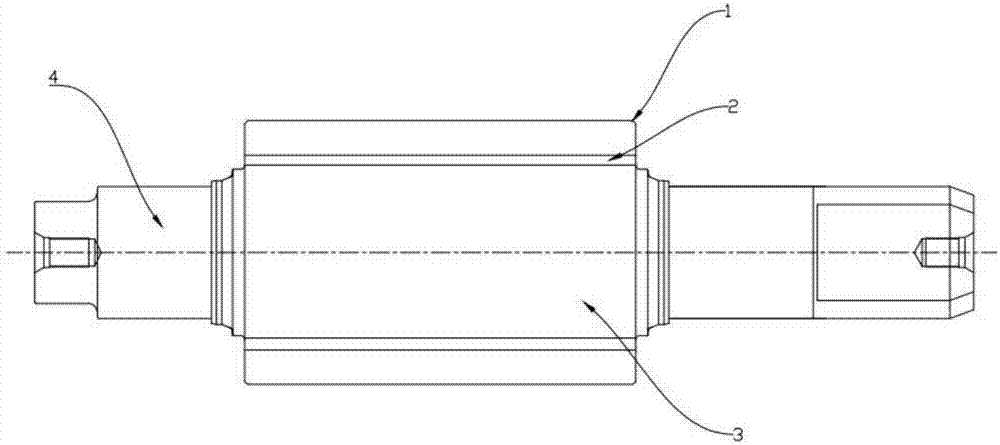

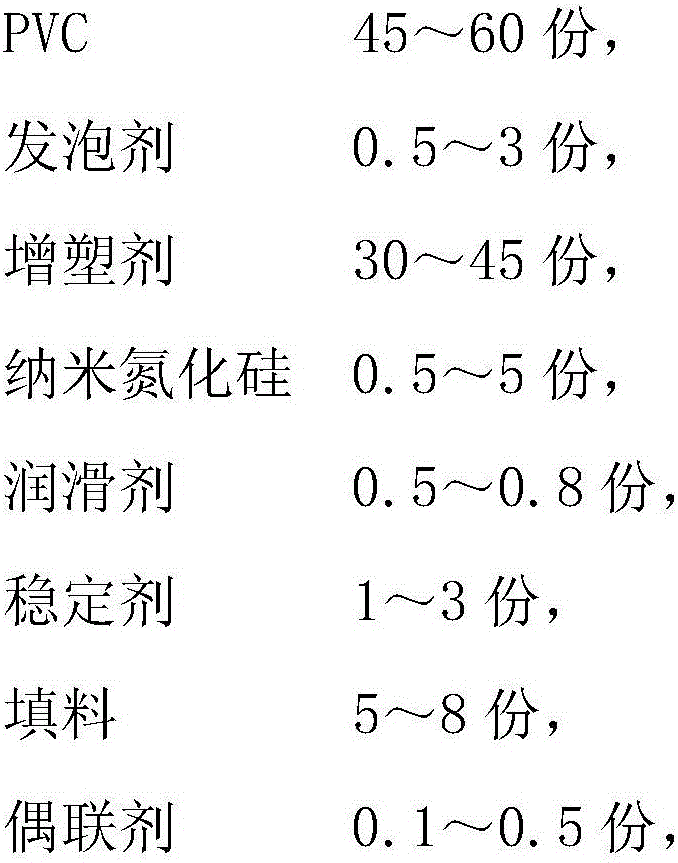

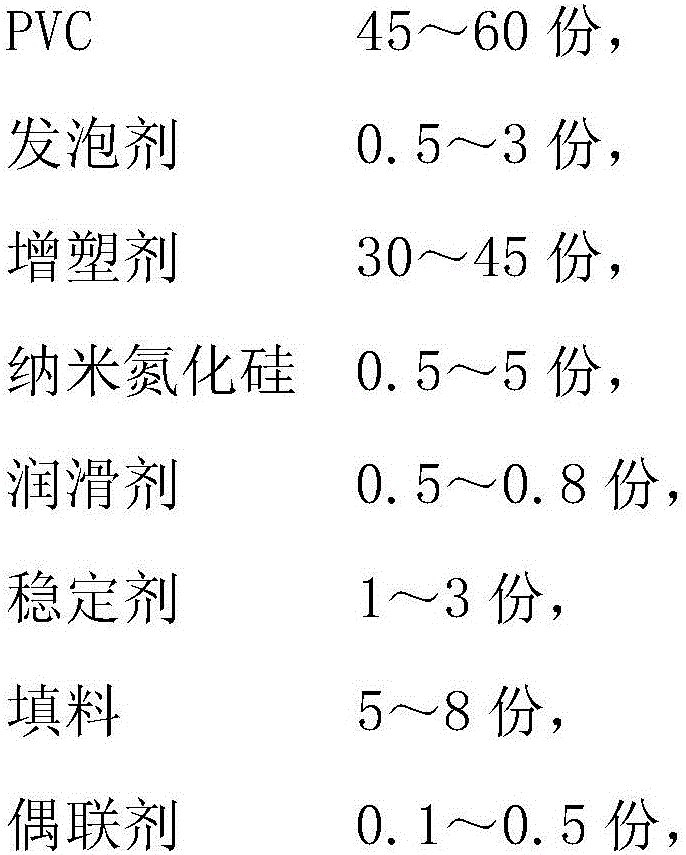

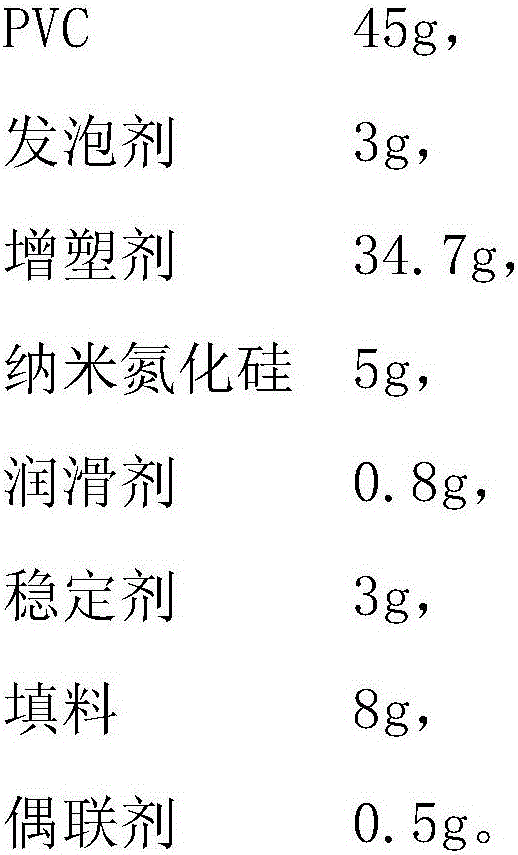

A kind of highly wear-resistant PVC foam sole material and its manufacturing method

ActiveCN104262821BGood self-lubricating performanceImprove wear resistanceSolesNano siliconFoaming agent

The invention provides a high wear-resistant PVC foamed sole material, comprising the following components in parts by weight: 45-60 parts of PVC, 0.5-3 parts of a foaming agent, 30-45 parts of a plasticizer, 0.5-5 parts of nano-silicon nitride, 0.5-0.8 part of a lubricating agent, 1-3 parts of a stabilizer, 5-8 parts of packing and 0.1-0.5 part of a coupling agent. The invention also discloses a preparation method of the high wear-resistant PVC foamed sole material. The wear-resisting property of the high wear-resistant PVC foamed sole material provided by the invention is excellent.

Owner:SUZHOU JINGRO TECH

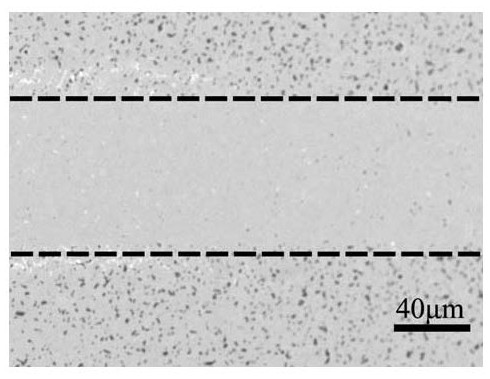

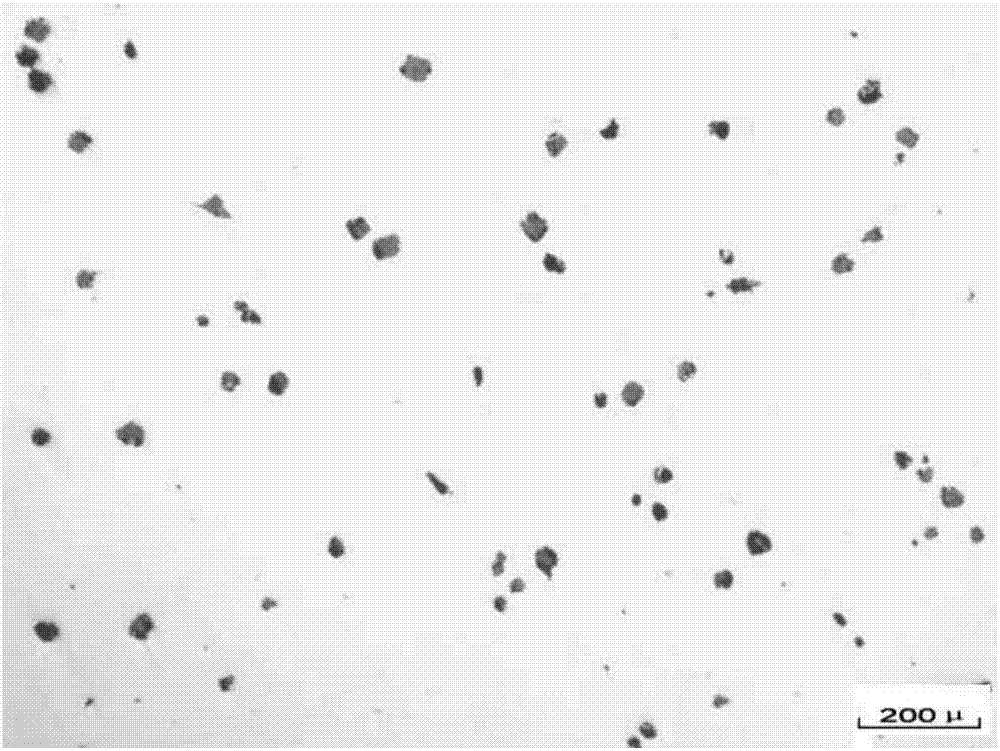

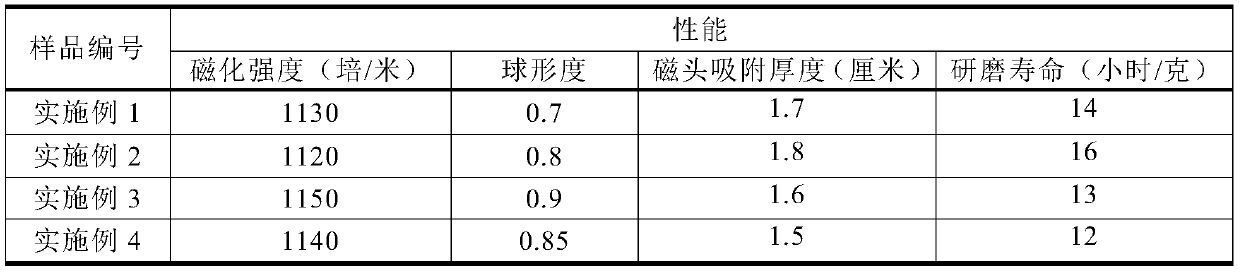

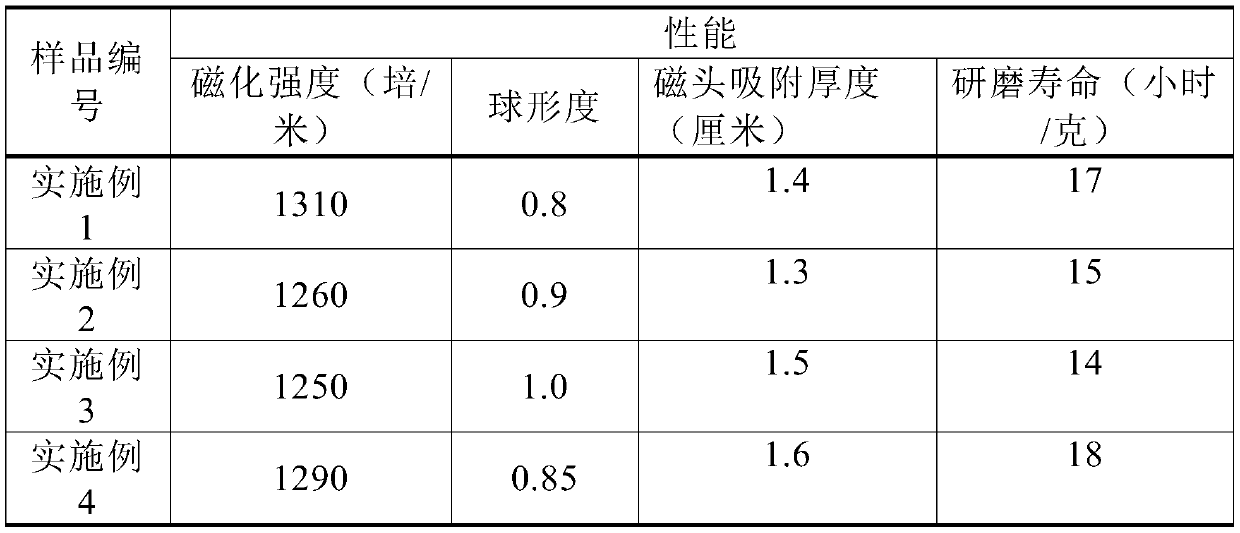

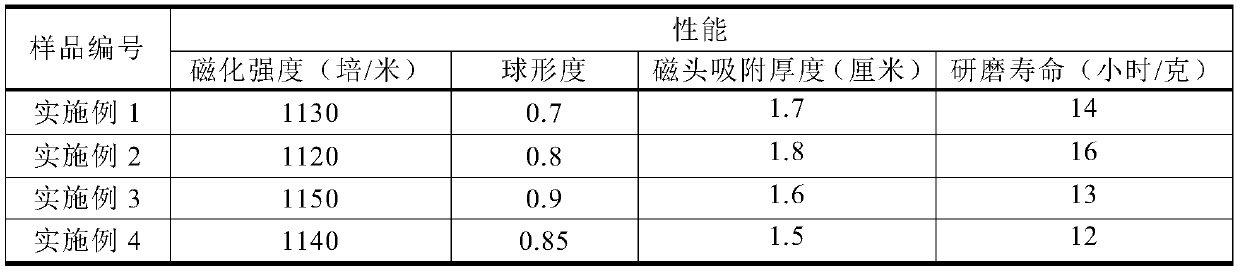

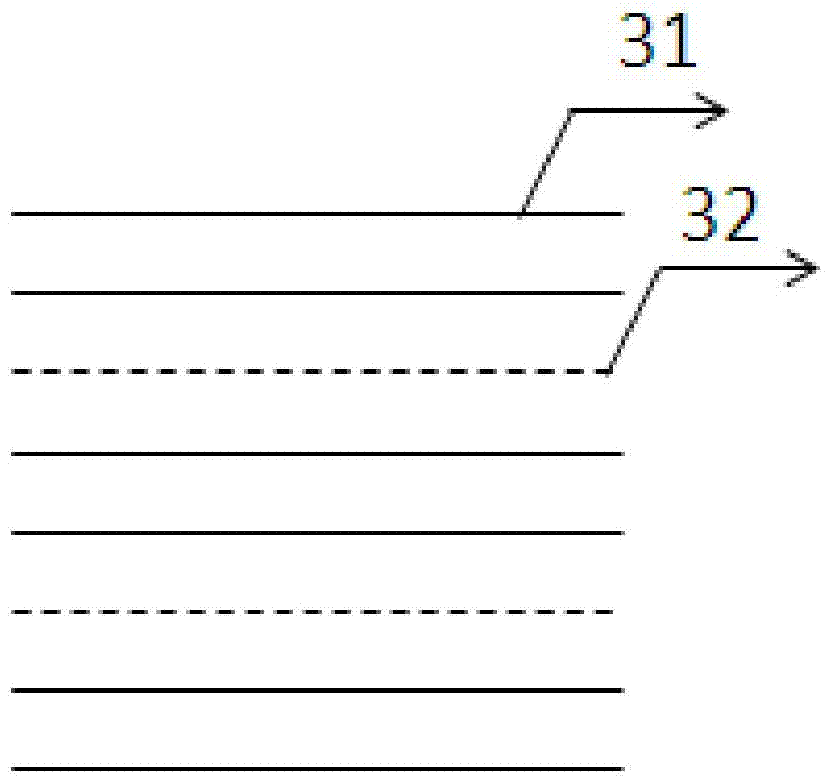

A kind of preparation method of iron-based magnetic grinding powder

ActiveCN110449576BHigh control precisionControl adhesion precisionTransportation and packagingMetal-working apparatusFiberCarbon fibers

The invention discloses a preparation method of iron-based magnetic grinding powder. First, atomized iron powder is treated by high-temperature oxygen spray for pitting corrosion, then oxide impurities are removed by slow cooling and vibration, and then a powder seeding device is used to uniformly disperse the iron powder in α-oxidized iron powder. The surface of the aluminum lattice carbon fiber screen mesh, and the reciprocating vibration screen mesh makes the alumina adhere to the surface of the iron powder, and finally the powder is degreased, and finally the iron-based magnetic grinding powder with a surface structure imitating C60 is obtained. The method has the advantages of high control precision of the surface cutting element array, strong process stability and repeatability, and can realize the high-efficiency processing performance and long life of the iron-based magnetic grinding powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

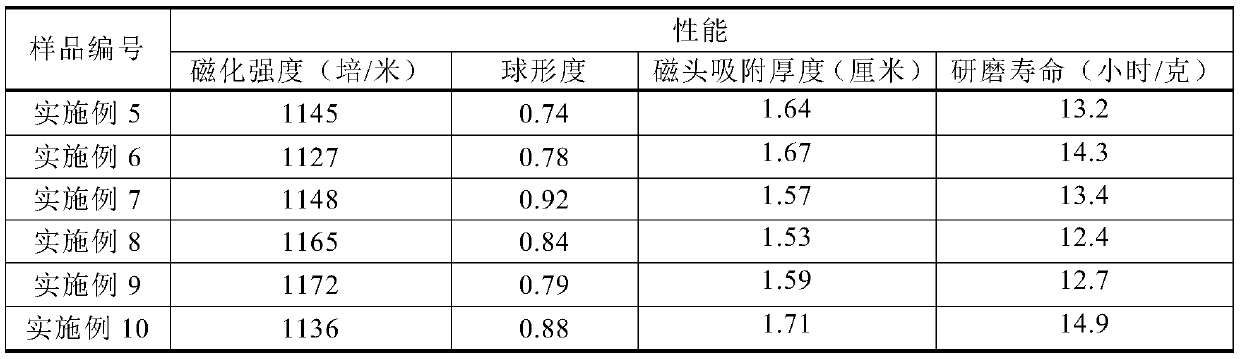

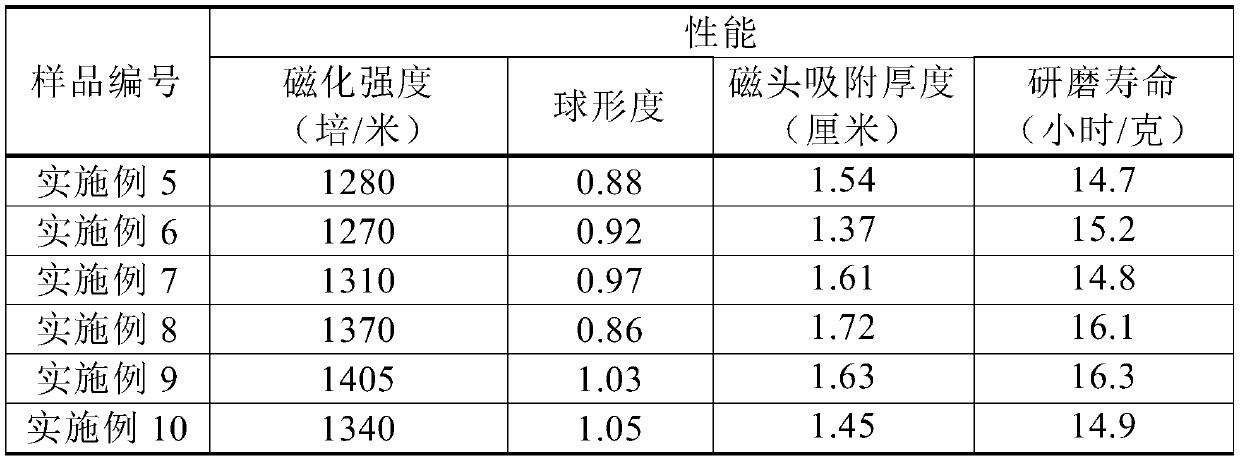

Preparation method of nano cutting element iron-based magnetic fine polishing powder

ActiveCN110508803BGood for chemical adhesionIncrease bezel forceTransportation and packagingMetal-working apparatusHoneycombCold air

The invention discloses a preparation method of nanometer cutting element iron-based magnetic fine throwing powder. First, the atomized iron powder is impacted into a honeycomb micro-involute mold at a high speed by using cold air-driven impact technology, and the mold is vibrated at the same time, and then the obtained double involute The open-line dent iron powder, nano-zirconia powder and dispersant are put into the ammonium hydrogen phosphate solution, and the nano-powder is evenly arranged on the dent of the iron-based powder by a water-bath heat collecting and stirring device, and then filtered, washed, dried, and finally The nano zirconium dioxide is adhered to the iron-based powder for quenching treatment, and finally the nano-cutting element iron-based magnetic fine polishing powder is obtained. This method has high control precision of cutting element array, strong process stability and repeatability, and can realize high performance and long life of iron-based magnetic fine polishing powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

An improved preparation process of flame-retardant and wear-resistant plate

The invention relates to the technical field of abrasion-resistant plates, in particular to a preparation technology of an improved flame retardant abrasion-resistant plate. The abrasion-resistant plate prepared through the technology comprises a flame retardant layer, abrasion-resistant posts and a reinforced plate body. A layer of adhesive is arranged between the flame retardant layer and the reinforced plate body. The material of the flame retardant layer is a glass-magnesium-plant-fiber composite flame retardant plate material; the material of the abrasion-resistant posts is an aluminum oxide ceramic material; the material of the reinforced plate body is an abrasion-resistant steel plate material; a plurality of mounting holes are formed in the flame retardant layer in an arrayed mode,and the abrasion-resistant posts are mounted in the mounting holes in a matched mode; a layer of fire retardant is arranged on the outer surfaces of the abrasion-resistant posts, threaded holes are formed in the bottom ends of the abrasion-resistant posts and the reinforced plate body correspondingly, counterbores are formed in the lower ends of the threaded holes located in the reinforced platebody, and screws used for reinforcing and fixing the abrasion-resistant posts and the reinforced plate body are mounted in the threaded holes and the counterbores; and a layer of fire retardant is arranged at the bottom of the reinforced plate body. The preparation technology provided by the invention is good in fire retardant performance, and good in practical value and popularization value.

Owner:车智路数据管理有限公司

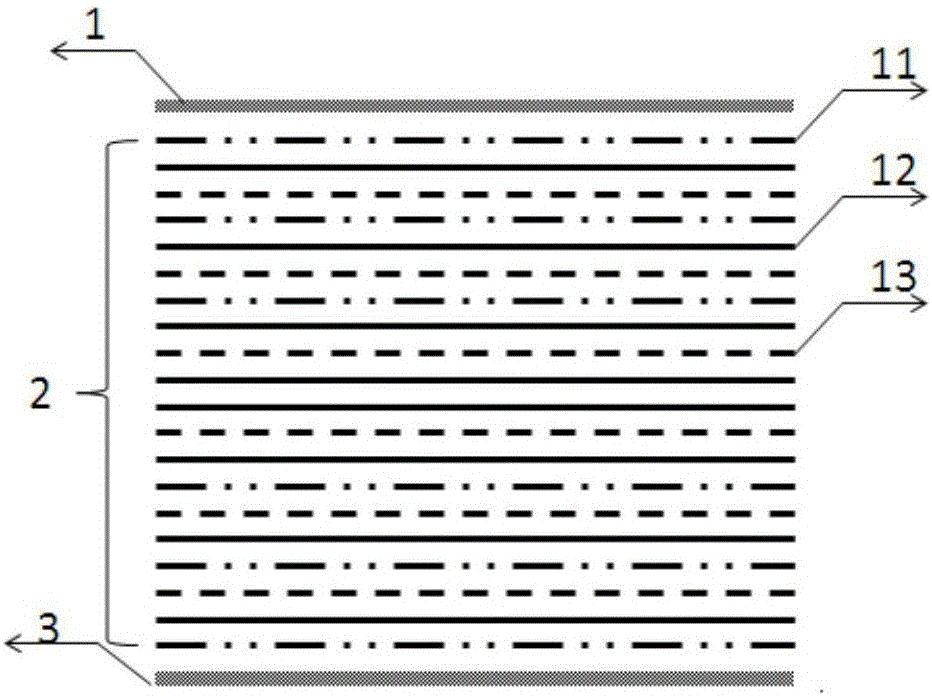

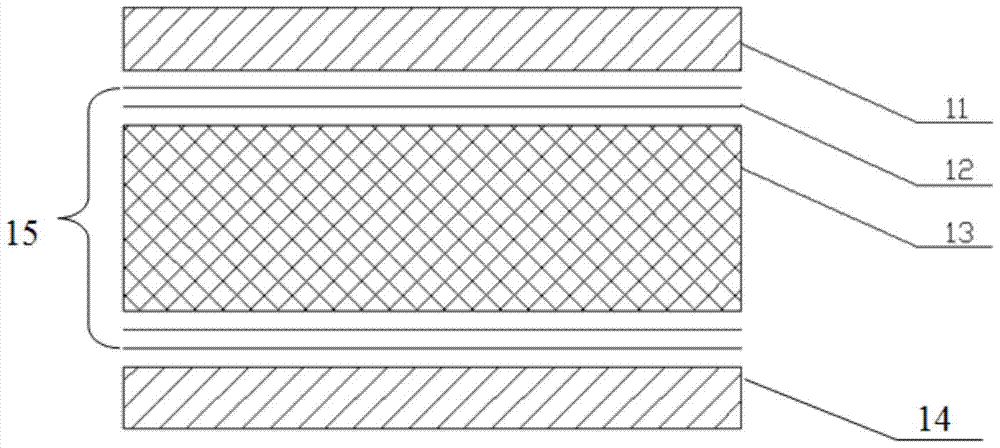

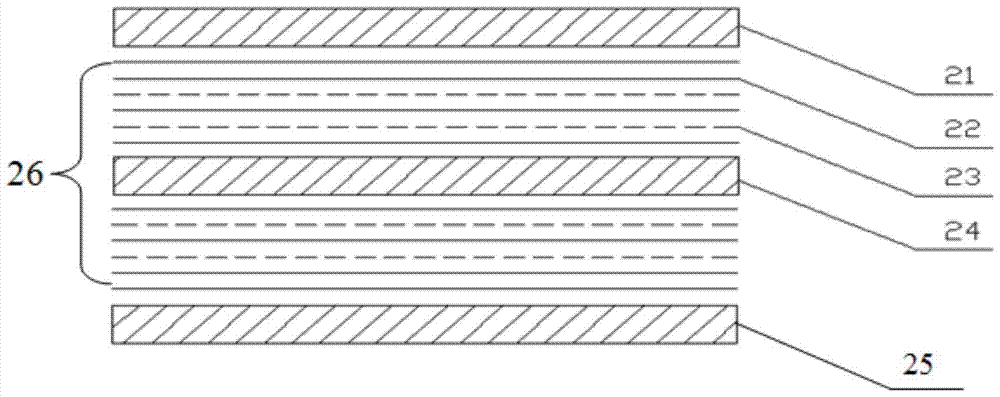

A kind of container bottom plate and preparation method thereof

ActiveCN104802233BStrong designabilityImprove economyLarge containersWood veneer joiningContainerizationSurface layer

The invention discloses a container baseboard. The container baseboard sequentially comprises a surface layer, a sandwich layer and a bottom layer from top to bottom, wherein upper and lower surfaces of the sandwich layer are respectively connected with the surface layer and the bottom layer. The invention further discloses a method for preparing the container baseboard comprises the following steps: paving the sandwich layer on the upper surface of the bottom layer, paving the surface layer on the upper surface of the sandwich layer, and performing hot pressing composite to prepare the container baseboard. The density, strength, elasticity modulus, surface quality and various property indexes of the container baseboard can meet a composite container baseboard with industry standards of the international container, and the container baseboard has strong design, and can reasonably select thickness and density of the surface layer, the bottom layer and the core material according to actual demands, thereby realizing the best economic effect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A preparation process of a multi-layer mixed nano-reinforced layer of iron+vanadium+titanium+titanium nitride deposited on a metal surface

ActiveCN104141110BHigh hardnessGradient distribution is flatVacuum evaporation coatingSputtering coatingSolubilityTitanium nitride

The invention discloses a preparation process for depositing iron+vanadium+titanium+titanium nitride multilayer mixed nano-reinforced layer on the surface of a metal, which utilizes the magnetron sputtering technology to sequentially deposit nanoscale thickness iron+ A mixed transition layer of iron-vanadium+vanadium+vanadium-titanium+titanium+titanium-titanium nitride; finally, a nano-scale titanium nitride strengthening layer is compositely deposited to form a multi-layer mixed transition composite strengthening layer with good bonding force. The present invention uses the concept of solid solubility of various metal atoms to seek alloy elements with infinite mutual solubility and high strength as the transition layer, and uses magnetron sputtering to deposit a mixed nano-transition layer on the surface of the metal material substrate, and finally deposits titanium nitride to form The multi-layer mixed nano-reinforced layer makes the composition gradient distribution of the transition layer gentle and the residual internal stress is small, which greatly increases the bonding strength of the film base and the bonding force with the substrate, and can give full play to the properties of the titanium nitride cermet film on the surface. Corrosion resistance, wear resistance, high hardness characteristics.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A kind of highly wear-resistant polyurethane shoe material and its manufacturing method

ActiveCN104262569BGood self-lubricating performanceHigh surface hardnessFootwearNano siliconFoaming agent

Owner:SUZHOU JINGRO TECH

Preparation method of iron-based magnetic grinding powder

ActiveCN110449576AHigh control precisionStrong process stability and repeatabilityTransportation and packagingMetal-working apparatusOxideFiber

The invention discloses a preparation method of iron-based magnetic grinding powder. Firstly, high temperature oxygen injection pitting treatment is carried out on atomized iron powder; then annealingvibration is carried out to remove oxide impurities; a powder seeding device is used for uniformly dispersing iron powder on the surface of an alphas aluminum oxide lattice carbon fiber screen, and the screen is subjected to reciprocating vibrating to make the alumina adhere to the surface of the iron powder; and finally the powder is degreased, and finally the iron-based magnetic grinding powderimitating a C60 surface structure is obtained. The method has the advantages of being high in control precision of surface cutting element arrays and strong in process stability and repeatability, and being capable of achieving high-efficiency processing performance and long life of the iron-based magnetic grinding powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

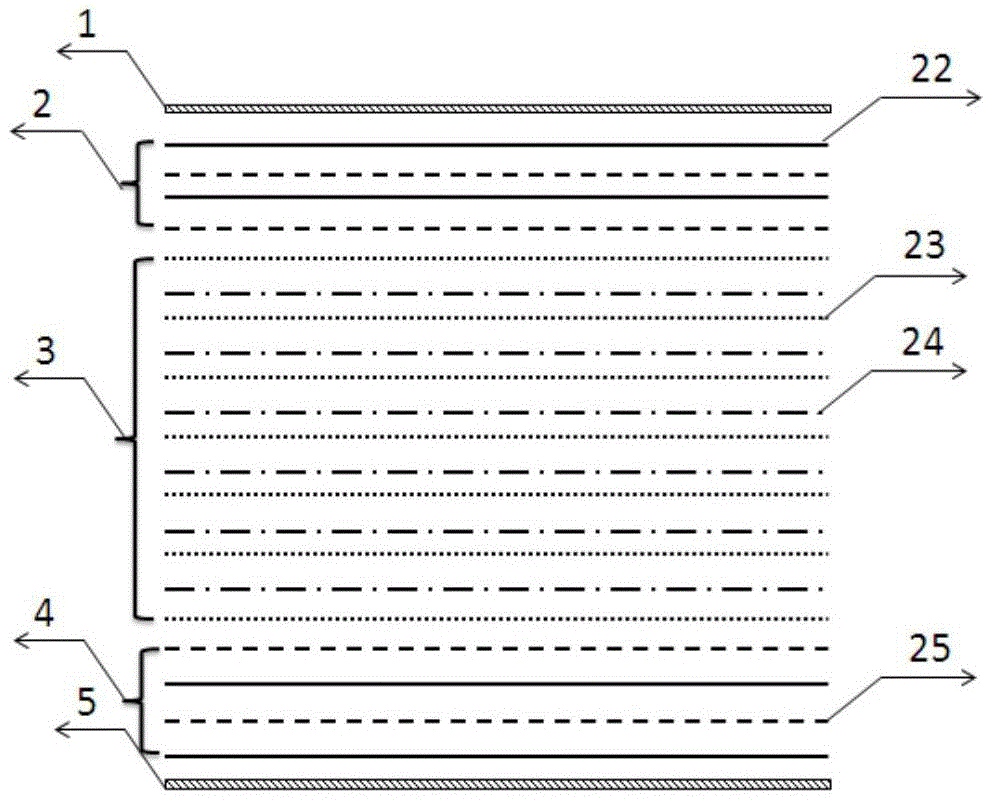

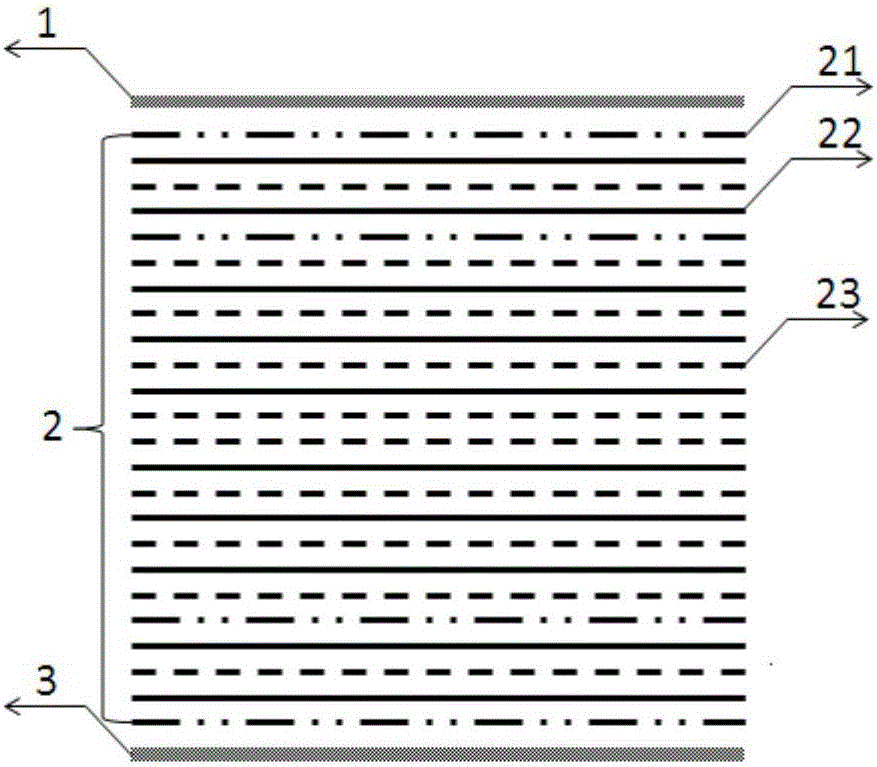

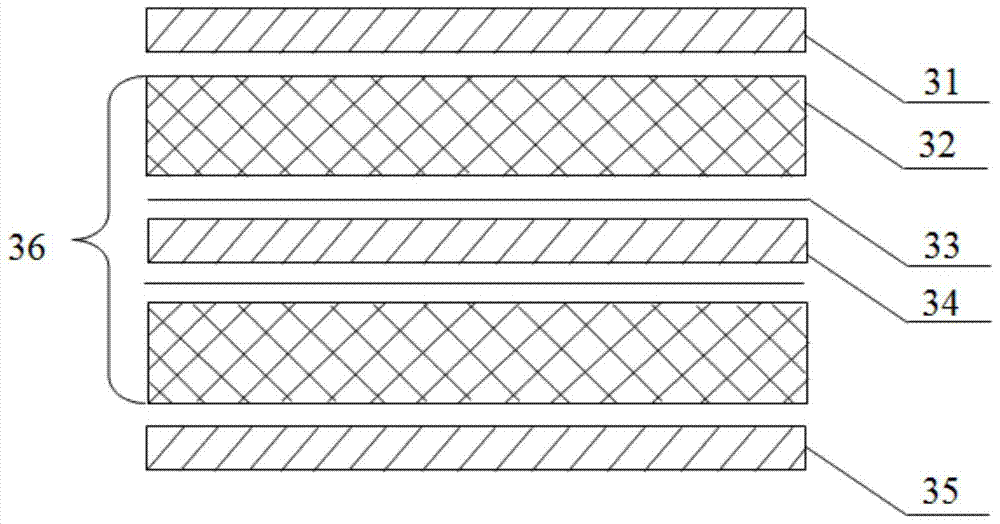

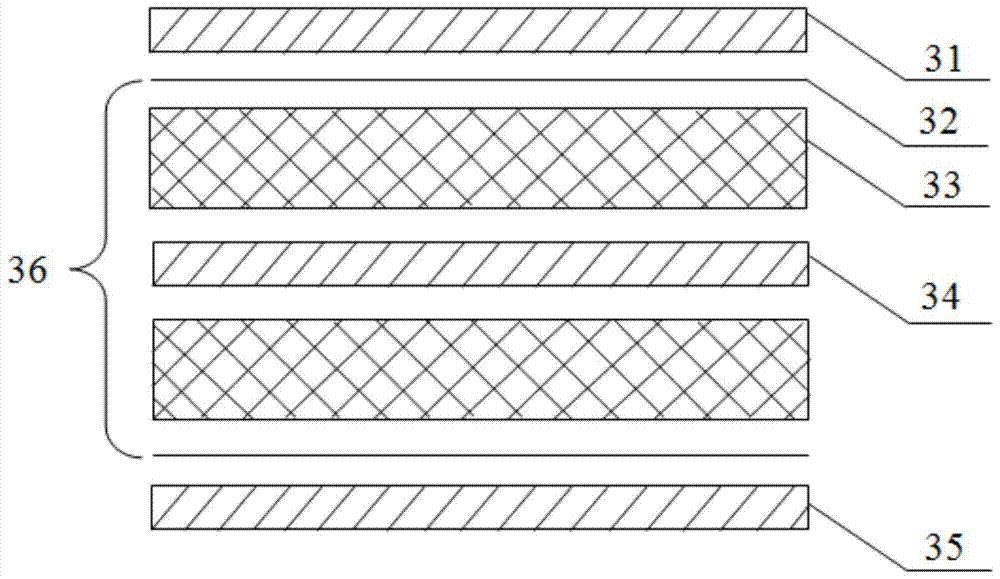

A kind of composite plate, preparation method and application thereof

ActiveCN104802234BStrong designabilityImprove economyNon-macromolecular adhesive additivesBio-packagingSurface layerWear resistance

The invention discloses a composite board. The composite board comprises a first surface layer, a first sandwich layer, a middle sandwich layer, a second sandwich layer and a second surface layer which are sequentially arranged from top to bottom, wherein upper and lower surfaces of the middle sandwich layer are respectively connected with one surface of the first sandwich layer and one surface of the second sandwich layer; the other surface of the first sandwich layer is connected with one surface of the first surface layer through an amphoteric glue film, and the other surface of the second sandwich layer is connected with one surface of the second surface layer through the amphoteric glue film. A method for preparing the composite board comprises the following steps: paving one layer of amphoteric glue films on the second surface layer, paving one layer of second sandwich layers on the amphoteric glue film, paving one layer of middle sandwich layers on the second sandwich layer, paving one layer of first sandwich layers on the upper surface of the middle sandwich layer, paving one layer of amphoteric glue films on the upper surface of the first sandwich layer, paving one layer of first surface layers on the upper surface of the amphoteric glue film, and finally performing hot pressing and pressure maintaining; depressurizing and exhausting or firstly cooling to ambient temperature and releasing pressure in a segmentation manner to prepare the composite board. The composite board has the advantages of abrasion performance and corrosion resistance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Wood-plastic composite board, preparation method and use thereof

ActiveCN104802226BStrong designabilityImprove wear resistanceSynthetic resin layered productsLaminationRoom temperaturePerformance index

The invention discloses a wood-plastic composite board. The wood-plastic composite board sequentially comprises a face layer, a core layer and a bottom layer from top to bottom, wherein the core layer comprises a middle core layer and a reinforcement layer, and the upper surface and the lower surface of the core layer are respectively connected with the face layer and the bottom layer through amphoteric adhesive films. A manufacturing method comprises the steps of respectively coating the amphoteric adhesive films on the upper surface and the lower surface of the core layer, then covering the face layer and the bottom layer respectively and finally performing hot pressing and pressure maintaining; performing segmented pressure reduction and exhausting or performing cooling to reach room temperature and then performing pressure relief to obtain the wood-plastic composite board. The density, strength, elasticity modulus, surface quality and other performance indexes of the wood-plastic composite board all meet the requirement of composite container base plates conforming to the international containerindustrial standard, so that the wood-plastic composite board serves as the composite container base plate and is high in designability, and the thickness and density of the face layer and the core layer are reasonably selected according to the actual demand to achieve the best economic effect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A plastic composite bottom plate, its preparation method and its use

ActiveCN104802486BStrong designabilityImprove wear resistanceSynthetic resin layered productsLarge containersSurface layerRoom temperature

The invention discloses a plastic composite bottom plate, which comprises a surface layer, a core layer and a bottom layer arranged in sequence from top to bottom, the core layer includes a central core layer and a reinforcement layer, and the upper and lower surfaces of the core layer are respectively bonded by amphoteric adhesive A film is attached to the top layer and the bottom layer. The preparation method is as follows: evenly cover the upper and lower surfaces of the core layer with a layer of amphoteric adhesive film, stick the upper layer and the bottom layer respectively, then heat press and hold the pressure; then depressurize and exhaust in stages or cool to room temperature first and then release the pressure ; Prepared plastic composite bottom plate. The plastic composite bottom plate in the present invention, its density, strength, elastic modulus and surface quality and other performance indicators all reach the composite container bottom plate of the international container industry standard, so it is used as a container bottom plate, which has strong designability and can be used according to actual conditions. The thickness and density of the surface layer and the core layer should be reasonably selected to achieve the best economic effect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com