Connection method of silicon carbide ceramics based on liquid phase sintering

A technology of silicon carbide ceramics and liquid phase sintering, which is applied in the field of ceramic connection, can solve the problems affecting the connection strength and service temperature, and achieve the effects of alleviating huge interface welding stress, excellent corrosion resistance, and widening the field of use and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Slurry preparation: Add SiC balls, absolute ethanol, castor oil phosphate, polyvinyl butyral and mixed powder (SiC, AlN and Y 2 o 3 ), carry out ball milling, the control speed is 300 rpm, the time is 12h, and the ball-to-material ratio is 1:1. Wherein, the massfraction of castor oil phosphate is 5.5%, the massfraction of polyvinyl butyral ester is 2.5%, solid content is 50%, slurry viscosity is 800mPa.s (when shear rate is 20 / S) . SiC:AlN:Y 2 o 3 The mass ratio is 90:2:8. D of SiC powder 50 0.35μm, AlN D 50 0.18μm, Y 2 o 3 The median particle size D 50 4.87μm;

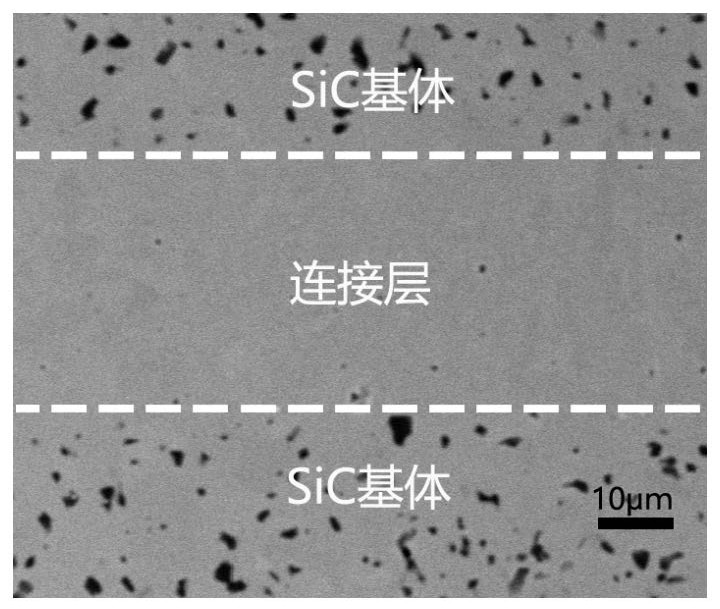

[0051] 2) Joining process: use a spin coater to coat two pieces of SiC ceramics whose surfaces have been treated by a grinder, and control the thickness of the slurry layer to 100 μm, and assemble it with a graphite fixture, with a pressure of 5 MPa. The joining is then performed in a pressureless sintering furnace. The specific process parameters are: rise to 1400°C at 10°C / min, then rise to 190...

Embodiment 2

[0054] 1) Slurry preparation: similar to Example 1, the difference is that the solid content is 50%, the slurry ball milling time is 24h, and the slurry viscosity is 630mPa.s (when the shear rate is 20 / S);

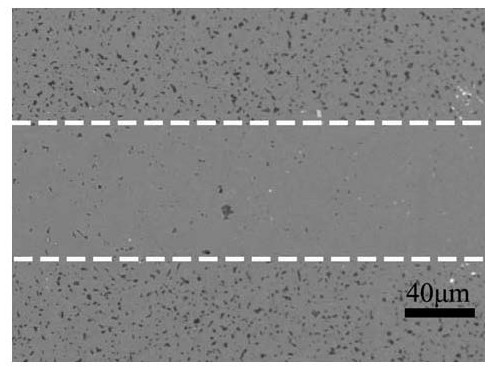

[0055] 2) Connection process: similar to the implementation case 1, the difference is that the highest temperature is 1700°C, and the holding time is 2h;

[0056] 3) Connection performance: The connection strength of the connected joint in this embodiment is 150 MPa at room temperature, and 100 MPa at a high temperature of 1400°C.

Embodiment 3

[0058] 1) Slurry preparation: similar to Example 1, the difference is that SiC:AlN:Y 2 o 3 The mass ratio is 95:1:4;

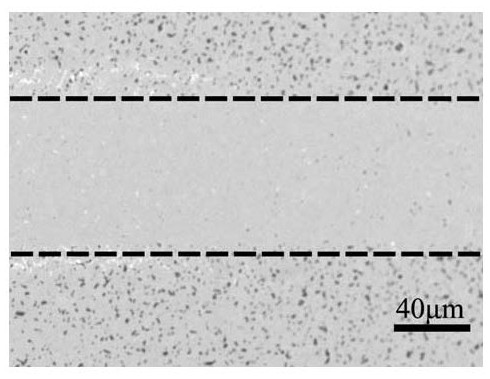

[0059] 2) Connection process: similar to Example 1, the difference is that the highest temperature is 1800°C and the holding time is 0.5h;

[0060] 3) Connection performance: the connection strength of the connected joint in this embodiment is 197 MPa at room temperature, and 167 MPa at a high temperature of 1400°C. After 72 hours of concentrated sulfuric acid corrosion, the connection strength is 170MPa; after 72 hours of concentrated nitric acid corrosion, the connection strength is 150MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com