A kind of composite plate, preparation method and application thereof

A composite board and board technology, applied in the application, chemical instruments and methods, manufacturing tools and other directions, can solve the problems of high cost, low processing efficiency and low utilization rate of bamboo container floors, and achieves strong designability and ease of use. Cleaning, environmental protection favorable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

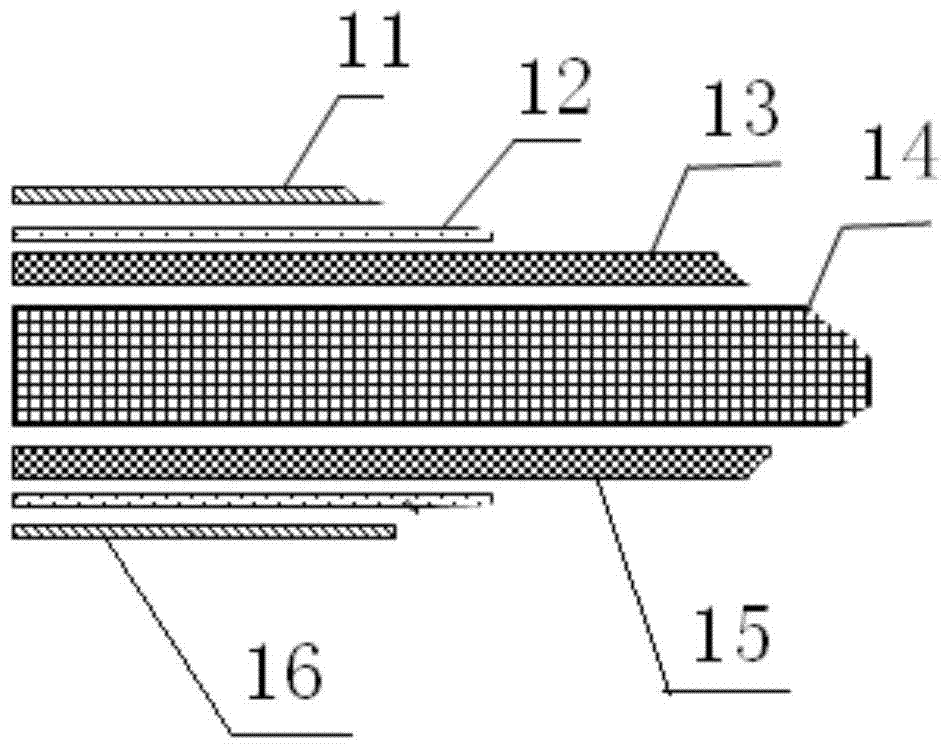

[0059] The first surface layer and the second surface layer are made by the following method:

[0060] The glass fiber is spread out and compounded with the extruded and melted resin matrix PP matrix, and then rolled to obtain a fiber-reinforced thermoplastic prepreg tape, in which the fiber accounts for 55% of the total mass of the prepreg tape, and then heated at a temperature of 180°C , under the condition of a pressure of 3MPa, the fiber-reinforced thermoplastic prepreg tape is hot-pressed into a sheet for 20 minutes, and then cold-pressed for 30 minutes to obtain a fiber-reinforced thermoplastic sheet, that is, the first surface layer and the second surface layer, The thickness is 2mm.

[0061] The first core layer and the second core layer are pretreated, and the pretreatment includes the following steps:

[0062] Moso bamboo is processed to form bamboo strips, and the bamboo strips are woven to form a crisscross bamboo mat material; the first drying is carried out; the...

Embodiment 2

[0069] The first surface layer and the second surface layer are made by the following method:

[0070] The glass fiber is spread out and compounded with the extruded and melted resin matrix PP matrix, and then rolled to obtain a fiber-reinforced thermoplastic prepreg tape, in which the fiber accounts for 50% of the total mass of the prepreg tape, and then heated at a temperature of 175°C , under the condition of a pressure of 4MPa, the fiber-reinforced thermoplastic prepreg tape is hot-pressed into a sheet for 30 minutes, and then cold-pressed for 35 minutes to obtain a fiber-reinforced thermoplastic sheet, that is, the first surface layer and the second surface layer, The thickness is 3mm.

[0071] The first core layer and the second core layer are pretreated, and the pretreatment includes the following steps:

[0072] Bamboo bamboo is processed to form bamboo strips, which form a criss-crossed bamboo mat material after weaving; first drying; then put into the dipping device...

Embodiment 3

[0078] The first surface layer and the second surface layer are made by the following method:

[0079] The glass fiber is spread out and compounded with the extruded and melted resin matrix PP matrix, and then rolled to obtain a fiber-reinforced thermoplastic prepreg tape, in which the fiber accounts for 45% of the total mass of the prepreg tape, and then heated at a temperature of 170°C , under the condition of a pressure of 4MPa, the fiber-reinforced thermoplastic prepreg tape is hot-pressed into a sheet for 30 minutes, and then cold-pressed for 35 minutes to obtain a fiber-reinforced thermoplastic sheet, that is, the first surface layer and the second surface layer, The thickness is 4mm.

[0080] The first core layer and the second core layer are pretreated, and the pretreatment includes the following steps:

[0081] Bamboo bamboo is processed to form bamboo strips, which form a criss-crossed bamboo mat material after weaving; first drying; then put into the dipping device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com