High-wear-resistance nitrile rubber composite cable material and preparation method thereof

A technology of composite cable material and nitrile rubber, which is applied in the direction of rubber insulators and organic insulators, and can solve the problems of easy wear, general physical and mechanical properties, and low air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

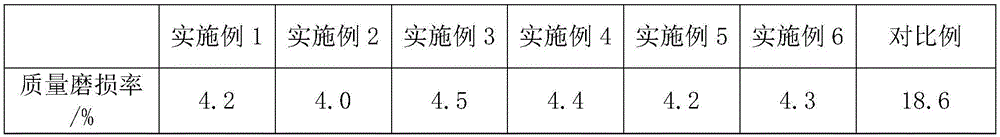

Examples

Embodiment 1

[0032] High wear-resistant nitrile rubber composite cable material, made of the following components in parts by weight: 100 parts of nitrile rubber, 4 parts of accelerator M, 2.5 parts of antioxidant 1068, 12 parts of antimony trioxide, white carbon 11 parts of black, 1.3 parts of coupling agent A151, 8 parts of dioctyl adipate, 1.1 parts of sulfur, 2.5 parts of antioxidant ODA, 8 parts of modified composite zirconia, 4 parts of zinc oxide, and 2 parts of stearic acid.

[0033] The preparation method of this nitrile rubber composite cable material comprises the following steps:

[0034] (1) Add cerium nitrate hexahydrate to zirconium nitrate trihydrate, stir until evenly mixed, then add citric acid, stir for 30 minutes and heat to 60°C, continue stirring for 5 hours, let stand for 1 hour, place in an oven to dry, Transfer to a high-temperature furnace and heat up to 900°C, calcining for 5 hours, and passing through a 100-mesh sieve after grinding to obtain composite zirconia,...

Embodiment 2

[0039] High wear-resistant nitrile rubber composite cable material, made of the following components in parts by weight: 100 parts of nitrile rubber, 4.4 parts of accelerator M, 2.3 parts of antioxidant 1068, 10 parts of antimony trioxide, white carbon 13 parts of black, 1.5 parts of coupling agent A151, 10 parts of dioctyl adipate, 1.3 parts of sulfur, 2.7 parts of antioxidant ODA, 7 parts of modified composite zirconia, 4 parts of zinc oxide, 2 parts of stearic acid.

[0040] The preparation method of this nitrile rubber composite cable material is the same as that of Example 1.

Embodiment 3

[0042] High wear-resistant nitrile rubber composite cable material, made of the following components in parts by weight: 100 parts of nitrile rubber, 4.2 parts of accelerator M, 2.1 parts of antioxidant 1068, 8 parts of antimony trioxide, white carbon 15 parts of black, 1.1 parts of coupling agent A151, 6 parts of dioctyl adipate, 1.5 parts of sulfur, 2.9 parts of antioxidant ODA, 7.5 parts of modified composite zirconia, 4 parts of zinc oxide, and 2 parts of stearic acid.

[0043] The preparation method of this nitrile rubber composite cable material is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com