Environmentally-friendly cutting-resistant off-the-road tyre tread rubber

A technology for construction machinery and tire treads, applied in special tires, tire parts, transportation and packaging, etc., can solve problems that affect products, affect the performance of rubber materials, and are not disclosed, and achieve excellent wear resistance and excellent cutting resistance. performance, the effect of enhancing cut resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

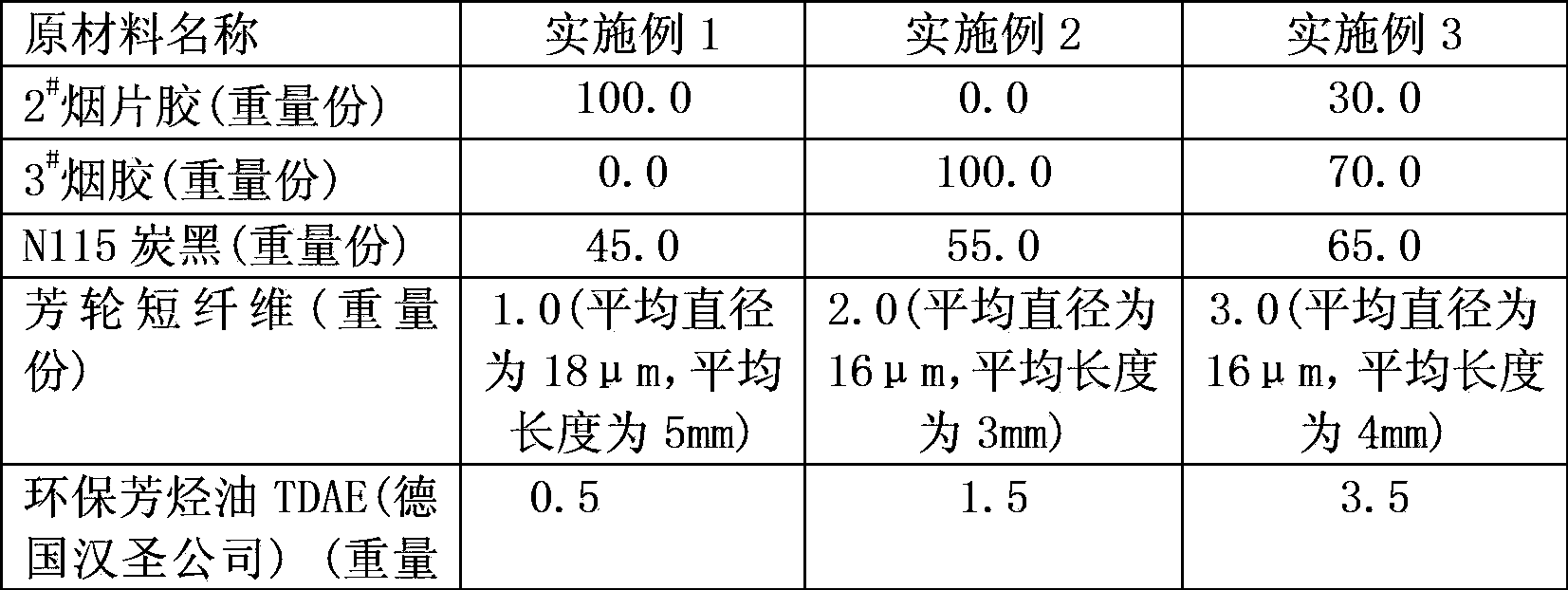

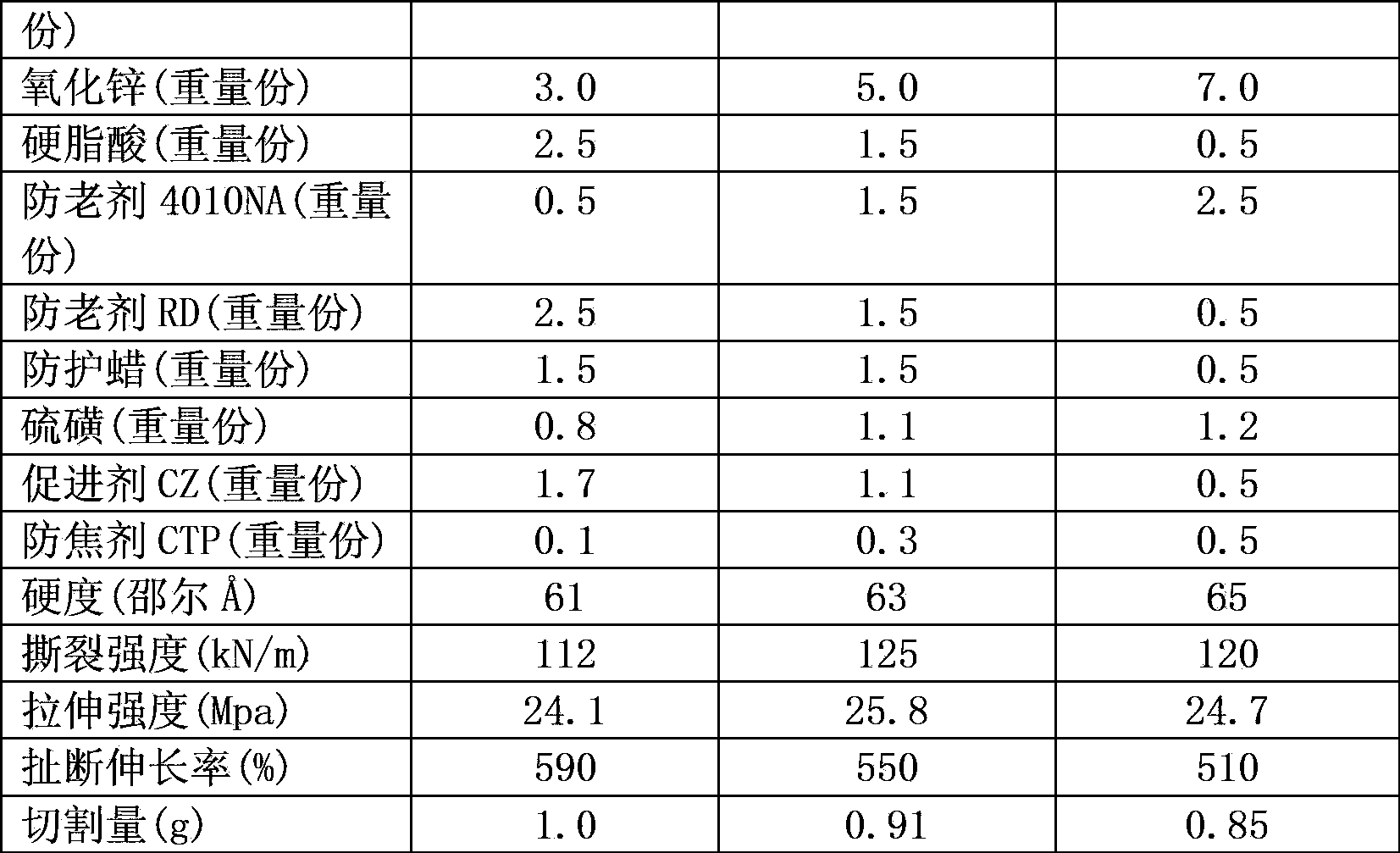

[0028] Carry out rubber mixing by each component specified in the following table 2, preparation method:

[0029] 1) Weigh 2 of them according to the formula # Smoke sheet glue, 3 # Smoked rubber, reinforcing carbon black, short fibers, environmentally friendly aromatic oil, zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD and protective wax were put into the rubber internal mixer (rotor speed is 40r / min), at 160°C Mixing at a speed of 40r / min for 4min to obtain rubber compound A;

[0030] 2) Weigh the sulfur, accelerator CZ and anti-scorch agent CTP according to the formula, put them into a rubber internal mixer and mix them with compound rubber A, and mix them at 90°C for 3 minutes at a speed of 20r / min to obtain an environmentally friendly Cut-resistant off-road tire tread compound.

[0031] The performance tests of the obtained rubber compounds are carried out, and the test results are listed in Table 2.

Embodiment 2

[0033] Carry out rubber mixing by each component specified in the following table 2, the preparation method of rubber material is the same as embodiment 1.

[0034] The performance tests of the obtained rubber compounds are carried out, and the test results are listed in Table 2.

Embodiment 3

[0036] Carry out rubber mixing by each component specified in the following table 2, the preparation method of rubber material is the same as embodiment 1.

[0037] The performance tests of the obtained rubber compounds are carried out, and the test results are listed in Table 2.

[0038] Table 2

[0039]

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com