A plastic composite bottom plate, its preparation method and its use

A technology of plastic plates and plastics, applied in chemical instruments and methods, synthetic resin layered products, transportation and packaging, etc., can solve the problems of high cost of bamboo container bottom plates, inability to use large-scale marketization, and low processing efficiency. Achieve the effect of saving drying and processing process and time, strong designability and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

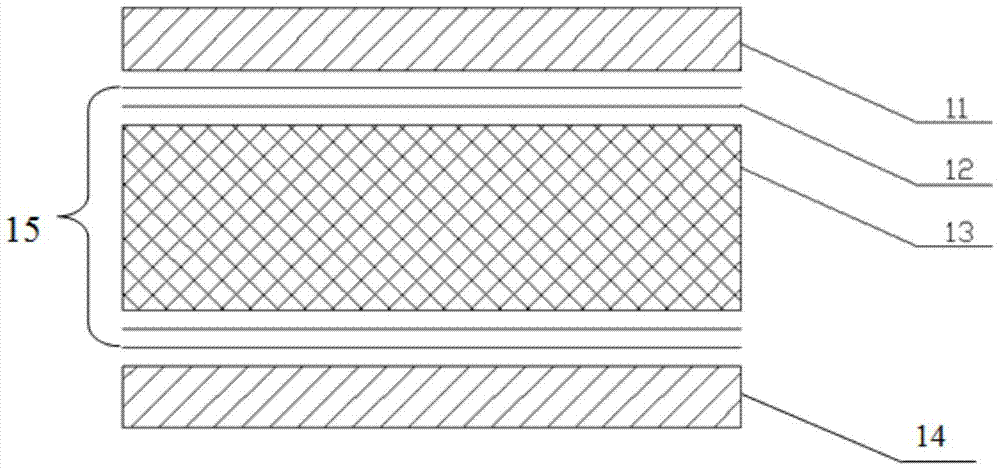

[0045] A preparation method of a plastic composite bottom plate is as follows:

[0046] The surface layer is a continuous glass fiber reinforced polypropylene sheet surface layer 11, and the preparation method of the surface layer 11 and the bottom layer 14 includes the following steps: spreading the continuous glass fiber and compounding it with the extruded and melted resin matrix polypropylene, and the fiber accounts for 1% of the resin matrix The mass percentage is 40%, and after rolling, the fiber-reinforced thermoplastic prepreg tape is obtained, and then the fiber-reinforced thermoplastic prepreg tape is hot-pressed at a temperature of 170-180°C and a pressure of 2-4MPa. The plate is hot-pressed for 20-30 minutes, and then cold-pressed for 30-40 minutes to obtain a continuous glass fiber reinforced polypropylene plate surface layer 11, and the laying method is longitudinal.

[0047] The core layer 13 is produced by the following method: put recycled polypropylene plasti...

Embodiment 2

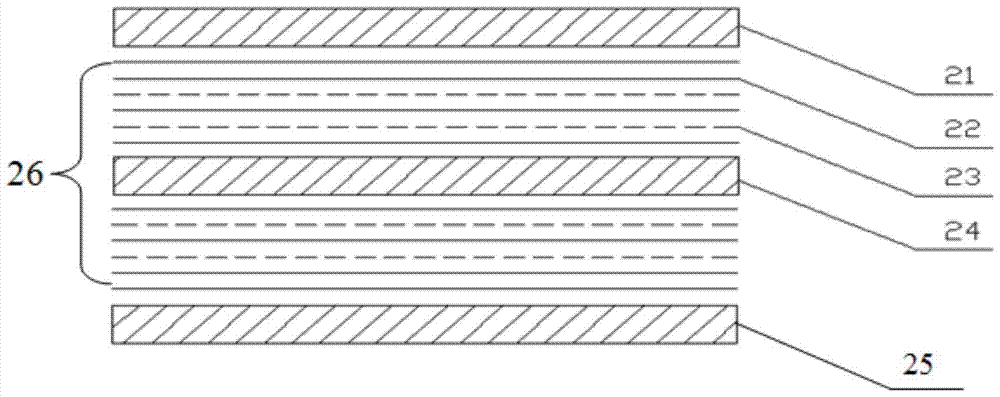

[0053] A preparation method of a plastic composite bottom plate is as follows:

[0054] The preparation method of the surface layer 21, the bottom layer 25 and the reinforcement layer 24 includes the following steps: spreading the continuous glass fiber, compounding it with the extruded molten resin matrix polyethylene, the fiber accounts for 48% by mass of the resin matrix, and then rolling After pressing, the fiber-reinforced thermoplastic prepreg tape is obtained, and then the fiber-reinforced thermoplastic prepreg tape is hot-pressed into a board at a temperature of 170-180°C and a pressure of 2-4MPa, and the hot-pressing time is 20-30min , and then cold pressed for 30 to 40 minutes to obtain a continuous glass fiber reinforced polyethylene sheet, and the laying method is longitudinal.

[0055] The central core layer 22 is produced by the following method: put recycled polyethylene plastic into an extruder to melt and extrude, cool and shape to obtain a recycled plastic sh...

Embodiment 3

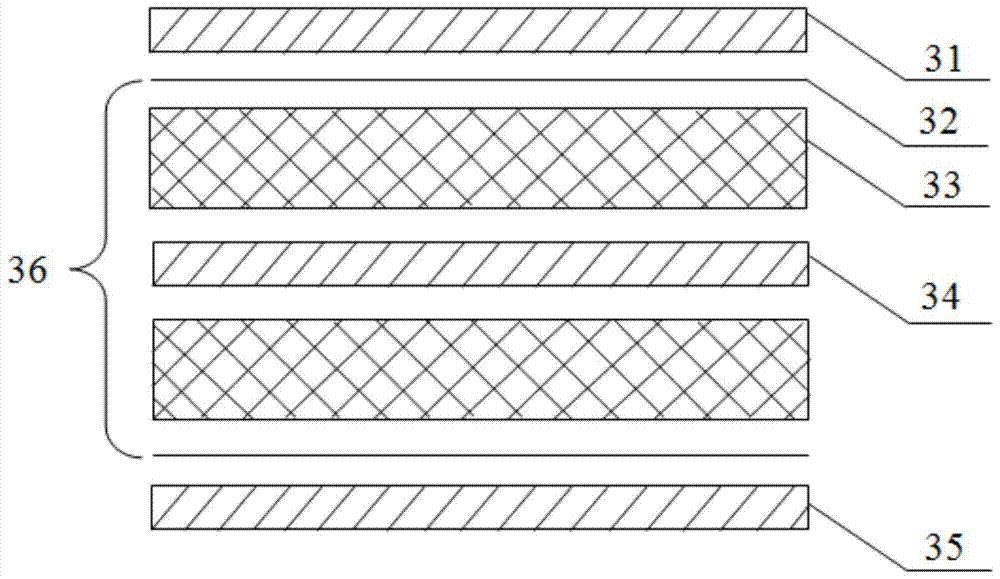

[0061] A preparation method of a plastic composite bottom plate is as follows:

[0062] The surface layer 31, the bottom layer 35 and the reinforcement layer 234 are all continuous glass fiber reinforced polystyrene sheets, and the preparation method includes the following steps: spreading the continuous glass fibers and compounding them with extruded molten resin matrix polystyrene, the fibers occupying the resin The mass percentage of the matrix is 55%, and after rolling, the fiber-reinforced thermoplastic prepreg tape is obtained, and then the fiber-reinforced thermoplastic prepreg tape is heated at a temperature of 160-180°C and a pressure of 2-4MPa. Press it into a board, hot press for 20-30 minutes, and then cold press for 30-40 minutes to obtain a continuous glass fiber reinforced polystyrene board, and the laying method is longitudinal.

[0063] The central core layer 33 is produced by the following method: put recycled polystyrene plastic into an extruder to melt an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com