An improved preparation process of flame-retardant and wear-resistant plate

A preparation process and wear-resistant plate technology, applied in the field of wear-resistant plates, can solve the problems of poor flame-retardant performance of wear-resistant plates, and achieve the effects of good flame-retardant function, enhanced fixed connection, and guaranteed wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

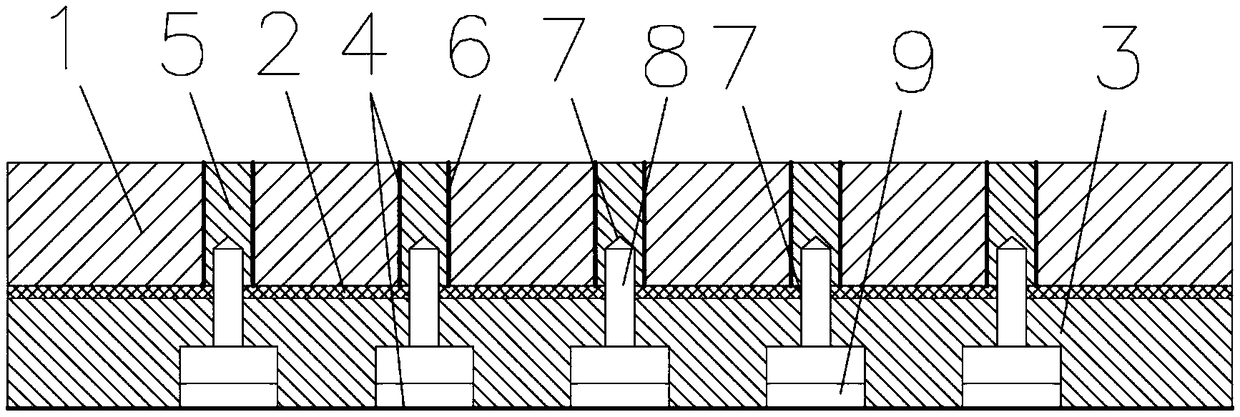

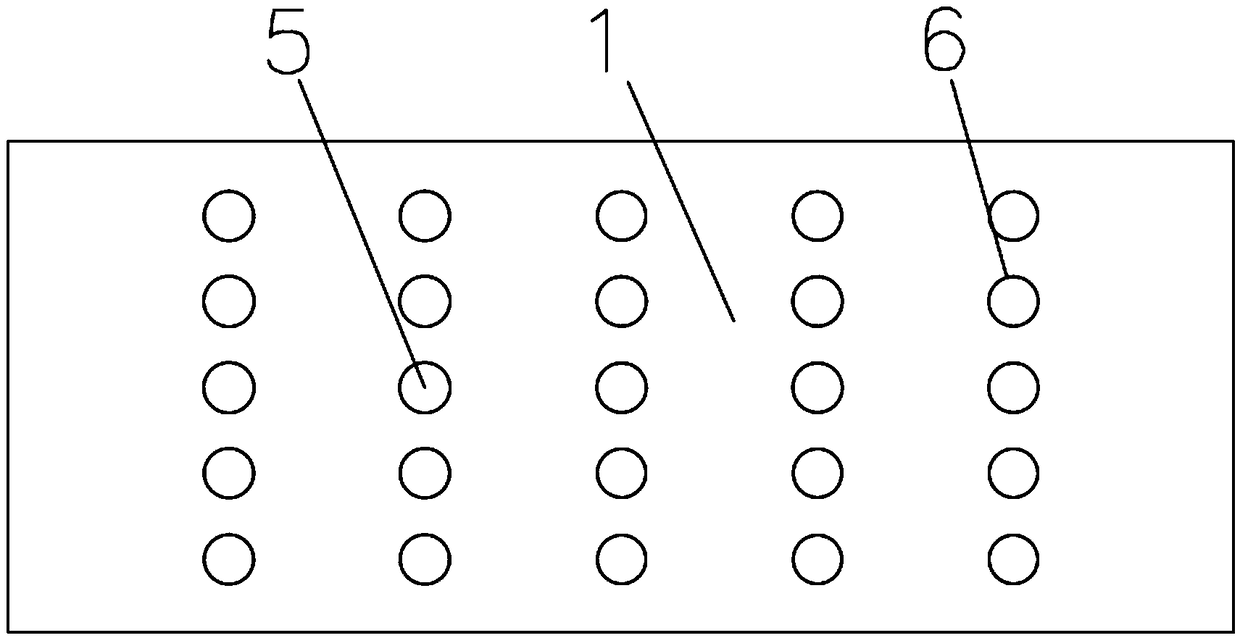

[0023] Example 1, such as Figure 1-2 Shown:

[0024] An improved process for preparing a flame-retardant and wear-resistant plate, comprising the following steps: (1) using a flame-retardant material to prepare a flame-retardant plate as a flame-retardant layer 1 of the wear-resistant plate, and processing several through holes on the flame-retardant layer 1 The mounting hole 6 of the structure; (2) using wear-resistant materials to process and prepare several wear-resistant columns 5 that match the mounting holes 6, and process the threaded hole 7 structure at the bottom of the wear-resistant column 5; (3) wear-resistant column 5 The outer surface is dipped and coated with a layer of flame retardant 4, which is ready for use after the flame retardant 4 is dried; prepare a reinforced plate 3 made of metal, process a countersunk hole 9 on the bottom surface of the reinforced plate 3, and process threads on the upper end of the countersunk hole 9 hole 7 structure; (4) coat a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com