Metal ceramic tool material and preparation method thereof

A tool material and cermet technology, applied in the field of cermets, can solve the problems of poor material stability, difficult control of metallographic structure, unsatisfactory cutting performance, etc., and achieve high bending strength, high cost performance and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

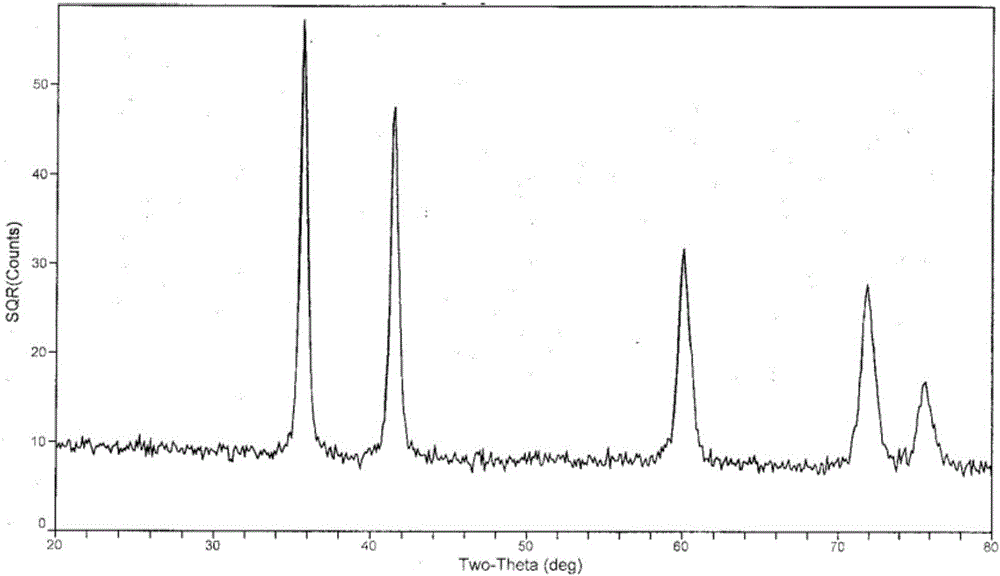

Image

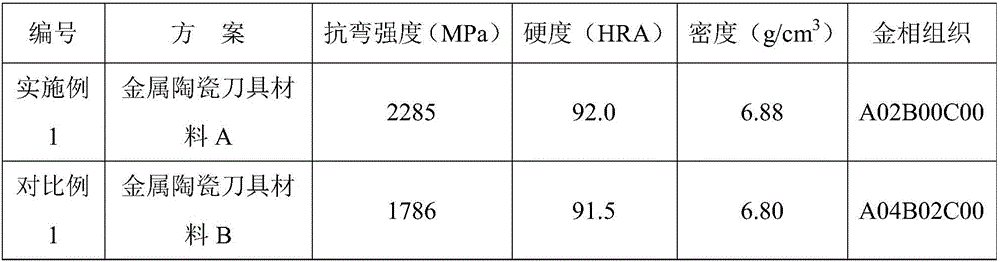

Examples

Embodiment 1

[0022] The cermet cutting tool material of the present embodiment contains 10 parts of Co, 8 parts of Ni, 10 parts of Mo in parts by mass. 2 C, 25 copies (W 0.3 Ta 0.22 Ti 0.48 )(C 0.75 N 0.25 ) and 50 parts of TiC 0.7 N 0.3 , where the chemical formula of the five-component solid solution is (W 0.3 Ta 0.22 Ti 0.48 )(C 0.75 N 0.25 ).

[0023] The preparation method of the cermet tool material specifically comprises the following steps:

[0024] (1) Calculated in parts by mass, weigh 50 parts of TiC respectively 0.7 N 0.3 , 25 copies (W 0.3 Ta 0.22 Ti 0.48 )(C 0.75 N 0.25 ), 7 parts of Co, 8 parts of Ni and 10 parts of Mo 2 C, mixing;

[0025] (2) Using hexane as the wet milling medium, ball milling for 70 hours to uniformly mix the raw materials, wherein the ball-to-material ratio is 4:1;

[0026] (3) Add wax and mix for 2 hours, dry and granulate, press into blade blanks, and sinter under low pressure for 1.5 hours at 1470°C and 4-6 MPa to obtain cermet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com