Lightweight high-strength calcium silicate board and preparation process thereof

A technology of calcium silicate board and preparation process, applied in the field of building materials, can solve the problems of reducing quality, increasing the deformation coefficient of calcium silicate board, darkening color, etc., to improve strength and qualification rate, improve impermeability and waterproof performance, The effect of promoting the formation of crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

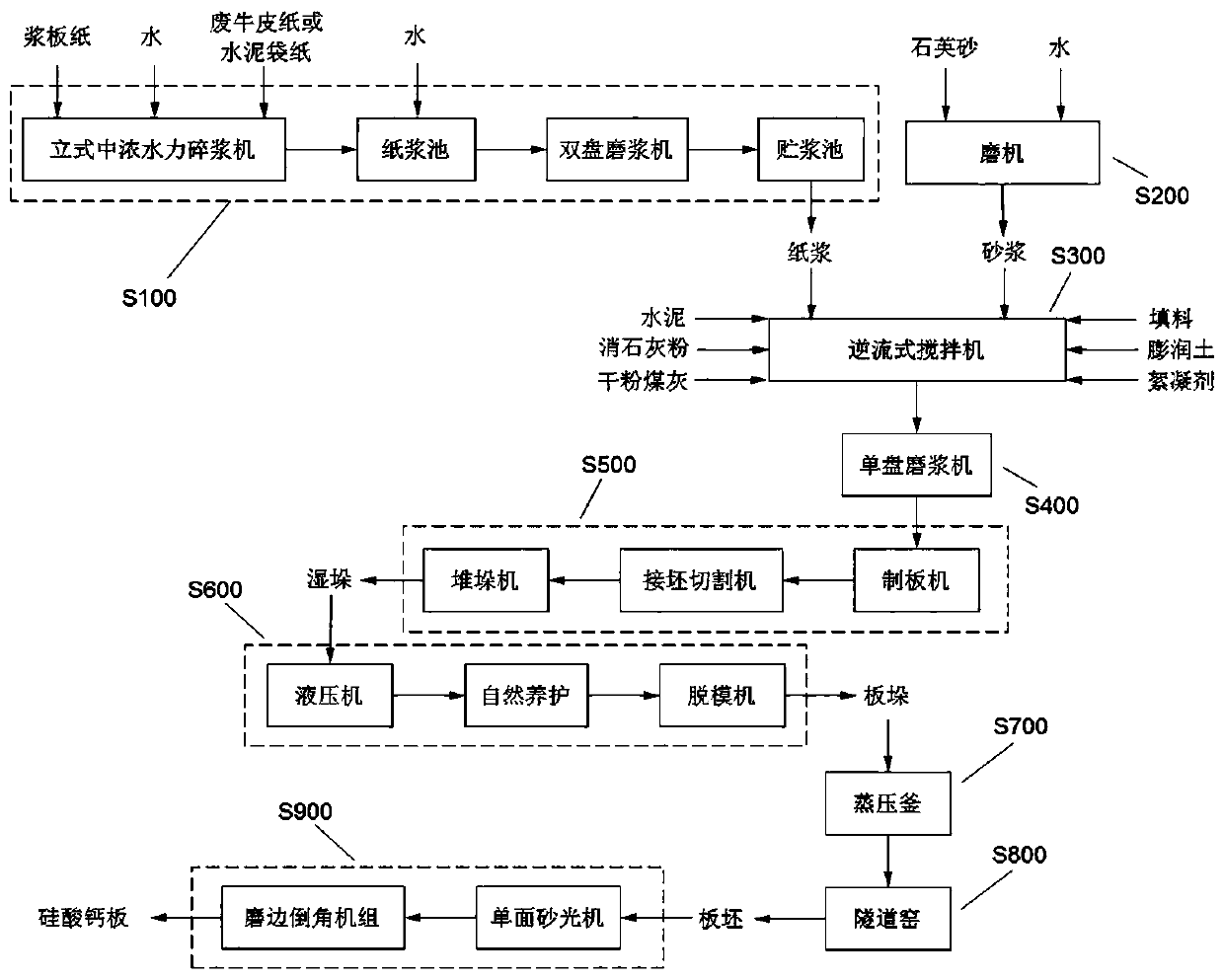

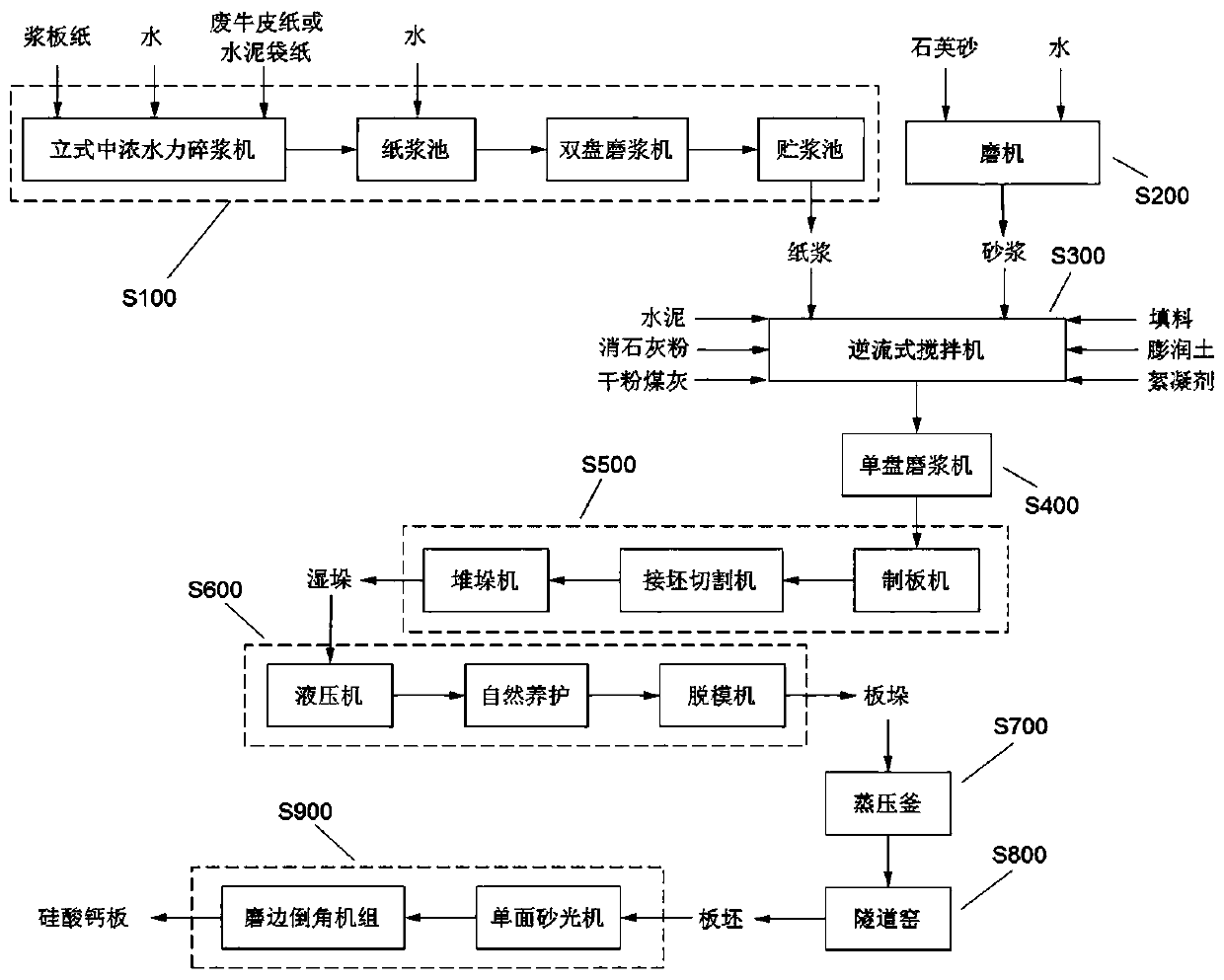

[0034] The preparation process of the light-weight high-strength calcium silicate board of the present invention includes fiber pulp preparation, quartz mortar preparation, pulping, refining and pre-stirring, board making, pre-curing, autoclaving curing, drying, and shaping steps, specifically as follows :

[0035] A. Preparation of fiber pulp: Pulp board paper and recovered waste kraft paper and / or waste cement bag paper are respectively added to a pulper in proportion to add water to loosen, after loosening, add water to dilute and grind to prepare paper pulp;

[0036] B. Quartz mortar preparation: Feed quartz sand into the mill and add water to grind to -200 mesh>95%, and prepare mortar;

[0037] C. Pulping: Send the pulp into the mixer, and add mortar, slaked lime powder, cement, dry fly ash and filler, bentonite, flocculant in sequence in proportion, and fully mix to prepare the slurry;

[0038] D. Refining and pre-mixing: The slurry is evenly supplied to the refiner for...

Embodiment 1

[0051] S100: Add 2000kg of purchased pulp board paper and 200kg of recycled waste kraft paper to the vertical medium-consistency hydraulic pulper, add water to fully loosen the material, and the time for each pot of material to be loosened is 40 minutes. The pulp after loosening is pumped Put it into the pulp tank, add water to dilute to 4-6%, and enter the double disc refiner for rough grinding to improve the beating degree of the pulp. Pulp is sent to the pulp metering tank for standby.

[0052] S200: Feed qualified quartz sand with a SiO2 content of more than 95% and fineness into the mill, add water and grind to -200 mesh and not less than 90%, and prepare a mortar with a concentration of 20%.

[0053] S300: Send 5000kg of pulp with a concentration of 10% and 30000kg of mortar with a concentration of 20% into the counter-current mixer, and then respectively mix 1000kg of 425# ordinary Portland cement, 1000kg of slaked lime powder, and 500kg of dry fly ash , 200kg of fille...

Embodiment 2

[0064] S100: Add 2,000kg of purchased pulp board paper, 500kg of recycled waste kraft paper, and 1,500kg of cement bag paper into a vertical medium-consistency hydraulic pulper, and add water to fully loosen it. The time for each pot of material is 60 minutes. The pulp is pumped into the pulp tank, diluted with water to 4-6%, and then enters the double-disc refiner for dredging, so as to improve the beating degree of the pulp. The pulp with a concentration of 5% is sent to the pulp metering tank for standby.

[0065] S200: Feed qualified quartz sand with a SiO2 content of more than 95% and fineness into the mill, add water and grind to -200 mesh and not less than 90%, and prepare a mortar with a concentration of 20%.

[0066] S300: Send 20,000kg of pulp with a concentration of 5% and 19,500kg of mortar with a concentration of 20% into the counter-current mixer, and then respectively mix 1,500kg of 425# ordinary Portland cement, 1,500kg of slaked lime powder, and 800kg of dry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com