Five-membered hard alloy solid solution and preparation method thereof

A cemented carbide and solid solution technology, applied in the field of cemented carbide, can solve the problems of unsatisfactory material properties, difficult to control the C/N ratio precisely, and achieve low oxygen content, long service life, and improved bending strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

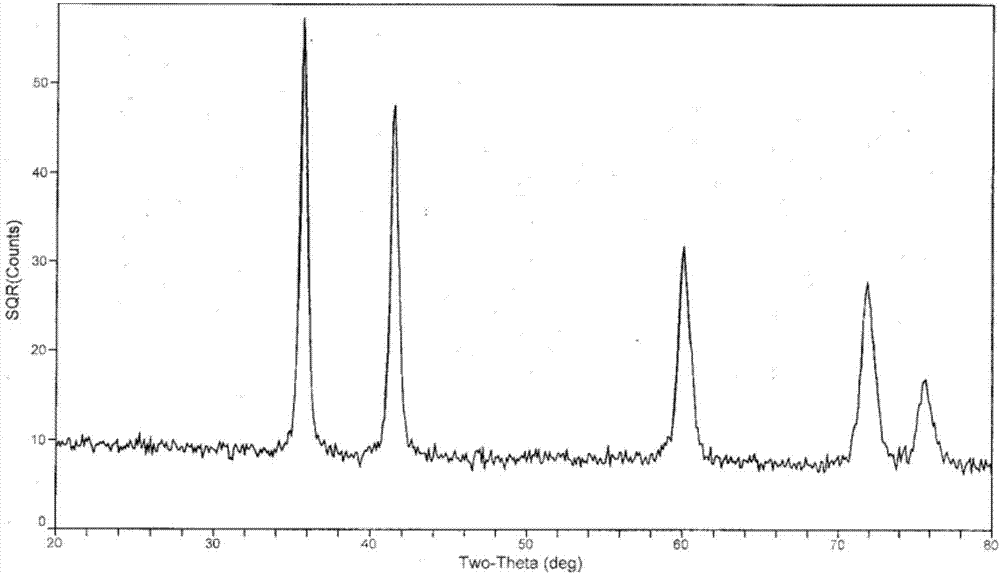

Image

Examples

Embodiment 1

[0025] In this embodiment, the preparation of the solid solution for five-element cemented carbide includes the following steps:

[0026] (1) Weigh 34.61 parts of WC and 29.33 parts of Ta in parts by weight 2 o 5 , 22.19 parts of TiO 2 And 13.87 parts of carbon black powder, mixed to obtain raw material mixture;

[0027] (2) Using alcohol as the ball milling medium, mix the raw materials evenly by rolling ball milling to obtain a mixture slurry, in which the ball-to-material ratio is 3:1, and the ball milling time is 12 hours;

[0028] (3) Transfer the mixture slurry into a vacuum drying oven, dry it at a pressure of -0.04Mpa and a temperature of 75°C, and wipe the sieve to obtain a mixture powder with a particle size of 0.5~1mm;

[0029] (4) Press the mixture powder into a blank of a certain shape at a pressure of 0.6MPa;

[0030] (5) Transfer the pressed blank into a vacuum reactor, and 2 Atmosphere, carbonization reduction reaction at 1700°C for 2h, and then in N 2 At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com