Patents

Literature

45results about How to "Good self-lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear resistant polytetrafluoroethylene material and preparation method thereof

The application discloses a wear resistant polytetrafluoroethylene material and a preparation method thereof. The method comprises steps of: preparing polytetrafluoroethylene, aluminum oxide, bronze powder, silica, glass fiber, LCP, a coupling agent, graphite, molybdenum disulfide, GF, a flame retardant, UHMWPA, POM, PC and nano-titanium dioxide in parts by weight; mixing the substances; and extruding the mixture. For a product, the tensile strength is 27-32 MPa, and the breaking elongation is 300-320%; the Shore hardness is 60-80, and the abrasion amount is 0.001-0.005 mg; and the relative density is 2.6-2.8, and the wear width is 3.4-3.5 mm / h.

Owner:苏州市德莱尔建材科技有限公司

Heat-resistant wear-resistant self-lubricating coating

InactiveCN103992726AGood self-lubricationGood wear resistanceEpoxy resin coatingsPolyester coatingsPolytetrafluoroethyleneCorrosion

The invention discloses a heat-resistant wear-resistant self-lubricating coating which is prepared from the following components in parts by weight: 100 parts of epoxy resin, 15-20 parts of polyester resin, 45-50 parts of curing agent, 35-40 parts of polytetrafluoroethylene, 9-12 parts of graphite, 25-35 parts of methylbenzene, 1-1.8 parts of silicon carbide, 41-45 parts of glass fibers, 2-4 parts of quartz powder, 1-3 parts of dispersant, 1.1-2.5 parts of flatting agent, 0.2-0.6 part of defoamer and 0.1-0.5 part of silane coupling agent. The coating disclosed by the invention has excellent self-lubricating property and good wear resistance, and can be widely applied to the field having requirements on high-temperature resistance, corrosion resistance, wear resistance and high-insulating performance. The glass fibers are added to improve the mechanical properties of heat generated by friction can be taken away in time, so that the temperature of the film is reduced.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

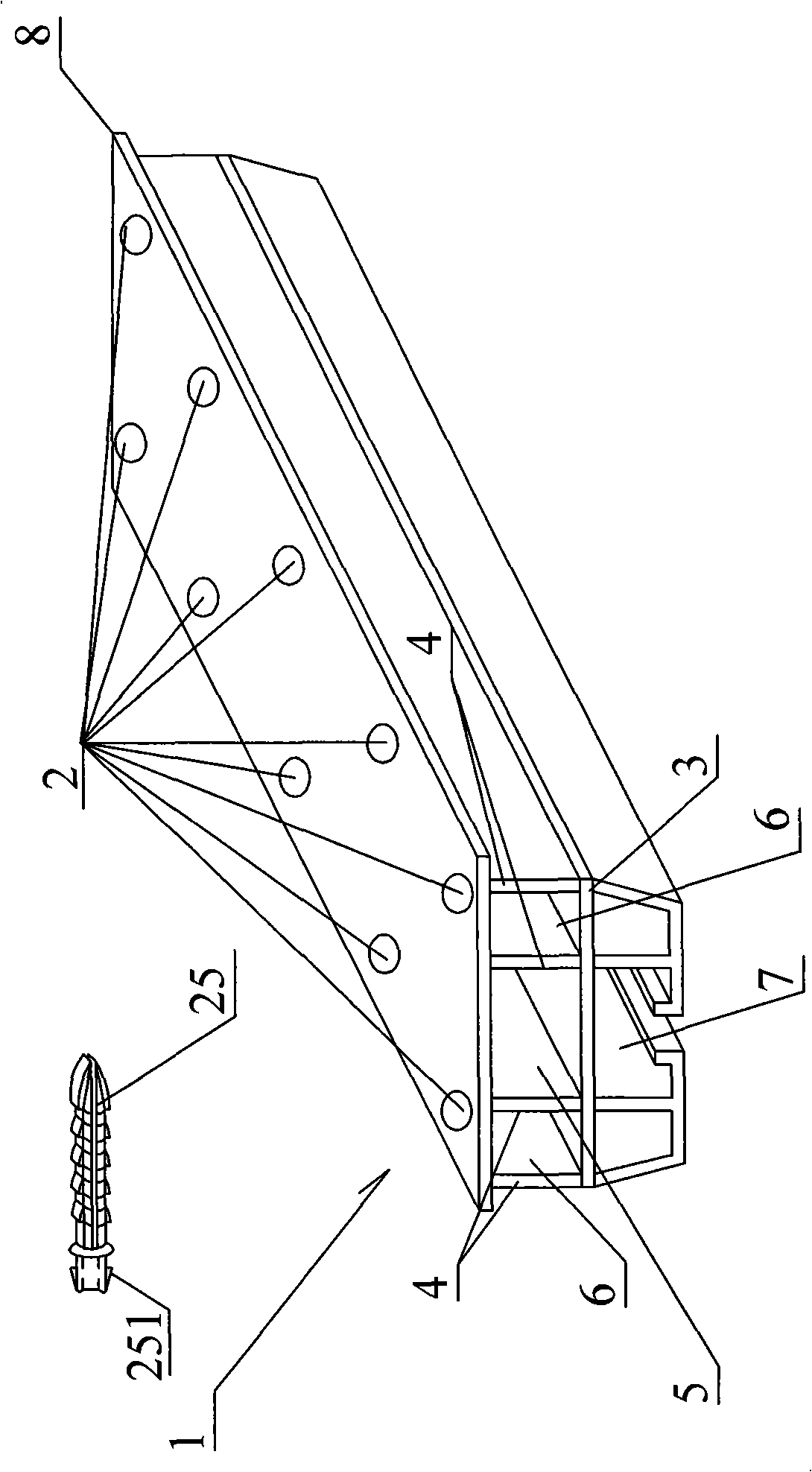

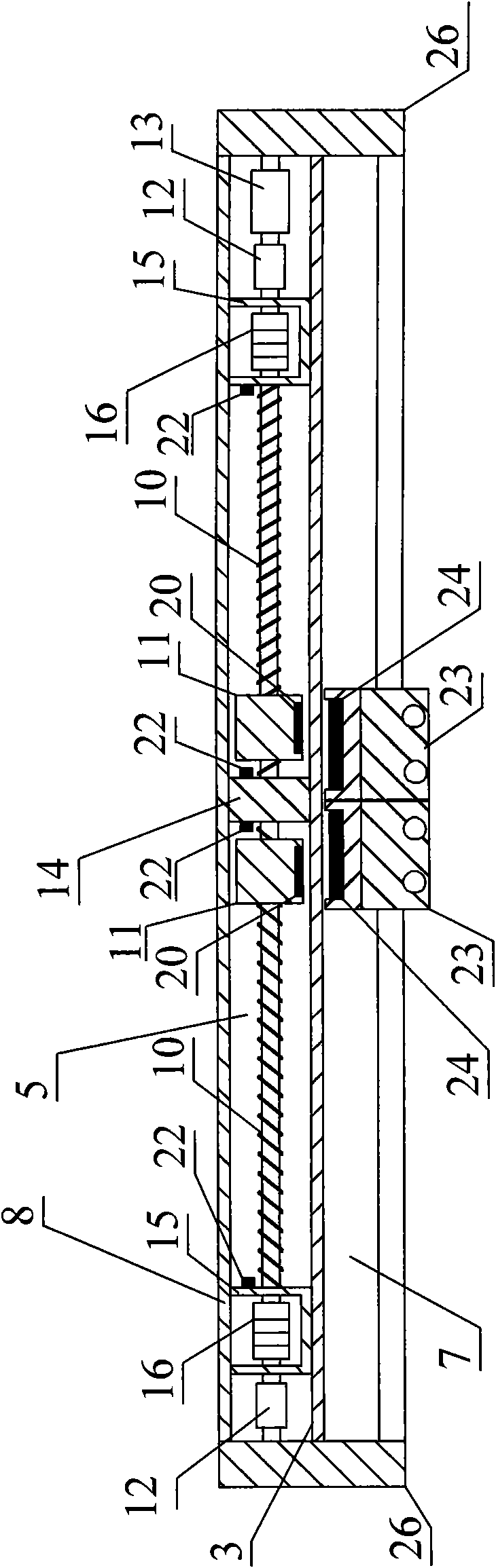

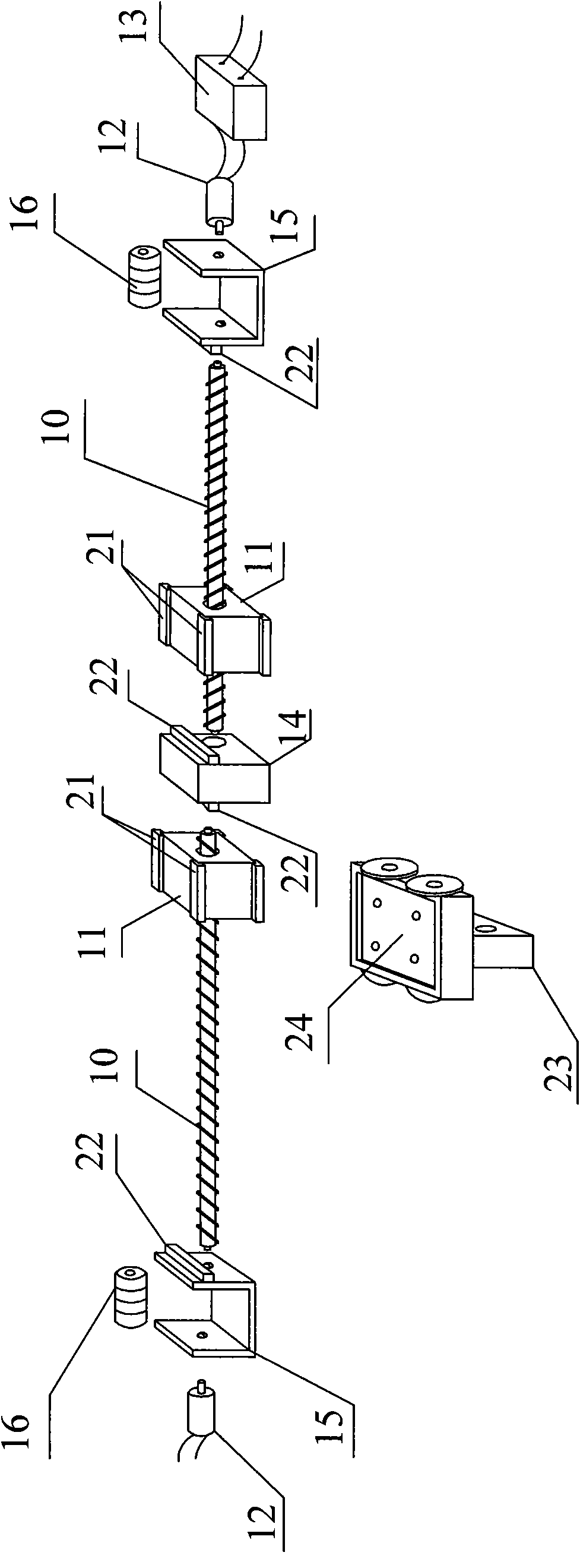

Electric curtain

InactiveCN101999835AGuaranteed uptimeGood self-lubricationCurtain suspension devicesCurtain rodsEngineering plasticEngineering

The invention discloses an electric curtain, wherein the mounting frame of the electric curtain is a box body; a transverse diaphragm plate is used to divide the box body into an upper part and a lower part; a vertical diaphragm plate is used to divide the upper part into a mounting chamber and a wiring chamber; the lower part of the box body is provided with a chute; the entire drive device is arranged in the sealed mounting chamber of the upper part of the box body, the drive device consists of a guide way, guiders, a gear motor and a variable voltage power supply; the guide way is driven by the gear motor to rotate and drive the two guiders to perform reverse movement or relative movement along the guide way; the bottom surface of each guider is provided with a permanent magnet; two pulleys are arranged in the chute of the lower part of the box body; a magnet is embedded in the top surface of each pulley; the magnet and the permanent magnet at the bottom of each guider are opposite and attract to each other; the guiders move left and right on the guide way and attract the pulleys to slide left and right in the chute; the guide way and the guiders are made from engineering plastic; and the threads on the guide way are multi-start trapezoidal threads. The electric curtain has low running noise, small volume and convenient mounting method; the curtain can move to an assigned position for opening or closing; and the electric curtain is safe to use.

Owner:王宇

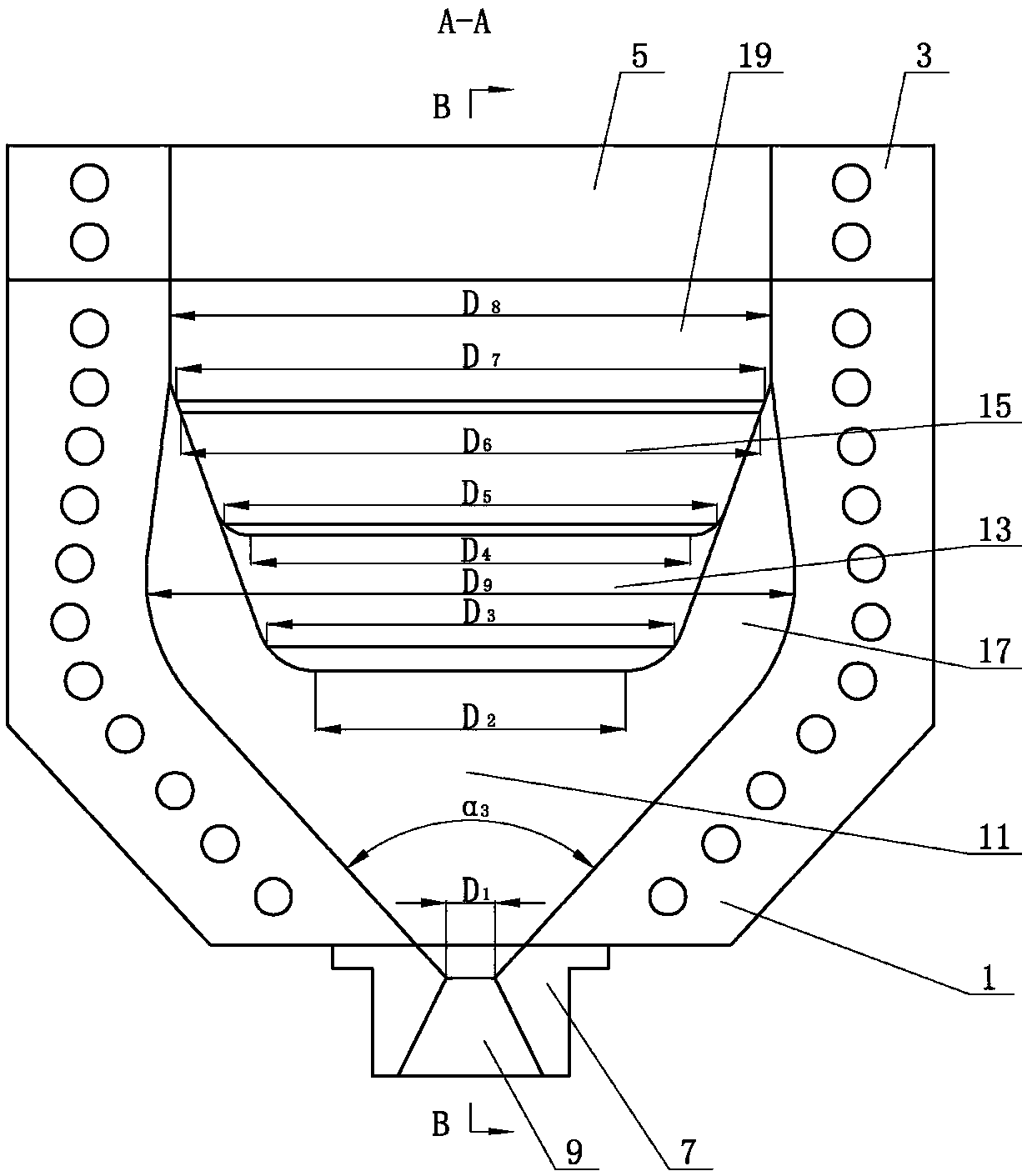

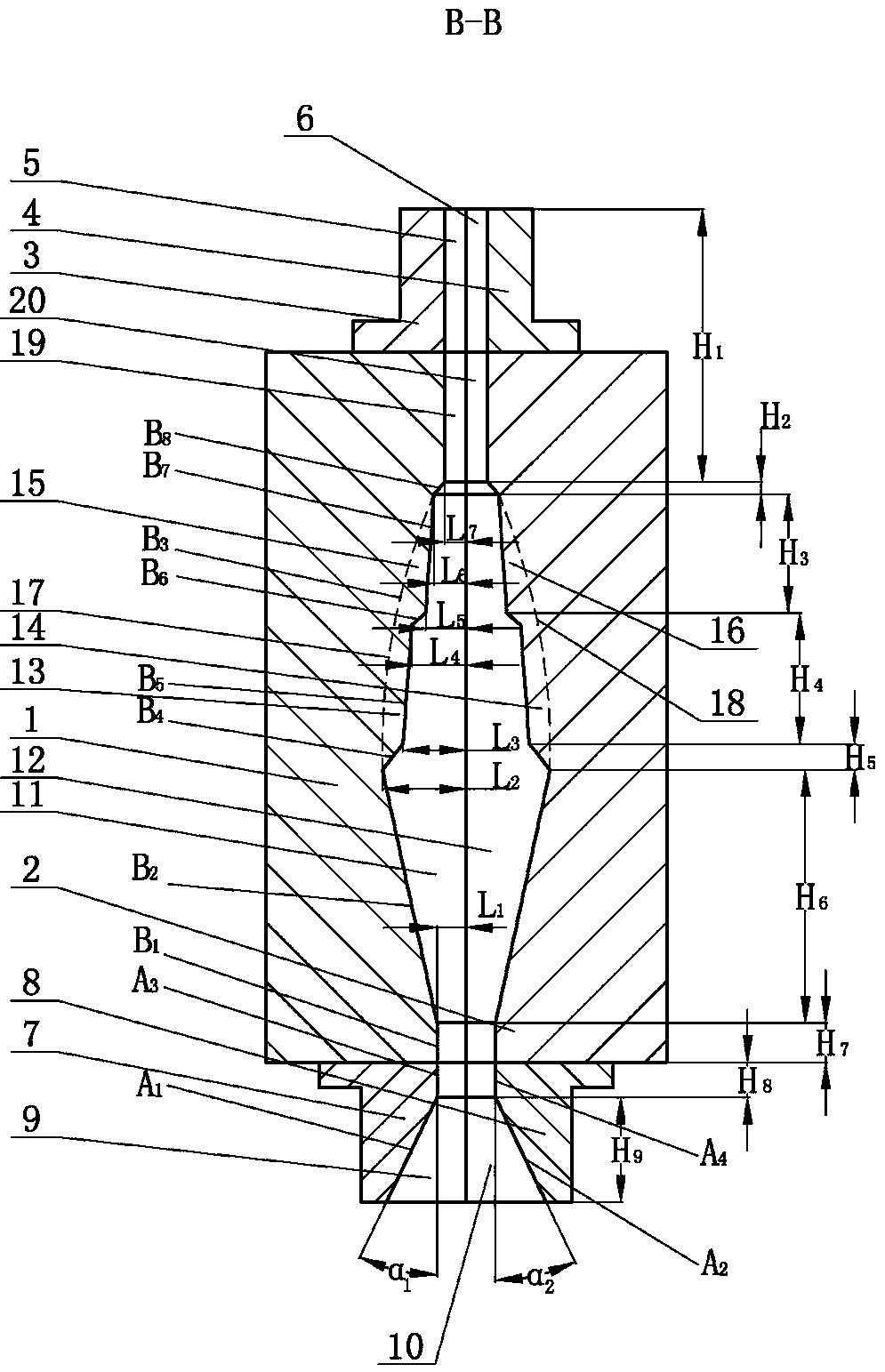

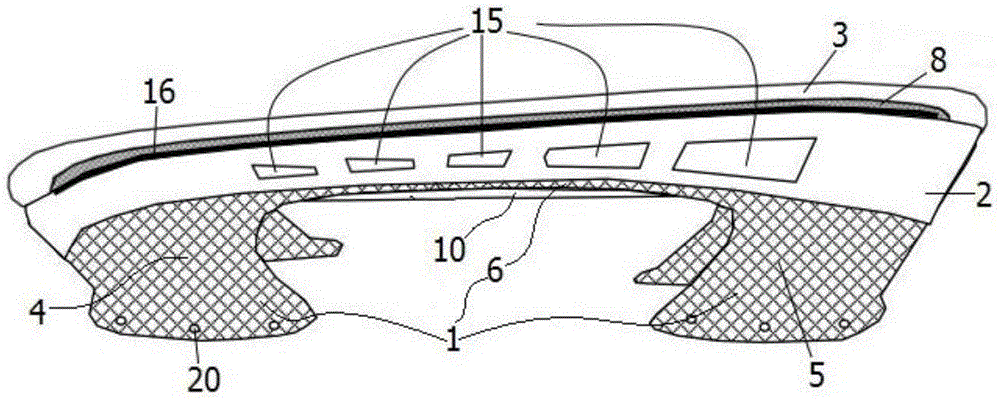

Heavy-duty vehicle disc brake pad and manufacturing process thereof

ActiveCN101838518AGood mechanical propertiesGood self-lubricationOther chemical processesFriction liningIron oxideCorrosion

The invention discloses a disc brake pad friction material, which is prepared from the following raw materials in percentage by weight: 12 to 17 percent of polyetheretherketone (PEEK) matrix, 6 to 12 percent of steel wool fiber, 4 to 8 percent of potassium titanate whisker, 8 to 16 percent of cashew nut shell powder, 4 to 6 percent of graphite, 4 to 6 percent of aluminum powder, 4 to 6 percent of antimony sulphide, 8 to 14 percent of barite, 4 to 6 percent of chromite fine powder, 8 to 14 percent of kaolin and / or fluorite and 6 to 8 percent of iron oxide red. In a manufacturing process, the polyetheretherketone of which the melting point is obviously higher than that of a normal resin is taken as a binder, and has the advantages of high temperature resistance, good self-lubricating property, corrosion resistance, flame retardant property, stripping resistance, radiation resistance, hydrolysis resistance and easy processing; and then a transfer film is formed on a friction surface in the brake process, and a cellular structure or a reticular structure that filler powder encircles the PEEK matrix is formed, so that the friction coefficient can be stabilized and the abrasion can be reduced through the formation of a surface film. The invention also discloses a disk brake pad and a manufacturing process thereof.

Owner:SHANDONG GOLD PHOENIX

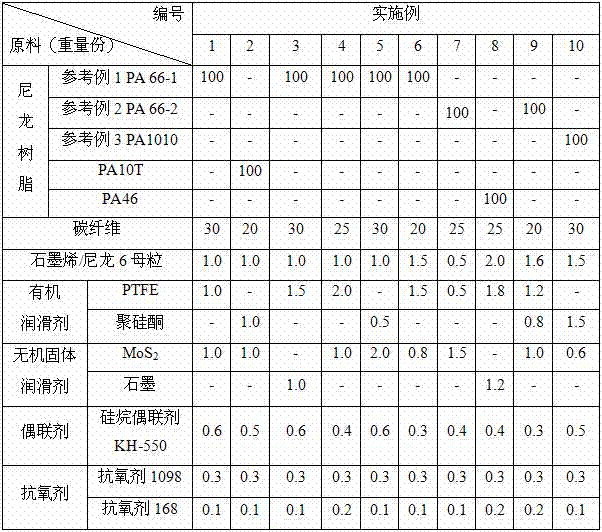

Graphene/carbon fiber enhanced nylon composite wear-resistant material and preparation method and application thereof

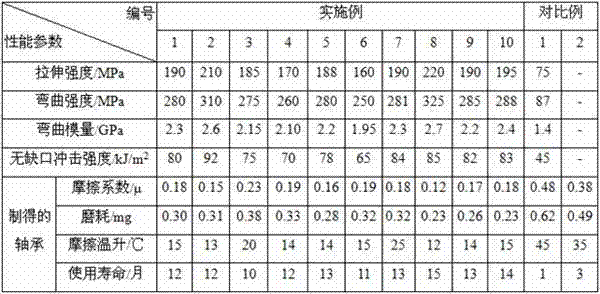

Disclosed are a graphene / carbon fiber enhanced nylon composite wear-resistant material and a preparation method and application thereof. The material includes a nylon resin, carbon fibers, graphene / nylon 6 master batch, an organic lubricant, an inorganic solid lubricant, a coupling agent and an anti-oxidant. The method comprises: (1) coupling the inorganic solid lubricant with the coupling agent to obtain a coupled inorganic solid lubricant; (2) mixing graphene / nylon 6 master batch, the organic lubricant, the coupled inorganic solid lubricant and the anti-oxidant; and (3) sending the nylon resin and a mixing auxiliary agent to an extruder, adding carbon fibers, performing mixing extrusion, and performing strap stretching, cooling, drying, and grain-sized dicing to obtain the material. The material is used for lubricating bearings and joint bearings of automobiles, and transmission gears of textile, food and packaging machinery or joint bearings of robots. The material is high in strength, good in thermal conductivity, self-lubrication, and wear resistance, and is long in service life. The method is simple and is suitable for industrial production.

Owner:长沙五犇新材料科技有限公司

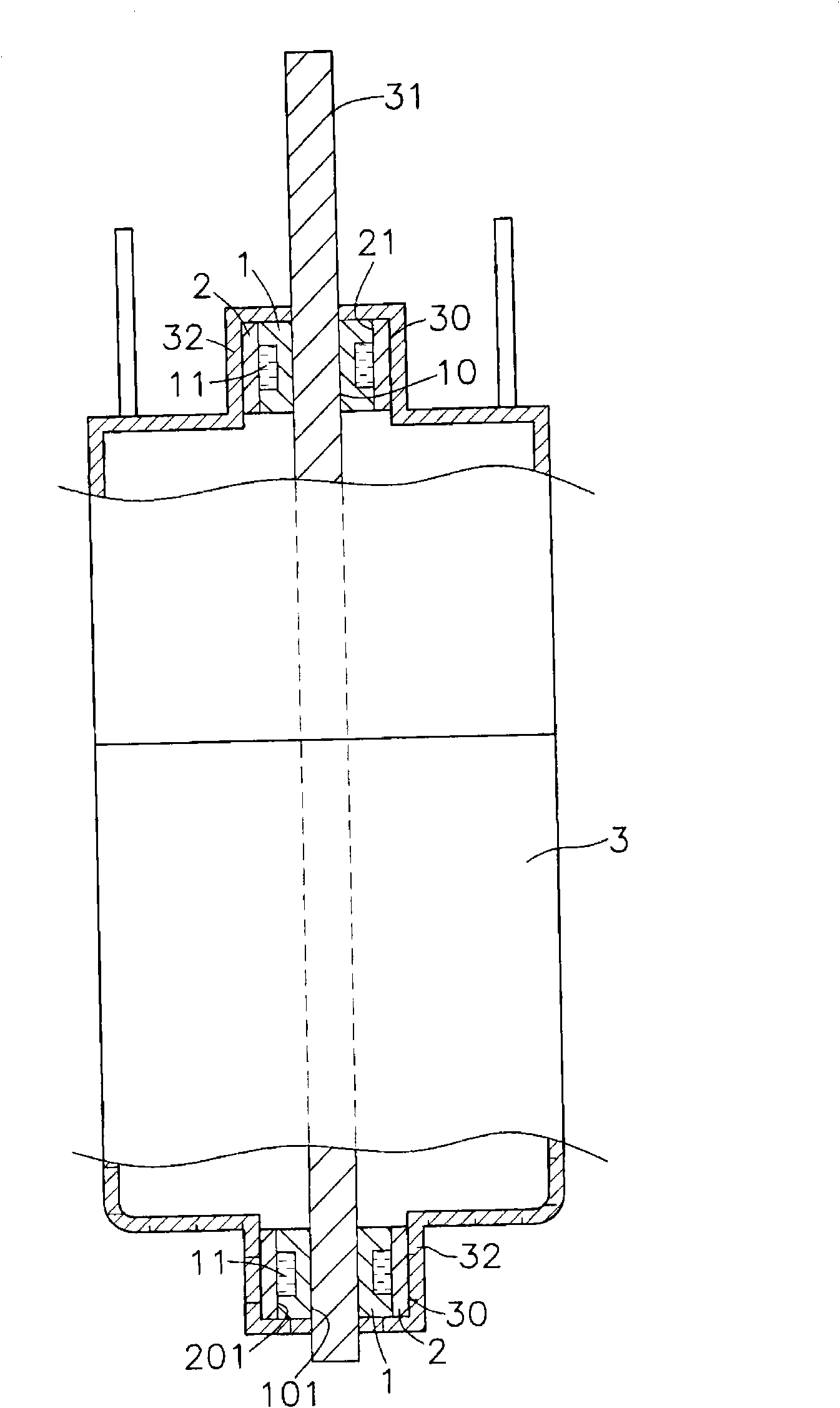

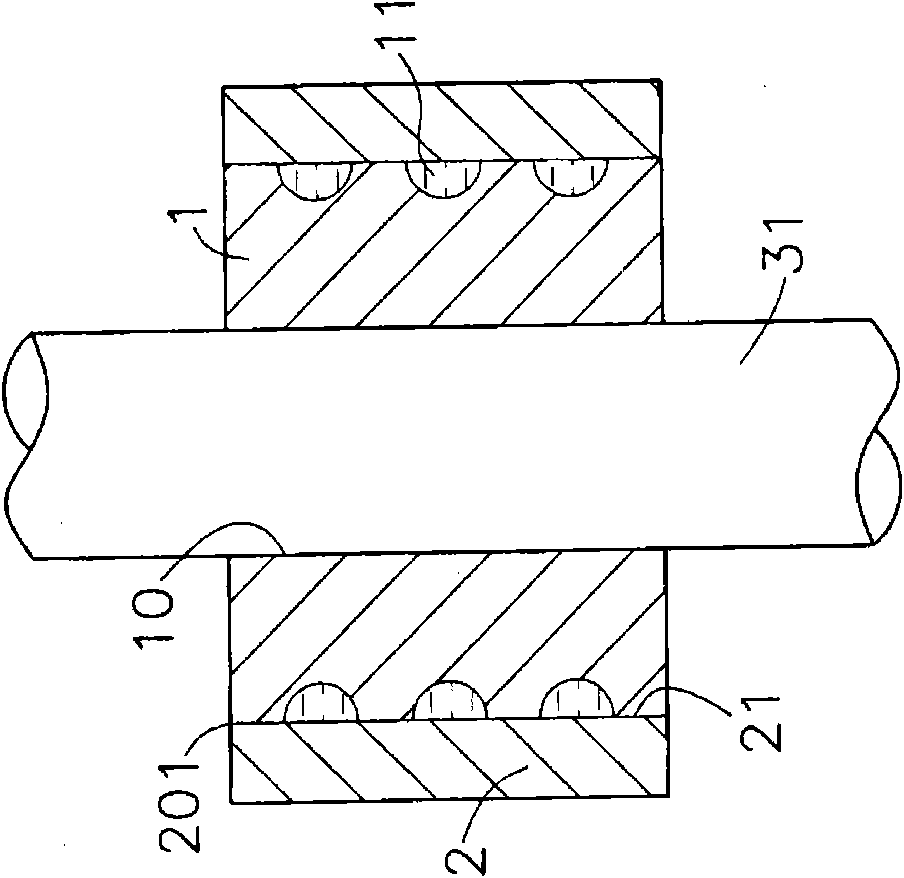

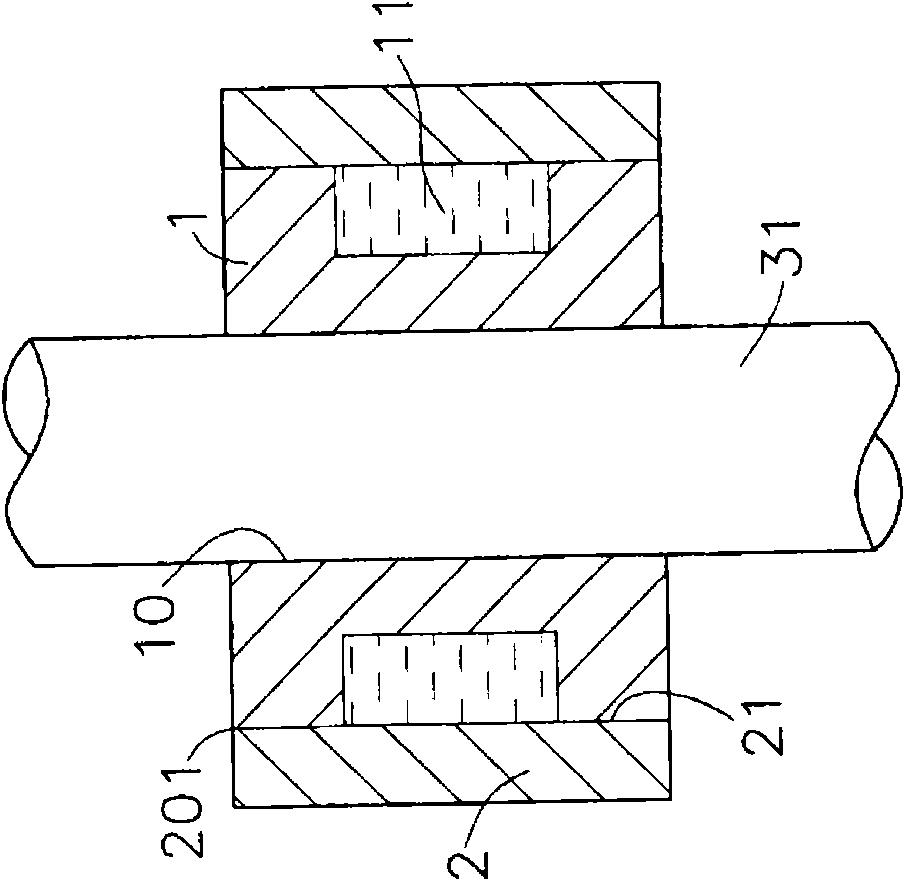

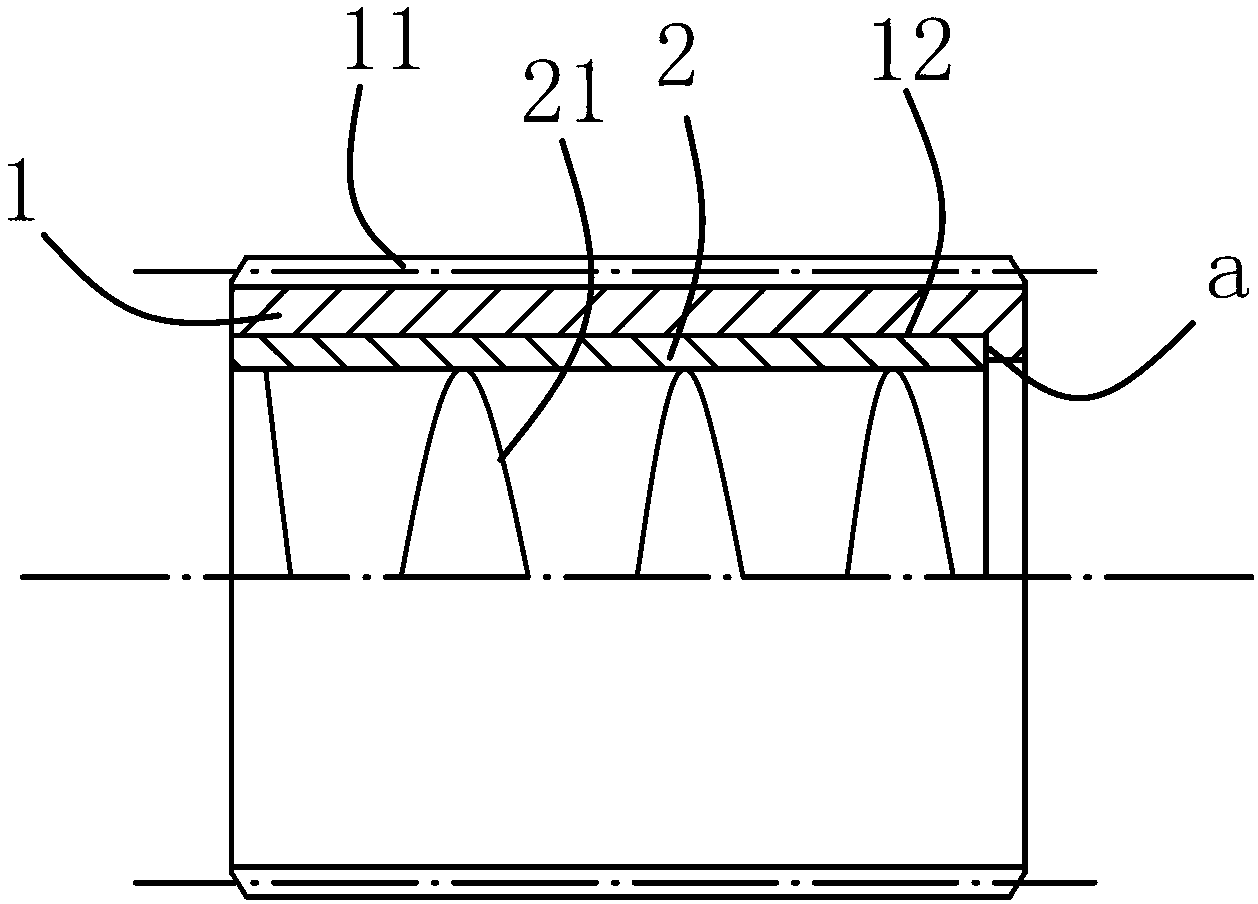

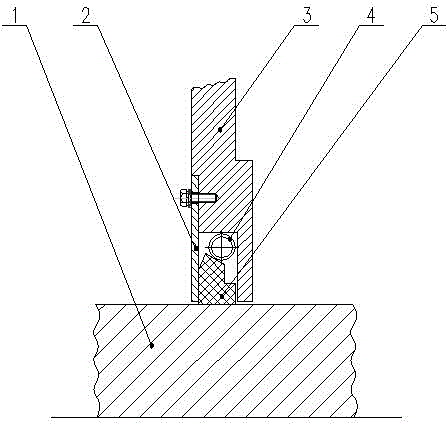

Self-lubricating bearing

InactiveCN101598177AGood self-lubricating effectExtended service lifeSliding contact bearingsSupports/enclosures/casingsLubricationOil storage

The invention discloses a self-lubricating bearing, in particular a bearing which has lubricant oil inside, and the lubricant oil can produce lubrication and can be recycled for reusing. The bearing can be made of porous materials; the inside of the bearing is provided with a penetrated central shaft holes, and the outer surface of the bearing or the inner wall surface of the central shaft hole is provided with an oil storage tank for accommodating the lubricant oil; the external part of the bearing is a shell which can be coated, can use the inner hole to accommodate the bearing, and is sleeved at a shaft core of a motor by the central shaft hole of the bearing; when the shaft core of the motor rotates, the lubricant oil contained in the bearing seeps along the direction of the shaft core to form lubrication between the outer surface of the shaft core and the inner surface of the central shaft hole of the bearing, and the lubricant oil seeps out to the part between the outer surface of the bearing and the inner hole wall surface of the shell to concentrate in the oil storage tank, thereby the functions of providing oil, returning oil, protecting oil, storing oil and the like are achieved, and the service life of the self-lubricating bearing is further prolonged.

Owner:NEWCERA TECH

Artificial lignumvitae and preparation method thereof

The invention belongs to the field of novel material, and relates to an artificial lignumvitae and a preparation method thereof. The invention solves the problems of natural lignumvitae, such as anisotropy of material, scarce resource and expensiveness. The artificial lignumvitae provided by the invention is prepared by uniform mixing and warm compaction on the following components, by mass percentage: 20-80% of a wood-plastic composite powder obtained by mixing, 10-50% of a wood powder, 3-10% of ceramic crystal whisker, 5-20% of an electrolytic copper powder and 0.1-2% of a toner. The product has adjustable color, isotropic material and good self-lubricating, is suitable for water lubrication condition, and can substitute natural lignumvitae for preparation of marine tail bearing, substitute iron / copper base powder metallurgy oil-retaining sliding bearing material for preparation of sliding bearing for electrical equipment in fields of food, medicine and textile, and also substitute rosewood and bovine bone for preparation of high-grade automotive interior.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

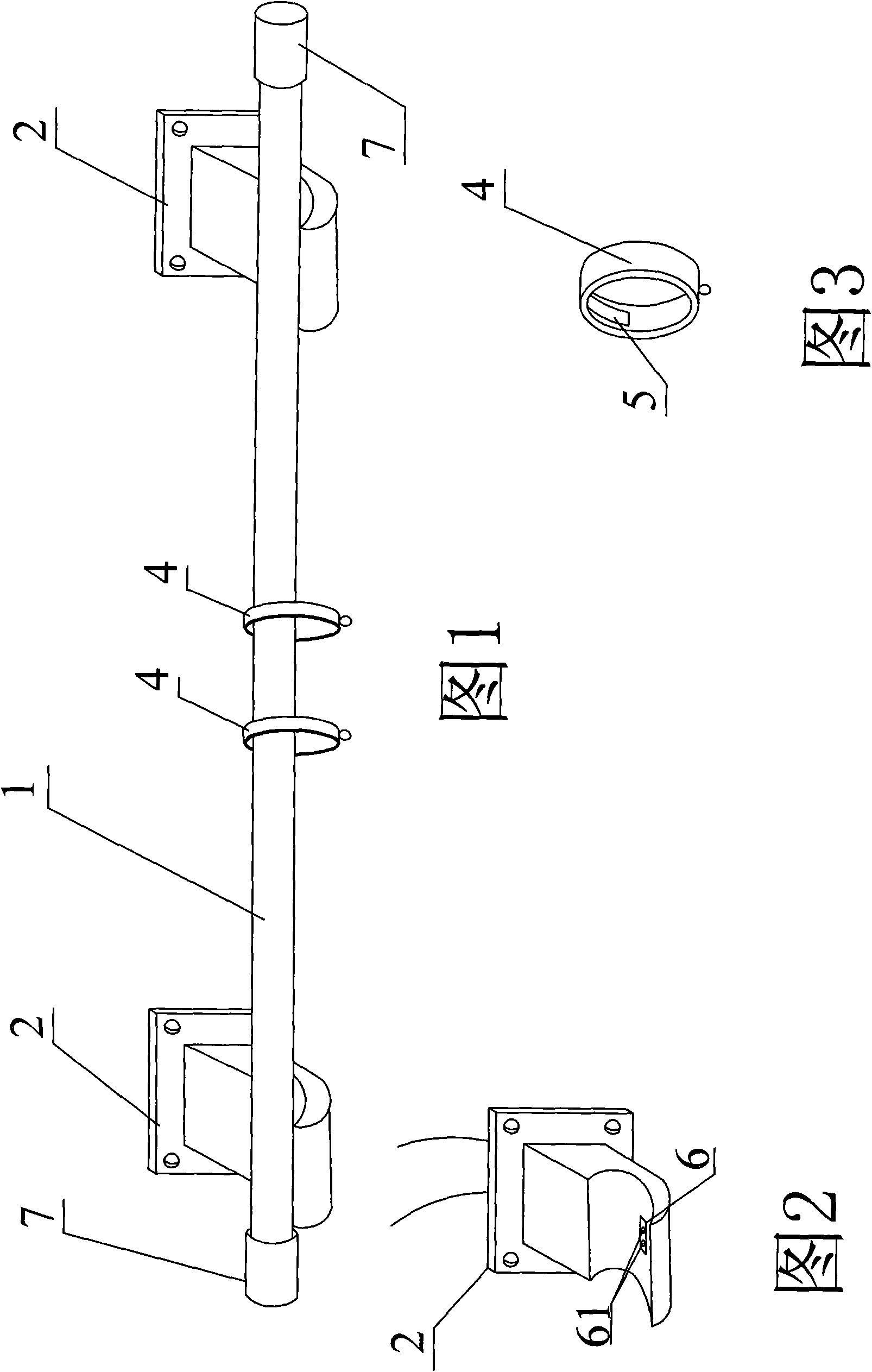

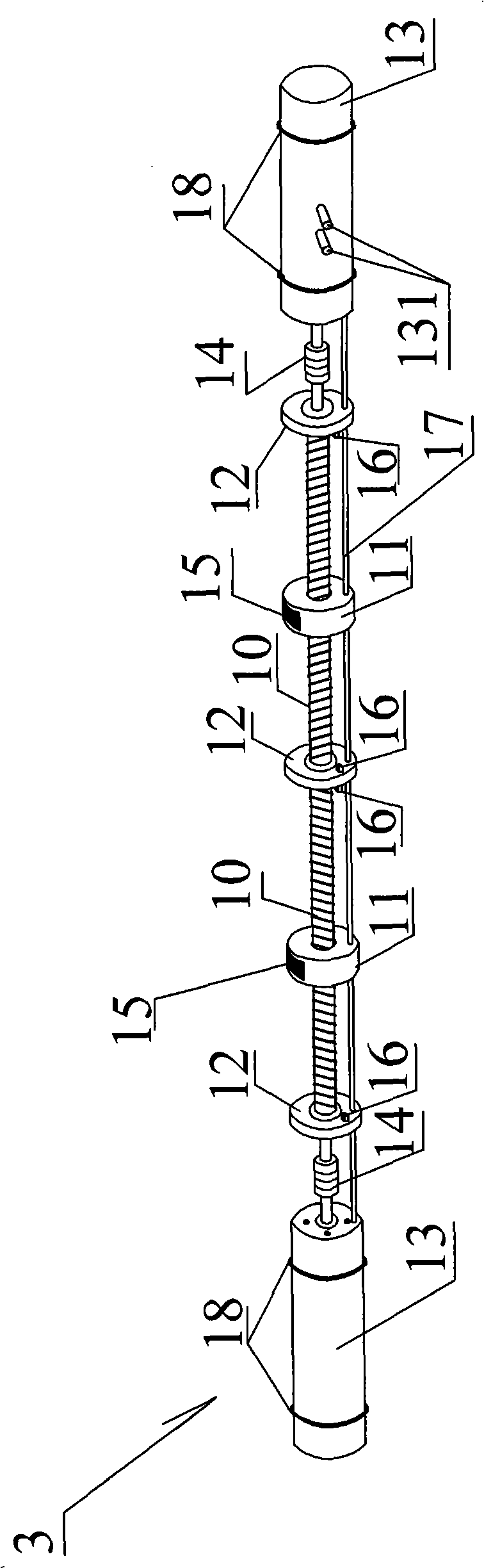

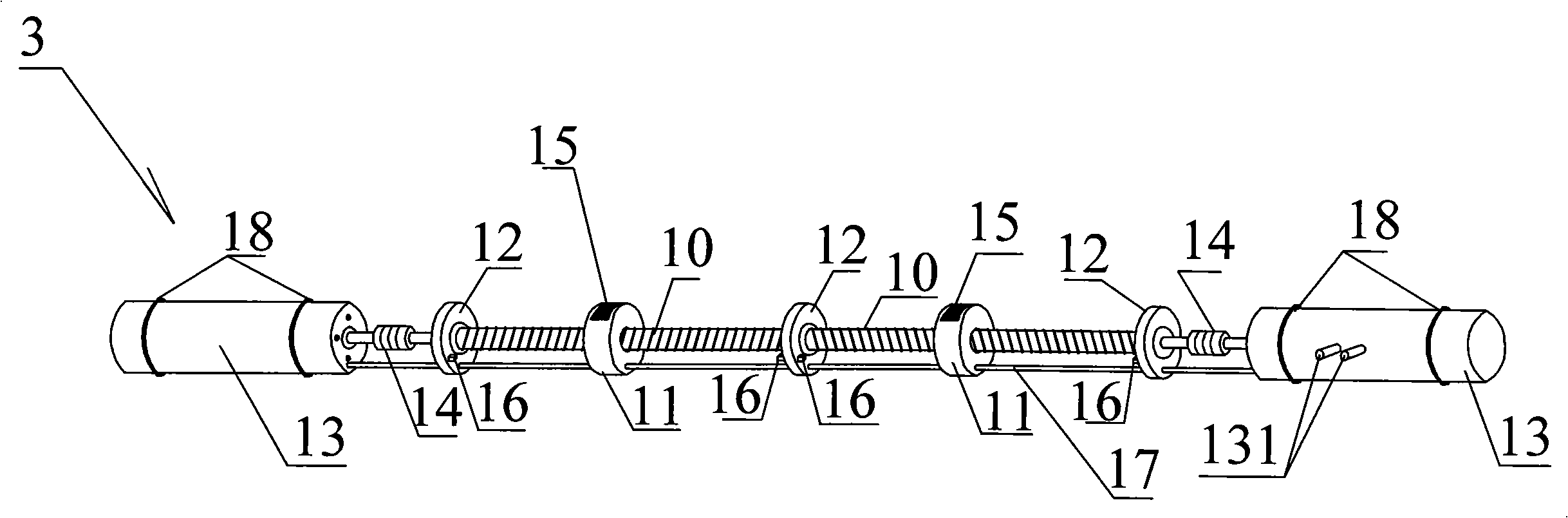

Electric curtain

InactiveCN101983605AReduce weightReduce noiseCurtain suspension devicesCurtain rodsEngineeringGuide tube

The invention discloses an electric curtain which comprises a bracket, a fixed seat, a driving device and a pull ring, wherein the fixed seat is arranged at two ends of the bracket; the bracket is a seamless tube body; the pull ring is sleeved outside the tube body; the driving device is arranged in an inner cavity of the bracket tube body; the driving device comprises two guide rails, two guiders, two speed reducing motors and a constant voltage / constant current power supply, wherein the guide rails are driven by the speed reducing motor to rotate and drive the guiders to travel left and right along the guide rails; a magnet is inlaid on the top surface of each guider; the magnet corresponds to a permanent magnet on the inner surface of the pull ring outside the tube body; the guiders which move left and right attract the pull ring to synchronously move on the tube body; a wiring guide tube is arranged through fixing blocks in the middle and at two ends and the two guiders; and the connection of all circuits is arranged in the wiring guide tube. The invention has the advantages of lower operation noise and compact and esthetic overall appearance, the curtain and a transmission mechanism are synchronously operated, the speed reducing motor uses a DC12V power supply, so that the use safety is ensured, and when the power is cut off, the curtain can be opened and closed by hand.

Owner:王宇

Rubber material

InactiveCN104072892AExcellent self-lubricating propertiesEasy to preparePolytetrafluoroethyleneDicumyl peroxide

The invention discloses a rubber material. The rubber material is composed of the following raw material in parts according to the formula: 100-150 parts of ethylene-propylene-diene-terpolymer rubber, 20-30 parts of organic silicon resin, 15-25 parts of silicone oil, 10-15 parts of a cross-linking agent, 15-25 parts of a polytetrafluoroethylene lubricant additive, 10-20 parts of diatomite powder, 10-15 parts of feldspar powder, 5-10 parts of dicumyl peroxide, 5-15 parts of 1,2-propylene glycol, 10-15 parts of a defoaming agent and 30-35 parts of epoxy resin. The rubber material has excellent self-lubricant performance and is convenient to prepare, and when applied to the windscreen wiper, the rubber material has good cleaning effect on glass, is capable of slowing down the rubber aging of a windscreen wiper and generates extremely small friction force on the surface of a windscreen.

Owner:谢伟杰

Improved structure planetary gear

InactiveCN103291884AImprove job stabilityReasonable designPortable liftingGear lubrication/coolingState of artTechnology development

The invention belongs to the technical field of differential mechanism accessories and particularly relates to an improved structure planetary gear. The technical problems that in the prior art, design is not reasonable, and service life is short are solved. The improved structure planetary gear comprises a body with a plurality of teeth, and a central hole is formed in the axial center of the body. The improved structure planetary gear is characterized in that the teeth are oblique teeth, an annular protruding shoulder which is placed on a hole opening at one end of the central hole is arranged on the body, a powder metallurgy lining is arranged in the central hole, one end of the powder metallurgy lining abuts against the annular protruding shoulder, and an oil storage structure is arranged on the powder metallurgy lining. Compared with the prior art, the improved structure planetary gear has the advantages that design is reasonable, assembling and disassembling are easy, an oil-storing effect is achieved, a self-lubrication effect is good, working stability of a differential mechanism is improved, and the improved structure planetary gear accords with the trend of technology development of current society.

Owner:孙维

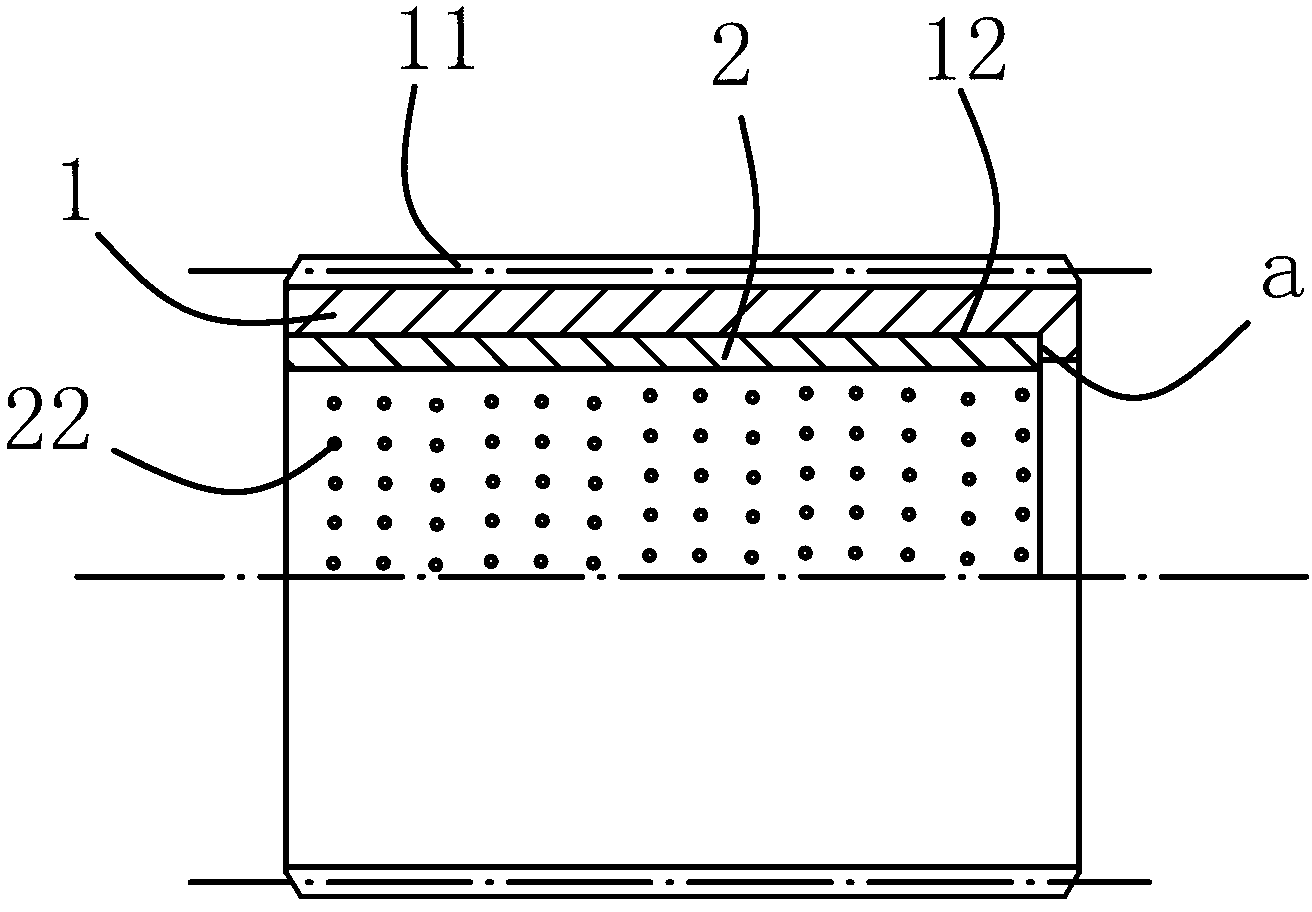

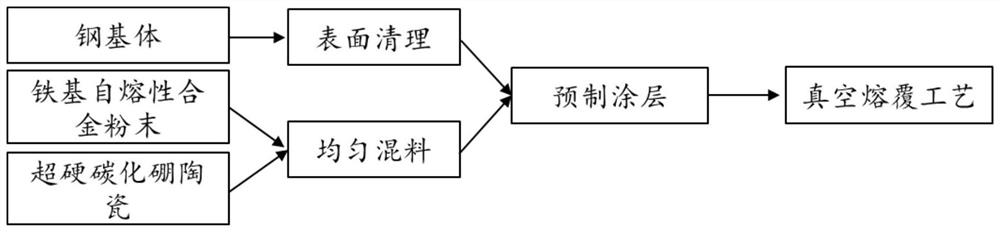

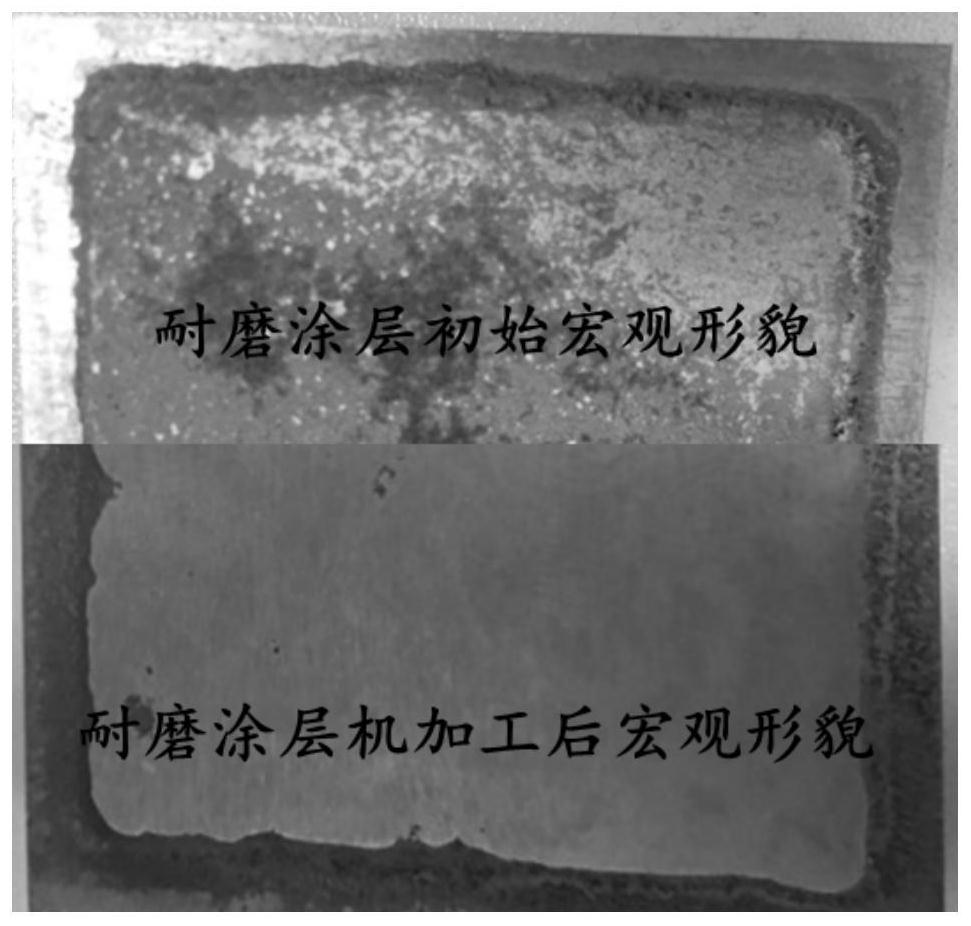

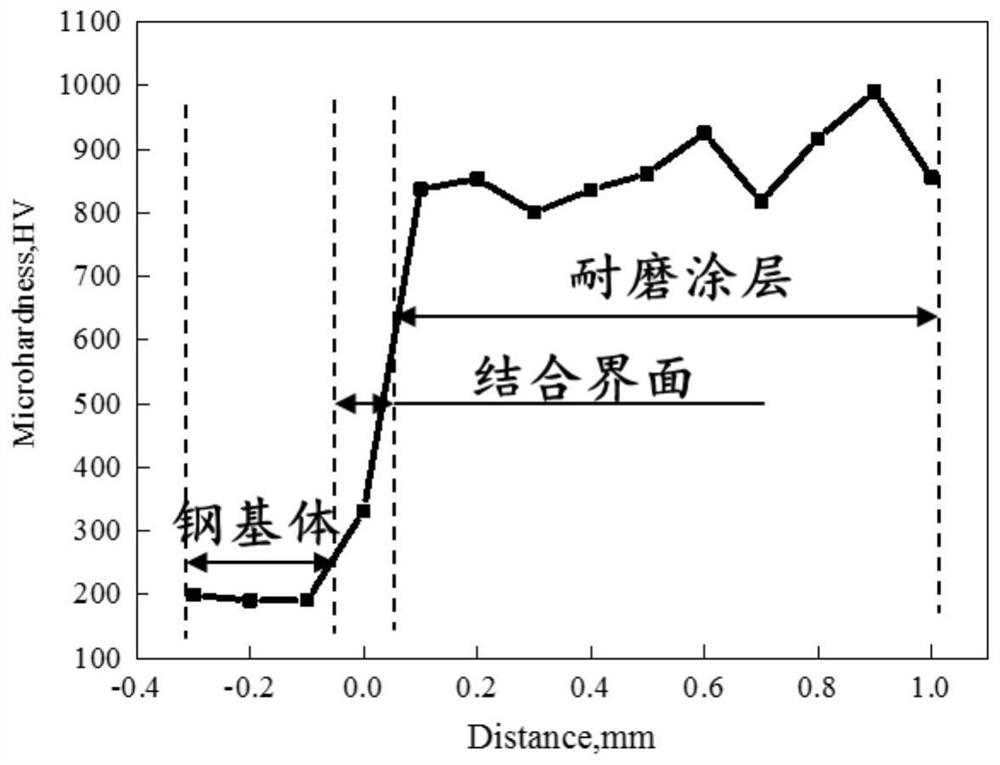

Preparation method of superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating

ActiveCN112708883AWide source of powderWide variety of sourcesMetallic material coating processesCrazingCeramic particle

The invention relates to a preparation method of a superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating. The preparation method comprises the following steps: (1) preparing boron carbide ceramic particles and iron-based self-fluxing alloy powder as raw materials; (2) preparing a steel substrate of which the surface is treated to form a surface to be cladded; (3) putting the boron carbide ceramic particles and the iron-based alloy powder into a ball mill for dry ball milling and mixing; (4) adding a binder into the mixed powder, uniformly stirring to form viscous paste, and coating the surface of the steel substrate with the viscous paste; (5) drying after air drying; and (6) carrying out vacuum cladding and then carrying out furnace cooling. The coating prepared by the method provided by the invention has no cracks and micropores penetrating through the whole thickness, is a continuous closed coating, and can significantly improve the wear resistance of mechanical parts, prolong the service life and improve the safety performance.

Owner:NORTHEASTERN UNIV

Method of vacuum pouring screw rod castings by adopting epoxy resin

InactiveCN107932807AGood self-lubricationGood thermal stability and dimensional performanceScrew-threads articlesLubricationEnergy consumption

The invention discloses a method of vacuum pouring screw rod castings by adopting epoxy resin. The method sequentially comprises the steps that vacuum drying treatment is conducted on the epoxy resin;auxiliary materials are added for two times, material mixing for two times and vacuum defoaming treatment for two times are conducted successively; pouring is conducted under a vacuum state; then solidifying for two times is conducted; and finally, demoulding cooling is conducted. The screw rod castings prepared by adopting the method are exclusively used for oilless compressors or oilless vacuumpumps and the like and pay attraction to the situation that under working conditions of 24-hour uninterrupted high-speed rotation, high temperature and oilless lubrication, and the screw rod castingsare high in thermal stability size performance, low in friction coefficient, long in service life, green and environmentally friendly and have no pollution to equipment and terminal products; in addition, due to the fact that the mass of the epoxy resin is about 20% of a metal material, the screw rod castings prepared by adopting the method are low in mass, and can greatly reduce energy consumption of the equipment and improve economic benefits of industrial production.

Owner:徐洪

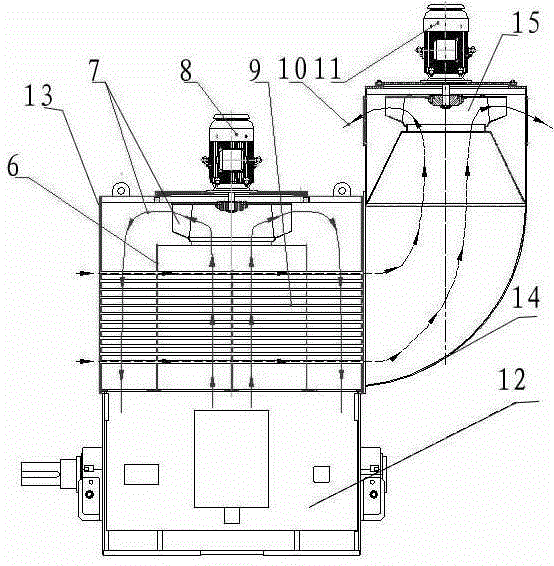

High-power, low-speed and positive-pressure type explosion-proof induction motor

InactiveCN105356648AHigh strengthGood self-lubricationCooling/ventillation arrangementSupports/enclosures/casingsPhysicsEngineering

The invention discloses a high-power, low-speed and positive-pressure type explosion-proof induction motor. The high-power, low-speed and positive-pressure type explosion-proof induction motor comprises a positive-pressure type explosion-proof induction motor body; a cover plate and an end cover are in clearance fit with a rotation shaft; a sealing device composed of a spring ring and a carbon ring is arranged between the cover plate and the end cover; and the top of the motor is provided an air-cooling cooler device. According to the high-power, low-speed and positive-pressure type explosion-proof induction motor of the invention, the spring ring and the carbon ring are adopted to seal a shaft penetration portion between a stator and a rotor, and the problem of leakage can be solved; a first set of forced air-cooling equipment is arranged at the upper part of the motor body so as to extract heat generated by the motor; extracted heat is cooled through a cooling tube and then enters a fan, so that internal circulation cooling can be performed on the fan; a second set of forced air-cooling equipment is adopted to extract air, and the air can assist in exhausting internal heat of the fan by means of the cooling tube, wherein the internal heat is exchanged through the cooling tube; and therefore, the cooling tube can continuously perform heat transfer, and the cooling of the motor can be completed finally.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

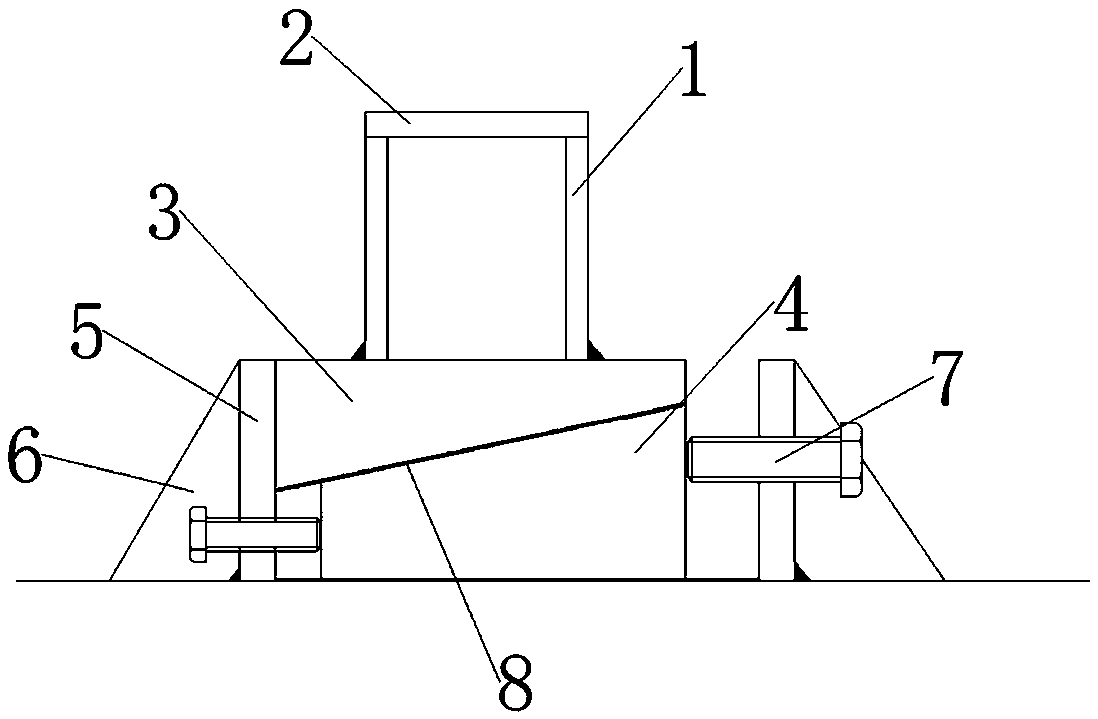

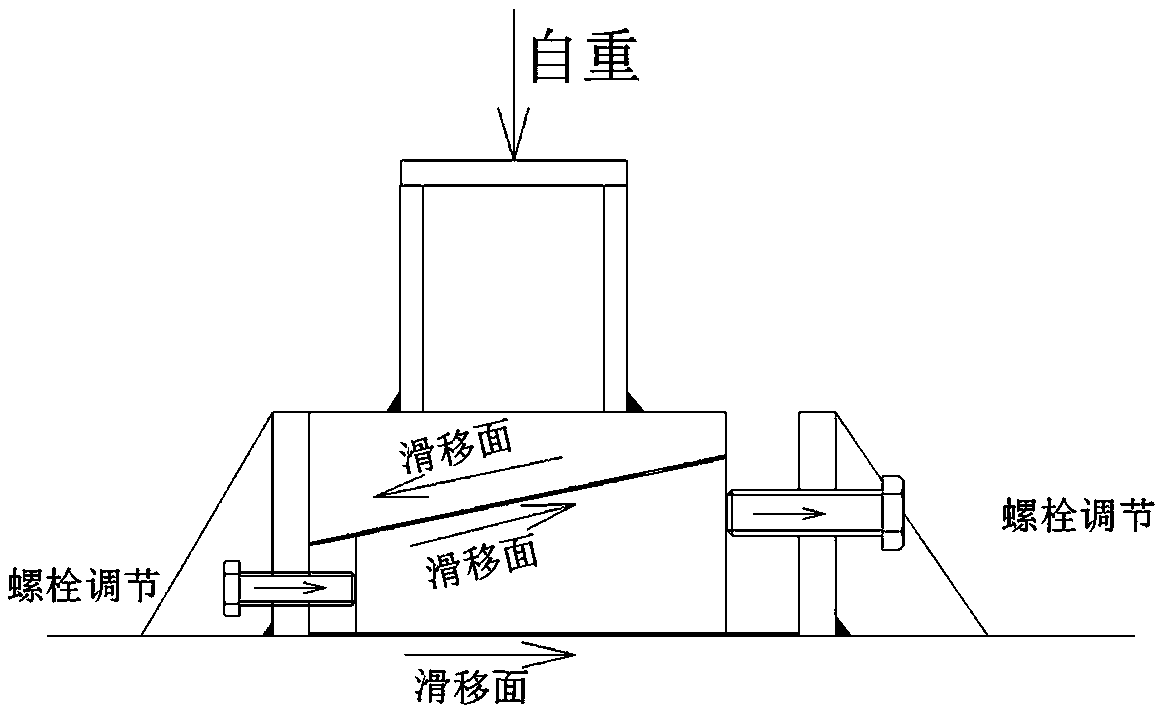

Steel structure bridge installation segmental linear adjustment and bridge overall descending device

PendingCN109338892AReduce coefficient of frictionGood self-lubricationBridge erection/assemblyBridge materialsLubricationEngineering

The invention relates to the technical field of steel structure bridge engineering installation and construction, in particular to a steel structure bridge installation segmental linear adjustment andbridge overall descending device. The descending device includes a short steel pipe, a jacking protection plate, a first inclined face sliding block, a second inclined face sliding block, two stop blocks, at least four stop block stiffening plates, at least four adjusting bolts and at least two sliding plates. According to the steel structure bridge installation segmental linear adjustment and bridge overall descending device, the contact face between the two inclined face sliding blocks and the contact face between the inclined face sliding blocks and the upper flange of a distributive beamare made of sliding plate materials, and the advantages of low friction coefficient, good self-lubrication, high adaptability, wear resistance, recycling and the like are achieved; and the descendingdevice can control the overall height of each jacking or descending of a bridge, safety of whole falling is ensured, the problems that previous industrial implementation tools of steel structure bridge installation segmental linear adjustment and overall installation location has high safety construction hidden dangers, and major safety accidents are prone to being caused are solved.

Owner:HUNAN JINHAI STEEL STRUCTURE

High-wear-resistant plastic electromagnetic valve element

The invention discloses a high-wear-resistant plastic electromagnetic valve element composed of the following components by mass percentage: 70-80% of PFA (Polyfluoroalkoxy), 5-15% of ETFE (Ethyl Tetra Fluoro Ethylene), 2-6% of bronze powder, 1-5% of nano molybdenum disulfide, 0.3-1.2% of carbon fiber, 0.2-0.8% of antioxidant, 0.5-5% of coupling agent and 0.1-2% of liquid paraffin. The high-wear-resistant plastic electromagnetic valve element disclosed by the invention and prepared by using a scientific preparation method is extremely good in wear resistance and self-lubrication property, favorable in performance, suitable for frequently moving back and forth, long in service life 3-8 times longer than that of a PTFE valve element, excellent in low and high temperature resistance and relatively high in impact strength at the temperature of 180 DEG C below zero to 250 DEG C above zero.

Owner:ANHUI JINDA INSTR

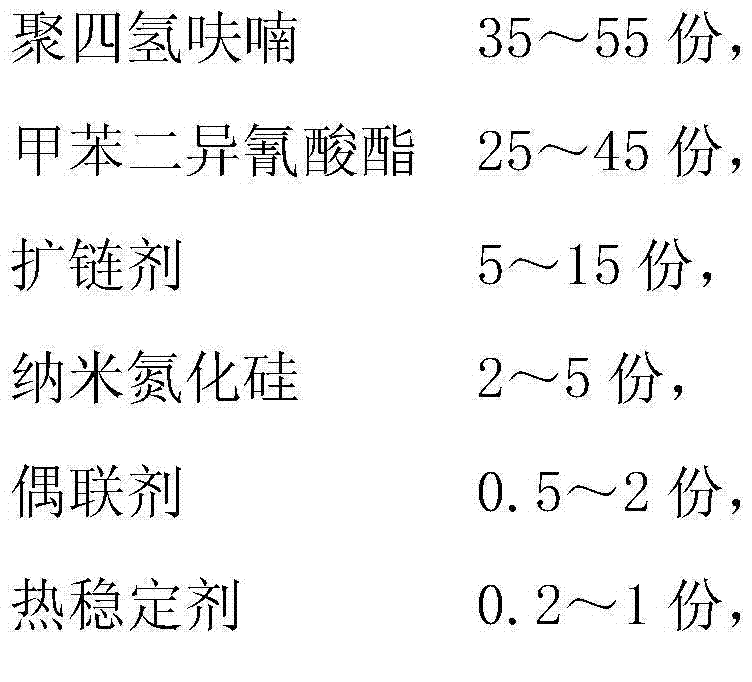

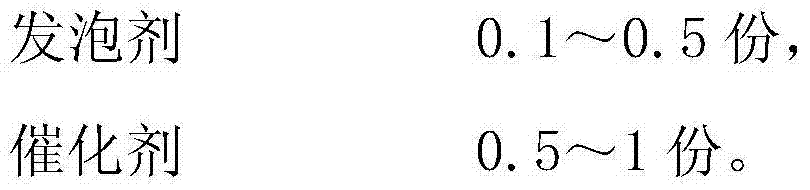

High-wear-resistance polyurethane shoe material and manufacturing method thereof

ActiveCN104262569AGood self-lubricationGood wear resistanceFootwearToluene diisocyanatePolytetrahydrofuran

The invention provides a high-wear-resistance polyurethane shoe material which is prepared from the following components in parts by weight: 35-55 parts of polytetrahydrofuran, 25-45 parts of toluene diisocyanate, 5-15 parts of chain extender, 2-5 parts of nano silicon nitride, 0.5-2 parts of coupling agent, 0.2-1 part of heat stabilizer, 0.1-0.5 part of foaming agent and 0.5-1 part of catalyst. The invention also provides a manufacturing method of the high-wear-resistance polyurethane shoe material. The polyurethane shoe material provided by the invention has favorable wear resistance.

Owner:SUZHOU JINGRO TECH

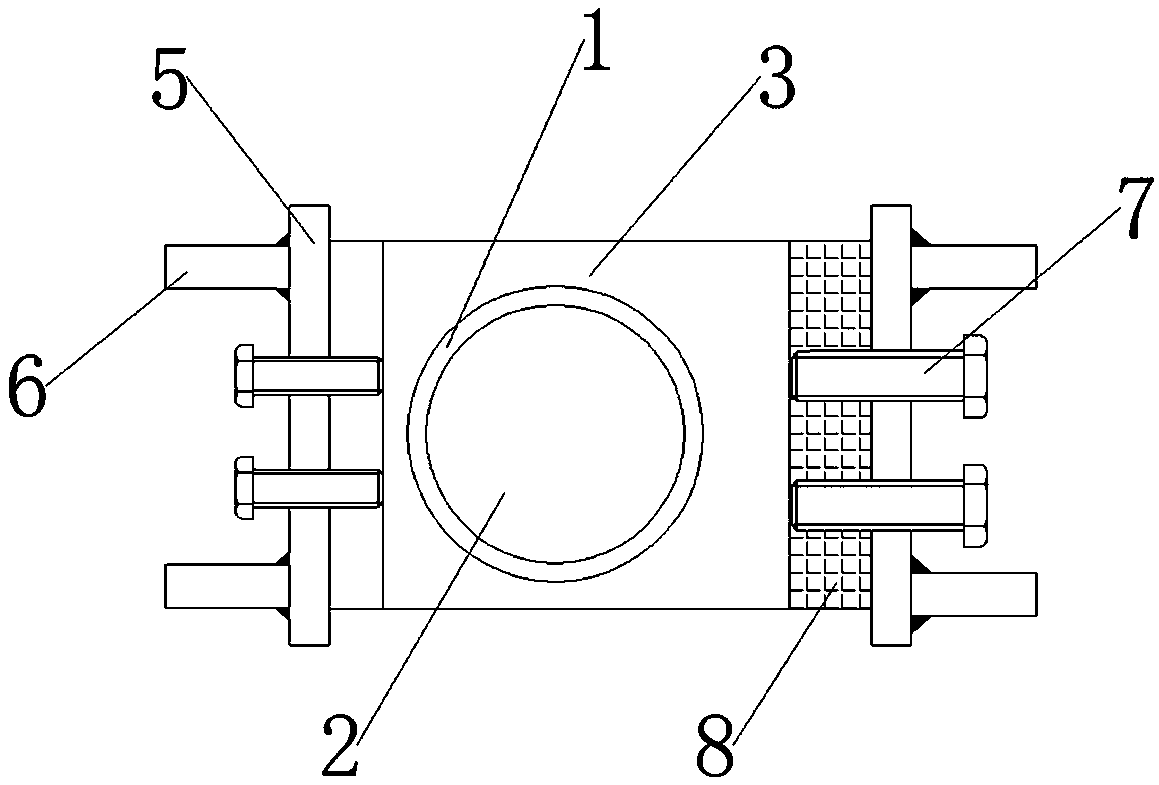

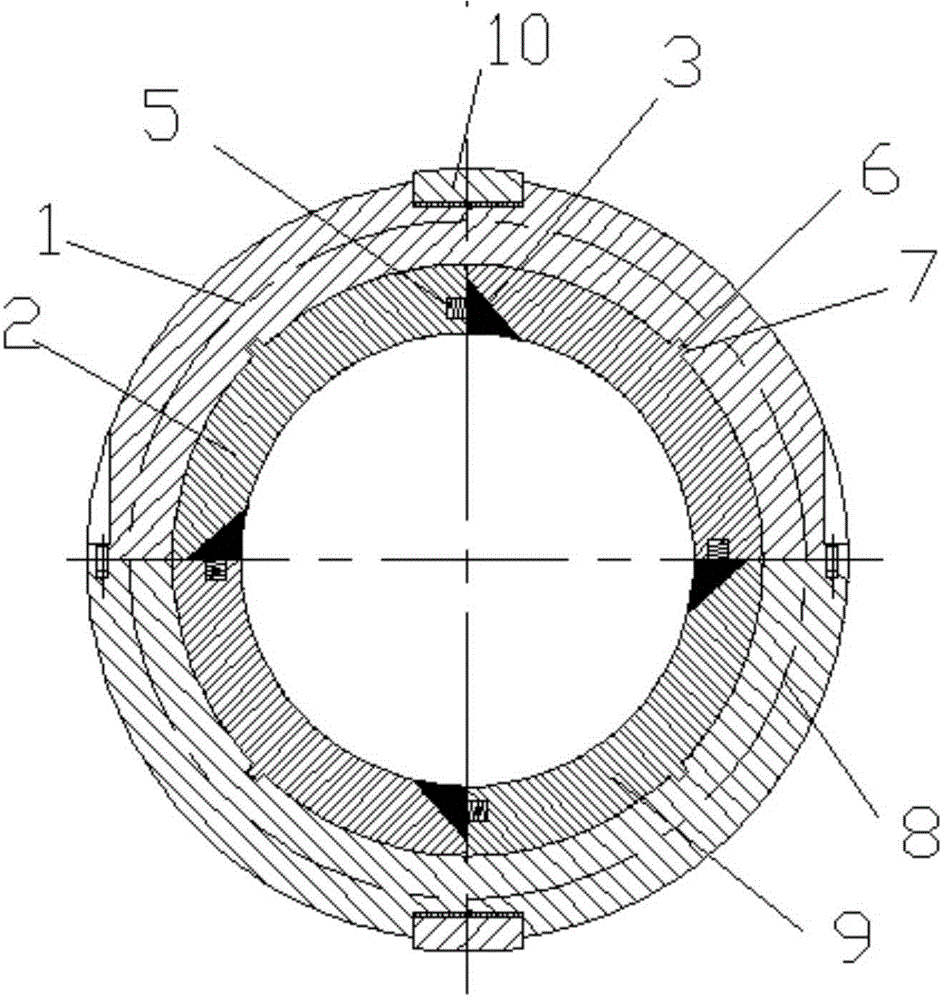

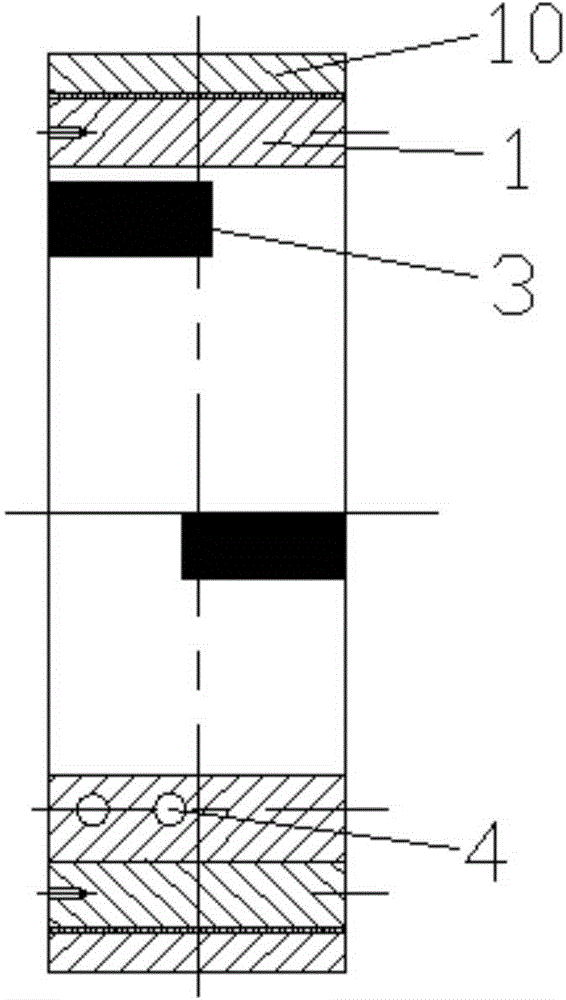

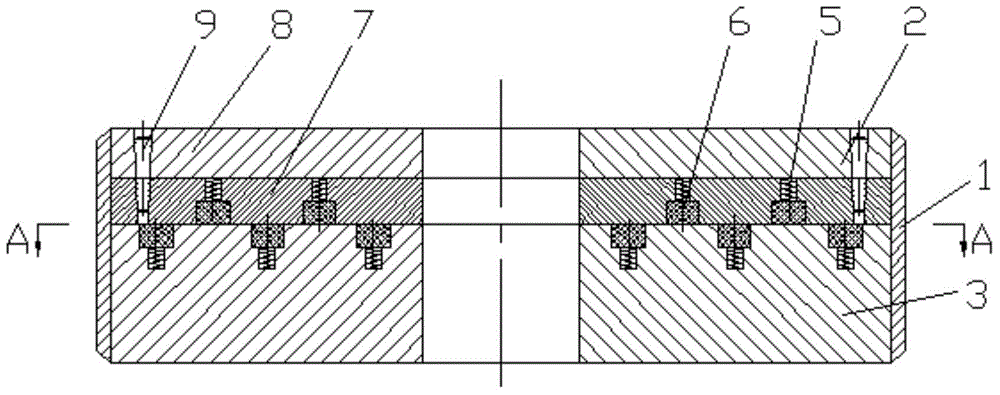

Combined continuous filling type solid lubricating bearing

The invention discloses a combined continuous filling type solid lubricating bearing, which comprises a base body and a solid lubricant, wherein the base body is composed of an outer carbon steel layer and an inner copper alloy layer; the outer carbon steel layer is composed of two semi-circular parts which are connected through bolts; a notch is formed in the outer side of the top end of each semi-circular part; an adjusting gasket is arranged in the notch; the inner copper alloy layer is composed of four arc-shaped copper alloy inner layer blocks; triangular strip-shaped solid lubricants are embedded between each two adjacent copper alloy inner layer blocks and are distributed on two sides of the copper alloy inner layer blocks in a staggered manner; two blind holes are tangentially formed in one end of each copper alloy inner layer block; a spring is arranged in each blind hole; one end of each spring is fixed in each blind hole and the outer end of each spring props against each triangular strip shaped solid lubricant. The bearing is high temperature resistant, high load resistant, good in self-lubricating and wear resistant under relatively large load condition and is simple in structure, convenient to dismount, and has no requirement on types of the solid lubricant; the solid lubricant is easy to replace, and the bearing can be continuously filled with the solid lubricant.

Owner:合肥庐阳科技创新集团有限公司

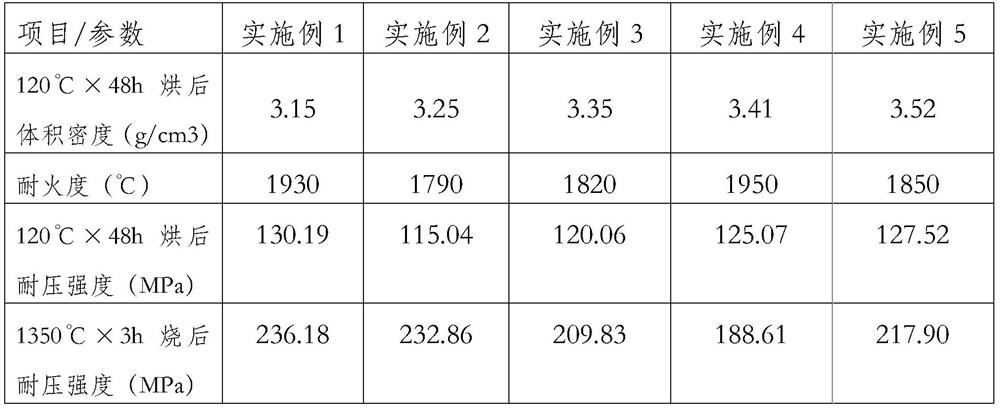

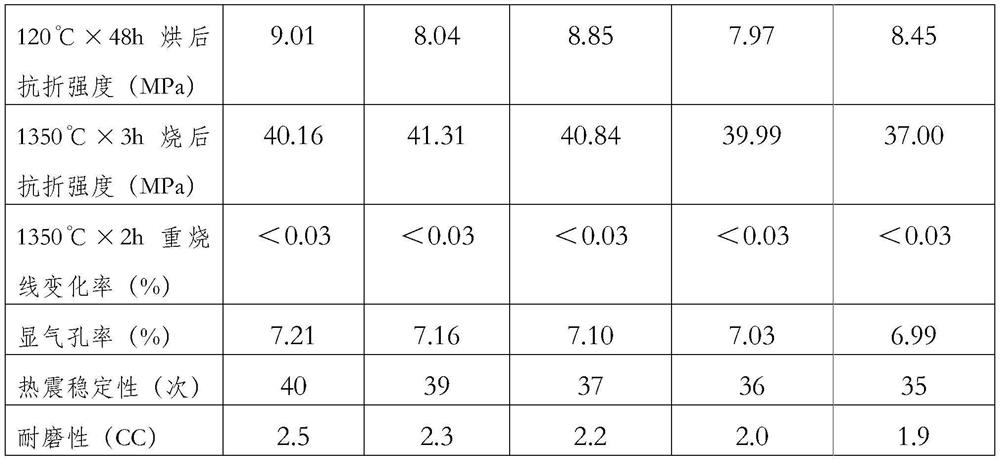

Anti-slagging high-temperature wear-resistant composite material and preparation method thereof

PendingCN111763092AImproved high temperature resistance and thermal shock stabilityImprove high temperature resistanceMagnesium AluminateAluminium

The invention discloses an anti-slagging high-temperature wear-resistant composite material. The material is prepared from corundum fine powder, aluminum dihydrogen phosphate, kyanite, pure calcium aluminate cement, silicon dioxide micro powder, rho-aluminum oxide, fine ceramic powder, magnesium aluminate spinel, sodium tripolyphosphate and explosion-proof fibers. The material has high strength and good wear resistance and can resist the abrasion of solid materials and the scouring of hot air flow; the composite material has excellent volume density, stability and acid and alkali resistance soas to resist erosion of acid and alkali substances in a furnace; the composite material has good thermal shock stability so as to resist damage of the temperature change of the furnace to the material; and the composite material has good erosion resistance so as to avoid cracking of the lining of the furnace due to erosion, so that the service life of the furnace is greatly prolonged.

Owner:YIXING GUOQIANG FURNACE IND

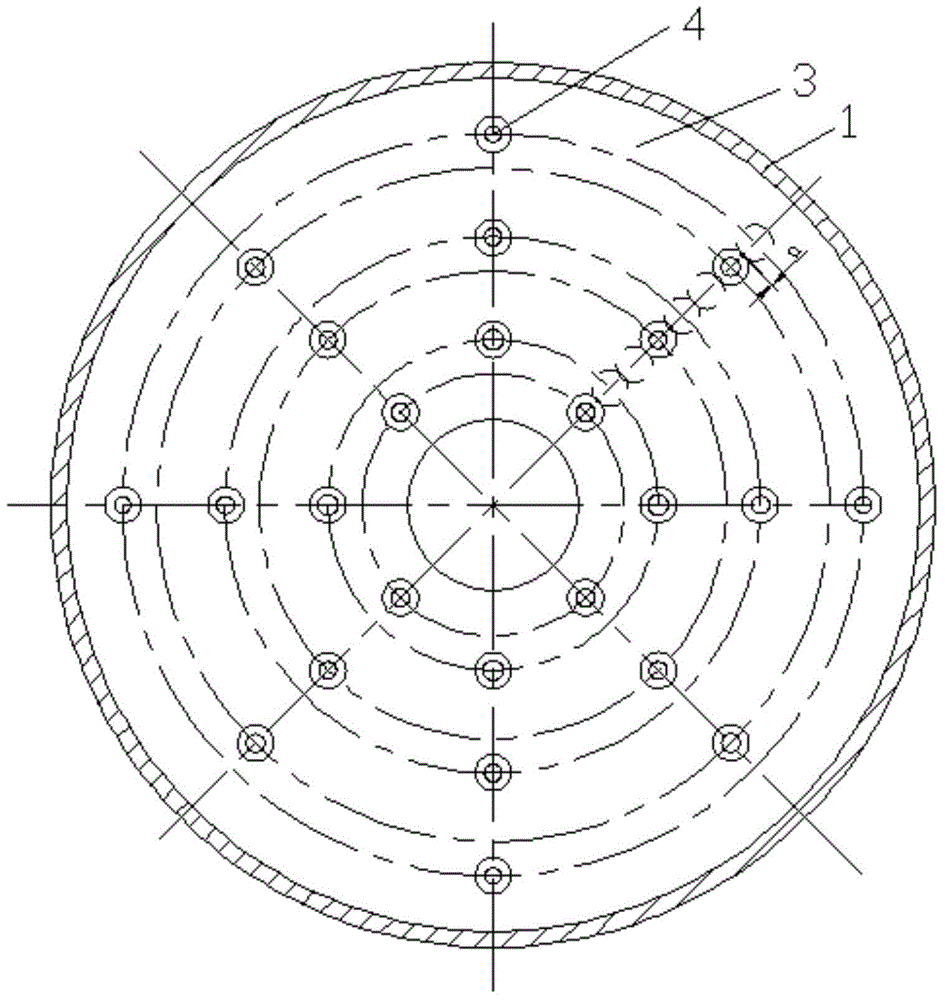

Solid lubricated thrust sliding bearing capable of being continuously filled

InactiveCN103982538AGood self-lubricationIncreased sustainable fillingBearing componentsSliding contact bearingsWear resistantEngineering

The invention discloses a solid lubricated thrust sliding bearing capable of being continuously filled. The bearing comprises a seal ring, an upper ring and a lower ring, wherein the lower ring is arranged at the lower part of the inner wall of the seal ring; the upper ring is arranged above the lower ring; the upper ring comprises an upper base layer and a lower wear resistant layer which are connected with each other through pins; step holes are formed in the wear resistant layer of the upper ring and in the upper plane of the lower ring; a spring is arranged in the small diameter of each step hole; a solid lubricating block is arranged in the large diameter of each step hole; one end of each spring is in contact with the bottom of each step hole; the other end of each spring is in contact with the solid lubricating block; the step holes in the contact planes of the upper and lower rings are upwards arranged in a overlapping manner along the relative sliding direction of the upper ring and the lower ring, so that transferring films generated by the solid lubricating blocks in the step holes during friction cover the whole friction surface. The solid lubricated thrust sliding bearing capable of being continuously filled has the advantage of being high temperature resistant, high load resistant, good in self-lubricating and wear resistant under non-oil lubricating situation and has no thermal expansion requirement on a solid lubricant.

Owner:HEFEI UNIV OF TECH

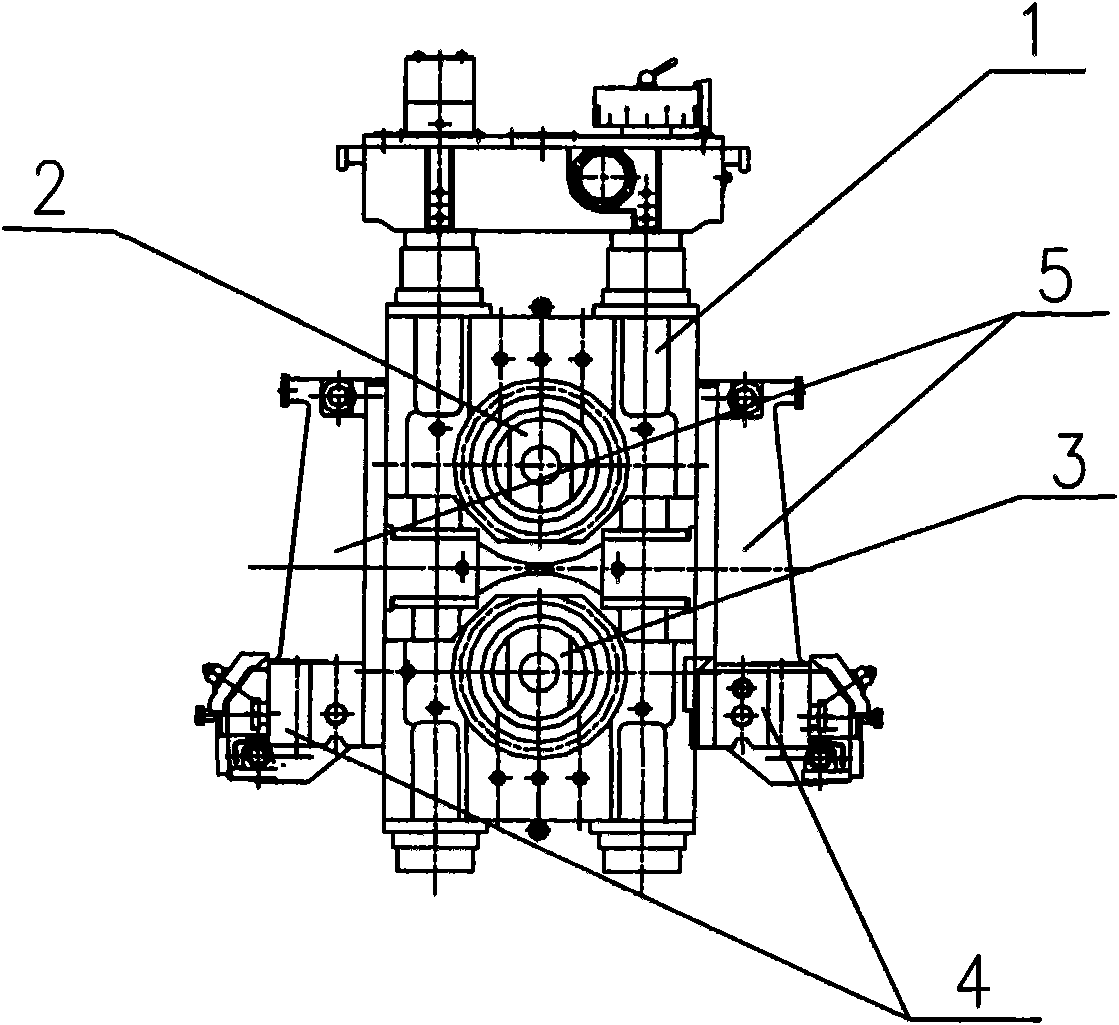

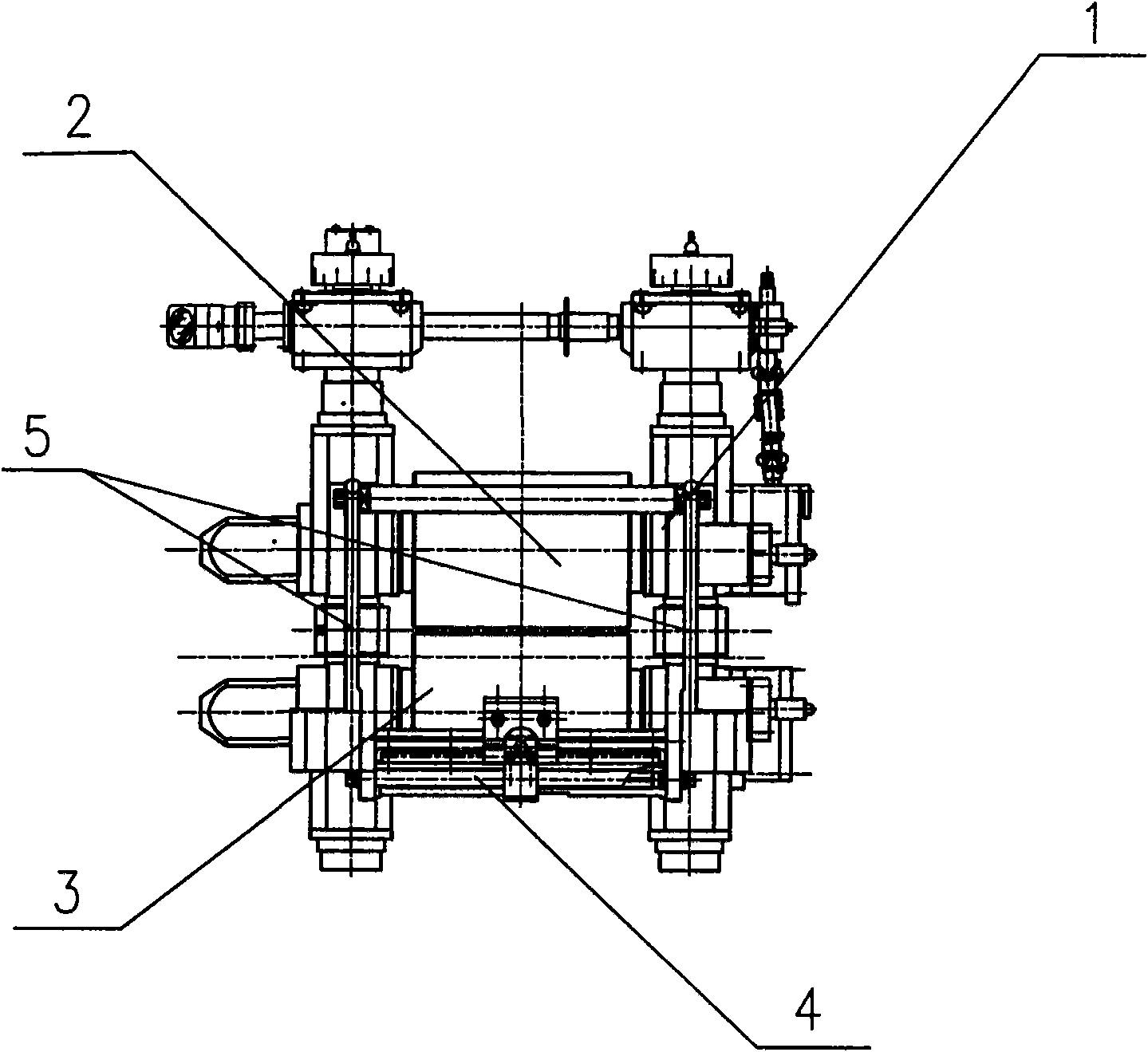

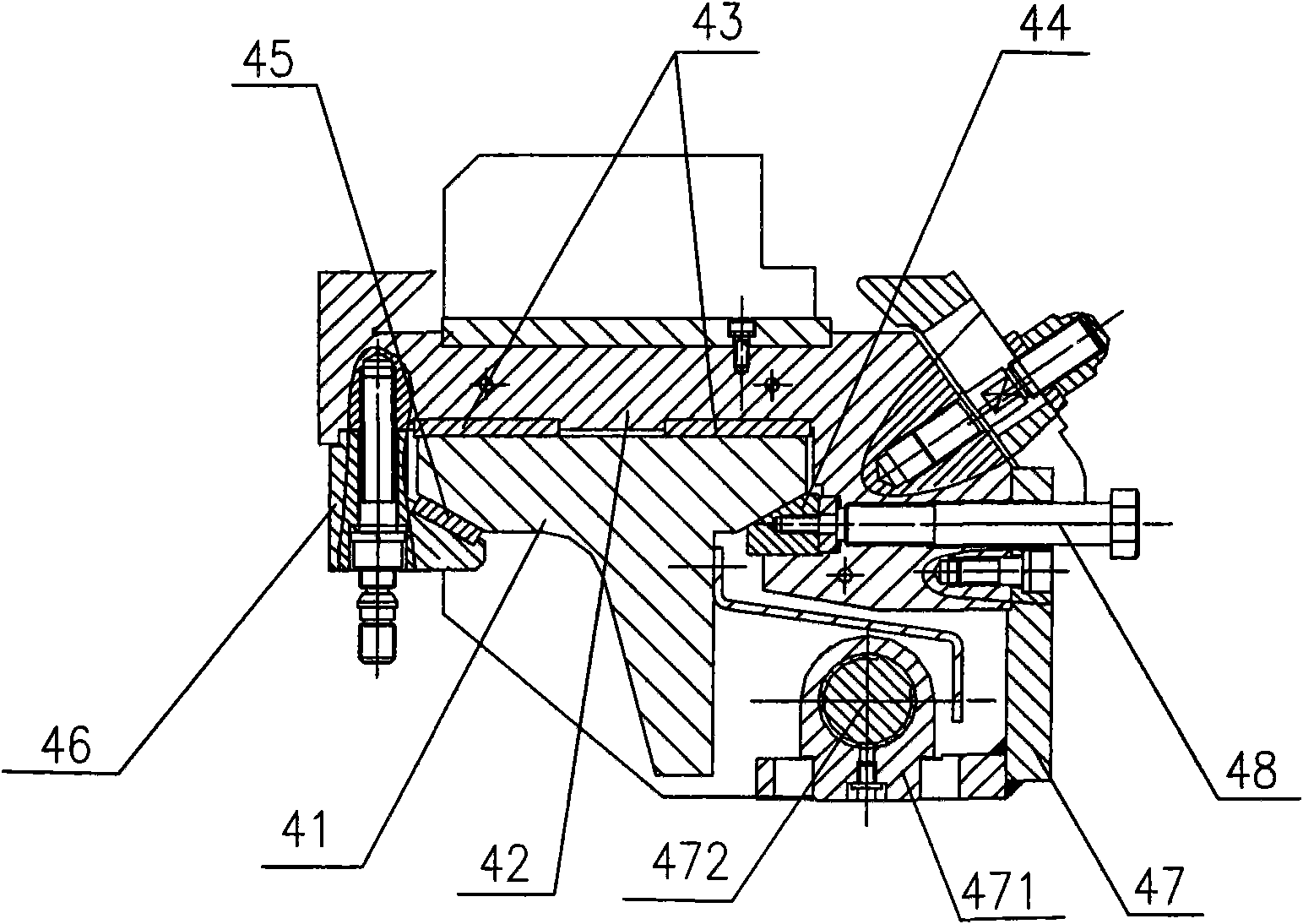

Guide crossbeam device for short stress bar rolling mill

InactiveCN101850369AGood self-lubricationGood pollution resistanceGuiding/positioning/aligning arrangementsPolytetrafluoroethyleneSelf locking

The invention discloses a guide crossbeam device for a short stress bar rolling mill. The guide crossbeam device comprises a guide crossbeam body, a guide seat and a downwards-pressing plate, wherein the guide seat is positioned above the guide crossbeam body; the downwards-pressing plate is fixed on the left lower part of the guide seat; left and right inclined planes on the lower part of the guide seat are matched with left and right inclined planes on the upper part of the guide crossbeam body respectively; an upper inclined plane polytetrafluoroethylene base plate fixed between the inclined planes is in fit with upper and lower inclined planes respectively; a worm bearing pedestal is fixed on the right lower part of the guide seat; a matching plane of the downwards-pressing plate and the upper part of the guide crossbeam body, and a matching plane of the worm bearing pedestal and the upper part of the guide crossbeam body are horizontal planes; the horizontal planes of the guide crossbeam body are positioned below the inclined planes; and a lower plane polytetrafluoroethylene base plate fixed between the horizontal planes is in fit with the upper and lower horizontal planes respectively. The guide crossbeam device has the characteristics of accurate location, high pollution-resistant and self-lubricating properties of sliding planes and driving pairs, and easy movement of the guide seat, self-locking reliability, low labor intensity and short operating time during groove changing, and long maintenance period. The guide crossbeam device can be widely applied in the field of steel rolling.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Fireproof cable material and preparation method thereof

InactiveCN107216515AMaterials are readily availableEasy to prepareRubber insulatorsBulk chemical productionFiberPolyolefin

The invention relates to a fireproof cable material and a preparation method thereof. The fireproof cable material is prepared from the following raw material ingredients in parts by weight: 10 to 15 parts of activated high-purity magnesium oxide, 5 to 8 parts of magnesium chloride, 14 to 17 parts of plant fiber, 6 to 10 parts of lithopone, 4 to 9 parts of glass fiber, 8 to 12 parts of 4,4'-bis(alpha,alpha-dimethylbenzyl)diphenylamine, 5 to 10 parts of ceramic fiber, 8 to 10 parts of polyolefin, 5 to 12 parts of synthetic resin, 6 to 10 parts of silicon carbide, 6 to 9 parts of synthetic mica, 15 to 20 parts of HY-109 rubber adhesive, 3 to 12 parts of PVC, 50 to 60 parts of ethyl alcohol and 30 to 40 parts of helium. The materials of the fireproof cable material disclosed by the invention are easy to obtain; the fireproof cable material has the advantages of simple preparation method, low cost, large tensile strength, good self-lubricating effect, good electric insulating performance, good high temperature resistance, strong stability, oxidization resistance, good anti-ageing effect, small dielectric index, superstrong fireproof performance, small density, excellent heat-resistant effect and no crack in high temperature, low temperature and high pressure; service life of the fireproof cable material is prolonged.

Owner:方碧水

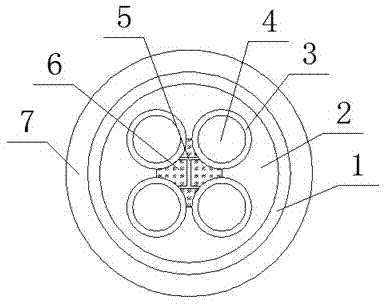

Fluoroplastic polymer insulation high temperature-resistant cable

InactiveCN103871595AGood electrical propertiesGood chemical resistancePlastic/resin/waxes insulatorsInsulated cablesGlass fiberInsulation layer

The invention discloses a fluoroplastic polymer insulation high temperature-resistant cable, which is formed by four insulation cable cores, a fluoroplastic polymer outer sheath, a copper clad steel shielding layer, a high-temperature glass fiber wrapping layer, a ceramic fluororubber insulation layer and galvanized copper core conductors; each insulation cable core is formed by extruding the ceramic fluororubber insulation layer on the galvanized copper core conductor; the four insulation cable cores are extruded to a cable core by the high-temperature glass fiber wrapping layer; an I-shaped enforcement frame is arranged in the cable core; inflaming retarding glass fiber rope fillers are arranged in gaps between the cable core and the I-shaped enforcement frame; the fluoroplastic polymer outer sheath and the copper clad steel shielding layer are extruded on the high-temperature glass wrapping layer from outside to inside. The fluoroplastic polymer insulation high-temperature cable has the characteristics of excellent electrical performances, chemical corrosion resistance, high temperature-low temperature resistance, waterproofness, no adhesion, high structure strength, low friction coefficient, difficulty for breaking and well self lubrication.

Owner:ANHUI JIANGHUAI CABLE GROUP

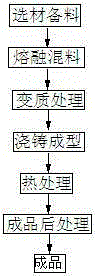

Production method of cast iron retainer with self-lubricating performance

The invention discloses a production method of a cast iron retainer with self-lubricating performance. The preparation method includes the steps: a, selecting and preparing materials; b, fusing and mixing the materials; c, performing modification; d, performing casting molding; e, performing thermal treatment; f, performing post-finishing of finished products. The preparation method has reasonably arranged steps, the process is simple to implement, the preparation cost is moderate, the added alloy elements may comprehensively improve various properties of the retainer, a more stable and excellent strengthening phase is formed, MoS2 molecules impart good self-lubricating performance to the retainer, and effective improvement is given to both wear resistance and service life of the retainer.

Owner:苏州市大力电器有限公司

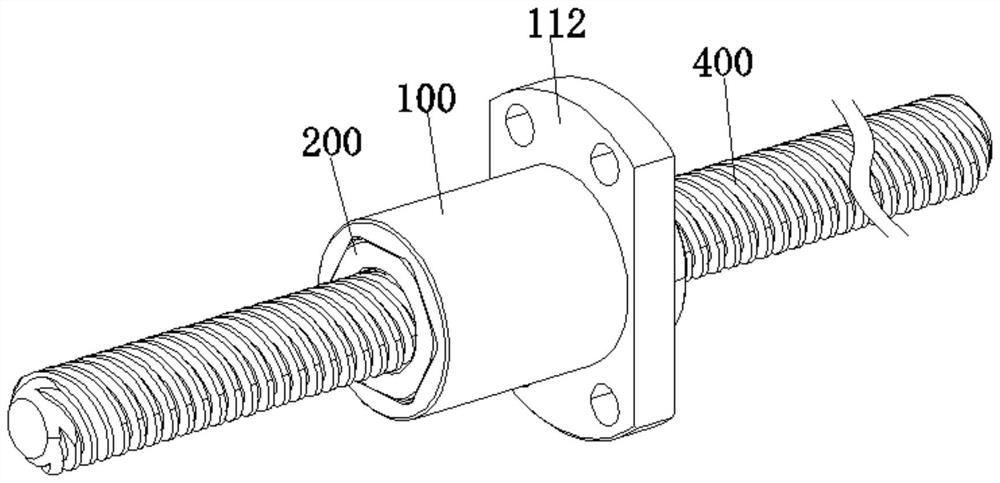

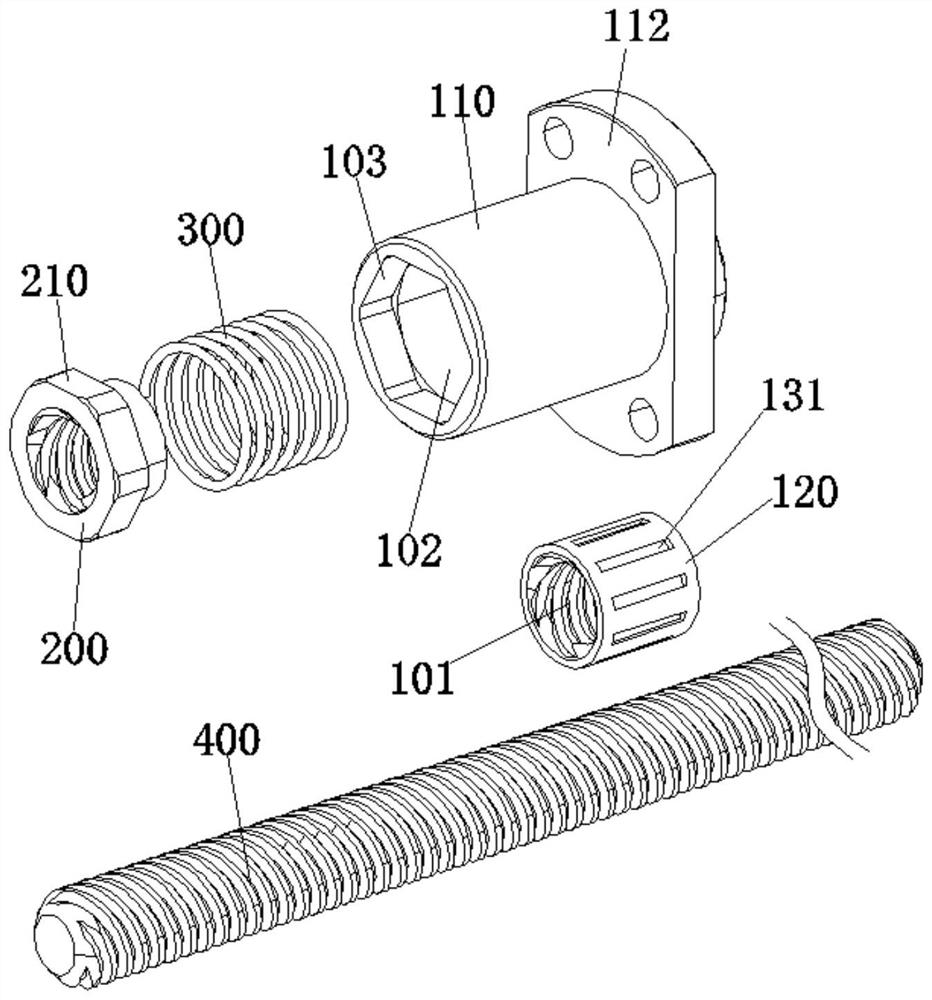

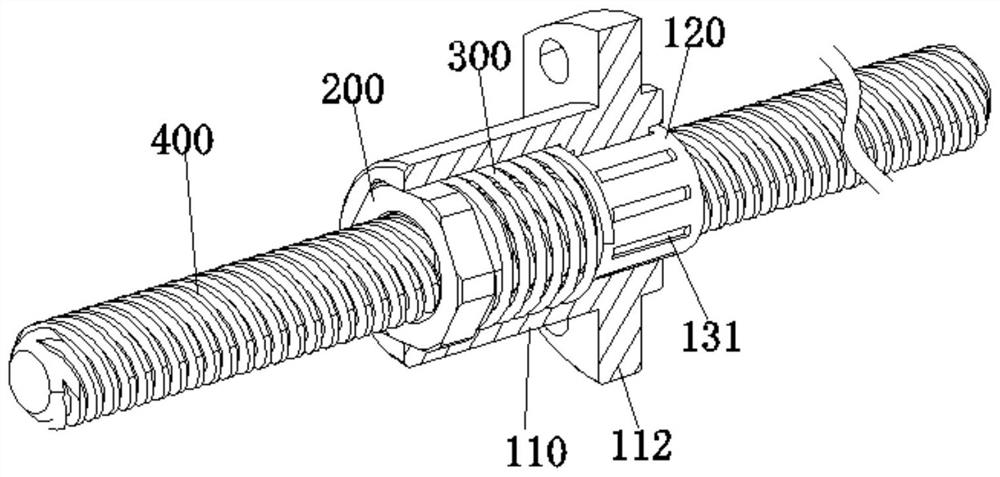

Nut with gap eliminating function

The invention discloses a nut with a gap eliminating function, and relates to the technical field of thread transmission. The nut comprises a first nut body, wherein one end of the first nut body is provided with a threaded hole assembled with a lead screw, the other end of the first nut body is provided with an assembly hole, the lead screw is arranged in the assembly hole in a penetrating mode, and the threaded hole communicates with the assembly hole; a second nut body, wherein the second nut body is matched with the lead screw, and the second nut body is assembled on the side, away from the threaded hole, in the assembly hole; and an elastic part arranged on the lead screw in a sleeving mode and located in the assembly hole, wherein one end of the elastic part is assembled with the second nut body, and the other end of the elastic part is assembled with the side, close to the threaded hole, of the inner wall of the assembly hole. The nut is mainly used in a lead screw transmission structure, and the lead screw transmission structure adopting the nut has the beneficial effects of being low in transmission noise, high in transmission precision, high in wear resistance, long in service life, high in bearing capacity and convenient to maintain in the later period.

Owner:广东安卓信传动科技有限公司

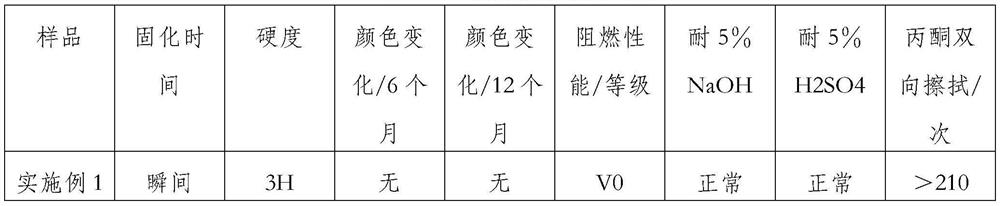

High-temperature corrosion-resistant anti-slagging composite material and preparation method thereof

PendingCN114853455ALow apparent porosityGood self-lubricationCombined combustion mitigationCorrosion resistantFatty alcohol

The anti-slagging corrosion-resistant high-temperature composite coating is prepared from the following components in parts by weight: 20 to 30 parts of corundum fine powder specification mixture, 2 to 5 parts of ceramic powder with the particle size of 0.01 to 0.025 mm, 10 to 15 parts of barium metaborate, 15 to 20 parts of nano silicon dioxide, 2 to 6 parts of quartz powder, 0.5 to 1 part of nano yttrium oxide with the particle size of 30nm, 1 to 2 parts of nano cerium oxide with the particle size of 30nm, 15 to 20 parts of binding agent, 0.2 to 0.5 part of dispersing agent and 1 to 5 parts of anti-settling aid, 10 parts of fatty alcohol-polyoxyethylene ether, 2-5 parts of sodium nitrite and 25 parts of FeCl. The problem that an existing garbage incinerator inner wall coating cannot have corrosion resistance while certain slagging resistance and high temperature resistance are guaranteed is solved.

Owner:林国强

Novel polymer composite material and preparation method thereof

The invention relates to a novel polymer composite material and a preparation method thereof. The raw materials of the novel polymer composite material comprise, by weight, 6-8 parts of calcium stearate, 5-7 parts of zinc stearate, 3-6 parts of TBHQ, 4-8 parts of octadecanoic acid, 2-6 parts of papain, 6-10 parts of silicone oil, 5-9 parts of cocoanut fatty acid diethanolamide, 2-5 parts of PPD, 3-10 parts of fatty alcohol polyoxyethylene ether and 8-10 parts of deionized water. The novel polymer composite material has the advantages of easiness in obtaining, low cost, environmental protection, greenness, reduced frictional performance, reduced resistance, easiness in absorption, acceleration of the lubrication speed, improvement of the wear resistance, increased wetness, increase of the surface tension, improved toughness, fast emulsification speed and good anti-oxidation effect and prolongation of the service life.

Owner:伊婕

Preparation method of high thermal stretching high molecular weight polyethylene sheet

The invention provides a preparation method of a high-ratio hot-stretched high molecular weight polyethylene sheet. The preparation method comprises the following steps: 1, taking 95 parts of ultra-high molecular weight polyethylene resin, 4.5 parts of polyethylene wax and 0.5 part of carbon black by weight, mixing the raw materials, placing the mixed raw materials in a single-screw extruder, and extruding the mixed raw materials to obtain a plate blank, wherein a sheet extrusion die is mounted at the outlet of the single-screw extruder; 2, leading the plate blank into a first calender for calendering to obtain a preformed plate blank; 3, leading the preformed plate blank into a hot channel for heating, and leading the heated preformed plate blank into a calendar for calendering to obtain a preformed sheet; 4, leading the preformed sheet into a hot channel for heating, and leading the heated preformed sheet into the calendar for calendering to obtain a finished sheet; and 5, placing the formed sheet in a heat-setting machine for heat setting to obtain the high-ratio hot-stretched high molecular weight polyethylene sheet. The sheet prepared according to the method provided by the invention has extremely smooth surfaces, a light weight and a small thickness, and thus can be widely adhered to the surfaces of various objects such as ship bodies and submarines, which are scaled and corroded easily.

Owner:刘嵩

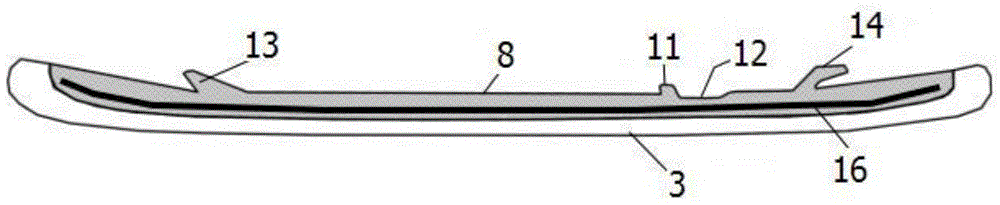

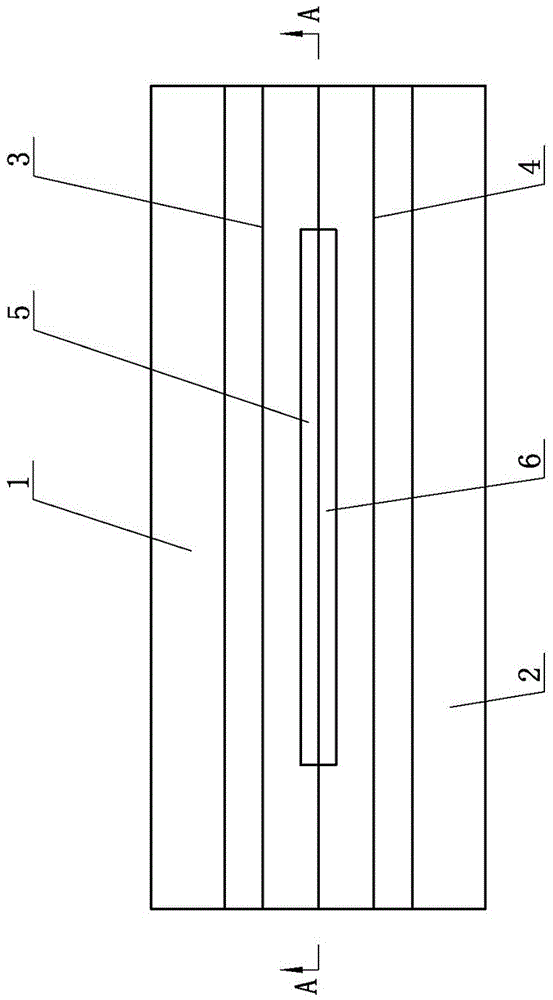

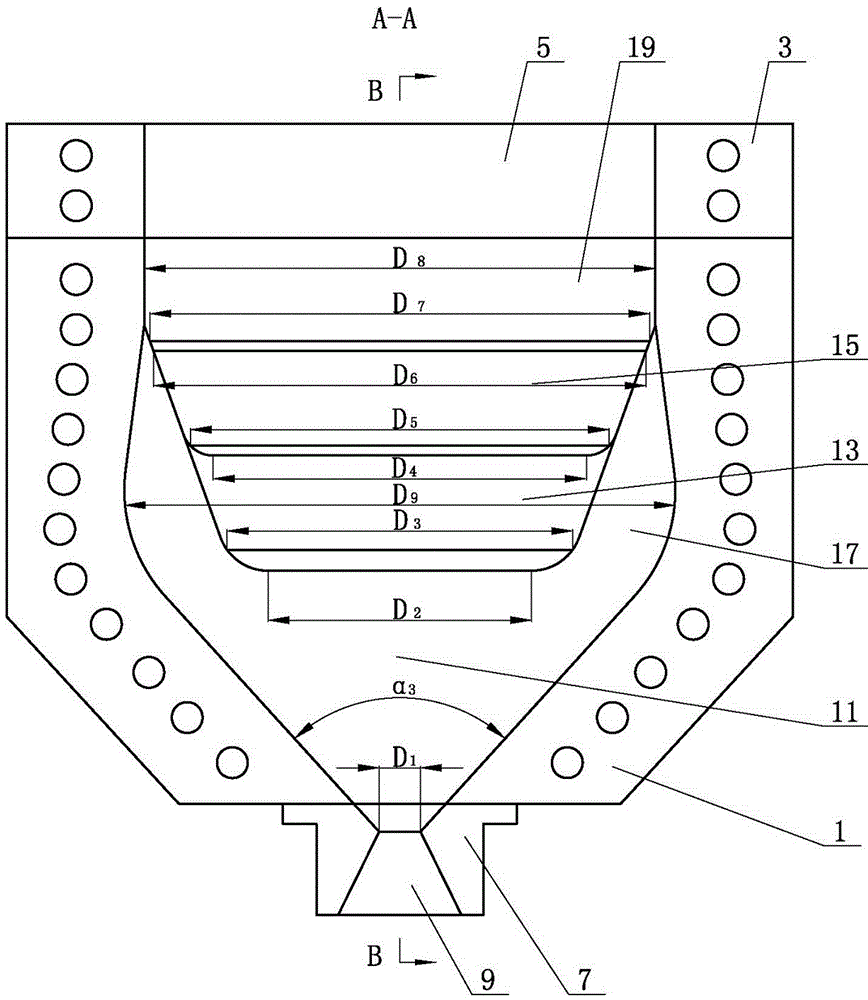

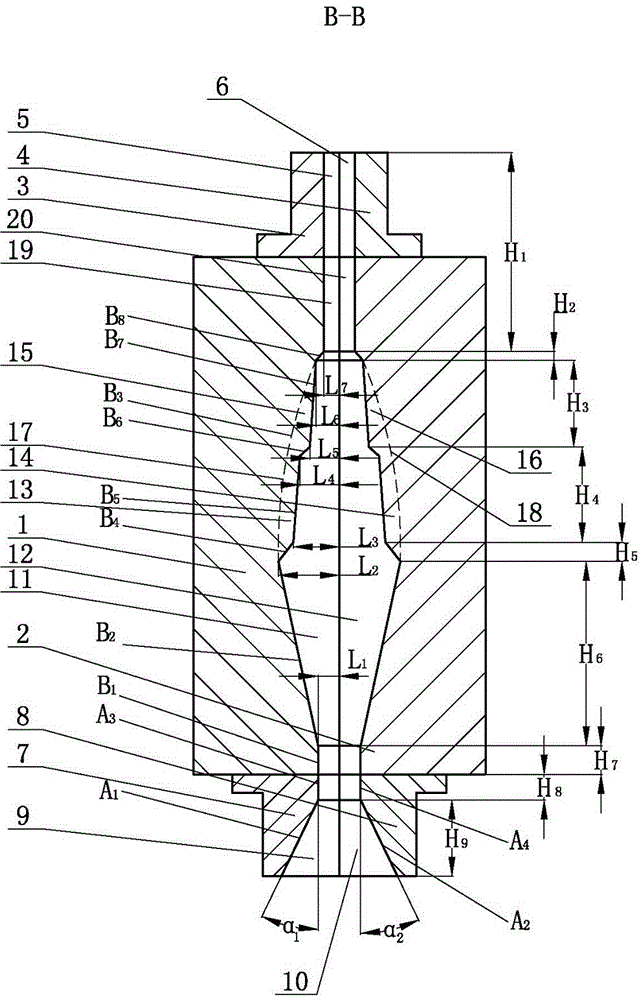

Skate rack and manufacturing method

The invention discloses a skating shoe frame and a manufacturing method. The skating shoe frame comprises shoe sole support seats, a strip-shaped vertical plate and an ice skate blade connected with the strip-shaped vertical plate, wherein the strip-shaped vertical plate is arranged on the shoe sole support seats and penetrates through the front and rear ends of lower surfaces of the shoe sole support seats; the shoe sole support seats comprise a front shoe sole support seat, a rear shoe sole support seat and a connecting strip which is used for connecting the front shoe sole support seat and the rear shoe sole support seat and is arched downwards; the front shoe sole support seat and the rear shoe sole support seat are barrel-shaped, upper ends of the front shoe sole support seat and the rear shoe sole support seat are open, cross sectional areas of the front shoe sole support seat and the rear shoe sole support seat are gradually increased from bottom to top, an opening is formed in the rear part of the front shoe sole support seat, an opening is formed in the front part of the rear shoe sole support seat, and the height of the upper end surface of the front shoe sole support seat is gradually increased from front to back. The skating shoe frame and the manufacturing method have the characteristics of simple manufacturing process, light weight, high elasticity and flexibility, small friction coefficient, high water absorptivity, stable quality and long service life.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

Preparation method of high-ratio hot-stretched high molecular weight polyethylene sheet

The invention provides a preparation method of a high-ratio hot-stretched high molecular weight polyethylene sheet. The preparation method comprises the following steps: 1, taking 95 parts of ultra-high molecular weight polyethylene resin, 4.5 parts of polyethylene wax and 0.5 part of carbon black by weight, mixing the raw materials, placing the mixed raw materials in a single-screw extruder, and extruding the mixed raw materials to obtain a plate blank, wherein a sheet extrusion die is mounted at the outlet of the single-screw extruder; 2, leading the plate blank into a first calender for calendering to obtain a preformed plate blank; 3, leading the preformed plate blank into a hot channel for heating, and leading the heated preformed plate blank into a calendar for calendering to obtain a preformed sheet; 4, leading the preformed sheet into a hot channel for heating, and leading the heated preformed sheet into the calendar for calendering to obtain a finished sheet; and 5, placing the formed sheet in a heat-setting machine for heat setting to obtain the high-ratio hot-stretched high molecular weight polyethylene sheet. The sheet prepared according to the method provided by the invention has extremely smooth surfaces, a light weight and a small thickness, and thus can be widely adhered to the surfaces of various objects such as ship bodies and submarines, which are scaled and corroded easily.

Owner:刘嵩

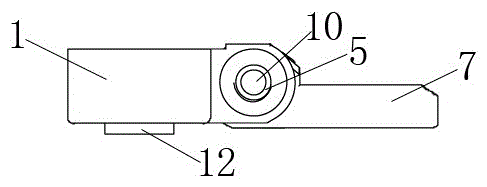

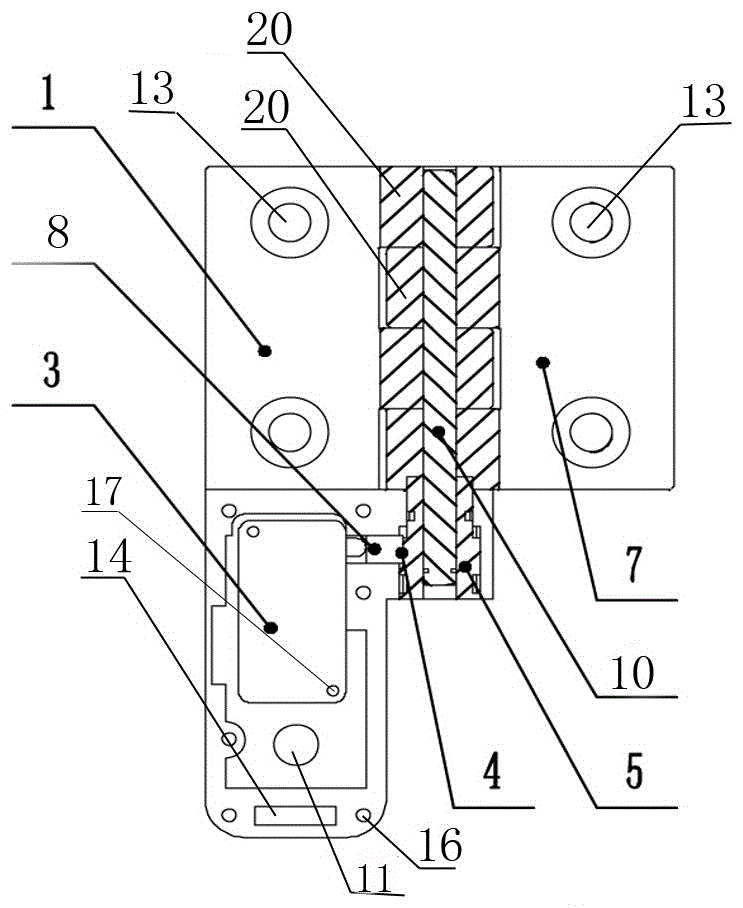

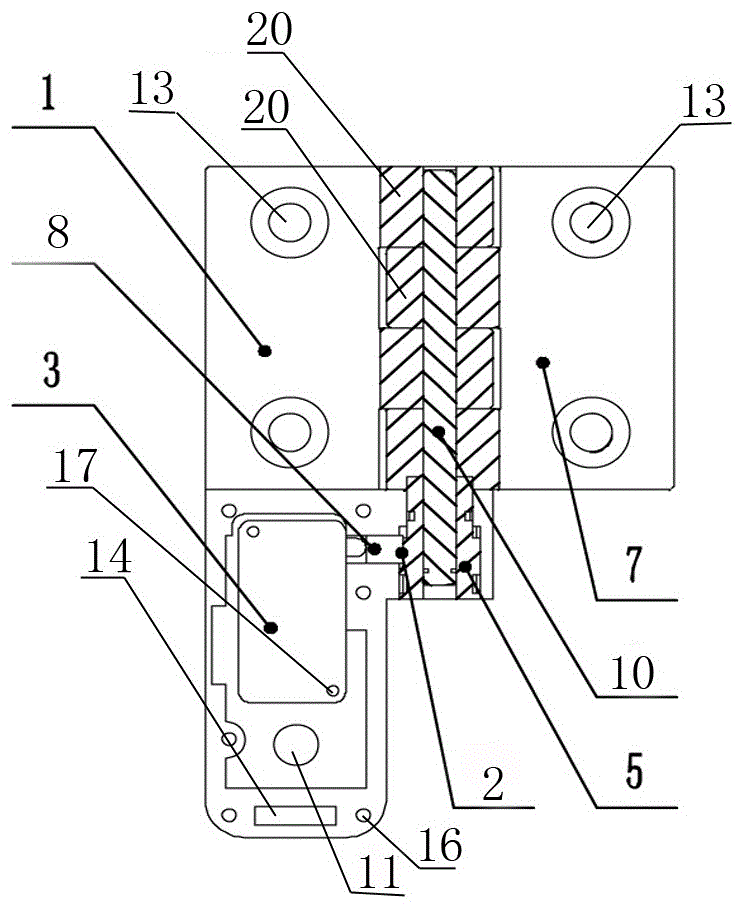

a hinge

InactiveCN103687388BHigh mechanical strengthImprove toughnessContact operating partsCasings/cabinets/drawers detailsHeat resistanceUltimate tensile strength

Owner:瑞安市盈通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com