Patents

Literature

37results about How to "Adjustable color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Four-color LED light mixing method based on visible light communication

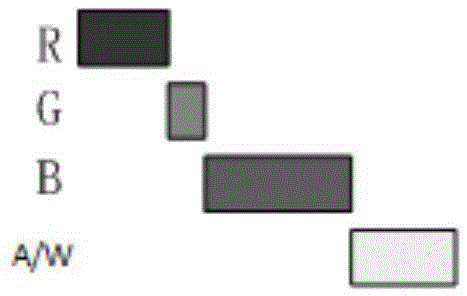

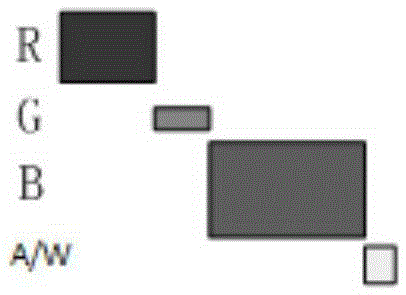

ActiveCN104053278ASpectrum richColor temperature adjustablePoint-like light sourceElectric lightingColor rendering indexSpectrograph

The invention discloses a four-color LED light mixing method based on visible light communication. The method comprises the steps that spectral power distribution of all monochromatic light is obtained through a spectrograph, and the tristimulus value of each corresponding monochromatic light is calculated; the target color temperature of mixed light is determined, and a corresponding reference light source is selected and used for obtaining the tristimulus value of a mixed color; according to the color addition principle, the sum of the tristimulus values of all the monochromatic light should be equal to the tristimulus value of the mixed color, and a color mixing equation set is obtained; the spectral power distribution of the mixed light can be obtained according to the light mixing coefficient of all the monochromatic light in the color mixing equation set, and the color rendering index Ra of the mixed light is calculated according to the spectral power distribution of the mixed light, wherein Ra is larger than or equal to epsilon; the range of the channel capacity C of the mixed light is calculated, and the maximum capacity Cmax is solved within the range; the ratio of all the colored light with the maximum capacity is output.

Owner:SOUTHEAST UNIV

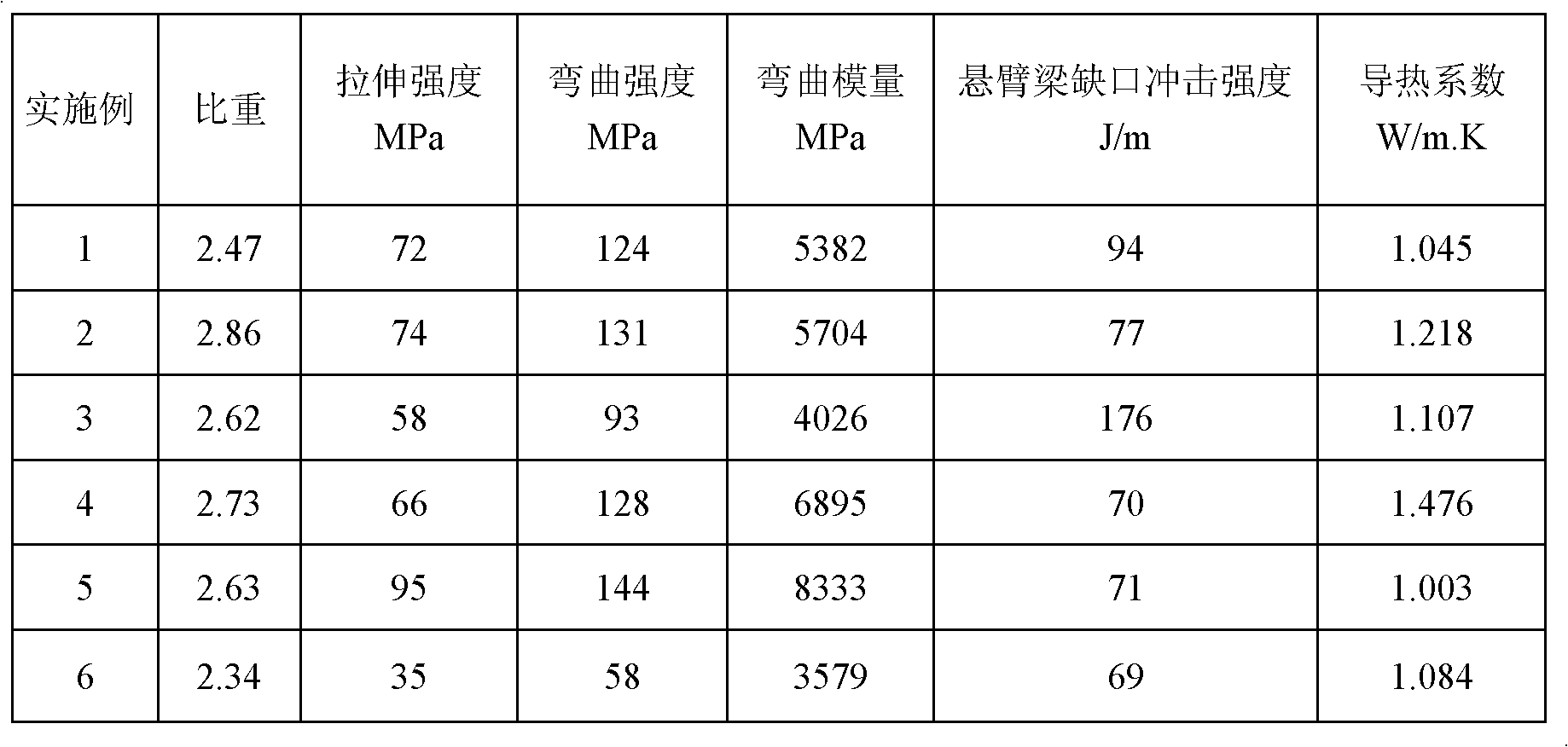

Ceramic-imitated plastic composite material and preparation method thereof

The invention discloses a ceramic-imitated plastic composite material and a preparation method thereof, relates to a high molecular composite material, and provides the imitative ceramic plastic composite material which has the combined advantages of plastic and ceramic, is impact-resistant, easy to form and recover and has high surface glossiness and the preparation method thereof. The imitative ceramic plastic composite material comprises the following components: a plastic material, zinc oxide, a coupling agent, a lubricant, a weighing filler, a toughening agent and fiber. The preparation method comprises the following steps of: adding the zinc oxide and the weighing filler into a mixer; spraying the coupling agent; adding the lubricant, the toughening agent and the plastic material into the mixer to obtain mixed raw materials; throwing the obtained mixed raw materials into a double-screw extrusion granulator; performing melt extrusion to form wires; cooling; and granulating to obtain the imitative ceramic plastic composite material. If the fiber is available in the formula, the fiber is fed from a side feed port of the double-screw granulator during extrusion granulation.

Owner:XIAMEN RUNNER IND CORP

Method for manufacturing laminated veneer lumber by using wood

InactiveCN102398288AHigh strengthReduce internal stressPlywood pressesVeneer manufactureHigh intensityPolymer chemistry

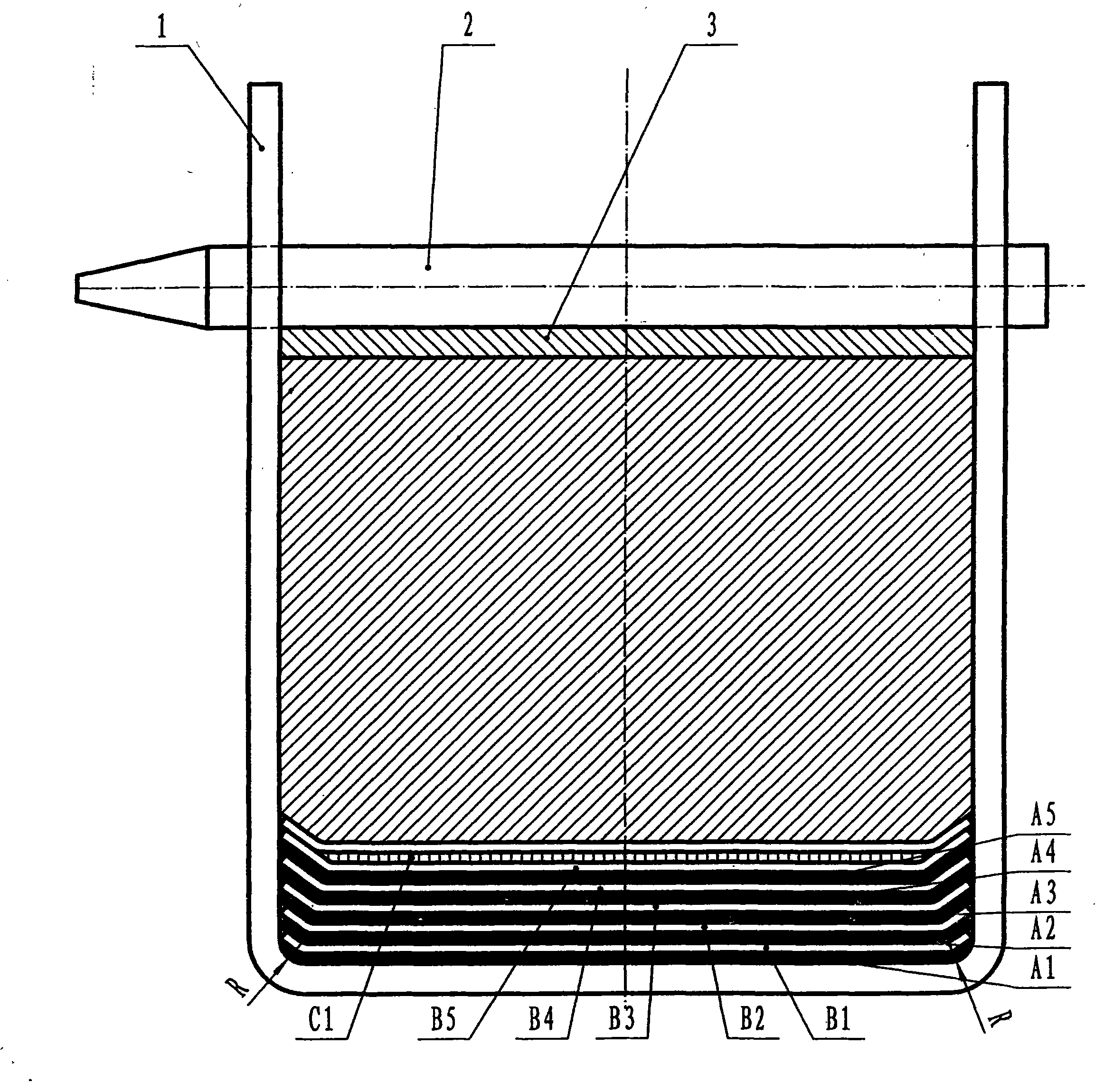

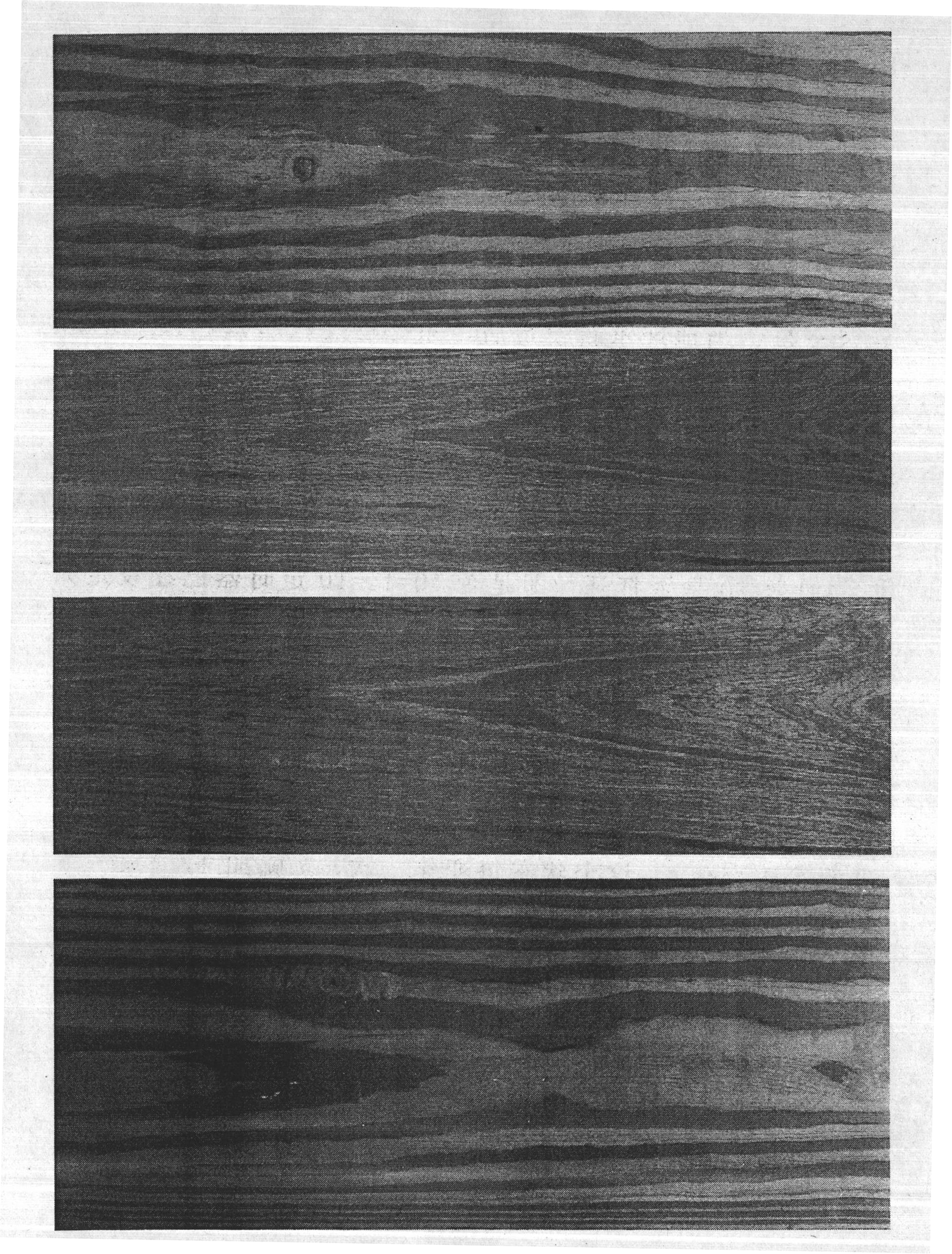

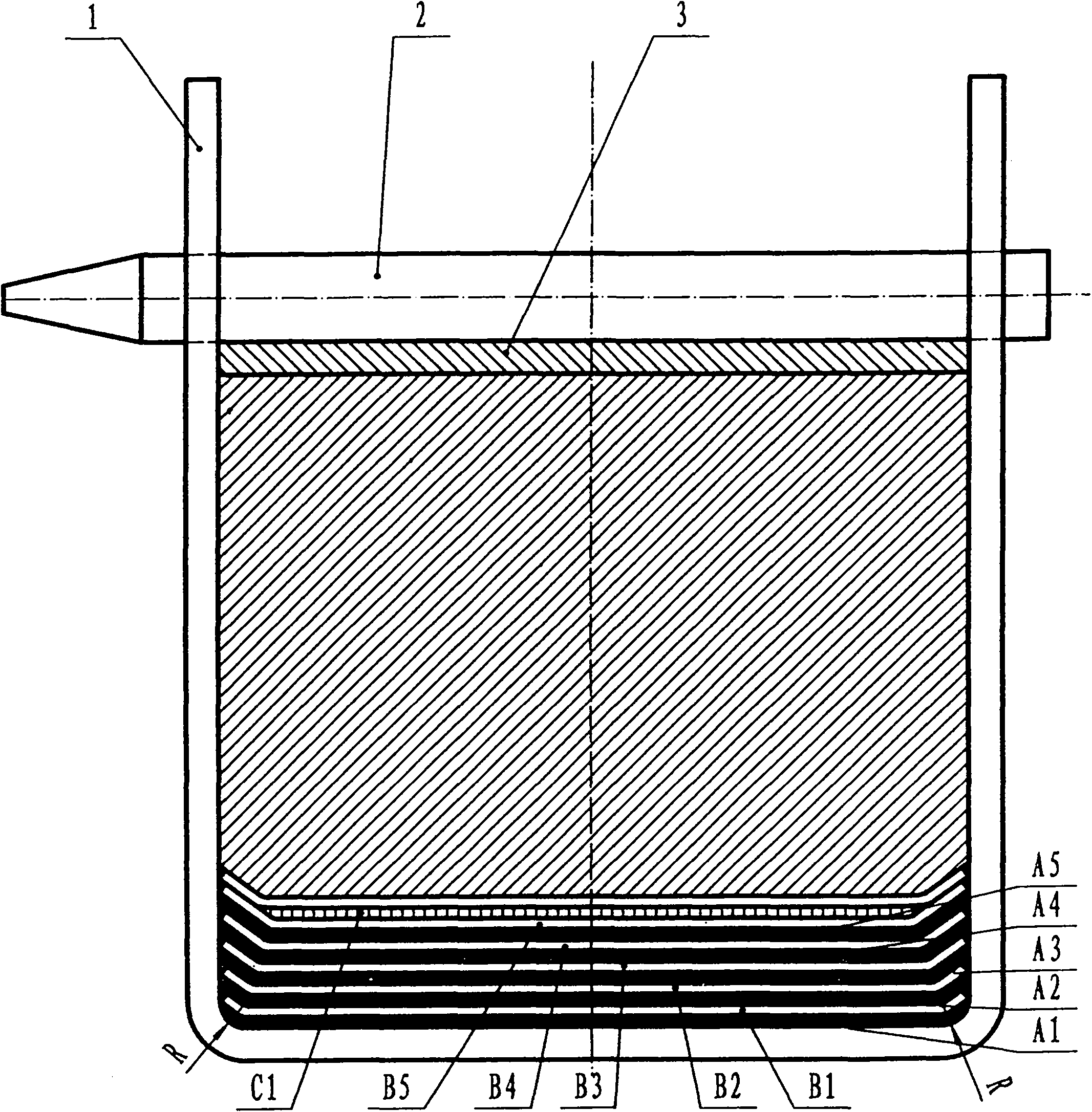

The invention discloses a method for manufacturing laminated veneer lumber by using wood to solve the problem that the laminated veneer lumber with high strength and simulated rich textures cannot be produced in the conventional methods. The method comprises the following steps of: (1) manufacturing the wood into veneers with the thickness of 0.3-5mm, and performing gum dipping and drying on the veneers, wherein the length and width dimensions of the veneers are the same as those of an internal mold of a mold, or the width dimension of the veneers is consistent with that of the internal mold and the length dimension of the veneers is a fraction of that of the internal mold; (2) superposing the veneers to obtain a blank, putting the blank into the internal mold of the mold, and ensuring that an included angle between a groove bottom and a groove wall is a fillet with the radius of R, wherein the R is more than or equal to 3mm and less than or equal to 20mm, the groove wall is provided with corresponding holes on the same horizontal plane, and the corresponding holes are matched with a pin; (3) pressing the blank in the internal mold of a movable mold of a press, making a pressing plate positioned below the corresponding holes, locking the internal mold by using the pin to penetrate the corresponding holes, and heating and curing the locked internal mold and the blank; and (4) cooling, detaching the pin, demolding the blank, ensuring that the exposed surface of the blank is provided with simulated annual rings, putting the blank in a natural environment, sheeting according to the annual rings of the blank, and ensuring that sheets have the simulated annul rings.

Owner:李和麟

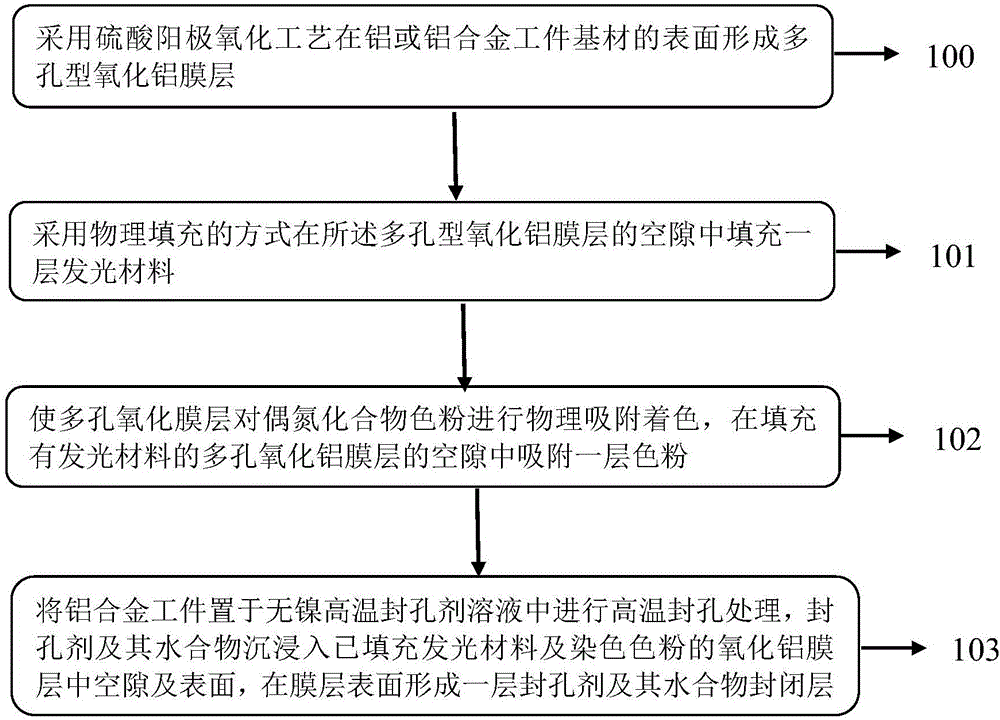

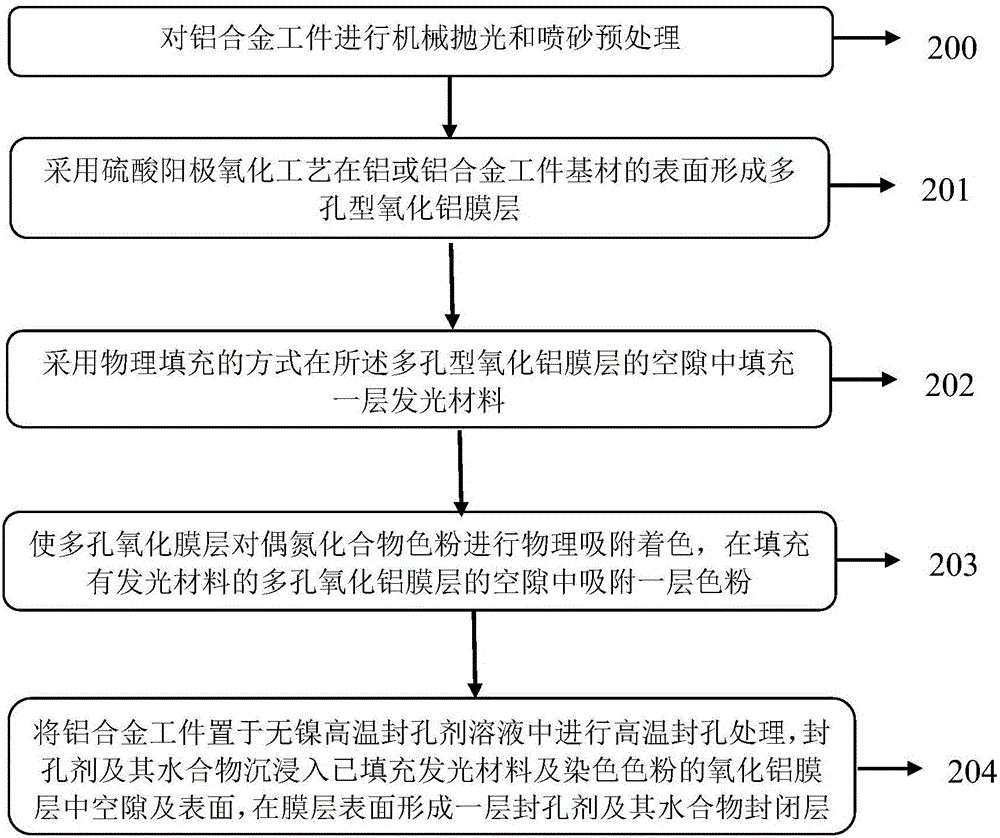

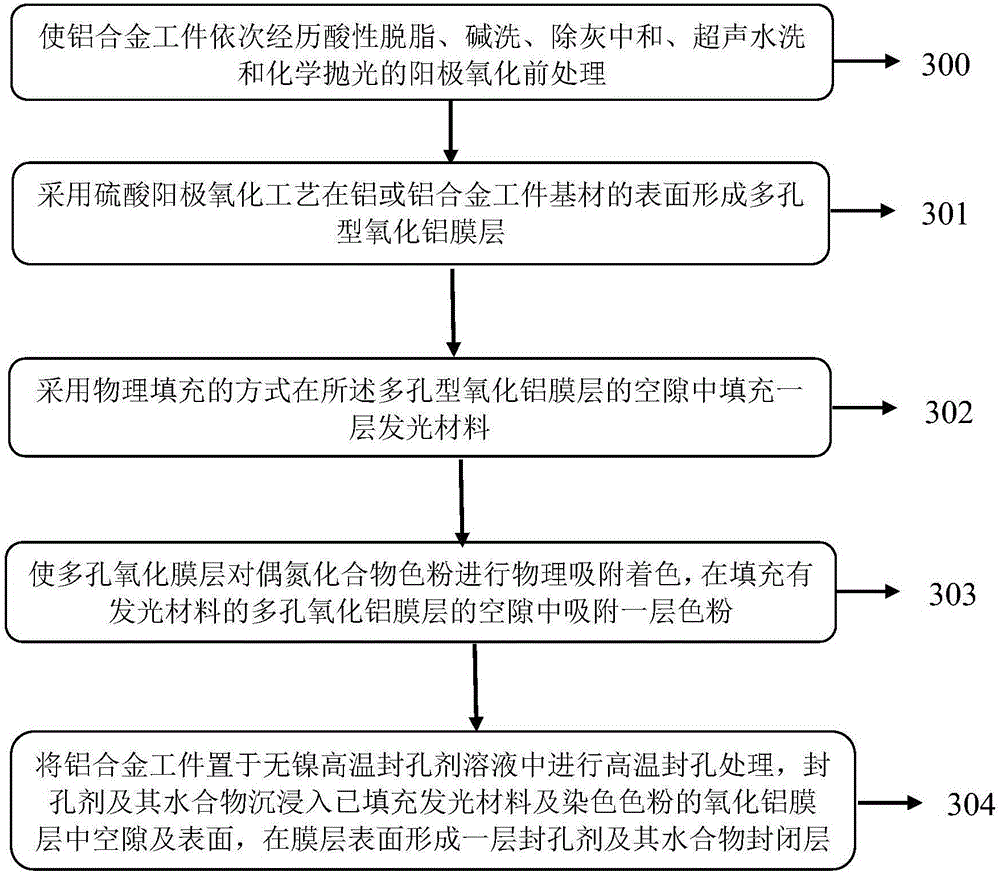

Self-luminous anodic oxidation process for aluminum or aluminum alloy, aluminum and aluminum alloy

InactiveCN105780083AAchieve functionTo achieve appearanceAnodisationAnodic oxidationMaterials science

The invention relates to a self-luminous anodic oxidation process for aluminum or an aluminum alloy. A porous type aluminum oxide film layer is formed on the surface of an aluminum or aluminum alloy workpiece through the sulfuric acid direct-current anodic oxidation process, gaps of the porous type aluminum oxide film layer are filled with light-emitting materials in a physical filling manner, then the porous type aluminum oxide film layer is colored, and hole sealing is finally conducted, so reaction with other substances in air is isolated and the function and appearance effect that the aluminum or the aluminum alloy can emit light are achieved. The self-luminous anodic oxidation process is suitable for processes of all aluminum or aluminum alloy materials, capable of meeting requirements for appearance effects of various terminal products, controllable in color and suitable for batched production.

Owner:SHENZHEN TINNO WIRELESS TECH

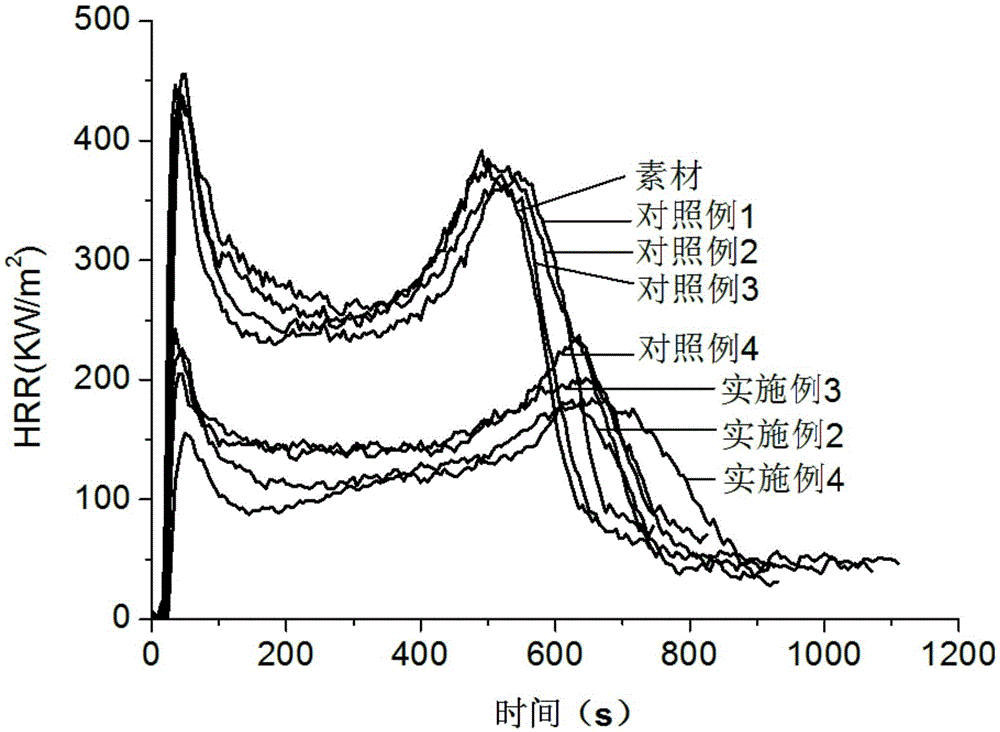

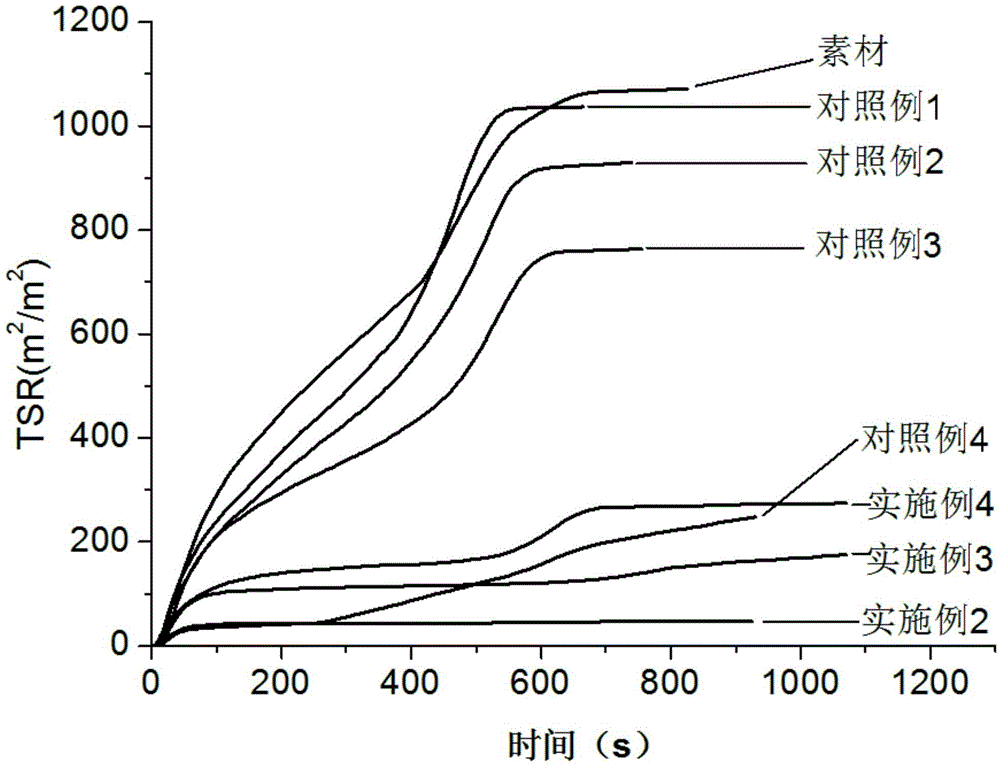

Flame-retardant thermal modification wood and preparation method thereof

ActiveCN105666612AImprove fire safetyGood surface decorationWood treatment detailsThermal wood treatmentCombustionMaterials science

The invention relates to flame-retardant thermal modification wood and a preparation method thereof. The preparation method comprises the step that after being subjected to immersion treatment, the wood is subjected to heat treatment. According to the flame-retardant thermal modification wood and the preparation method thereof, the flame-retardant thermal modification wood is prepared by combining the wood high-temperature heat treatment with the wood flame-retardant technology; the dual characteristics that the wood is subjected to high-temperature heat treatment and flame retarding are achieved at the same time; the flame-retardant thermal modification wood has the good surface decorative performance, dimensional stability and the like, and the excellent flame-retardant property is also achieved; the combustion heat release rate and smoke production are substantially decreased, and the fireproof safety of processed wood products is greatly increased.

Owner:BEIJING FORESTRY UNIVERSITY

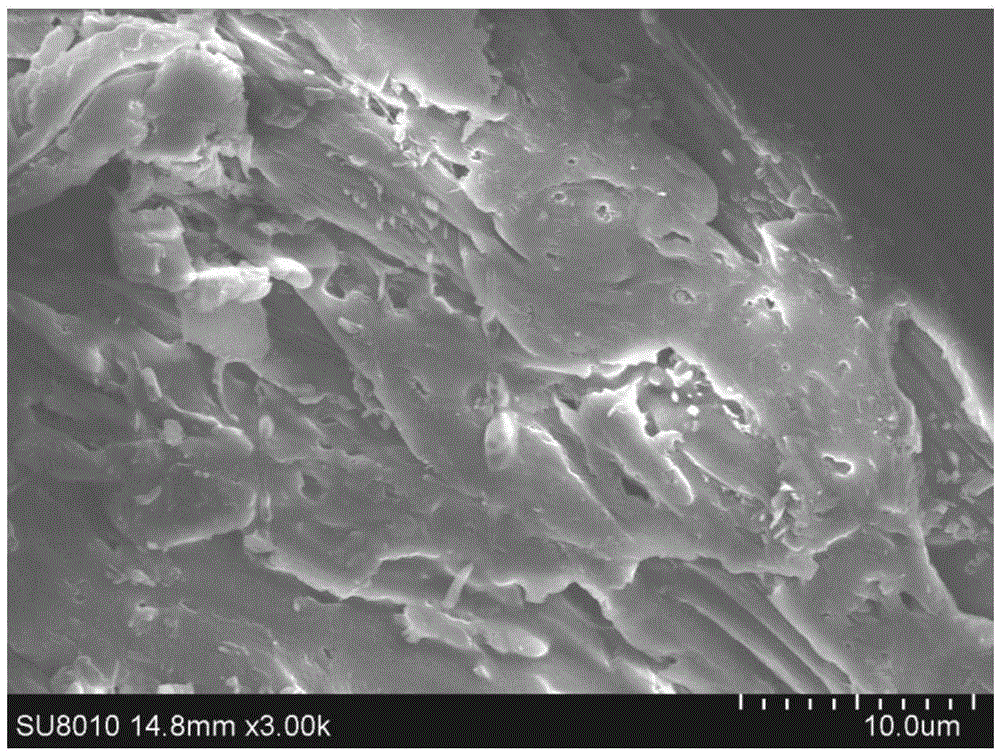

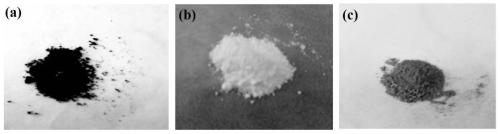

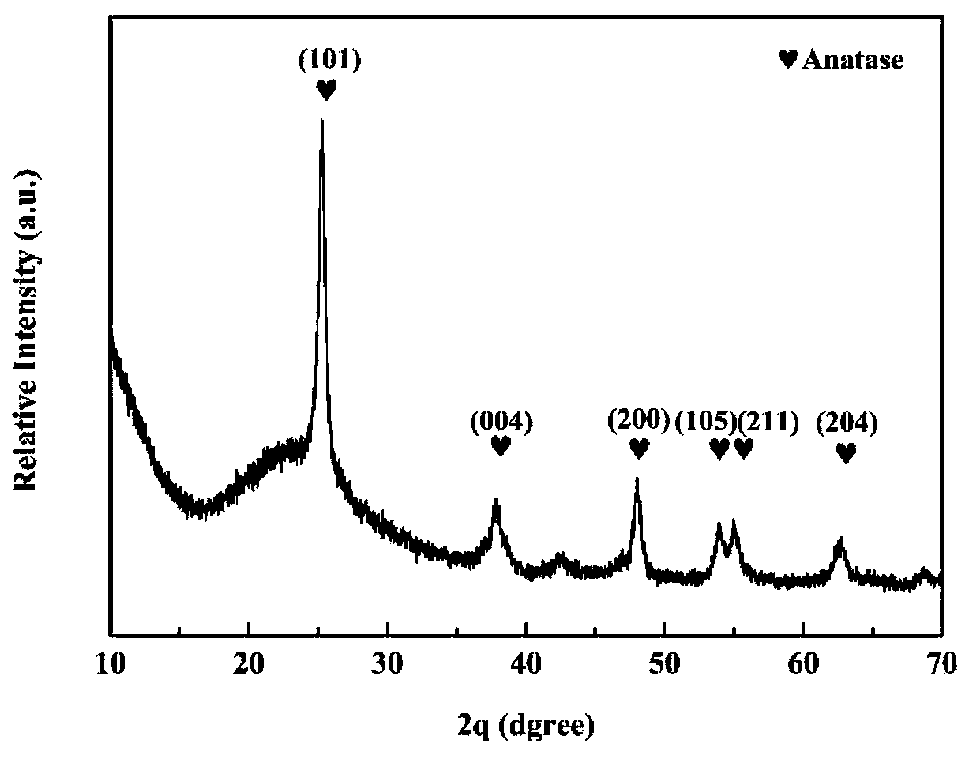

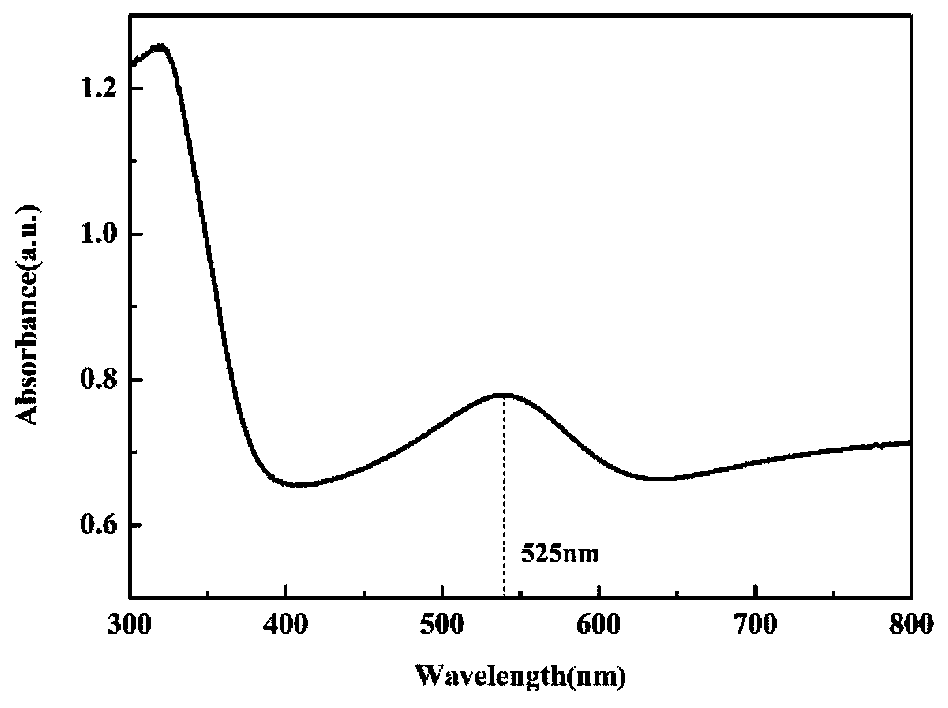

Amorphous photonic crystal schemochrome material based on black titanium dioxide and silicon dioxide composite and preparation method of amorphous photonic crystal schemochrome material

InactiveCN110304654AGood photocatalytic effectSimple preparation processMaterial nanotechnologySilicaPhotocatalytic degradationPollutant

The invention provides an amorphous photonic crystal schemochrome material based on black titanium dioxide and silicon dioxide composite and a preparation method of the amorphous photonic crystal schemochrome material. The material component comprises SiO2 amorphous photonic crystal and black TiO2, and the mass ratio of the black TiO2 and the SiO2 amorphous photonic crystal is 1 to (0.1-1). The preparation method comprises the steps that (1) black TiO2 nanoparticle powder is prepared, and SiO2 amorphous photonic crystal microsphere powder is prepared; (2) the black TiO2 / SiO2 materials are prepared, specifically, the SiO2 amorphous photonic crystal microsphere powder and the black TiO2 nanoparticle powder are dissolved in ethanol, ultrasonic dispersion is conducted after stirring, and theproduct is dried. According to the preparation method, the schemochrome is combined with the photocatalysis function, the limitation of preparing non-angle independent color material by absorbing coherent scattering light with carbon black as the back bottom is broken, and the obtained material has the function of photocatalytic degradation of pollutants at the same time.

Owner:SHAANXI UNIV OF SCI & TECH

Artificial lignumvitae and preparation method thereof

The invention belongs to the field of novel material, and relates to an artificial lignumvitae and a preparation method thereof. The invention solves the problems of natural lignumvitae, such as anisotropy of material, scarce resource and expensiveness. The artificial lignumvitae provided by the invention is prepared by uniform mixing and warm compaction on the following components, by mass percentage: 20-80% of a wood-plastic composite powder obtained by mixing, 10-50% of a wood powder, 3-10% of ceramic crystal whisker, 5-20% of an electrolytic copper powder and 0.1-2% of a toner. The product has adjustable color, isotropic material and good self-lubricating, is suitable for water lubrication condition, and can substitute natural lignumvitae for preparation of marine tail bearing, substitute iron / copper base powder metallurgy oil-retaining sliding bearing material for preparation of sliding bearing for electrical equipment in fields of food, medicine and textile, and also substitute rosewood and bovine bone for preparation of high-grade automotive interior.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

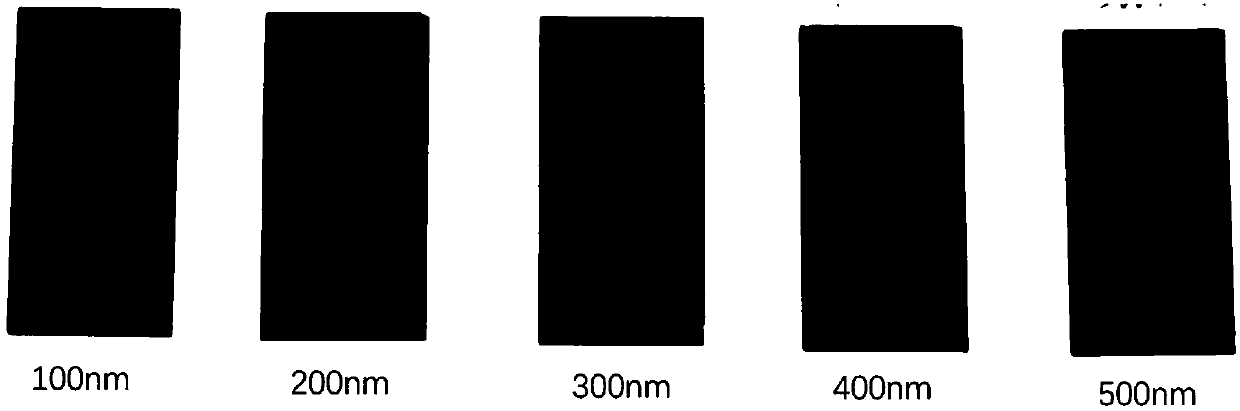

Colorful anticorrosion decorative film with controllable surface color of matrix and preparation method thereof

ActiveCN102744926ABreak through the environmentBreakthrough in corrosion resistanceVacuum evaporation coatingSputtering coatingHardnessApplication areas

The invention discloses a colorful anticorrosion decorative film with controllable surface colors of a matrix and a preparation method thereof. The colorful anticorrosion decorative film is composed of a metal transition layer disposed in a matrix layer and a tetrahedron amorphous carbon film disposed on the surface of the metal transition layer, wherein the thickness of the tetrahedron amorphous carbon film is 10 nm-300 nm; and the colors of the colorful anticorrosion decorative film can be regulated by controlling the thickness of the tetrahedron amorphous carbon film to make the colorful anticorrosion decorative film present colors of prunosus, skyblue, golden yellow, grayish brown, silver grey, light green, etc. Compared with a conventional decorative film, the colorful anticorrosion decorative film has the characteristics of controllable colors, abundant colors, environmental protection, high hardness and excellent corrosion resistant performance, is not only a supplement and improvement for the field of the conventional decorative film, but also breaks through the common application field of the conventional tetrahedron amorphous carbon film, broadens the practical application field thereof, and has good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

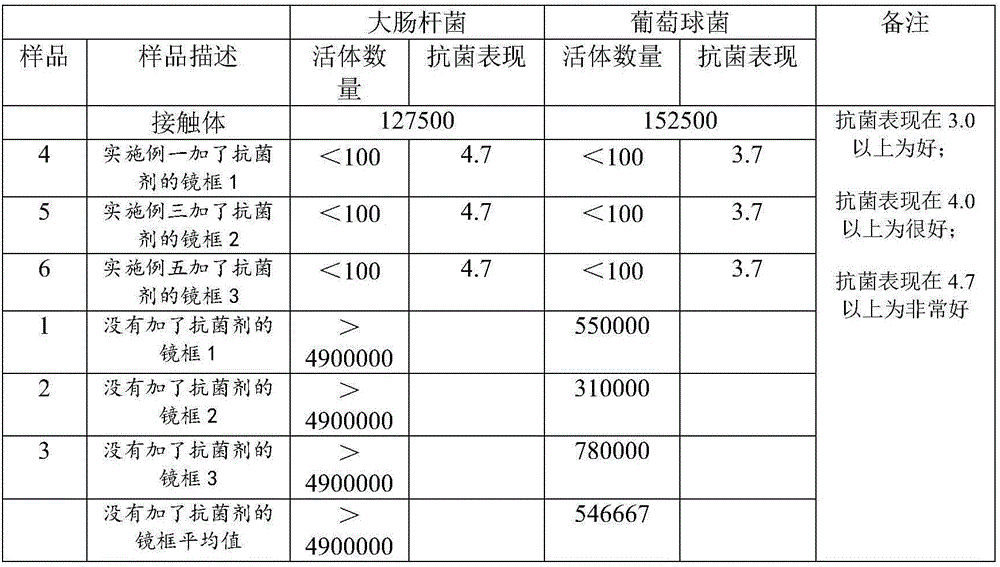

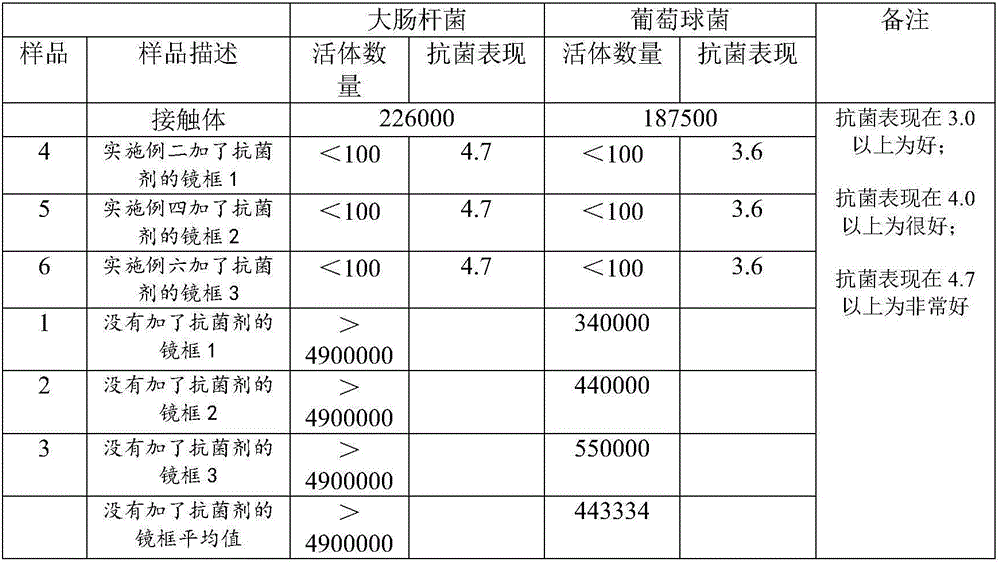

Antibacterial spectacles frame and preparation method thereof

InactiveCN106291969AThe preparation process is simple to operateGood antibacterial and deodorant effectBiocideDead animal preservationSilver particlesAntibacterial efficacy

The invention discloses an antibacterial spectacles frame. The spectacles frame comprises an antibacterial agent, wherein the antibacterial agent comprises nano silver particles and glass wool fibers, wherein the particle size of the nano silver particles is 10nm to 30nm, and a unit weight of the glass wool fibers is 16Kg / m<3> to 200Kg / m<3>. Spectacles have an antibacterial efficacy and also have an advantage of aging resistance.

Owner:东莞市懋泰眼镜有限公司

Method for producing pine needle powder

InactiveCN101411726AAnti agingProtect blood vesselsPowder deliveryMetabolism disorderPins needlesPre treatment

The invention relates to a method for producing pine needle powder and pine needle powder production is blank in the market currently. The method for producing the pine needle powder comprises the following steps: the pretreatment, extraction, filtering, powder spraying, drying, pulverization and sterilization of pin needle, wherein the extraction is water extraction and is divided into three times; 10 weight portions of the pine needle and 10 portions of water and are mixed and steamed; when the water reaches 8 weight portions, water is added into the mixture till the water reaches 10 weight portions; the mixture is continuously steamed; when the water reaches 6 weight portions, the mixture is added with water again till the water reaches 10 weight portions and is steamed; and when the water reaches 4 weight portions, the mixture is warmly cooled, is added with egg white accounting for 2 percent of the weight of the residual mixture, is subjected to dissociation, filtering, powder spraying, drying, pulverization treatment and sterilization. The method is used for producing the pine needle powder.

Owner:李旭东

Method for inhibiting side reaction of tetrahydrofuran in polymerizing process

The invention relates to a method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process. According to the method, in the process of preparing a polymer by using terephthalic acid and 1,4-butanediol as main raw materials, ester, titanium-silicon-cobalt composite catalyst dispersant and pH regulator are generated by adding the terephthalic acid and dihydric alcohol in the esterifying stage, the molar ratio of the terephthalic acid to the 1,4-butanediol is controlled to be 1:(1.05-1.10) to inhibit the side reaction of tetrahydrofuran, so that the content of tetrahydrofuranin the polymer is less than or equal to 10wt%; the dispersing medium in the titanium-silicon-cobalt composite catalyst dispersant is 1,4-butanediol, and the titanium-silicon-cobalt composite catalystis prepared by combining a titanium-silicon composite catalyst and a cobalt catalyst, and the titanium-silicon composite catalyst is prepared from a silicon catalyst-supported titanium catalyst. According to the method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process, the final product has concentrated molecular weight distribution, few byproduct and high quality, andhas a great application prospect.

Owner:DONGHUA UNIV

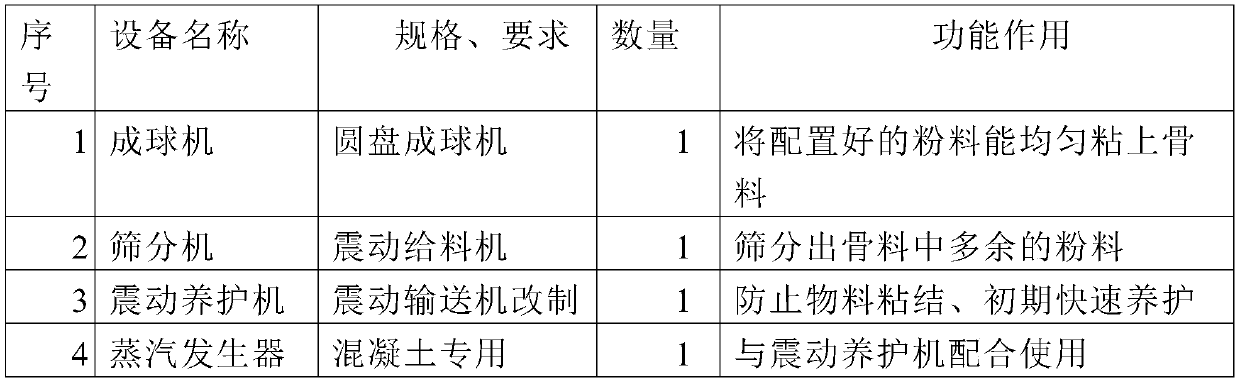

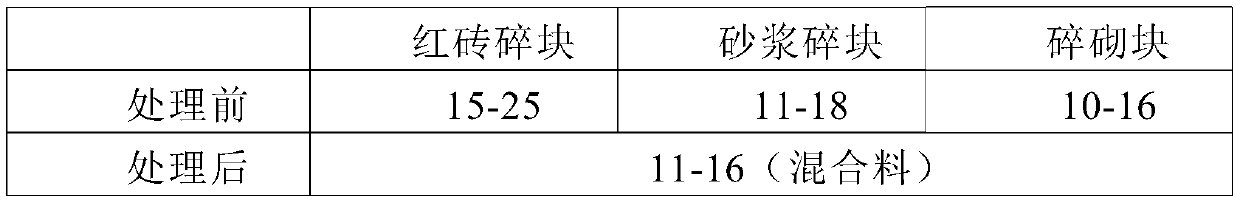

Method for producing recycled aggregates by taking sorted decoration wastes as raw materials

InactiveCN110590211AAdjustable colorImprove performanceSolid waste managementExpanded clay aggregateWater diversion

The invention discloses a method for producing recycled aggregates by taking sorted decoration wastes as raw materials. The method is characterized by comprising the steps: wrapping outer surfaces ofaggregates having the particle sizes being 5-15 mm and 15-30 mm after being crushed with a layer of prepared cement mortar, and carrying out sufficient curing to form lightweight recycled aggregates.The sorted decoration wastes treated by using the method are uniformly wrapped with a layer of cement mortar, so that various performances are improved, and particularly, the improvement on the waterabsorption index is embodied in the consistency of water absorption. The recycled aggregates can be used as material substitutes in various fields and aspects. Specifically speaking, the recycled aggregates can be used as lightweight concrete aggregates and raw materials of wall boards or can be used as water diversion materials for a roof garden to substitute natural stone with the same particlesize; and after a color pigment is added for wrapping, the recycled aggregates can be used as covering materials for landscape planting surfaces, not only can substitute lightweight ceramsites, but also can adjust the color of stone.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD +1

Fireproof wear-resistant environment-friendly material and preparation method thereof

The invention relates to an environment-friendly material, in particular to a fireproof wear-resistant environment-friendly material and a preparation method thereof, and belongs to the field of a material. The fireproof wear-resistant environment-friendly material disclosed by the invention is prepared from the following ingredients in percentage by mass: 50 to 60 percent of quartz sand, 20 to 30 percent of thermoplastic plastics, 5 to 15 percent of calcium carbonate, 1 to 5 percent of compatibilizers, 1 to 5 percent of lubricating agents and 1 to 5 percent of stabilizing agents, wherein the compatibilizers are cyclic acid anhydride (MAH) compounds; the lubricating agents are one or several kinds of materials selected from zinc stearate, fatty acid and fatty acid ester, and fatty acid amide; the stabilizing agents are calcium zinc stabilizing agents. The environment-friendly material has the advantages that 60-percent fire-resistant performance and 50-percent wear-resistant performance can be improved; the production stability is high; the color can be freely regulated; the product observability is high; no pollution is caused; the environment is protected; the energy is saved; the resource can be reused, and the like.

Owner:安徽创能环保材料有限公司

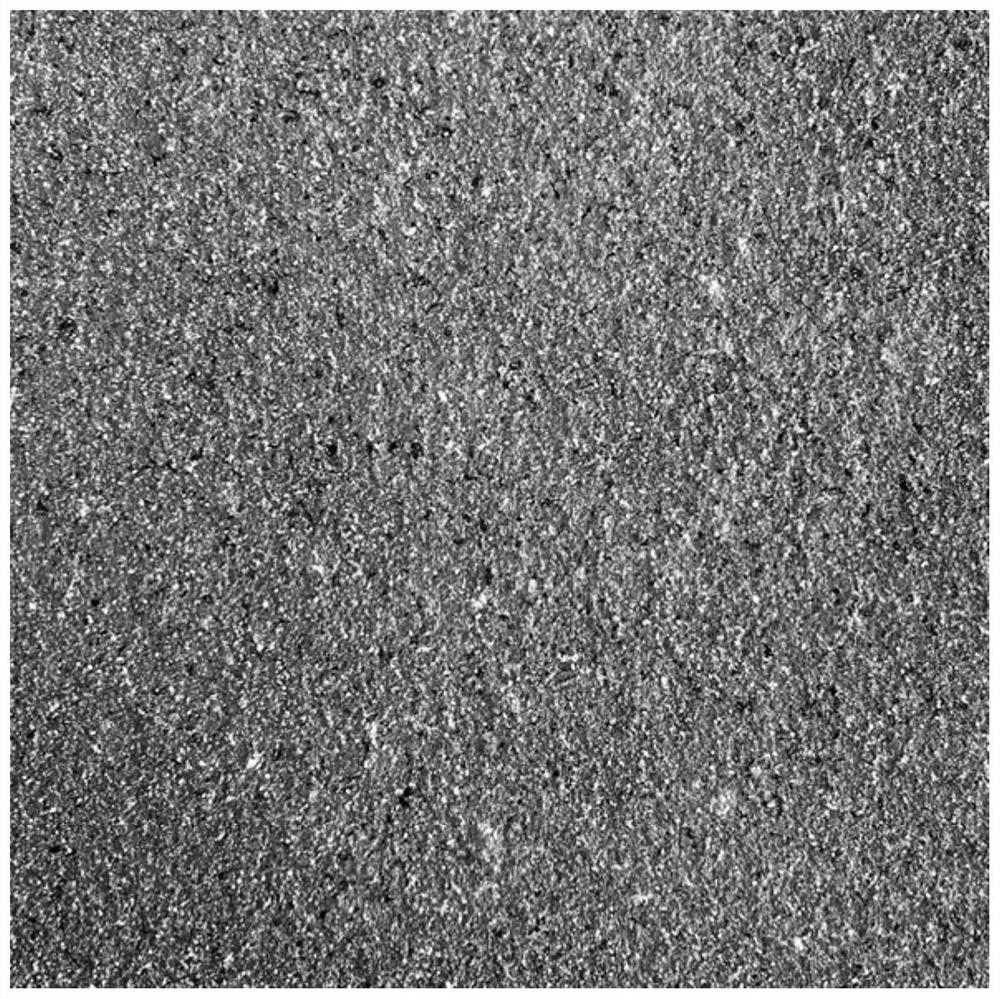

Natural-colored-sand-free real stone paint granite-effect-like coating and construction method thereof

PendingCN114525061AGood overall coverageReduce consumptionAntifouling/underwater paintsPaints with biocidesChemistryMining engineering

The invention belongs to the technical field of coatings, and particularly relates to a stone-like paint granite effect coating without natural colored sand addition and a construction method of the stone-like paint granite effect coating. The granite coating of the real stone paint comprises the following raw materials in parts by weight: 15-20 parts of granulation liquid, 45-75 parts of toning sand-containing base paint and 15-35 parts of sand-containing continuous phase. The cost of the granite effect coating similar to the stone-like paint is far lower than that of sand in water, the overall construction cost is lower than that of the stone-like paint, and the effect is obviously richer than that of the stone-like paint. Natural colored sand is replaced by multi-color-point color matching, the overall covering power is good, the consumption is lower when the colored sand is matched with the same-color base, and the floating risk is obviously reduced.

Owner:德爱威(中国)有限公司

A kind of method suppressing THF side reaction in polymerization process

The invention relates to a method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process. According to the method, in the process of preparing a polymer by using terephthalic acid and 1,4-butanediol as main raw materials, ester, titanium-silicon-cobalt composite catalyst dispersant and pH regulator are generated by adding the terephthalic acid and dihydric alcohol in the esterifying stage, the molar ratio of the terephthalic acid to the 1,4-butanediol is controlled to be 1:(1.05-1.10) to inhibit the side reaction of tetrahydrofuran, so that the content of tetrahydrofuranin the polymer is less than or equal to 10wt%; the dispersing medium in the titanium-silicon-cobalt composite catalyst dispersant is 1,4-butanediol, and the titanium-silicon-cobalt composite catalystis prepared by combining a titanium-silicon composite catalyst and a cobalt catalyst, and the titanium-silicon composite catalyst is prepared from a silicon catalyst-supported titanium catalyst. According to the method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process, the final product has concentrated molecular weight distribution, few byproduct and high quality, andhas a great application prospect.

Owner:DONGHUA UNIV

Rare earth activated aluminate system fluorescent material for electrodeless lamp and preparation method of rare earth activated aluminate system fluorescent material

InactiveCN102311735AImprove luminous efficiencyReduce manufacturing costLuminescent compositionsRare earthEuropium

The invention relates to a rare earth activated aluminate system fluorescent material for an electrodeless lamp. The rare earth activated aluminate system fluorescent material for the electrodeless lamp is a mixture of a red material, a blue material and a green material, wherein the ratio of the red material to the blue material to the green material is 46: 25: 35, the red material, the blue material and the green material are fully mixed and then are mixed with appropriate amount of binder Na2SiO3, thus the product is obtained. The red material comprises yttrium oxide, europium oxide and boron oxide; the blue material comprises aluminium oxide, magnesium oxide, boric acid, barium carbonate, calcium carbonate, europium oxide, cerium oxide and dysprosium oxide; and the green material comprises aluminium oxide, magnesium oxide, boric acid, europium oxide, cerium oxide and terbium oxide. The production process of the preparation method of the rare earth activated aluminate system fluorescent material comprises the steps of sorting, mixing in proportion, placing the materials into a crucible reacting furnace, igniting and heating, insulating heat, cooling, smashing and sieving, carrying out dry grinding and wet grinding, cleaning, dehydrating and stoving, sieving and checking as well as bagging.

Owner:吴振华

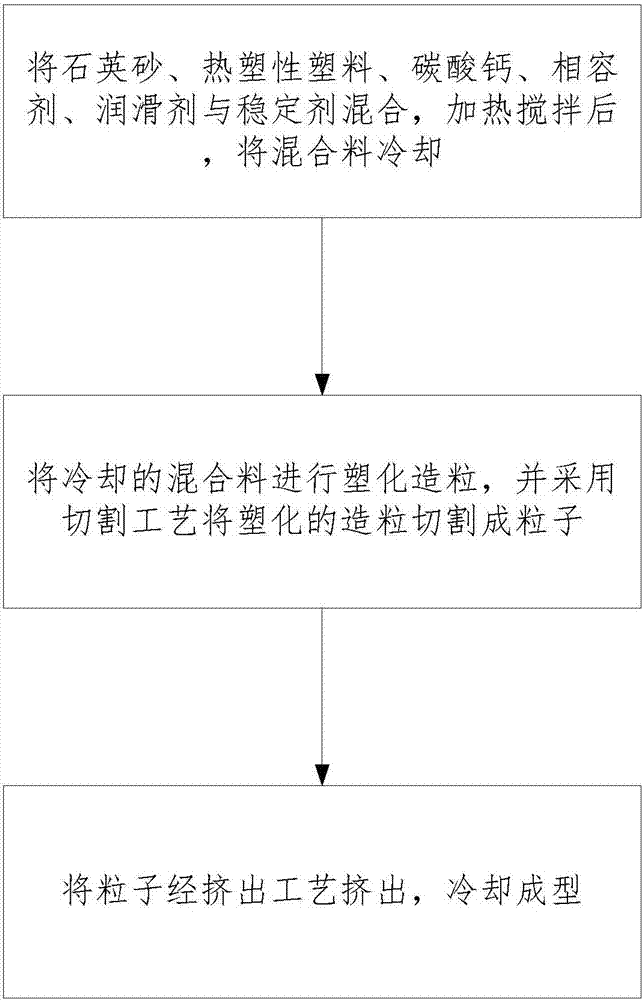

Fireproof wear-resistant environment-friendly material and preparation method thereof

The invention discloses a fireproof wear-resistant environment-friendly material and a preparation method thereof, and belongs to the technical field of novel environment-friendly materials. The preparation method comprises the following steps: mixing 20 to 30 percent of thermoplastic, 30 to 60 percent of calcium carbonate, 10 to 15 percent of flame retarding polyether, 5 to 10 percent of sodium carbonate, 2 to 5 parts of a plasticizer, 1 to 5 parts of a compatibilizer, 1 to 5 percent of a lubricant and 1 to 5 percent of a stabilizer, heating and stirring, and cooling the mixture; plasticizingand pelletizing the cooled mixture with a plasticizing-pelletizing process; cutting the plasticized particles into particles with a cutting process; extruding the particles with an extrusion process;cooling and molding. The environment-friendly material has the advantages of higher fire resistance, higher wear resistance, high production stability, optional adjustment of color, high product attractiveness, no pollution, environmental friendliness, energy conservation, resource recycling and the like. By adopting the method, the mechanical stability, size accuracy and machining speed of the environment-friendly material can be improved effectively.

Owner:徐州涌新环保科技有限公司

Manufacturing method of colored super-hydrophobic bamboo wood

ActiveCN112549224AEasy to operateEasy to scale upWood treatment detailsPretreatment apparatusComposite materialMetal-organic framework

The invention discloses a manufacturingmethod of colored super-hydrophobic bamboo wood, wherein the whole manufacturing process is carried out in an open environment at room temperature, organic solvents and reaction devices are not needed, operation is easy, and therefore large-scale amplification manufacturing is easy; meanwhile, a metal organic framework material growing on the surface of bamboo wood is used as a precursor, a metal hydroxide prepared through in-situ conversion has good binding force on the surface of the bamboo wood, the adhesive force of a manufactured super-hydrophobic coating is improved, and the super-hydrophobic stability of the super-hydrophobic coating is improved; and the color of the prepared hydroxide can be regulated and controlled by changing the types of metal salts used in the in-situ conversion preparation process of the double-metal hydroxide, so that the manufacturing of the colored super-hydrophobic bamboo wood is realized.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Building water-proof coiled material

InactiveCN101117562ANo pollution in the processGood weather resistanceOther chemical processesRoof covering using flexible materialsIsolation layerNeoprene

A construction waterproof membrane is formed by mixing and matching with talcum powder, stearic butyl rubber, dye and recuperated rubber cement, the upper of the butyl rubber matrix layer is a waterproof dye layer, the lower is a neoprene latex or recuperated rubber cement layer, the lowest is a vinyon film isolation layer, and the butyl rubber matrix layer is the butyl rubber mixed and added with talcum powder and stearic acid. When in working, the plastic film is uncovered, and is felted on the base level of a building. The present invention has the advantages of good weather resisting property, no rupture at the low temperature, no aging in high temperature and solarization, long service life, tight plastering with the house surface, good waterproof effect, convenient working, no environmental pollution, adjustable color and luster, and cheap in price.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

Light flame-retardant thermal insulation board and manufacturing method thereof

PendingCN111546731AEasy to produceImprove production continuitySynthetic resin layered productsThermal insulationMixed materials

The invention relates to a light flame-retardant thermal insulation board and a manufacturing method thereof, and belongs to the technical field of composite materials and novel chemical building materials. The insulation board is composed of a core layer, a middle layer and a shell layer; the core layer, the middle layer and the shell layer are independently extruded by three extruders to form acore layer material flow, a middle layer material flow and a shell layer material flow respectively; the core-layer material flow, the middle-layer material flow and the shell-layer material flow converge in the mouth mold, the core-layer material flow is located at the innermost part, the middle-layer material flow wraps the periphery of the core-layer material flow, the shell-layer material flowwraps the periphery of the middle-layer material flow to form a mixed material flow, and the mixed material flow is extruded in the mouth mold to obtain the light flame-retardant thermal-insulation board. The invention is convenient to produce and manufacture, high in production continuity and high in production efficiency; the insulation board is small in density, light in weight, flame-retardant, good in heat preservation effect, waterproof, corrosion-resistant, mothproof, free of cracking, aging and deformation, free of color difference, free of paint falling in the using process, free ofmoisture absorption and moisture regaining and the like.

Owner:NANJING FORESTRY UNIV

Anticorrosion cast multi-element Cu-alloy simulating golden colour and its preparing process

The invention discloses a corrosion-resistant multi-element imitation golden cast copper alloy and a manufacturing method thereof. The components thereof are as follows in percentage by weight: Cu60-84%; Zn0-35%; Al 0.5-10%; Ni 0.5-15%; Mn0 .1~8%; Fe≤5%, but not equal to 0; Ti0.01~15%; Ce0.001~5%; Sn0~8%, manufactured by conventional casting method. It uses the chemical inactivity of certain elements or forms a dense inert protective film on the surface of the copper alloy to protect the imitation gold-copper alloy from discoloration in the atmosphere; it uses certain elements to form metals with zinc, copper and other easily oxidized and discolored elements. The nature of the intermediate compound can inhibit the corrosion of elements such as zinc and copper in the atmosphere or acid rain and other corrosive media. The present invention omits expensive metals such as gold, and obtains 18K-22K imitation gold, and the processed surface and the non-processed surface are all golden yellow, which is basically the same. Soak in aqueous solution for two months without discoloration, and can withstand corrosion in 1%, 5%, 10%, 20% sulfuric acid aqueous solution for 4 days and nights.

Owner:ZHEJIANG UNIV

Artificial lignumvitae and preparation method thereof

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

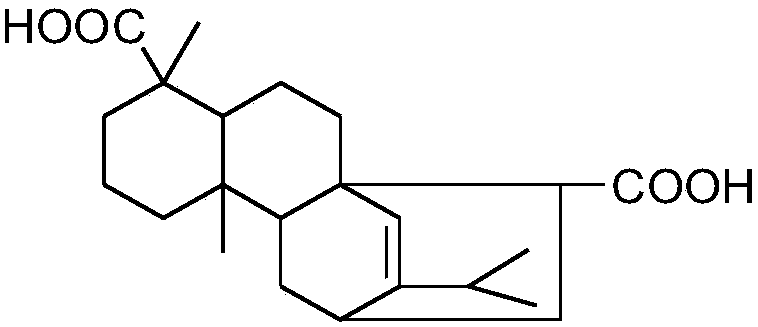

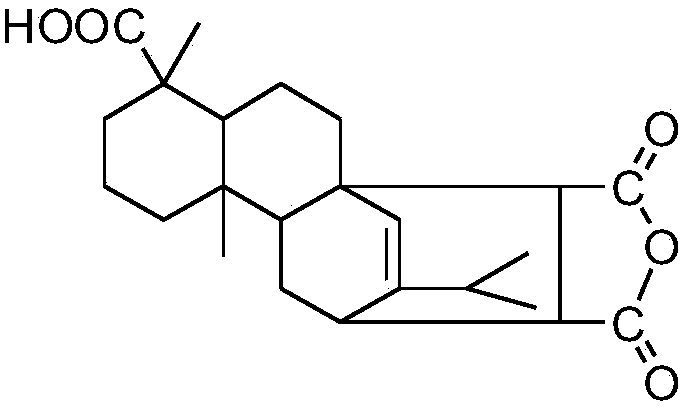

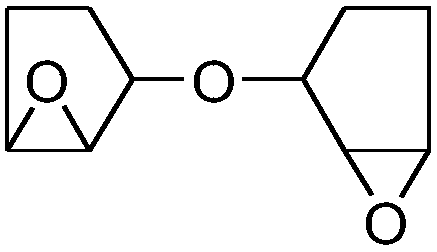

A kind of rosin epoxy resin composition and preparation method thereof

Owner:SHANDONG UNIV OF SCI & TECH

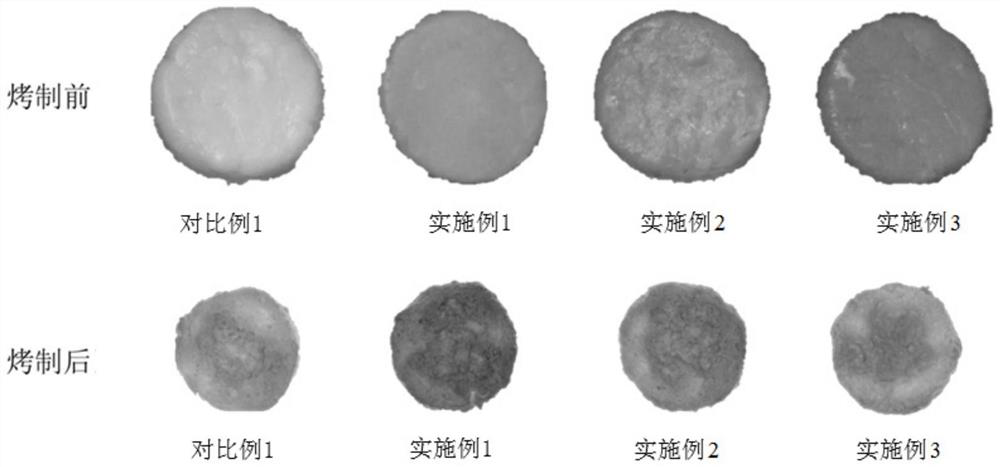

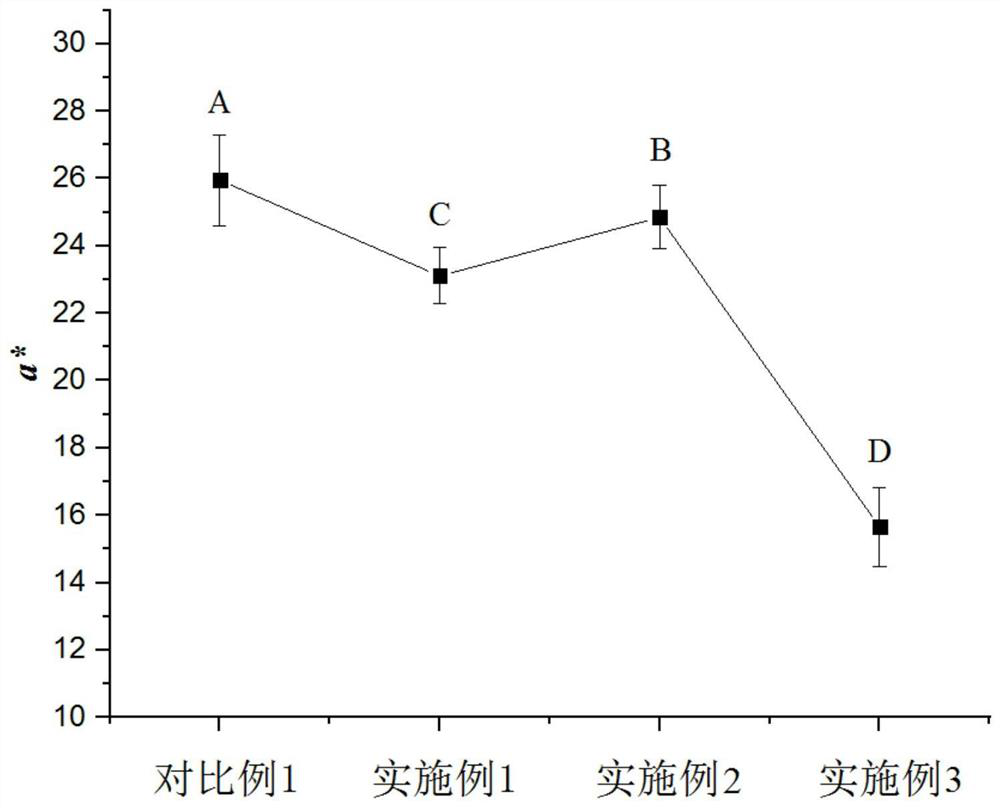

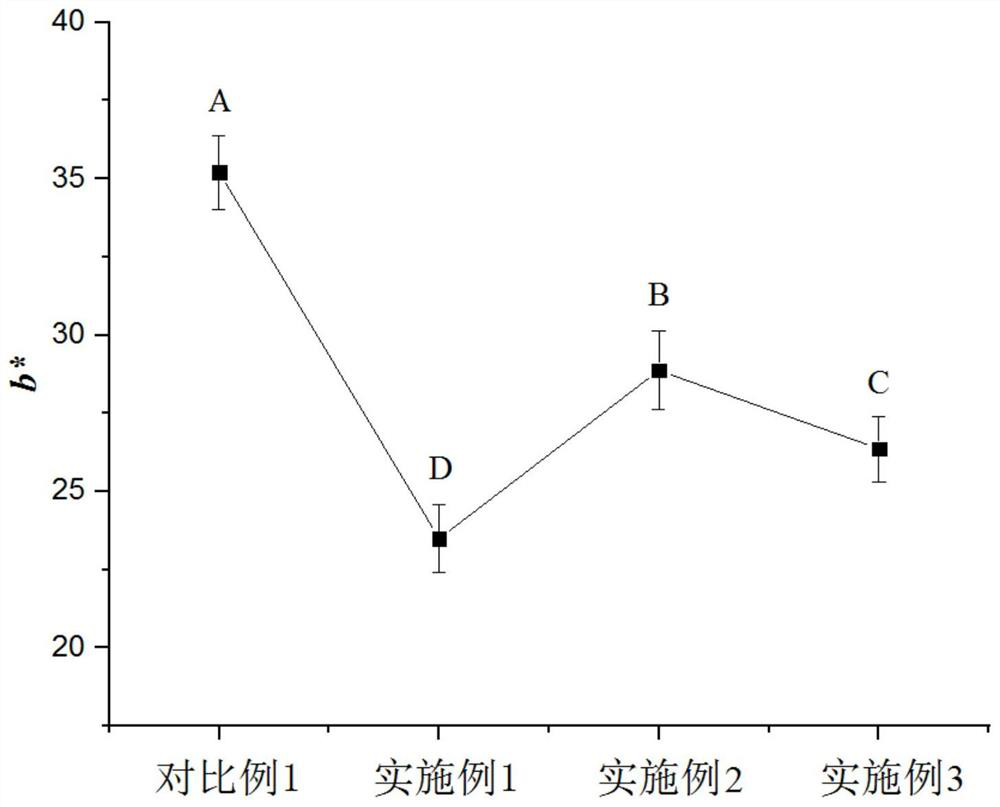

Nutritional and healthy microalgae-based roast chicken cake with improved color and preparation method thereof

The invention relates to the technical field of food processing, and provides a nutritional and healthy microalgae-based roast chicken cake with improved color and a preparation method thereof. Microalgae are added into the chicken paste and baked, so that the prepared roast chicken product can be obviously colored, the color of the roast chicken product is improved, the roast chicken product canshow various colors by adjusting the variety of the microalgae, the color of the roast chicken product can be controllably adjusted, meanwhile, the fatty acid composition of the roast chicken productcan be improved, so that the roast chicken product prepared from the microalgae has higher polyunsaturated fatty acid content.

Owner:SHENZHEN UNIV

Solid wood fireproof door

InactiveCN105569512AAvoid deformationAdjustable colorDomestic upholsteryFireproof doorsAmmonium polyphosphatePhosphoric acid

The invention discloses a solid wood fireproof door. The solid wood fireproof door comprises flame-retardant powder at an uppermost layer, a fireproof adhesion layer serving as a middle layer and a basic material at a lowermost layer, wherein the flame-retardant powder comprises phosphoric acid, urea, water-soluble ammonium polyphosphate and dipentaerythritol; the fireproof adhesion layer is made of fireproof silica gel; the flame-retardant powder accounts for 20-24% of the total components of the solid wood fireproof door; the fireproof adhesion layer accounts for 10-12% of the total components of the solid wood fireproof door; and the basic material accounts for 65-69% of the total components of the solid wood fireproof door. The solid wood fireproof door provided by the invention has the advantages of low possibility of deformation, adjustable color and luster and capability of showing natural aesthetic feeling of wood grains.

Owner:CHANGSHU FENGSHENG BUILDING DECORATION WOOD IND CO LTD

Four-color LED light mixing method based on visible light communication

ActiveCN104053278BSpectrum richColor temperature adjustableElectric lightingElectric light circuit arrangementColor rendering indexSpectrograph

The invention discloses a four-color LED light mixing method based on visible light communication. The method comprises the steps that spectral power distribution of all monochromatic light is obtained through a spectrograph, and the tristimulus value of each corresponding monochromatic light is calculated; the target color temperature of mixed light is determined, and a corresponding reference light source is selected and used for obtaining the tristimulus value of a mixed color; according to the color addition principle, the sum of the tristimulus values of all the monochromatic light should be equal to the tristimulus value of the mixed color, and a color mixing equation set is obtained; the spectral power distribution of the mixed light can be obtained according to the light mixing coefficient of all the monochromatic light in the color mixing equation set, and the color rendering index Ra of the mixed light is calculated according to the spectral power distribution of the mixed light, wherein Ra is larger than or equal to epsilon; the range of the channel capacity C of the mixed light is calculated, and the maximum capacity Cmax is solved within the range; the ratio of all the colored light with the maximum capacity is output.

Owner:SOUTHEAST UNIV

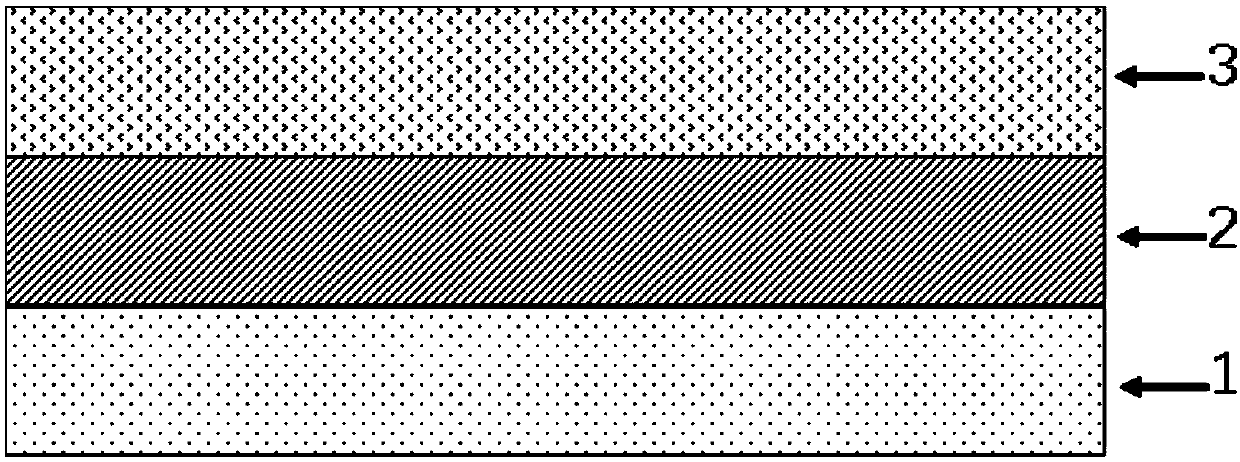

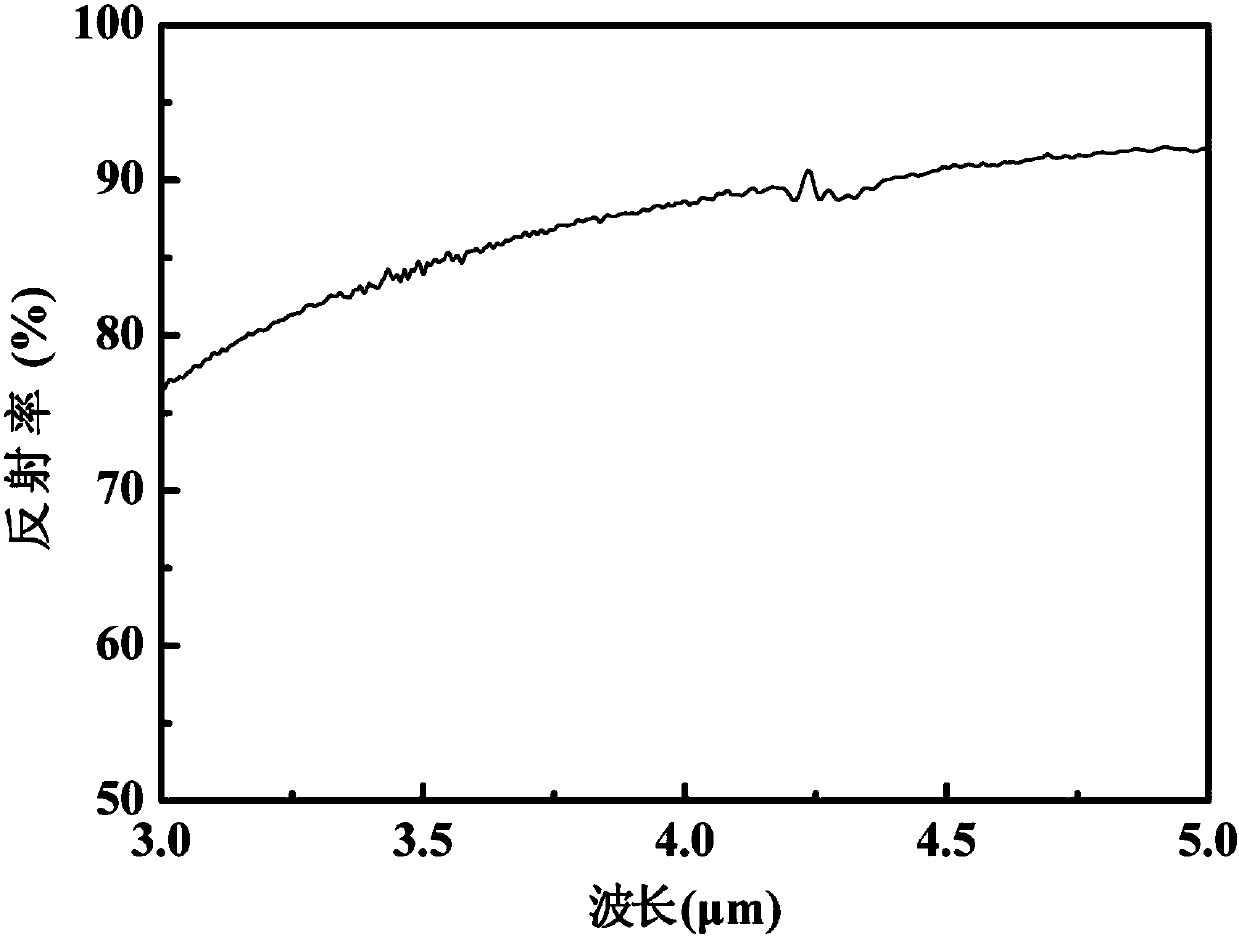

A visible light and infrared compatible camouflage material and preparation method thereof

ActiveCN106382854BAdjustable colorAchieve compatible camouflage effectProtective equipmentLayered productsEmissivityRadio frequency magnetron sputtering

The invention discloses a visible light and infrared light compatible camouflage material which is of a layered structure and sequentially comprises a substrate, a low infrared emissivity layer and an oxide film layer from bottom to top; and the oxide film layer is a Cr2O3 film. A preparation method comprises the following steps: (1) preparing the low infrared emissivity layer on the substrate through a radio frequency magnetron sputtering method; and (2) preparing the Cr2O3 film on the surface of the low infrared emissivity layer through the radio frequency magnetron sputtering method, and finishing preparation of the visible light and infrared light compatible camouflage material. According to the visible light and infrared light compatible camouflage material, the color of the oxide film layer can be regulated and controlled and can be green and also other multiple colors, and the visible light and infrared light compatible camouflage material can be suitable for camouflage requirements under different conditions.

Owner:NAT UNIV OF DEFENSE TECH

A kind of preparation method of colored superhydrophobic bamboo wood

ActiveCN112549224BAchieve preparationAdjustable colorWood treatment detailsPretreatment apparatusSuperhydrophobeOrganic solvent

Owner:ZHEJIANG FORESTRY UNIVERSITY

Light rigid plate and manufacturing method thereof

InactiveCN112140674AEasy to produceImprove production continuitySynthetic resin layered productsFlat articlesEngineeringMoisture absorption

The invention relates to a light rigid plate and a manufacturing method thereof, and belongs to the technical field of composite materials and novel chemical building materials. The light rigid plateis composed of a core layer, a middle layer and an outer shell layer, wherein the middle layer is located between the core layer and the outer shell layer, the core layer, the middle layer and the outer shell layer are independently extruded by three extruders to form a core layer material flow, a middle layer material flow and an outer shell layer material flow respectively, the core layer material flow, the middle layer material flow and the outer shell layer material flow converge in a die to form a mixed material flow, and the mixed material flow is extruded in the die to obtain the lightrigid plate. According to the invention, the light rigid plate is convenient to produce and manufacture, high in production continuity, high in production efficiency, light in weight, high in rigidity, high in strength, not prone to deformation, resistant to flame, water and corrosion, resistant to worm damage, free of cracking and aging, free of color difference, free of paint falling in the using process, free of moisture absorption and moisture regaining and the like.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

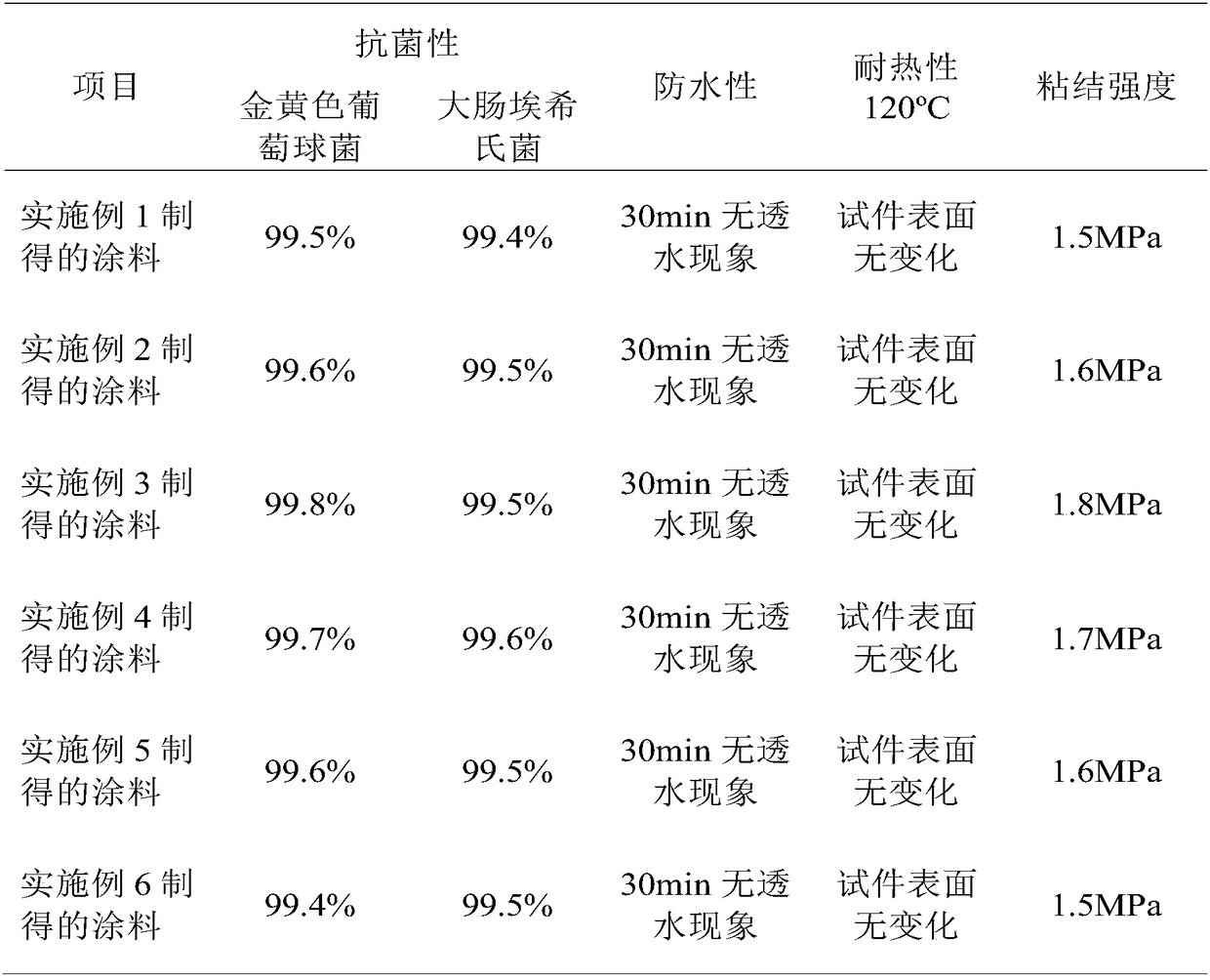

A coating for sanitary products and its preparation method and application

ActiveCN106800853BImprove flow smoothnessIncrease viscosityLiquid surface applicatorsAntifouling/underwater paintsSilanesKaolin clay

The invention discloses a paint for bathroom products, and a preparation method and application thereof. The paint for bathroom products is composed of a primer and a finish paint. The primer is prepared from a polyacrylate emulsion, polyoxyethylene ether, calcium carbonate and food-grade barium sulfate. The finish paint is prepared from fluorine silicon carbon compounds, polysiloxane, polyfluorocarbene, a silane coupling agent, calcium carbonate, food-grade barium sulfate, silicon dioxide, kaolin, titanium dioxide and a defoaming agent. The preparation method comprises the following steps: mixing and stirring the primer raw materials to obtain a transparent uniform mixed solution which is the primer; and uniformly mixing and stirring the fluorine silicon carbon compounds, polysiloxane and polyfluorocarbene, sequentially adding the silane coupling agent, calcium carbonate, food-grade barium sulfate, silicon dioxide, kaolin, titanium dioxide and defoaming agent, and stirring to obtain a uniform viscous white oily liquid which is the finish paint. The paint for bathroom products has the advantages of favorable water resistance, stable antibacterial effect, high firmness and durability and stable service life.

Owner:张海淼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com