Colorful anticorrosion decorative film with controllable surface color of matrix and preparation method thereof

A decorative film and color technology, which is applied in the surface decoration and protective treatment of substrate materials, can solve the problems of easy-aging decorations, weakened anti-corrosion performance, and difficult decoration, etc., achieve rich colors, excellent anti-corrosion performance, and broaden the practical application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

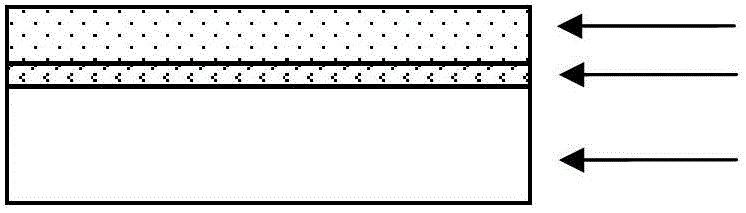

[0038] In this embodiment, the substrate material is silicon, and the structure of the colored anti-corrosion decorative film on the surface of the silicon substrate consists of a titanium transition layer positioned on the silicon substrate and a tetrahedral amorphous carbon film positioned on the surface of the titanium transition layer. The thickness of the titanium transition layer is The thickness of the tetrahedral amorphous carbon film is 80nm, and the color anticorrosion decorative film is golden yellow.

[0039] The following is the preparation process of the above-mentioned colored anticorrosion decorative film:

[0040] (1) Put the silicon substrate into acetone or alcohol, clean it with an ultrasonic cleaner for 10-20 minutes, then rinse it with deionized water and dry it for later use;

[0041] (2) After fixing the substrate on the sample stage, place it on the turntable in the vacuum chamber of the cathode vacuum arc composite sputtering coating instrument, and eva...

Embodiment 2

[0045] Example 2: Preparation of purple-red high-hardness corrosion-resistant decorative film on Ti6Al4V substrate

[0046] In this embodiment, the substrate material is Ti6Al4V, and the structure of the colored anti-corrosion decorative film on the surface of the Ti6Al4V substrate consists of a titanium transition layer positioned on the Ti6Al4V substrate and a tetrahedral amorphous carbon film positioned on the surface of the chromium transition layer. The thickness of the chromium transition layer is The thickness of the tetrahedral amorphous carbon film is 70nm, and the thickness of the tetrahedral amorphous carbon film is 160nm. The color anti-corrosion decorative film appears purple.

[0047] The following is the preparation process of the above-mentioned colored anticorrosion decorative film:

[0048] (1) Put the Ti6Al4V substrate into acetone or alcohol, clean it with an ultrasonic cleaner for 10-20 minutes, then rinse it with deionized water and dry it for later use; ...

Embodiment 3

[0053] Example 3: Preparation of a silver-gray high-hardness corrosion-resistant decorative film on a stainless steel substrate

[0054] In this embodiment, the substrate material is stainless steel, and the structure of the colored anti-corrosion decorative film on the surface of the stainless steel substrate consists of a titanium transition layer positioned on the Ti6Al4V substrate and a tetrahedral amorphous carbon film positioned on the surface of the chromium transition layer. The thickness of the chromium transition layer is The thickness of the tetrahedral amorphous carbon film is 20nm, and the thickness of the tetrahedral amorphous carbon film is silver gray.

[0055] The following is the preparation process of the above-mentioned colored anticorrosion decorative film:

[0056] (1) Put the stainless steel substrate into acetone or alcohol, clean it with an ultrasonic cleaner for 10-20 minutes, then rinse it with deionized water and dry it for later use;

[0057] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com