Amorphous photonic crystal schemochrome material based on black titanium dioxide and silicon dioxide composite and preparation method of amorphous photonic crystal schemochrome material

A technology of black titanium dioxide and photonic crystals, applied in the direction of titanium oxide/hydroxide, silicon dioxide, titanium dioxide, etc., can solve the problems of being unable to reduce environmental pollution and not degrading pollutants by sunlight, so as to avoid oxygen vacancy defects, Simple preparation process and good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2)SiO2 2 Preparation of microspheres

[0036] Drop the ethanol solution of ethyl orthosilicate into the ethanol solution of ammonia water, make the concentration of ammonia water 0.1-0.6mol / L, and the concentration of ethyl orthosilicate 0.4-1.2mol / L, stir the reaction, centrifuge after the reaction is completed, Washed and dried to obtain SiO 2 microsphere powder;

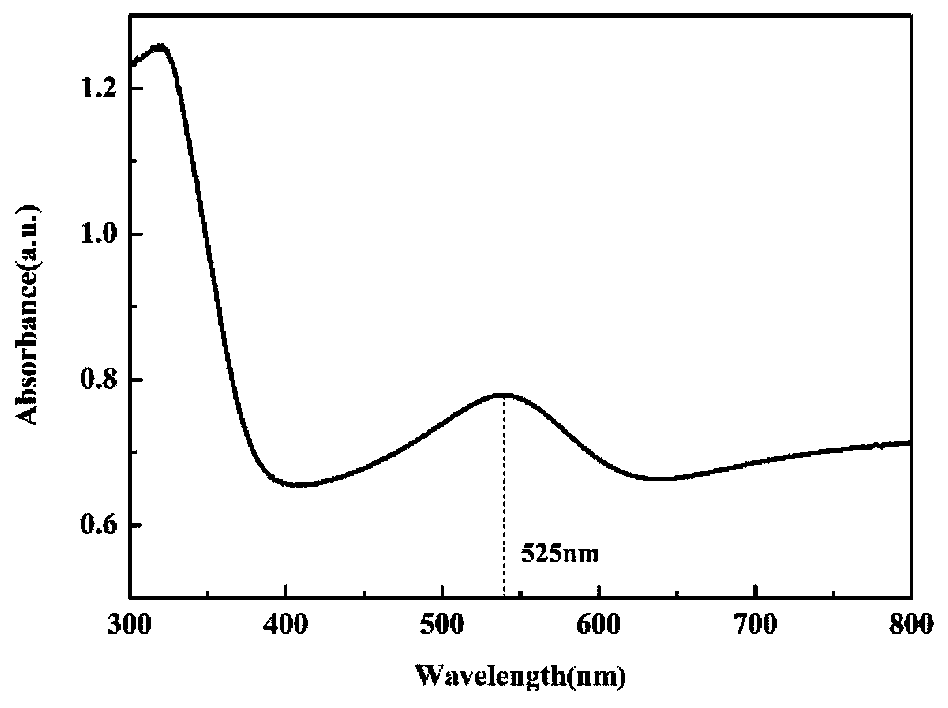

[0037] 3) B-TiO 2 / SiO 2 material preparation

[0038] Weigh SiO according to the mass ratio of 1:(0.1~1) 2 Powder and B-TiO2 Powder, according to the ratio of (1 ~ 2) g: 50ml SiO 2 The powder was dissolved in ethanol, and then the corresponding B-TiO was added 2 The powder is ultrasonically dispersed for a certain period of time after being stirred for 2 hours, and dried at room temperature after sufficient reaction to obtain an amorphous photonic crystal structural color material based on black titanium dioxide and silicon dioxide with a photocatalytic effect.

[0039] In step 1), the grinding tim...

Embodiment 1

[0043] An amorphous photonic crystal structural color material with photocatalytic effect based on the composite of black titanium dioxide and silicon dioxide and a preparation method thereof, comprising the following steps:

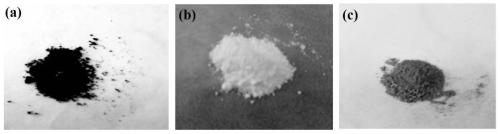

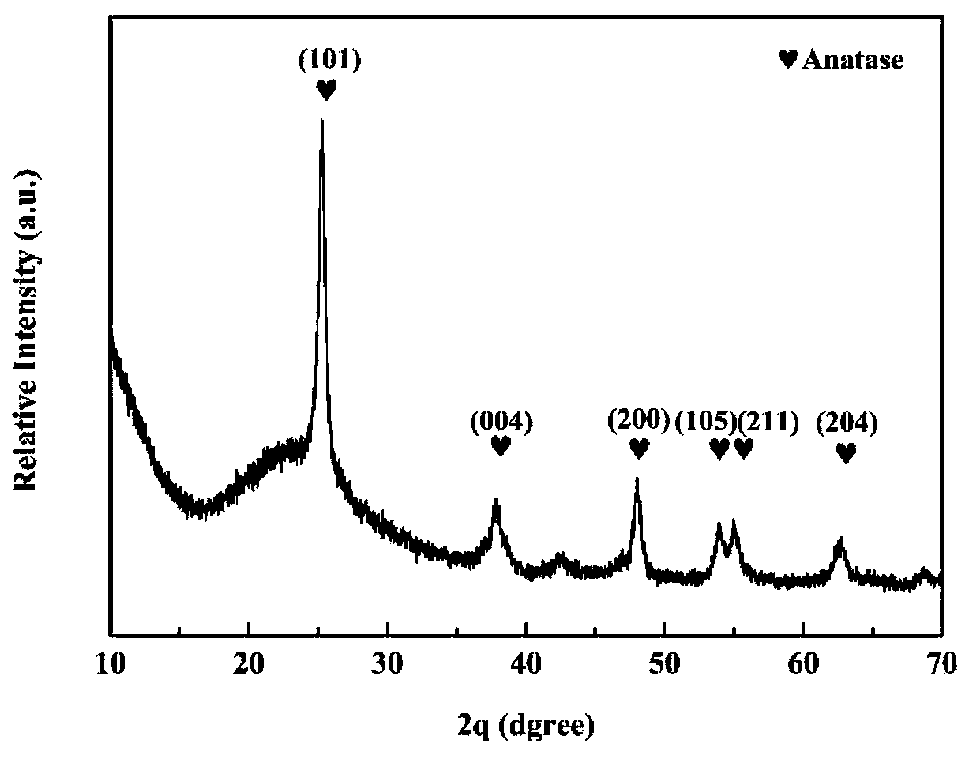

[0044] 1) Black TiO2 2 (B-TiO 2 ) Preparation of nanoparticles

[0045] Weigh P25(TiO 2 ) and NaHB 4 , ground with an agate mortar, mixed evenly, heated up to 380°C at a heating rate of 7°C / min, heat-treated at 380°C in vacuum for 3 hours, and cooled naturally. After the reaction was completed, cross-wash with deionized water and ethanol four times, and dry at room temperature to obtain B-TiO 2 Nano powder.

[0046] 2)SiO2 2 Preparation of microspheres

[0047] Drop the ethanol solution of ethyl orthosilicate into the ethanol solution of ammonia water, so that the concentration of ammonia water is 0.1mol / L, and the concentration of ethyl orthosilicate is 0.8mol / L. Stir and react at 36°C for 4 hours. After the reaction is completed, centrifuge, Wa...

Embodiment 2

[0052] 1) Black TiO2 2 (B-TiO 2 ) Preparation of nanoparticles

[0053] Weigh P25(TiO 2 ) and NaHB 4 , ground with an agate mortar, mixed evenly, heated up to 250°C at a heating rate of 7°C / min, heat treated in vacuum at 250°C for 2 hours, and cooled naturally. After the reaction was completed, cross-wash with deionized water and ethanol four times, and dry at room temperature to obtain B-TiO 2 Nano powder.

[0054] 2)SiO2 2 Preparation of microspheres

[0055] Drop the ethanol solution of ethyl orthosilicate into the ethanol solution of ammonia water, so that the concentration of ammonia water is 0.2mol / L, and the concentration of ethyl orthosilicate is 0.4mol / L. Stir and react at 25°C for 6h. After the reaction is completed, centrifuge, Washing and drying to obtain SiO with a diameter of 180nm 2 powder of microspheres;

[0056] 3) B-TiO 2 / SiO 2 material preparation

[0057] Weigh SiO at a mass ratio of 1:0.1 2 Powder and B-TiO 2 Powder, according to the ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com