Solar photocatalysis glass and preparation method thereof

A technology of photocatalysis and solar light, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of reducing the photocatalytic activity of thin films, low quantum yield, and low specific surface area, and achieve good photocatalytic effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of sunlight photocatalytic glass, its preparation method comprises the steps:

[0037] 1) Preparation of halogen-containing boroaluminosilicate glass:

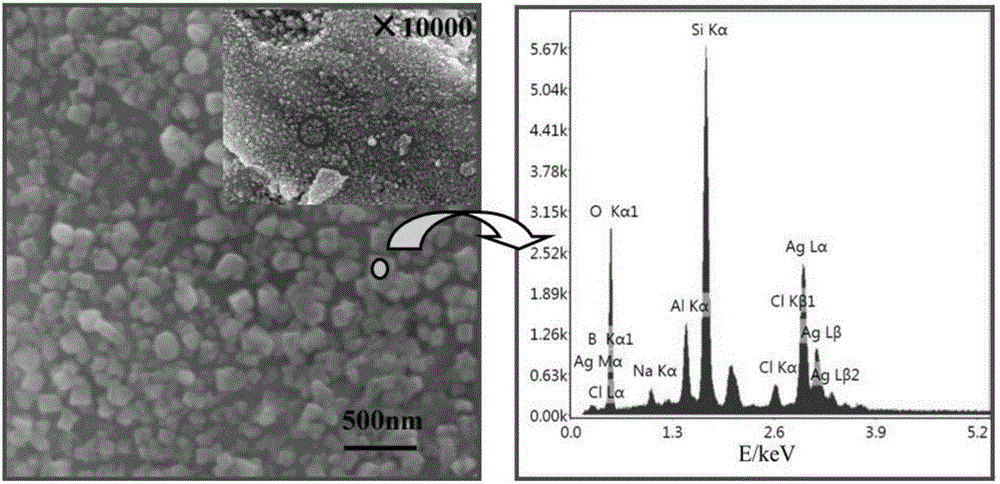

[0038] ①Using the components of boroaluminosilicate-based glass and NaCl as raw materials, the mass percentage of each component of boroaluminosilicate-based glass is: SiO 2 56%, Al 2 o 3 9%, B 2 o 3 22%, Na 2 O 13%; The external addition of NaCl is 0.02wt%;

[0039] ② Mix the weighed raw materials evenly, and mix the raw materials;

[0040] ③ Place the obtained mixed raw materials in a crucible, heat them in an electric furnace at a heating rate of 2°C / min to 1450°C, and heat them for 1 hour to melt them. The obtained molten glass is cast and annealed (at 550°C for 2 hours) to obtain Halogen-containing boroaluminosilicate glass blocks;

[0041] ④ cutting the obtained halogen-containing boroaluminosilicate glass block into sheets, and obtaining halogen-containing boroaluminosilicate glass sheets for use a...

Embodiment 2

[0052] A kind of sunlight photocatalytic glass, its preparation method comprises the steps:

[0053] 1) Preparation of halogen-containing boroaluminosilicate glass:

[0054] ①Using the components of boroaluminosilicate-based glass and NaCl as raw materials, the mass percentage of each component of boroaluminosilicate-based glass is: SiO 2 59%, Al 2 o 3 8%, B 2 o 3 19%, Na 2 O 14%; the external addition of NaCl is 0.06%;

[0055] ② Mix the weighed raw materials evenly, and mix the raw materials;

[0056] ③ Place the obtained mixed raw materials in a crucible, heat them in an electric furnace at a rate of 5°C / min to 1440°C, and heat them for 4 hours to melt them. Halogen boroaluminosilicate glass blocks;

[0057] ④ cutting the obtained halogen-containing boroaluminosilicate glass block into sheets, and obtaining halogen-containing boroaluminosilicate glass sheets for use after cleaning;

[0058] 2) Ion exchange heat treatment:

Embodiment 3

[0068] A kind of sunlight photocatalytic glass, its preparation method comprises the steps:

[0069] 1) Preparation of halogen-containing boroaluminosilicate glass:

[0070] ①Using the components of boroaluminosilicate-based glass and NaI as raw materials, the mass percentage of each component of boroaluminosilicate-based glass is: SiO 2 54%, Al 2 o 3 9%, B 2 o 3 21%, Na 2 O 16%; the external addition of NaI is 0.07%;

[0071] ② Mix the weighed raw materials evenly, and mix the raw materials;

[0072] ③ Place the obtained mixed raw materials in a crucible, heat them in an electric furnace at a rate of 2°C / min to 1430°C, and heat them for 1 hour to melt them. Halogen boroaluminosilicate glass blocks;

[0073] ④ cutting the obtained halogen-containing boroaluminosilicate glass block into sheets, and obtaining halogen-containing boroaluminosilicate glass sheets for use after cleaning;

[0074] 2) Ion exchange heat treatment:

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com