Molybdenum sulfide nano-sheet/titanium dioxide nano-sheet/graphite fiber composite material and method for preparing same

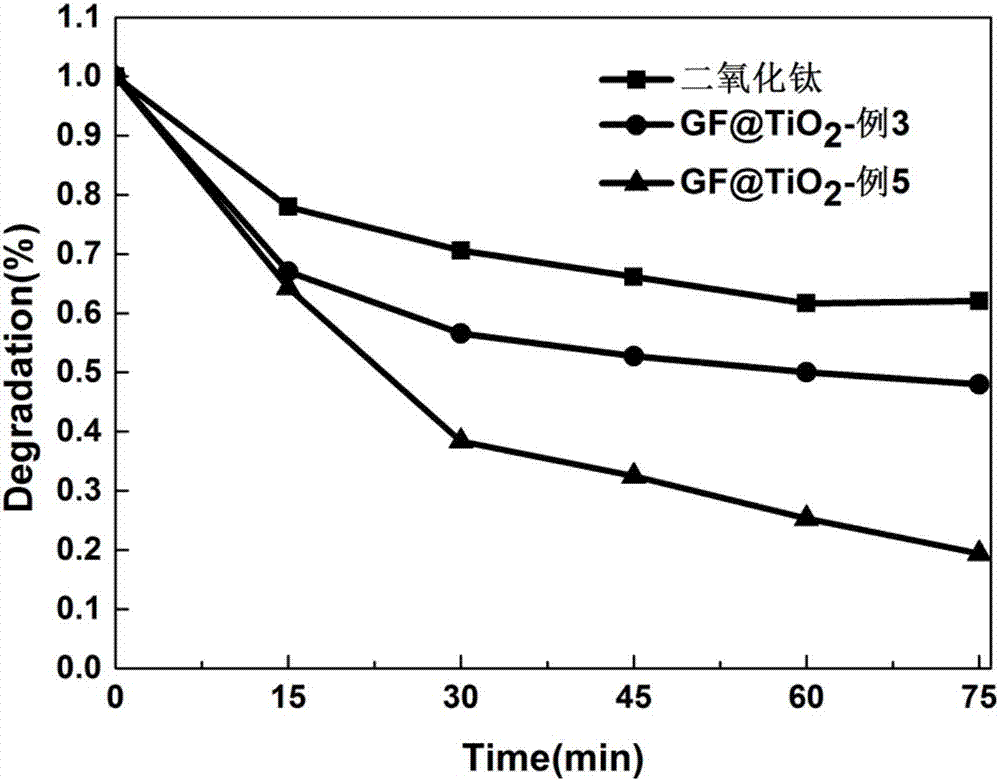

A titanium dioxide and graphite fiber technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low photocatalytic efficiency and can only absorb ultraviolet light, and achieve high photocatalytic efficiency, easy to use. The effect of promotion and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

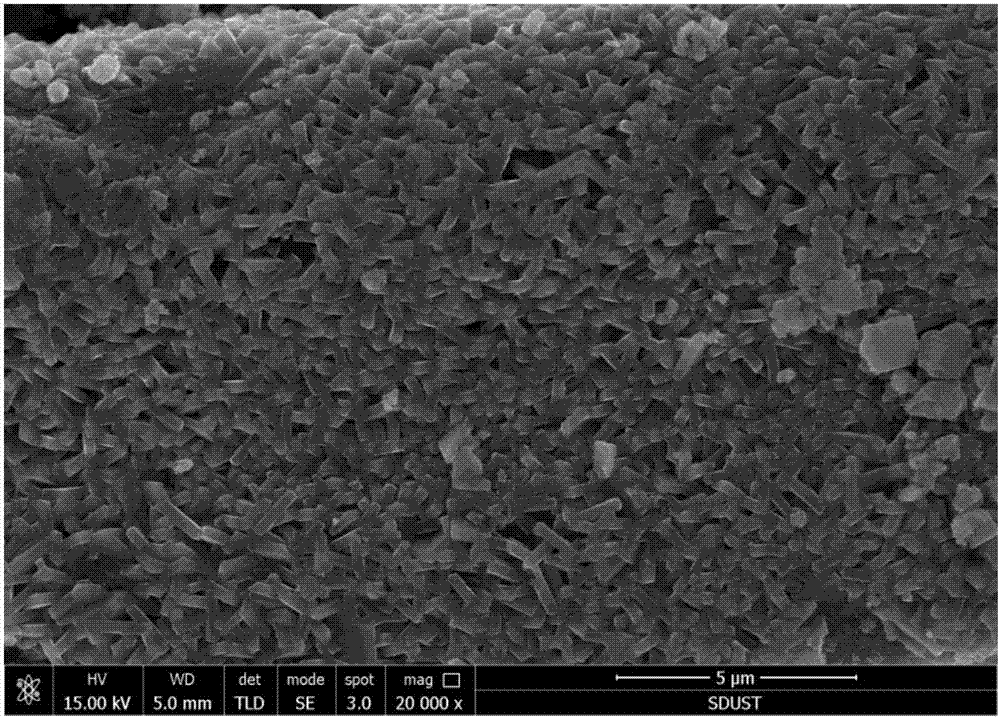

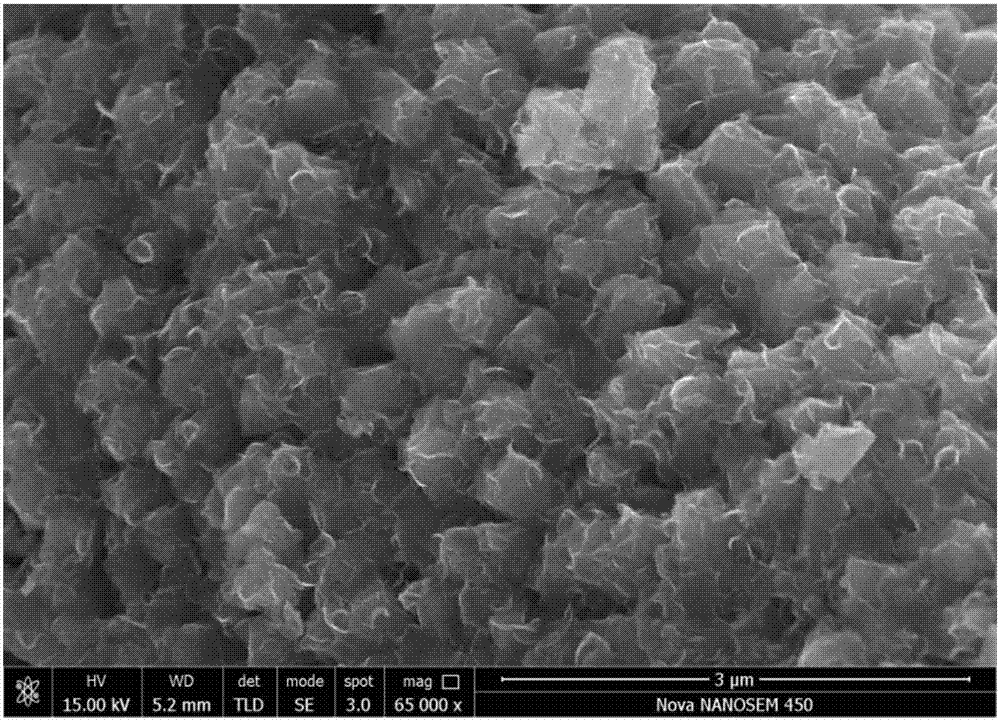

[0043] A kind of preparation method of molybdenum sulfide nano-sheet / titanium dioxide nano-sheet / graphite fiber composite material provided by the invention, the specific steps are as follows:

[0044] Step 1: Take 0.3 grams of graphite fiber, add it to 18 milliliters, 5 moles per liter of hydrochloric acid solution, and sonicate for 10 minutes to prepare the first mixed solution.

[0045] Step 2: Take 3 parts of the first mixed solution, add different amounts of butyl titanate dropwise to the 3 parts of the first mixed solution, and stir thoroughly for 30 minutes to prepare the second mixed solution.

[0046] Step 3: Add 0.35 ml of hydrogen fluoride solution with a mass fraction of 47% to the second mixed solution, and stir thoroughly for 5 minutes to prepare the third mixed solution.

[0047] Step 4: Put the third mixed solution in a hydrothermal reaction kettle, and fully react at 180° C. for 4 hours to prepare the fourth mixed solution.

[0048] Step 5: Filter the fourth ...

Embodiment 1

[0053] Step 1: First, measure 18 milliliters of 5 mol per liter hydrochloric acid solution and 0.3 grams of graphite fibers and mix and stir for 10 minutes to prepare the first mixed solution.

[0054] Step 2: Then measure 0.5 ml of butyl titanate, add butyl titanate dropwise to the first mixed solution, and then stir the solution for 30 minutes by magnetic force to fully mix the solution evenly to prepare the second mixed solution.

[0055] Step 3: Next, measure 0.35 ml of hydrofluoric acid with a mass fraction of 47%, add the hydrofluoric acid dropwise into the second mixed solution, and stir for 5 minutes to prepare the third mixed solution.

[0056] Step 4: The third mixed solution was placed in a hydrothermal reactor, and reacted at 180°C for 4 hours to prepare the fourth mixed solution.

[0057] Step 5: Filter the fourth mixed solution to obtain a precipitate, and ultrasonically clean the obtained precipitate with isopropanol solution (the volume ratio of deionized water...

Embodiment 2

[0063] Step 1: First, measure 18 milliliters of 5 mol per liter hydrochloric acid solution and 0.3 grams of graphite fibers and mix and stir for 10 minutes to prepare the first mixed solution.

[0064] Step 2: Measure 1.0 ml of butyl titanate, add the butyl titanate dropwise to the first mixed solution, and then stir the solution by magnetic force for 30 minutes to fully mix the solution evenly to prepare the second mixed solution.

[0065] Step 3: Next, measure 0.35 ml of hydrofluoric acid with a mass fraction of 47%, add the hydrofluoric acid dropwise into the second mixed solution, and stir for 5 minutes to prepare the third mixed solution.

[0066] Step 4: The third mixed solution was placed in a hydrothermal reactor, and reacted at 180°C for 4 hours to prepare the fourth mixed solution.

[0067] Step 5: Filter the fourth mixed solution to obtain a precipitate, and ultrasonically clean the obtained precipitate with isopropanol solution (the volume ratio of deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com