BiZn hydrotalcite photocatalyst, and preparation method and application thereof

A catalyst, Shiguang's technology, applied in the direction of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of unfavorable practical application, cumbersome production process, harsh reaction conditions, etc., and achieve low raw material cost and high reaction rate. The effect of low condition requirement and reduction of reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 0.72g sodium lauryl sulfate, 20mL ethylene glycol and 1.1mL water, then add 1.5mL n-butanol solution dropwise (the volume ratio of ethylene glycol and n-butanol to water is 19.5:1, the surface active The dosage ratio of agent and water is 0.0025:1mol / ml), wait for the solution to stir until it is transparent. Add 0.002 mol of zinc acetate and 0.002 mol of bismuth nitrate pentahydrate (the ratio of zinc salt to water is 0.1:1 mol / L). After stirring for 1 h, 1.35 g of thiourea was added (the ratio of thiourea to water was 0.017:1 mol / mL), and the oil bath was heated to 80°C, and the heating was continued for 20 hours. After the heating is completed, cool down and perform suction filtration to collect the solid product, transfer the solid product to a constant temperature box and dry it at 60° C. to obtain a BiZn hydrotalcite photocatalyst.

Embodiment 2

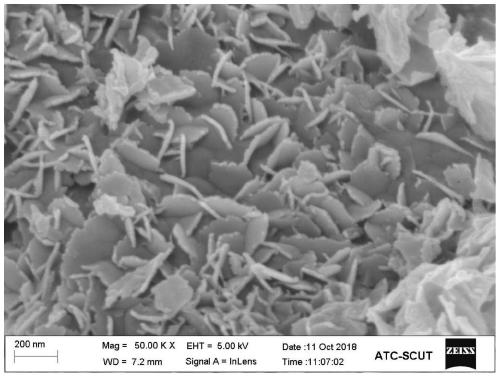

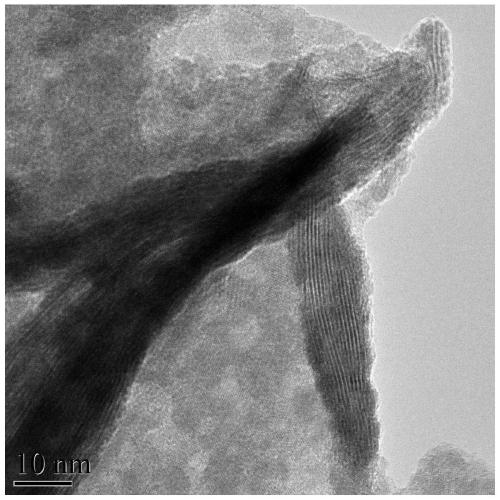

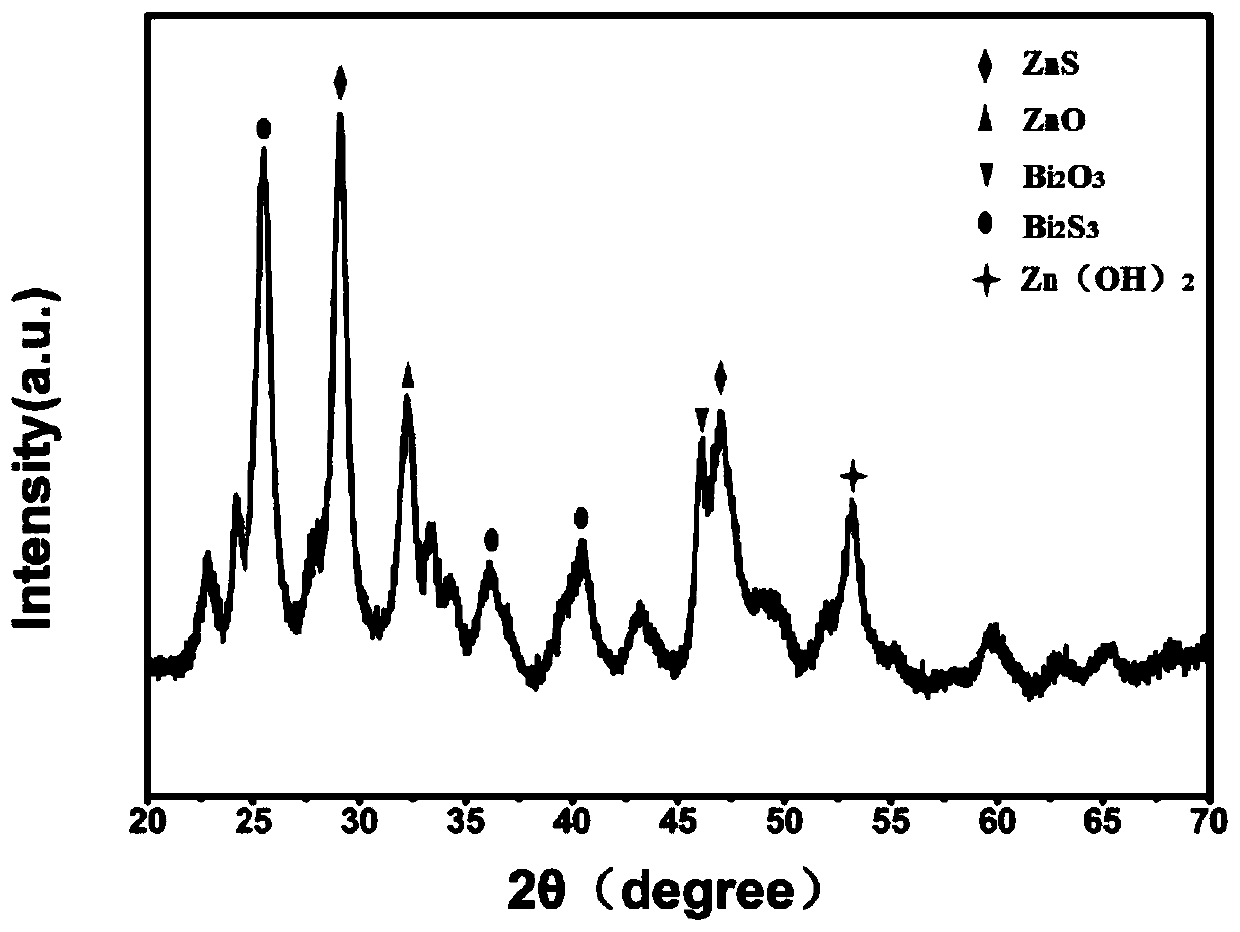

[0040] Mix 0.72g of sodium lauryl sulfate, 20mL of ethylene glycol and 1.1mL of water, then add 1.5mL of n-butanol solution dropwise, and wait until the solution is stirred until it becomes transparent. 0.002 mol of zinc acetate and 0.002 mol of bismuth nitrate pentahydrate were added. After stirring for 1 h, 1.35 g of thiourea (or urea of the same concentration) was added, and the oil bath was heated to 90° C., and the heating was continued for 26 hours. After the heating is completed, cool down and perform suction filtration to collect the solid product, transfer the solid product to a constant temperature box and dry it at 60° C. to obtain a BiZn hydrotalcite photocatalyst. figure 1 The SEM image obtained for this embodiment has a relatively clear two-dimensional ultra-thin nanosheet structure, and the thickness of the nanosheet is 5-10 nm. figure 2 The TEM image obtained in this example shows typical lattice fringes of BiZn hydrotalcite. image 3 For the XRD image obt...

Embodiment 3

[0042] Mix 0.72g of sodium lauryl sulfate, 20mL of ethylene glycol and 1.1mL of water, then add 1.5mL of n-butanol solution dropwise, and wait until the solution is stirred until it becomes transparent. 0.002 mol of zinc acetate and 0.002 mol of bismuth nitrate pentahydrate were added. After stirring for 1 h, 1.35 g of thiourea was added, and the oil bath was heated to 100° C., and the heating was continued for 30 hours. After the heating is completed, cool and perform suction filtration to collect the solid product, transfer the solid product to a constant temperature box and dry it at 60° C. to obtain a BiZn hydrotalcite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com