Preparation method of two-dimensional Bi12TiO20 nanosheet with high visible light response

A visible light, nanosheet technology, applied in nanotechnology, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of high cost, complicated operation steps, time-consuming, etc., and achieve morphology rules, process and process simplicity. , the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 0.35g of bismuth oxide, 0.01g of P25, 0.466g of potassium chloride and 0.365g of sodium chloride in a mortar, and their molar ratios are 6:1:50:50, and grind evenly. The ground powder was transferred to a quartz boat and calcined at 800 °C for 2 h to prepare 2D Bi 12 TiO 20 Nanosheets.

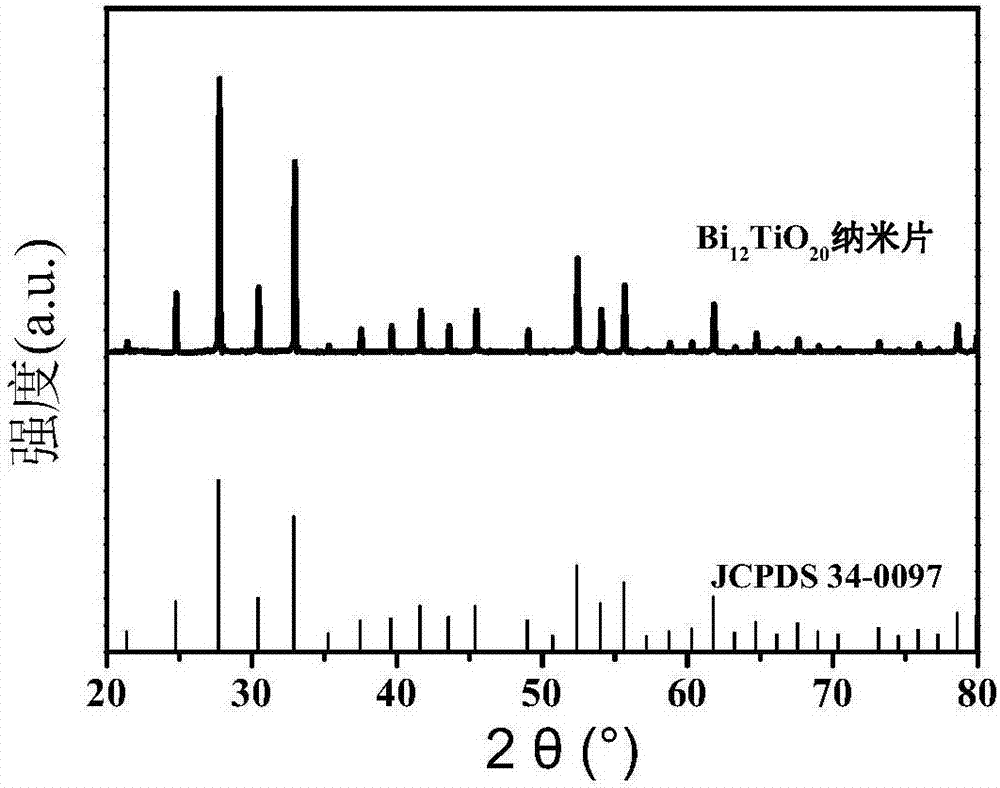

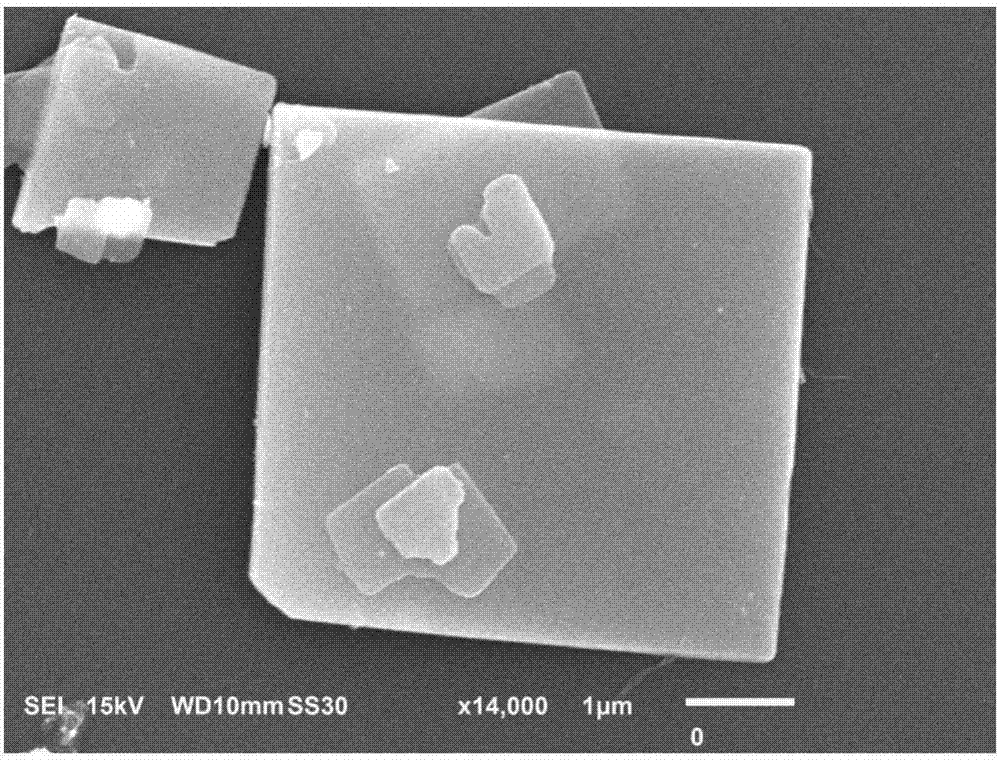

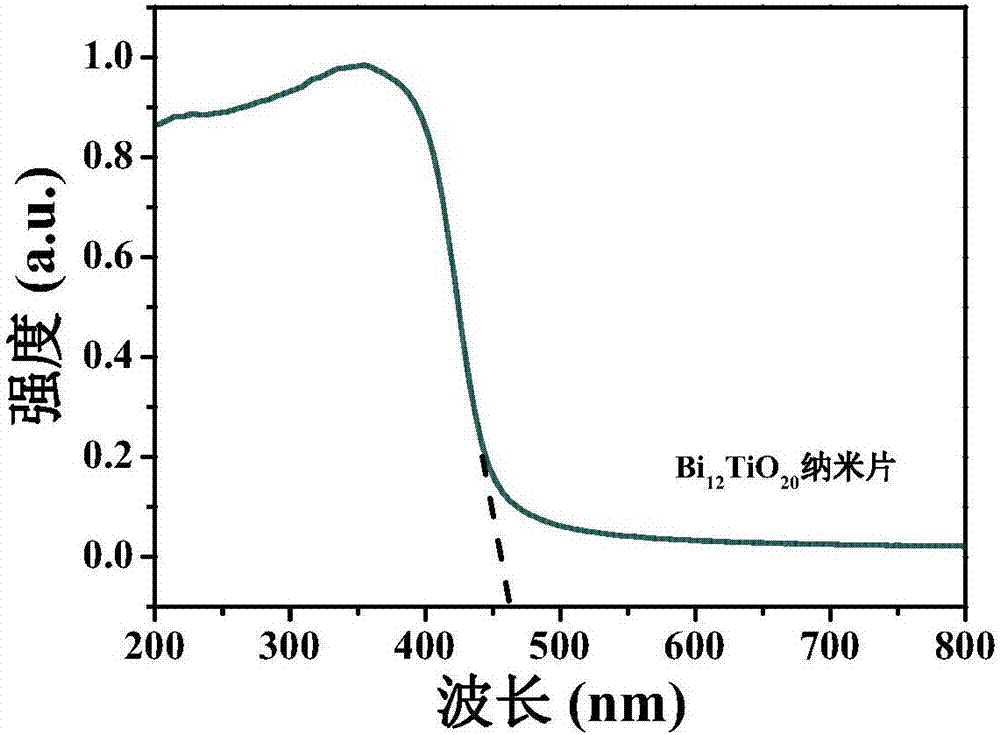

[0024] figure 1 is the XRD diffraction pattern of the prepared material, the peaks at each position in the figure belong to Bi 12 TiO 20 , compared with the standard JCPDS card (34-0097), it can be confirmed that the prepared soft bismuthite Bi with good crystallinity 12 TiO 20 Material; figure 2 For the scanned photo, it can be seen from the scanned image that the as-prepared Bi 12 TiO 20 It presents an obvious two-dimensional sheet structure. image 3 It is a solid ultraviolet curve. It can be seen that the obtained curve has obvious absorption intensity when the wavelength is greater than 400nm (visible light) (the vertical axis is greater than 0, which means that it...

Embodiment 2

[0026] Take 0.35g of bismuth oxide, 0.01g of P25, 0.280g of potassium chloride and 0.219g of sodium chloride in a mortar, and their molar ratios are 6:1:30:30, and grind evenly. The ground powder was transferred to a quartz boat and calcined at 600° C. for 0.5 h to obtain bismuth titanate.

Embodiment 3

[0028] Take 0.35g of bismuth oxide, 0.01g of P25, 0.466g of potassium chloride and 0.365g of sodium chloride in a mortar, and their molar ratios are 6:1:50:50, and grind evenly. The ground powder was transferred to a quartz boat and calcined at 700°C for 1 hour to obtain bismuth titanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com